Retrofitting a 1986 Maho MH400E

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

26 May 2020 09:19 #168951

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Attachments:

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

26 May 2020 09:29 #168953

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Servus Hanno.

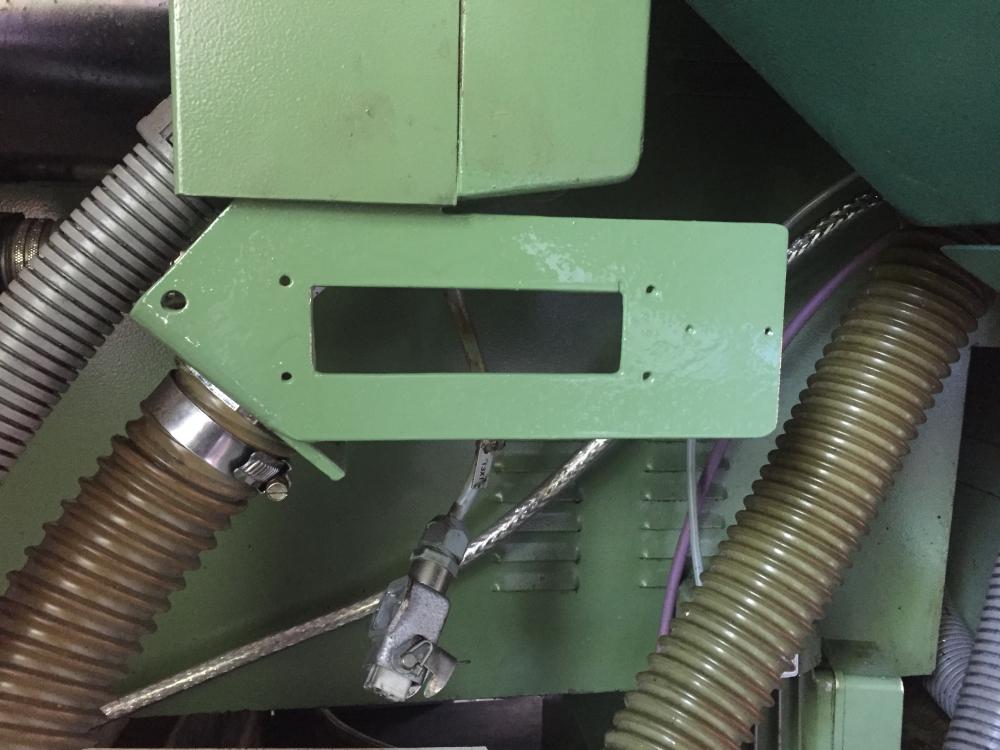

Fourth axis connector?

Fourth axis connector?

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

26 May 2020 10:06 #168957

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi Mark,

exactly !

I like to have a proper wiring from the beginning.

This includes the conduit and connectors.

There is nothing more frustrating (for me) than having the axis working and the cables still have to to be cut, relocated and wired up.

Cheers

exactly !

I like to have a proper wiring from the beginning.

This includes the conduit and connectors.

There is nothing more frustrating (for me) than having the axis working and the cables still have to to be cut, relocated and wired up.

Cheers

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

26 May 2020 10:16 #168958

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Nice. You are using an original Maho manual rotary table with encoder feedback into the control arent you?

My Maho has a connector for a fourth axis feedback, but that was all. Sooner or later I am sure I'll get motivated to do some sort of fourth axis as well. I like the cast iron framed harmonic drive Andy did, although I'd use a hollow shaft one like this:

www.ebay.at/itm/ONE-USED-harmonic-drive-...p2060353.m1438.l2649

and belt drive it to allow stock to pass through the body.

Or maybe I get lucky and pick up a 150-250 sized Nikken for a good price.

Mark

My Maho has a connector for a fourth axis feedback, but that was all. Sooner or later I am sure I'll get motivated to do some sort of fourth axis as well. I like the cast iron framed harmonic drive Andy did, although I'd use a hollow shaft one like this:

www.ebay.at/itm/ONE-USED-harmonic-drive-...p2060353.m1438.l2649

and belt drive it to allow stock to pass through the body.

Or maybe I get lucky and pick up a 150-250 sized Nikken for a good price.

Mark

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

26 May 2020 10:53 - 26 May 2020 15:00 #168965

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi Mark,

no, it is all DIY with a Sumitomo Fine Cyclo Gear:

www.cncecke.de/forum/showthread.php?1026...chse-f%FCr-Maho-400E

I'm gonna use the 4 or 5-pin original connector of MAHO's fourth-axis feedback for my z-height setter or the 3D-Digitizer and the large multi-pin Harting connector for the axis.

The axis needs cables for servo, encoder and resolver.

The next pictures, maybe tomorrow, will show that

no, it is all DIY with a Sumitomo Fine Cyclo Gear:

www.cncecke.de/forum/showthread.php?1026...chse-f%FCr-Maho-400E

I'm gonna use the 4 or 5-pin original connector of MAHO's fourth-axis feedback for my z-height setter or the 3D-Digitizer and the large multi-pin Harting connector for the axis.

The axis needs cables for servo, encoder and resolver.

The next pictures, maybe tomorrow, will show that

Last edit: 26 May 2020 15:00 by hanmon.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

07 Jun 2020 11:45 - 07 Jun 2020 12:26 #170467

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Cool, thisoldtony posted an update on his MAHO 400P project.

It really does show how much simpler machine tools have become since numeric control took over.

It really does show how much simpler machine tools have become since numeric control took over.

Last edit: 07 Jun 2020 12:26 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Christophe C.

-

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

20 Jun 2020 12:53 #172153

by Christophe C.

Replied by Christophe C. on topic Retrofitting a 1986 Maho MH400E

Hello,

First, congrats for the hard work, that's a nice machine you have now. I've been myself restoring a MH800T for a Fablab here in France ( some pictures here ); it's a lot of work but these machines are worth it.

It's running on Heidenhain and it works great so no Linux CNC for now, but that's definitely something I'd like to do one day, to maybe add a 4th axis and that kind of stuff.

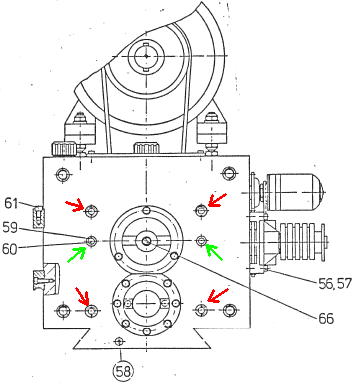

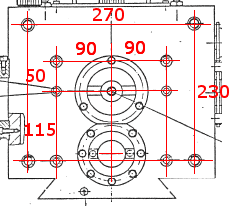

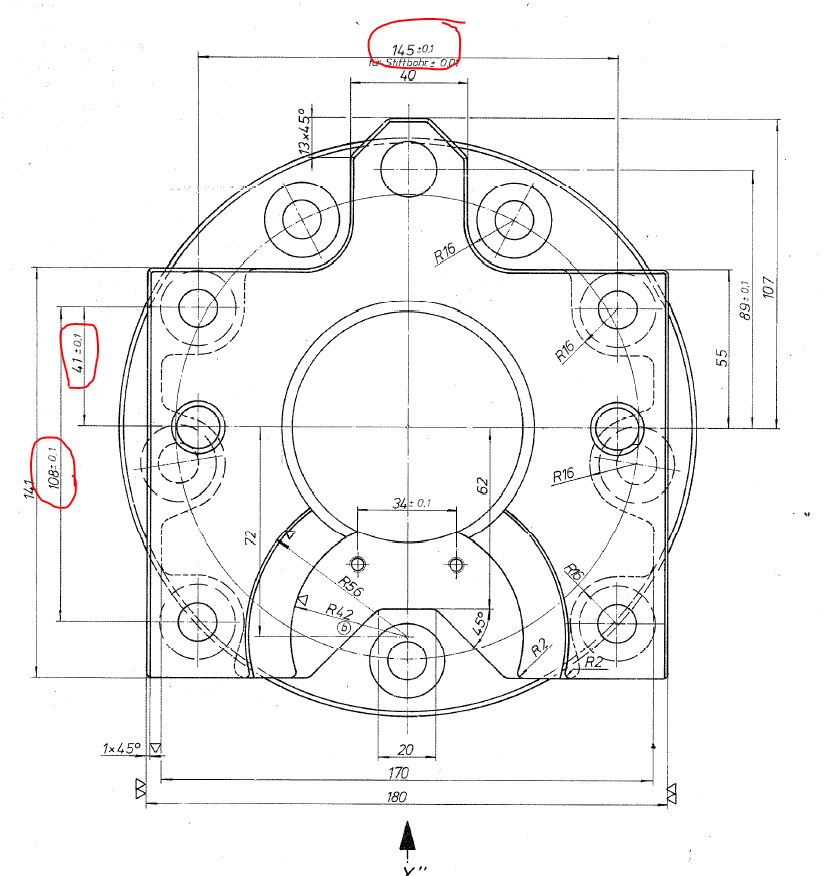

Anyway, loosing track here; I came to ask a question on your machine; I'm looking for an overarm support for horizontal milling for my machine, and I can't even find a picture of this support for 800 Maho - just a drawing on the user manual. I'm wondering if for some weird reason, the 400 and 800 may share the same support. The horizontal spindle has two bolt patterns; the largest one is used for the vertical milling head, and I have no clue what the smaller one is for, only thing I know is that it seems very similar to the bolt pattern on the 400 machine. I'm talking about these 4 threaded holes and two dowel pins :

Could you please measure the spacing of these threaded holes on your machine? Here are the measurements I have on the 800.

Thanks for you answer,

Christophe

First, congrats for the hard work, that's a nice machine you have now. I've been myself restoring a MH800T for a Fablab here in France ( some pictures here ); it's a lot of work but these machines are worth it.

It's running on Heidenhain and it works great so no Linux CNC for now, but that's definitely something I'd like to do one day, to maybe add a 4th axis and that kind of stuff.

Anyway, loosing track here; I came to ask a question on your machine; I'm looking for an overarm support for horizontal milling for my machine, and I can't even find a picture of this support for 800 Maho - just a drawing on the user manual. I'm wondering if for some weird reason, the 400 and 800 may share the same support. The horizontal spindle has two bolt patterns; the largest one is used for the vertical milling head, and I have no clue what the smaller one is for, only thing I know is that it seems very similar to the bolt pattern on the 400 machine. I'm talking about these 4 threaded holes and two dowel pins :

Could you please measure the spacing of these threaded holes on your machine? Here are the measurements I have on the 800.

Thanks for you answer,

Christophe

Attachments:

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

20 Jun 2020 13:26 - 20 Jun 2020 13:27 #172154

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Christophe,

The 800 is quite a beast! I looked at your thread. You have put a lot of work into that machine. Thanks for posting that link. It looks like you have a similar 18 speed gearbox as my little Maho, so if you do even need to retrofit it, you could use the gearbox comp for it.

When the shaping and horizontal support for a 400P came up for sale, I had the same question. I wrote to DMG and asked, and they responded by sending me this drawing from the shaping head mount. The hole pattern is 145mm wide, by 108mm high, I went in the basement and double checked that.

Either you need to improve your measuring accuracy considerably , or the 800T needs bigger accessories. Sorry.

, or the 800T needs bigger accessories. Sorry.

Mark

The 800 is quite a beast! I looked at your thread. You have put a lot of work into that machine. Thanks for posting that link. It looks like you have a similar 18 speed gearbox as my little Maho, so if you do even need to retrofit it, you could use the gearbox comp for it.

When the shaping and horizontal support for a 400P came up for sale, I had the same question. I wrote to DMG and asked, and they responded by sending me this drawing from the shaping head mount. The hole pattern is 145mm wide, by 108mm high, I went in the basement and double checked that.

Either you need to improve your measuring accuracy considerably

Mark

Last edit: 20 Jun 2020 13:27 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Christophe C.

-

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

20 Jun 2020 13:42 #172155

by Christophe C.

Replied by Christophe C. on topic Retrofitting a 1986 Maho MH400E

I will sure come back to you if/when it goes Linux CNC. I'd better start working on that before the control die as having it running would make all the retro engineering much easier.

I've seen a video of your shaping head, it's a beauty. Not a word on these accessories in the user manual? Now I need one for the 800

Regarding my measurements, I made them on a blueprint with no scale so I may be off... but sure not by that much. I will double check next time I'll be near the machine - unfortunately it doesn't fit in my basement!

Thanks for taking the time to answer!

I've seen a video of your shaping head, it's a beauty. Not a word on these accessories in the user manual? Now I need one for the 800

Regarding my measurements, I made them on a blueprint with no scale so I may be off... but sure not by that much. I will double check next time I'll be near the machine - unfortunately it doesn't fit in my basement!

Thanks for taking the time to answer!

Please Log in or Create an account to join the conversation.

- chris mcm

- Offline

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 1

12 Aug 2020 11:25 #178029

by chris mcm

Replied by chris mcm on topic Retrofitting a 1986 Maho MH400E

Hello All

You have not heard from me for a while. The capacitors were changed in the Indromat 3TRM 2. I used the machine today on a small project and all went well. I still have no DRO but that will happen shortly. We have bypassed the troublesome TNC . Impossible to do good work without the DRO as the only controls are at the consul so without reading numbers you can't see what you are doing on the work piece. I need to fit a foot switch for tool changing. Sorry about the delay. Some will think I have given up. Thanks to all who have supported me in the past. Cheers Chris .

You have not heard from me for a while. The capacitors were changed in the Indromat 3TRM 2. I used the machine today on a small project and all went well. I still have no DRO but that will happen shortly. We have bypassed the troublesome TNC . Impossible to do good work without the DRO as the only controls are at the consul so without reading numbers you can't see what you are doing on the work piece. I need to fit a foot switch for tool changing. Sorry about the delay. Some will think I have given up. Thanks to all who have supported me in the past. Cheers Chris .

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.242 seconds