Hurco KMB-IS CNC update

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

29 Aug 2020 02:57 - 29 Aug 2020 03:01 #179904

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

@Mike_Eitel

Yes I agree with you, not the best times. I have had my parents in isolation since March as they both are recovering from cancer. I am on the other end of the farm from them and their link to the outside world.

I have not made it to Oregon yet, but want to go (Mt. Hood). I am on the opposite side of the country in completely flat land (state of Georgia). I have been to Washington the state above Oregon and have hiked Mt Rainier and Mt St. Helens. Mt Rainier is awesome when the weather is clear.

EDIT: Well not as awesome as your Swiss Alps..

Leith lives in the state of Colorado. He has some excellent National Parks close to his area. I have been to Colorado years ago, but want to go back for Rocky Mountain National Park. I am still on that trek to see as many National Parks as I can see. I've got some hard one's under my belt, but some are impossible for me like Gates of the Arctic (bush plane to get there).

Yes I hope that this virus mess is over soon. It has not been good for the world, and wish it had never happened. We were planning on going to Glacier National Park this month of August, but that was put on hold way back. We had been planning for over a year. Will be glad when the world is finally rid of it, and everyone can safely move around....

Robert

Yes I agree with you, not the best times. I have had my parents in isolation since March as they both are recovering from cancer. I am on the other end of the farm from them and their link to the outside world.

I have not made it to Oregon yet, but want to go (Mt. Hood). I am on the opposite side of the country in completely flat land (state of Georgia). I have been to Washington the state above Oregon and have hiked Mt Rainier and Mt St. Helens. Mt Rainier is awesome when the weather is clear.

EDIT: Well not as awesome as your Swiss Alps..

Leith lives in the state of Colorado. He has some excellent National Parks close to his area. I have been to Colorado years ago, but want to go back for Rocky Mountain National Park. I am still on that trek to see as many National Parks as I can see. I've got some hard one's under my belt, but some are impossible for me like Gates of the Arctic (bush plane to get there).

Yes I hope that this virus mess is over soon. It has not been good for the world, and wish it had never happened. We were planning on going to Glacier National Park this month of August, but that was put on hold way back. We had been planning for over a year. Will be glad when the world is finally rid of it, and everyone can safely move around....

Robert

Last edit: 29 Aug 2020 03:01 by CORBETT.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

29 Aug 2020 19:21 #179959

by CORBETT

Leith,

Happen to see this on the rear of a Hurco BMC 20... which they are a later model than our time period (late 80's-early 90's). It had the dual screen Ultimax II control. Personally I think they took it off the previous machine and added it to this one... the Amphenol looks old and is missing one bolt.... Most likely to re-use the indexer from the previous machine. Plus this had a DB9 connector at a different location for DNC. I am sure it was a previous Hurco machine to re-use the Amphenol connector, as our Hyperdex indexer was wired for Monarch VMC's and it could be moved between our three VMC's, but not work with anything else we had (Cincinnati Milacron, Bridgeport, etc..) without re-wiring..

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Happen to see this on the rear of a Hurco BMC 20... which they are a later model than our time period (late 80's-early 90's). It had the dual screen Ultimax II control. Personally I think they took it off the previous machine and added it to this one... the Amphenol looks old and is missing one bolt.... Most likely to re-use the indexer from the previous machine. Plus this had a DB9 connector at a different location for DNC. I am sure it was a previous Hurco machine to re-use the Amphenol connector, as our Hyperdex indexer was wired for Monarch VMC's and it could be moved between our three VMC's, but not work with anything else we had (Cincinnati Milacron, Bridgeport, etc..) without re-wiring..

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

29 Aug 2020 19:49 - 29 Aug 2020 20:29 #179962

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Attachments:

Last edit: 29 Aug 2020 20:29 by CORBETT.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

29 Aug 2020 22:26 - 29 Aug 2020 22:27 #179977

by CORBETT

Leith,

Me and my Dad built this years ago for our larger excavator. We needed to repack one of the large hydraulic cylinders and this was the quick and dirty spanner wrench we made. You can make the same concept for your kwik switch spindle to get by until finding a good one at a cheap price.

This one is pretty big as it is 5' long and has a 4-1/2" spanner on the end. The handle is 1" pipe and the spanner is nothing more than 4" pipe cut about 1-1/2" long for width and then we split the piece to what you see welded to the 1" handle. Then drilled a 3/8" hole, then cut off a 3/8" shoulder bolt to fit down in making the pin. You could weld the pin in... we had to put ours in after spanner was put in place is why it is removable.

Just a idea to get by....

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Me and my Dad built this years ago for our larger excavator. We needed to repack one of the large hydraulic cylinders and this was the quick and dirty spanner wrench we made. You can make the same concept for your kwik switch spindle to get by until finding a good one at a cheap price.

This one is pretty big as it is 5' long and has a 4-1/2" spanner on the end. The handle is 1" pipe and the spanner is nothing more than 4" pipe cut about 1-1/2" long for width and then we split the piece to what you see welded to the 1" handle. Then drilled a 3/8" hole, then cut off a 3/8" shoulder bolt to fit down in making the pin. You could weld the pin in... we had to put ours in after spanner was put in place is why it is removable.

Just a idea to get by....

Last edit: 29 Aug 2020 22:27 by CORBETT. Reason: spelling

The following user(s) said Thank You: _big_

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

31 Aug 2020 15:27 #180180

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Hi Robert,

I think we've got a kwik switch spindle wrench solution. Thanks for the pics.

And, we've got a line on a couple servo motors on Ebay. Most of them are the -049 suffix and we need the -089 suffix. Hopefully we can get them for a low price and then we'll find out if they work.

I think we've got a kwik switch spindle wrench solution. Thanks for the pics.

And, we've got a line on a couple servo motors on Ebay. Most of them are the -049 suffix and we need the -089 suffix. Hopefully we can get them for a low price and then we'll find out if they work.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Sep 2020 01:28 #180248

by CORBETT

Leith,

I have been out of town all day and just got back... haven't had a chance to check in until now.

Good deal on the motors... hopefully you will get something that will work. I think really it's all about how long the shaft out the front that will matter. I am pretty sure they all have the same bolt pattern on the front of the motor...

Ok good deal on the wrench. I was thinking you still needed to do something is why I was sending pics. Was trying to give the cheap elbow grease approach LOL.

Ok I still need to try and get the parts manual taken care of for you. I have not pushed my Dad about getting everything out as he has been feeling rough for the last week. When I think he is feeling up to par I will get him to start pulling everything so I can scan the sheets. I will keep you posted about it and work on getting it done soon. Like before, if you need something specific let me know and I will start searching. Wish I had more done, but just not enough time.

Your moving along well, you have made a lot of progress figuring things out in a short period of time... you should be up and running way quicker than I was.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

I have been out of town all day and just got back... haven't had a chance to check in until now.

Good deal on the motors... hopefully you will get something that will work. I think really it's all about how long the shaft out the front that will matter. I am pretty sure they all have the same bolt pattern on the front of the motor...

Ok good deal on the wrench. I was thinking you still needed to do something is why I was sending pics. Was trying to give the cheap elbow grease approach LOL.

Ok I still need to try and get the parts manual taken care of for you. I have not pushed my Dad about getting everything out as he has been feeling rough for the last week. When I think he is feeling up to par I will get him to start pulling everything so I can scan the sheets. I will keep you posted about it and work on getting it done soon. Like before, if you need something specific let me know and I will start searching. Wish I had more done, but just not enough time.

Your moving along well, you have made a lot of progress figuring things out in a short period of time... you should be up and running way quicker than I was.

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

13 Sep 2020 16:22 #182019

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Got three used 0703-02-049 motors off of Ebay.

The only discernible differences between the 0703-02-049 and the currently installed 0703-02-089 motors is the leads and a slightly different location for the keyway. Fortunately, our machine isn't sensitive to either of these issues.

I installed a new-used motor on the Y axis, and it seems to work. I can apply +-1V across the drive input and get the Y axis to move in both directions. The over current light on the drive no longer comes on.

So I think I'm back in business.

I did look at some of the brushes. The new-used one I looked at was about 3/8 inches long. The brushes I've seen in the existing motors are about 1/2 inch long. Hurco says the brushes are good to go until they get down to about 0.2 inches.

I'm a bit reluctant to mess with/clean the existing motors... if it ain't broke, don't fix it.

The only discernible differences between the 0703-02-049 and the currently installed 0703-02-089 motors is the leads and a slightly different location for the keyway. Fortunately, our machine isn't sensitive to either of these issues.

I installed a new-used motor on the Y axis, and it seems to work. I can apply +-1V across the drive input and get the Y axis to move in both directions. The over current light on the drive no longer comes on.

So I think I'm back in business.

I did look at some of the brushes. The new-used one I looked at was about 3/8 inches long. The brushes I've seen in the existing motors are about 1/2 inch long. Hurco says the brushes are good to go until they get down to about 0.2 inches.

I'm a bit reluctant to mess with/clean the existing motors... if it ain't broke, don't fix it.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7228

13 Sep 2020 17:39 #182026

by tommylight

Replied by tommylight on topic Hurco KMB-IS CNC update

Remove the brushes and blow some air through, does not break anything and the drive will thank you for not having to work more than it should.

The following user(s) said Thank You: _big_

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

13 Sep 2020 22:51 #182041

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

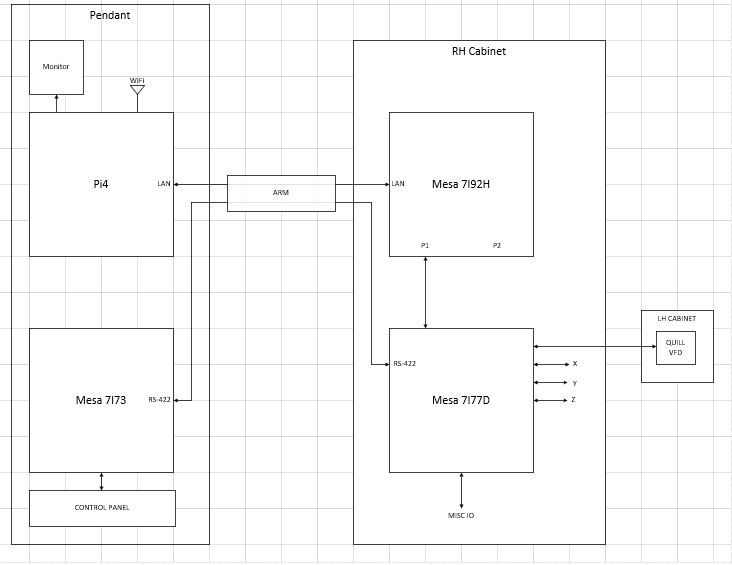

First pass at Pi4/Mesa block diagram for the Hurco.

The idea is to keep the Pi4 in the pendant, run CAT5 to the 7192H in the RH cabinet. This keeps the HDMI/keyboard/mouse near the operator console. CAT5 cable is relatively small and should be robust over such a short distance.

Expectation is there will be a keyboard and mouse to run the LinuxCNC. And also some set of buttons and an RPG for manual movement control.

The 7I33 is probably not absolutely necessary. Could possibly use the Pi4 GPIO. But maybe the 7I73 is more compatible with LinuxCNC. Use of the 7I73 will require another CAT5 through the arm, but that shouldn't be a problem.

I haven't found a definitive ruling on the suitability of Pi4 with LinuxCNC. I happen to have a Pi4 lying around. Will start with that and keep the option open for some x86 based computer, the Odroid-H2+ looks promising.

The idea is to keep the Pi4 in the pendant, run CAT5 to the 7192H in the RH cabinet. This keeps the HDMI/keyboard/mouse near the operator console. CAT5 cable is relatively small and should be robust over such a short distance.

Expectation is there will be a keyboard and mouse to run the LinuxCNC. And also some set of buttons and an RPG for manual movement control.

The 7I33 is probably not absolutely necessary. Could possibly use the Pi4 GPIO. But maybe the 7I73 is more compatible with LinuxCNC. Use of the 7I73 will require another CAT5 through the arm, but that shouldn't be a problem.

I haven't found a definitive ruling on the suitability of Pi4 with LinuxCNC. I happen to have a Pi4 lying around. Will start with that and keep the option open for some x86 based computer, the Odroid-H2+ looks promising.

Attachments:

Please Log in or Create an account to join the conversation.

- Chungus

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 0

27 Sep 2020 18:03 #184010

by Chungus

Replied by Chungus on topic Hurco KMB-IS CNC update

Hello I am working on a hurco km3 refit and I came across this thread and has already given me a lot of useful information. Thank you! I had some questions about the e-stop circuit on how to find it and how to wire it into the mesa card? My machine was running briefly when I first got it home but only with one screen. Shortly after the other screen has went out and will cost more than I even paid for the machine to fix. So as it sits I can still power it up and jog around the axis. I made a short video showing some of what I have figured out so far and my cabinet looks very similar to the kmb. Any help would be appreciated on the e-stop circuit and how I should go about tying into the existing terminal blocks.

Link to the video:

just trying to save myself some headaches before I start disconnecting anything I don't need to.

I also have some close up pictures that I can post

Link to the video:

just trying to save myself some headaches before I start disconnecting anything I don't need to.

I also have some close up pictures that I can post

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.325 seconds