Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3915

18 Apr 2022 00:14 #240527

by rodw

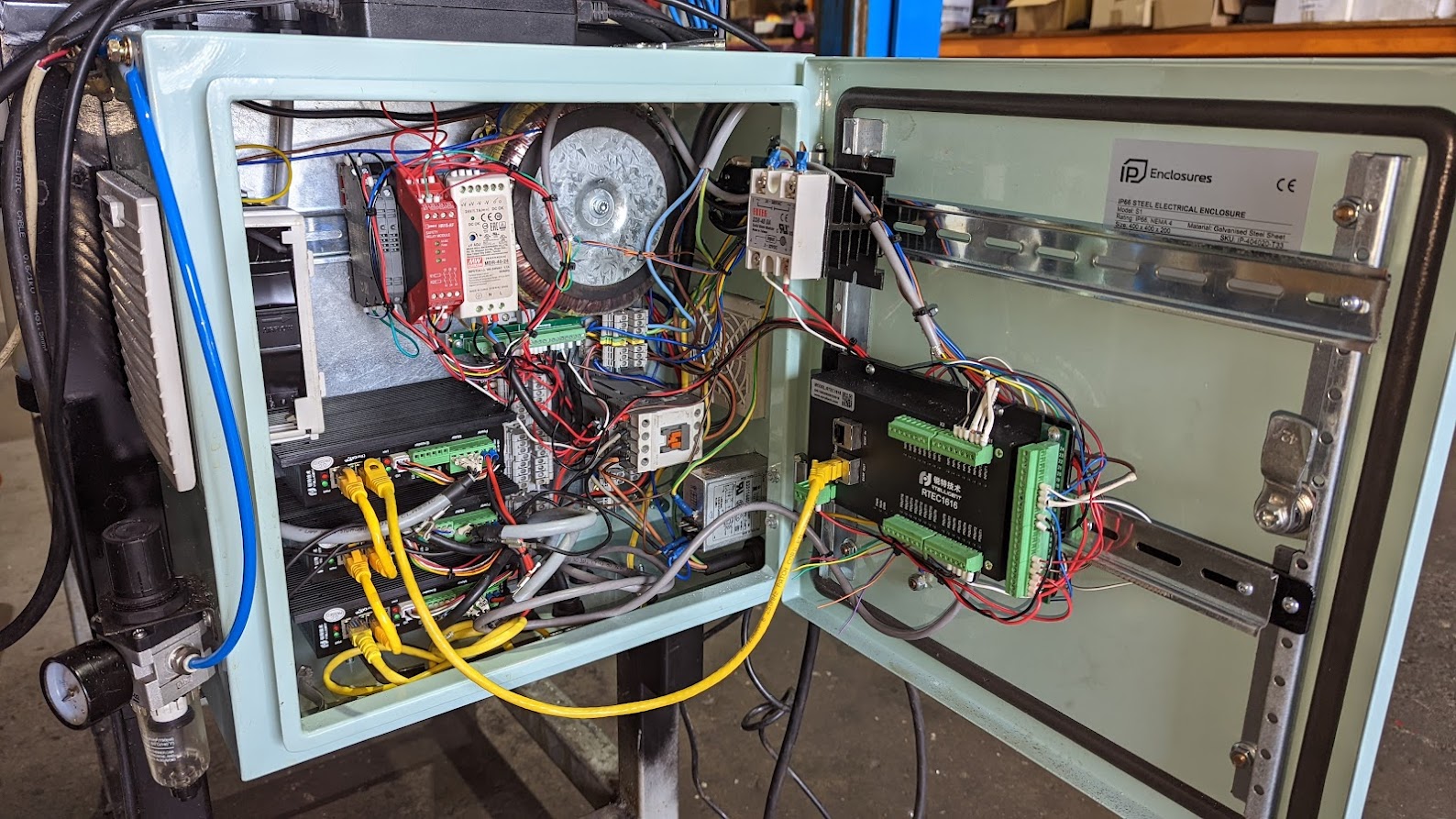

The other thing I've been playing with are ethercat drives. This enclosure is on my mill conversion. 400 x 400mm was all they had in stock and its just not big enough to use conduit.

It has very simliar bones to the plasma control box. Same safety circuit, same power supplies same fan, just not enough room to be tidy.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Hmm, still a lot cheaper than what the drives and power supply in that box are.Bypassed the 48v DC altogether and put in some DM2282T drivers connected directly to the 220v in. Made a much cleaner system, and I could run the steppers with about 4 times the acceleration and more than double the ultimate speed with those drives at the higher voltages.

Made me wonder why I wouldn't go that route on any homebuilt machine. The DM2282T were not cheap, but compared to drivers and a good DC transformer setup it wasn't that big a difference. And definitely would simplify the enclosure!

The other thing I've been playing with are ethercat drives. This enclosure is on my mill conversion. 400 x 400mm was all they had in stock and its just not big enough to use conduit.

It has very simliar bones to the plasma control box. Same safety circuit, same power supplies same fan, just not enough room to be tidy.

Attachments:

The following user(s) said Thank You: tommylight, RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

21 Apr 2022 10:58 #240788

by RNJFAB

Replied by RNJFAB on topic Rods "Spaceship" Scratch built Plasma Cutter build

I'll have to head up soon Rod and check out all the amazing work.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3915

21 Apr 2022 12:19 #240796

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

You can look at the big lump of billet in the vice I have not worked out how to machine yet!I'll have to head up soon Rod and check out all the amazing work.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

23 Apr 2022 02:49 #240959

by RNJFAB

Replied by RNJFAB on topic Rods "Spaceship" Scratch built Plasma Cutter build

Don't you just push the green button, and then it goes and does it all for you??

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3915

23 Apr 2022 03:14 #240961

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Yes, it will use the run/step pause/resume hal example here on the forum. Works well on my mill.Don't you just push the green button, and then it goes and does it all for you??

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

23 Apr 2022 07:29 #240970

by machinedude

Replied by machinedude on topic Rods "Spaceship" Scratch built Plasma Cutter build

what is it that you are trying to figure out how to machine? maybe i can help point you in the right direction.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3915

23 Apr 2022 07:37 #240971

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

23 Apr 2022 08:21 - 23 Apr 2022 09:55 #240975

by machinedude

Replied by machinedude on topic Rods "Spaceship" Scratch built Plasma Cutter build

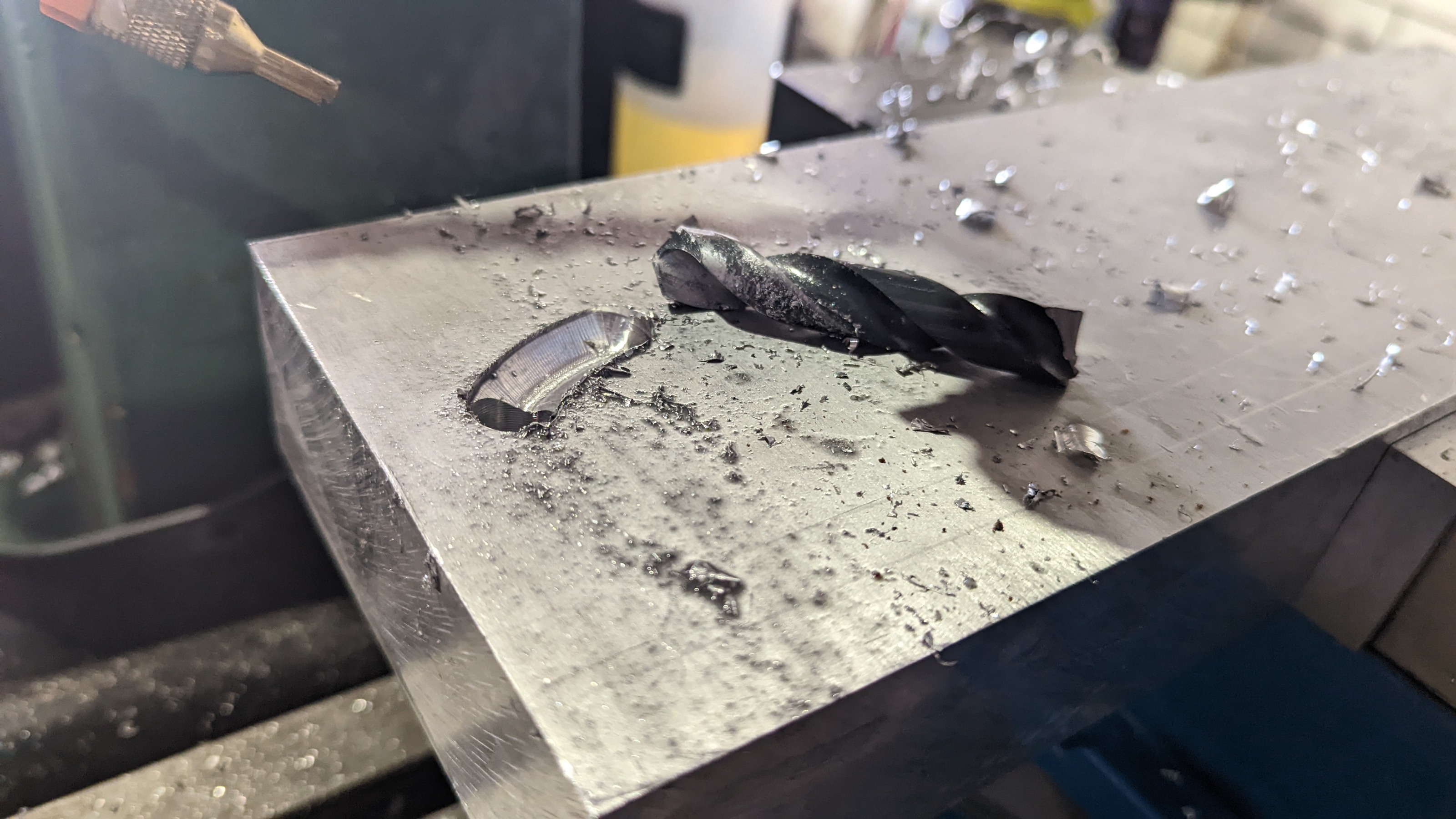

sometimes drills slip in the chuck and when that happens your height offset gets lost so if you don't see anything in the code this could be what caused this. when drills break through sometimes they can grab. brass is good for doing this but can happen with a lot of material.

one other thing i see is that your part is sticking out quite a bit from the vise. when you are drilling your force is pushing downward and this will kick the part in the vise with no doubt. if you have to drill something like this you need to support the piece with some screw jacks so the part can't kick in the vise. you don't need to make them tight just enough pressure to keep the part from being pushed down while you are drilling.

one other thing i see is that your part is sticking out quite a bit from the vise. when you are drilling your force is pushing downward and this will kick the part in the vise with no doubt. if you have to drill something like this you need to support the piece with some screw jacks so the part can't kick in the vise. you don't need to make them tight just enough pressure to keep the part from being pushed down while you are drilling.

Last edit: 23 Apr 2022 09:55 by machinedude. Reason: more information

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3915

23 Apr 2022 12:10 - 23 Apr 2022 12:11 #240984

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

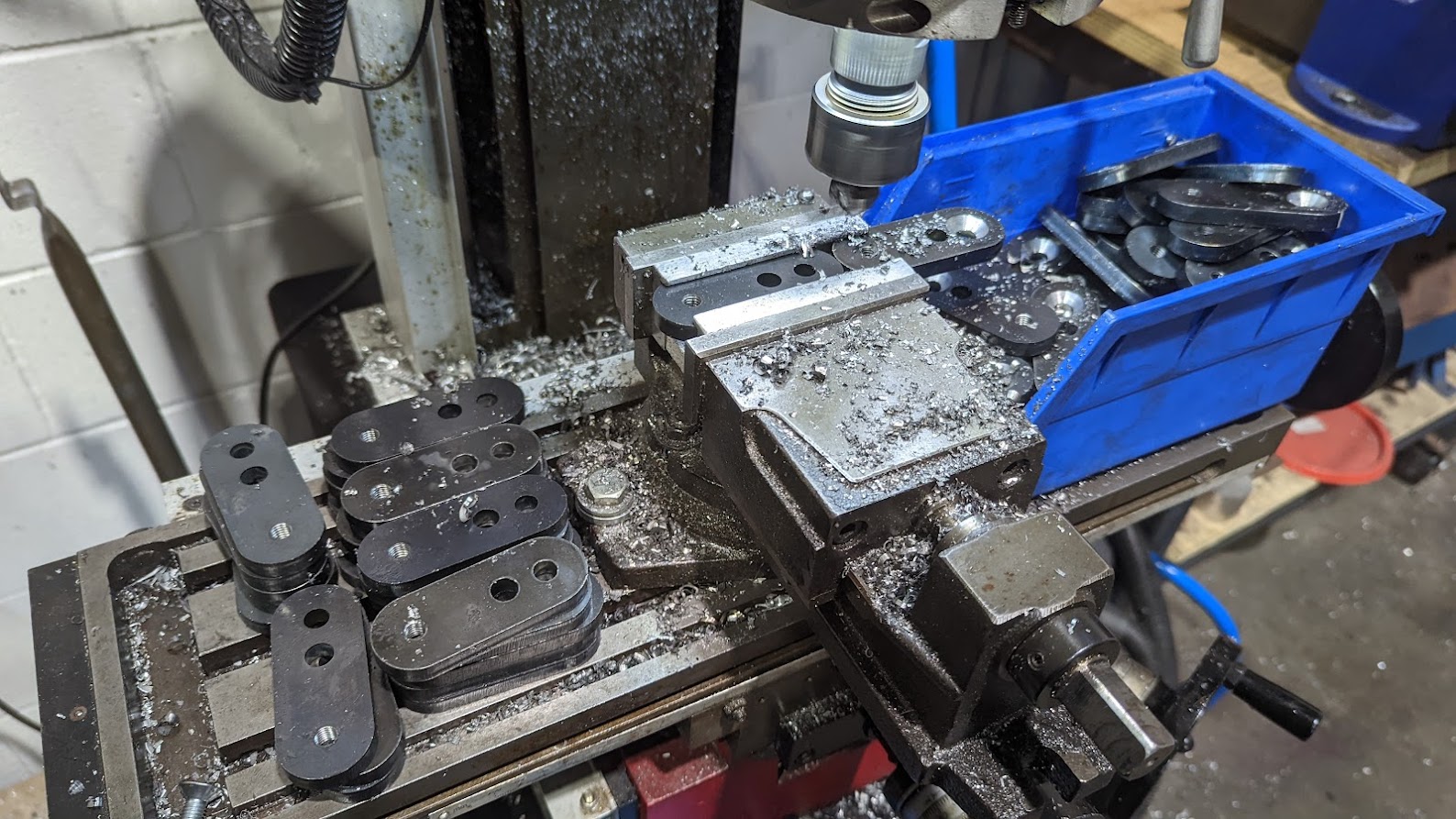

Thanks, The bit was held in an ER32 collet so I doubt it would slip. I think the real issue is the Z axis motor coupler has been slipping where the bellows attaches to the end (eg not on the shaft). I have another one here but have not had time to try swapping it out. I wanted to make a jig to hold parts for drilling and tapping but I ran out of time so I did a batch of 200 on my manual mill.

This is pretty easy with a sliding jig but its a bit underpowered on the countersinking

This means the pressure is off for now but the job is still setup so I can counterbore the holes 30mm diameter for a nut to hold it to the mill T slots and the plan is to press in some dowell pins I have to align it in the T slot.

But yes, the jacks underneath are a good idea. Thanks.

This is pretty easy with a sliding jig but its a bit underpowered on the countersinking

This means the pressure is off for now but the job is still setup so I can counterbore the holes 30mm diameter for a nut to hold it to the mill T slots and the plan is to press in some dowell pins I have to align it in the T slot.

But yes, the jacks underneath are a good idea. Thanks.

Attachments:

Last edit: 23 Apr 2022 12:11 by rodw.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

23 Apr 2022 15:42 #241000

by machinedude

Replied by machinedude on topic Rods "Spaceship" Scratch built Plasma Cutter build

ER 32 is bigger in size so if you tighten it well it should not move on you. drill chucks i don't have as much faith in. i don't really have trouble with slipping in a tool holder but my belief is there is no such thing as too tight for the most part.

i have done manual stuff like you are doing in the past just not on parts that big. the sliding fixtures work it just gets old fast doing large runs. you might be able to use a tapping head and tap holes like that as well. tapping heads are expensive to begin with and only get more expensive as the size gets bigger but i have used them in the same way you are working now with the sliding fixture. once again not fun doing tens of thousands of parts this way but it does work fast.

sometimes work is not very precise and you get into a need for just the basics and simple quick operations like this. the work i have seen like this was from stamped out parts.

i have done manual stuff like you are doing in the past just not on parts that big. the sliding fixtures work it just gets old fast doing large runs. you might be able to use a tapping head and tap holes like that as well. tapping heads are expensive to begin with and only get more expensive as the size gets bigger but i have used them in the same way you are working now with the sliding fixture. once again not fun doing tens of thousands of parts this way but it does work fast.

sometimes work is not very precise and you get into a need for just the basics and simple quick operations like this. the work i have seen like this was from stamped out parts.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.175 seconds