Rods "Spaceship" Scratch built Plasma Cutter build

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

13 Nov 2021 10:20 - 13 Nov 2021 10:22 #226304

by RNJFAB

Replied by RNJFAB on topic Rods "Spaceship" Scratch built Plasma Cutter build

Hey Rod,

New video's are awesome !! Great work.

LINK ->

New video's are awesome !! Great work.

LINK ->

Last edit: 13 Nov 2021 10:22 by RNJFAB.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

25 Mar 2022 08:29 #238313

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

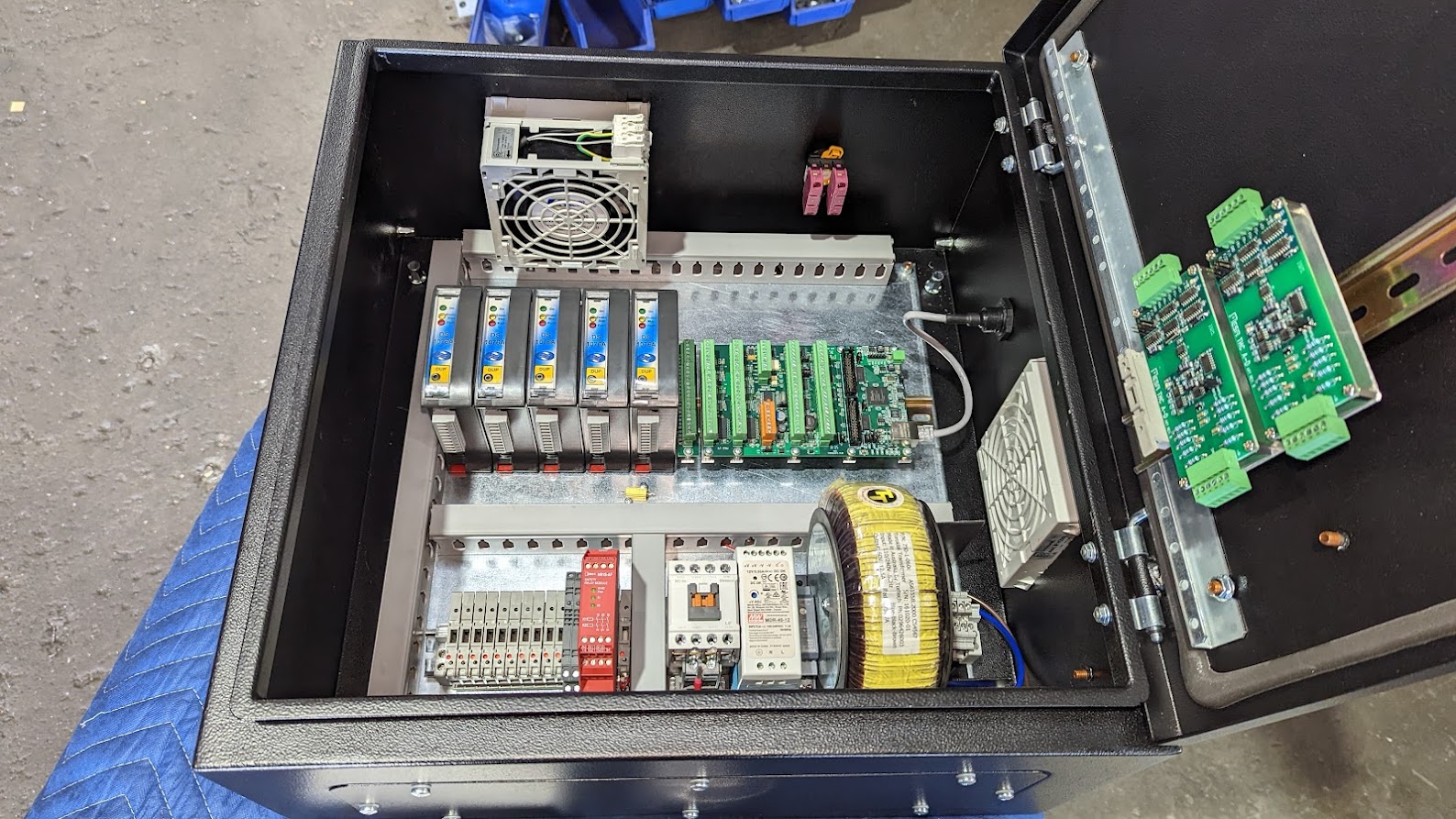

This might become Spaceship Mk II but I've got a near new 3 phase Hypertherm 45 XP here that we purchased cheap for a customer who wanted me to build a controller for him.

It only has a hand torch so that will be interesting.

I was able to get the CPC port kit and cable but the RS485 is on backorder...

I've got most of the hardware installed now so the wiring begins.

Its the identical 500 x 500 mm enclosure I used for the original spaceship but man its tight to get everything in.

So we have:

The obligatory Mains filter built in the IEC connector

An Idec safety relay triggering a breaker for estop

A 60 volt custom made AC toroid

Meanwell HDR-15-24 for ohmic sensing

plasma cut and folded a mounting bracket for the toroid to save space.

Meanwell MDR-40 for Field power (I ordered a 12 volt one so a replacement 24V one is coming grrr)

5 x Lam Technologies DS1076A stepper drivers for gantry machine and rotary axis. These accept AC power for a clean install

A heap of fuse holders as per Lam's recommendations

Mesa 7i76e with IP67 bulkhead ethernet connector

Mesa THCAD-10 for voltage reading

Mesa THCAD-5 for ohmic sensing (using my special magic)

Supply chain constraints meant the only enclosure in stock was black but its growing on me.

Lam recommended a fan located directly above the drives. I put the estop beside it.

I think I will make the operator stand in front of the enclosure and then add some run/stop and pause/resum buttons on the top too.

Still to fit is the 433 Mhz pendant control I have here. I ran out of din rail terminals so probably need to get a few more.

All in all, it should be a nice clean build

Tell me what you think so far.

It only has a hand torch so that will be interesting.

I was able to get the CPC port kit and cable but the RS485 is on backorder...

I've got most of the hardware installed now so the wiring begins.

Its the identical 500 x 500 mm enclosure I used for the original spaceship but man its tight to get everything in.

So we have:

The obligatory Mains filter built in the IEC connector

An Idec safety relay triggering a breaker for estop

A 60 volt custom made AC toroid

Meanwell HDR-15-24 for ohmic sensing

plasma cut and folded a mounting bracket for the toroid to save space.

Meanwell MDR-40 for Field power (I ordered a 12 volt one so a replacement 24V one is coming grrr)

5 x Lam Technologies DS1076A stepper drivers for gantry machine and rotary axis. These accept AC power for a clean install

A heap of fuse holders as per Lam's recommendations

Mesa 7i76e with IP67 bulkhead ethernet connector

Mesa THCAD-10 for voltage reading

Mesa THCAD-5 for ohmic sensing (using my special magic)

Supply chain constraints meant the only enclosure in stock was black but its growing on me.

Lam recommended a fan located directly above the drives. I put the estop beside it.

I think I will make the operator stand in front of the enclosure and then add some run/stop and pause/resum buttons on the top too.

Still to fit is the 433 Mhz pendant control I have here. I ran out of din rail terminals so probably need to get a few more.

All in all, it should be a nice clean build

Tell me what you think so far.

Attachments:

The following user(s) said Thank You: tommylight, RNJFAB, Joeymcc

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

25 Mar 2022 13:03 #238336

by my1987toyota

Replied by my1987toyota on topic Rods "Spaceship" Scratch built Plasma Cutter build

That control cabinet looks clean. It seems the supply/shortage is effecting everybody everywhere . I know a certain

chip were I work cost us 15$ just a few years ago now cost 45$ and if we want them it's $7000 minimum buy. YIKES !

chip were I work cost us 15$ just a few years ago now cost 45$ and if we want them it's $7000 minimum buy. YIKES !

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

25 Mar 2022 20:16 #238370

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Clean now, but I'm sure I cam make it look messy when I run the wires!

Fortunately I had the Mesa hardware on hand.

Costs have gone up everywhere. I used to pay USD $45 per cubic metre sea freight China to Australia. Now its USD $160 and takes months instead of weeks.

Fortunately I had the Mesa hardware on hand.

Costs have gone up everywhere. I used to pay USD $45 per cubic metre sea freight China to Australia. Now its USD $160 and takes months instead of weeks.

The following user(s) said Thank You: my1987toyota, RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

09 Apr 2022 09:38 #239719

by RNJFAB

Replied by RNJFAB on topic Rods "Spaceship" Scratch built Plasma Cutter build

Looks Awesome Rod.

Have you taken your CNC offline for the change over? Or is this for SpaceShip Mk2 ??

Have you taken your CNC offline for the change over? Or is this for SpaceShip Mk2 ??

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

09 Apr 2022 11:36 #239727

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

No this is a seperate project for a Hypertherm 45XP build. I'm struggling for time right now...

Please Log in or Create an account to join the conversation.

- billykid

-

- Offline

- Platinum Member

-

Less

More

- Posts: 470

- Thank you received: 80

09 Apr 2022 12:12 #239728

by billykid

Replied by billykid on topic Rods "Spaceship" Scratch built Plasma Cutter build

Very nice Rod!

I'm almost ashamed to show you mine at least the panel is milled and written with my cnc.

I'm almost ashamed to show you mine at least the panel is milled and written with my cnc.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

09 Apr 2022 12:47 #239731

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

So many ways. I did think of making a plasmacut enclosure and folding it up. I have done one before which looked amazing once it was powdercoated. But really for $200, the enclosure seemed to be the easier way. The needed to be a lot of standoffs for DIN rails etc to be welded on.Very nice Rod!

I'm almost ashamed to show you mine at least the panel is milled and written with my cnc.

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

09 Apr 2022 13:01 #239732

by my1987toyota

Replied by my1987toyota on topic Rods "Spaceship" Scratch built Plasma Cutter build

Building an actual enclosure box seems to be one of those things you do once, then understand why they are the price they are.

At least that's how it was with me. LOL

At least that's how it was with me. LOL

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- BruceCharlesDesigns

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 8

17 Apr 2022 18:19 #240481

by BruceCharlesDesigns

Replied by BruceCharlesDesigns on topic Rods "Spaceship" Scratch built Plasma Cutter build

That looks awesome! Your mention of running the stepper drivers on AC reminded me of some experimenting I did on an old Tormach 1100. Bypassed the 48v DC altogether and put in some DM2282T drivers connected directly to the 220v in. Made a much cleaner system, and I could run the steppers with about 4 times the acceleration and more than double the ultimate speed with those drives at the higher voltages.

Made me wonder why I wouldn't go that route on any homebuilt machine. The DM2282T were not cheap, but compared to drivers and a good DC transformer setup it wasn't that big a difference. And definitely would simplify the enclosure!

I almost never see these drivers used anywhere.

Regardless, I have learned a lot from your posts and your youtube vid on your build. Thanks for sharing all of it!

Made me wonder why I wouldn't go that route on any homebuilt machine. The DM2282T were not cheap, but compared to drivers and a good DC transformer setup it wasn't that big a difference. And definitely would simplify the enclosure!

I almost never see these drivers used anywhere.

Regardless, I have learned a lot from your posts and your youtube vid on your build. Thanks for sharing all of it!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.206 seconds