Hurco KMB-IS CNC update

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

25 Aug 2020 23:29 #179465

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

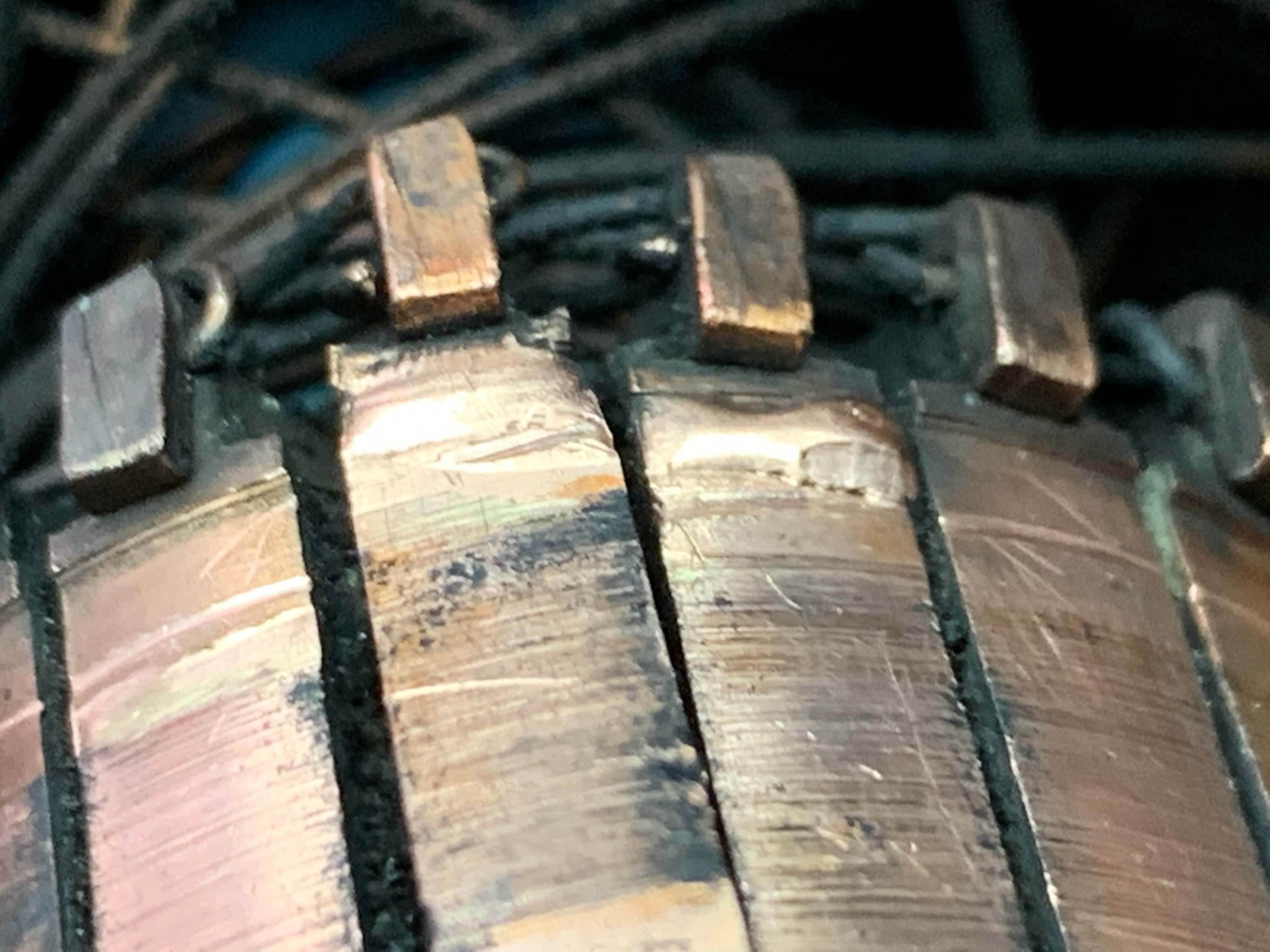

Took the ailing Y-Axis servo motor apart today. And it ain't good.You can see what looks like solder/braze blobs at the top of these commutator segments.

While trying to clean the space between the commutator segments, I noticed the left segment above was loose, sorta like a loose tooth. Pretty sure the commutator got too hot. Why is a good question.

Now my guess about the story behind this machine is the Y-Axis quit. It became the donor shop machine which is why so many pieces are missing.

Checked with a servo rebuild house. They said sure, we can rebuild your armature. Be sure and include a check for $1200 when you send us the motor.

We would end up with essentially a brand new servo motor. But I gotta wonder if we might be better off getting a new(er) motor and drive. Anybody out that have a suggestion where I could find a serviceable 1KW servo for cheap? Doesn't have to be brand new.

And, are there any issues with LinuxCNC managing heterogeneous servo paths? The two existing paths are analog with I think 200 clicks per turn encoders. A new(er) servo is likely to be step/dir and a finer encoder.

While trying to clean the space between the commutator segments, I noticed the left segment above was loose, sorta like a loose tooth. Pretty sure the commutator got too hot. Why is a good question.

Now my guess about the story behind this machine is the Y-Axis quit. It became the donor shop machine which is why so many pieces are missing.

Checked with a servo rebuild house. They said sure, we can rebuild your armature. Be sure and include a check for $1200 when you send us the motor.

We would end up with essentially a brand new servo motor. But I gotta wonder if we might be better off getting a new(er) motor and drive. Anybody out that have a suggestion where I could find a serviceable 1KW servo for cheap? Doesn't have to be brand new.

And, are there any issues with LinuxCNC managing heterogeneous servo paths? The two existing paths are analog with I think 200 clicks per turn encoders. A new(er) servo is likely to be step/dir and a finer encoder.

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

26 Aug 2020 01:49 #179479

by CORBETT

Holy freaking ouch... yeah that is bad. I was about to ask in a post last night if you had done anything with the motor. That is terrible. The only thing worse is the $1200 repair quote.

Your not dead in the water, I will give some options of what I would do and maybe others can chime in with their thoughts also.

I will be back later or worse case tomorrow. I have burned the candle from both ends too long and I need to get some sleep tonight, but I will try to post a few comments on things I saw from your pics.

Your making a lot happen, so good deal....

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Holy freaking ouch... yeah that is bad. I was about to ask in a post last night if you had done anything with the motor. That is terrible. The only thing worse is the $1200 repair quote.

Your not dead in the water, I will give some options of what I would do and maybe others can chime in with their thoughts also.

I will be back later or worse case tomorrow. I have burned the candle from both ends too long and I need to get some sleep tonight, but I will try to post a few comments on things I saw from your pics.

Your making a lot happen, so good deal....

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

26 Aug 2020 02:44 #179483

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Inspired by this....

The Electro Craft is nowhere near as bad as the motor in the video.

So why not. What's the worst that could possibly happen? I think it would still be $1200 to rebuild the armature.

If it does work, wouldn't trust my life to it. Maybe it will work long enough to find a replacement.

The Electro Craft is nowhere near as bad as the motor in the video.

So why not. What's the worst that could possibly happen? I think it would still be $1200 to rebuild the armature.

If it does work, wouldn't trust my life to it. Maybe it will work long enough to find a replacement.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

26 Aug 2020 03:02 #179487

by CORBETT

This is not a problem for each axis as in the INI file you will have separate sections for each axis/joint that can be configured for the type of equipment you have. Just as an example, (and I would not do this at all) but you could technically keep the X and Z as they are existing with servo motors. Then change the Y to a NEMA 42 stepper motor and simply configure in INI. So yes you can mix up hardware as it is no different than having a small sherline CNC lathe with steppers on each axis, but changing the DC spindle motor to a servo motor with encoder to get spindle feedback for threading.... same concept. For a short period I ran a parallel port card (base thread) along with EtherCAT driver (servo thread), so yeah no issue. LinuxCNC is super versatile and there are fixes and work around's for all types of problems. Can do ladder logic and there is basically a HAL component for practically any problem.

The only problem with step/dir is that you are adding the "base thread" back into your code to get the step generators. The only drawback to using the "Base Thread" is that latency will show up worse. So it would be more critical for getting a motherboard from the list with proven low latency if you did go the step/dir route. When you are using an analog setup only without step/direction then you can use the "servo thread" only and latency becomes way less of a factor. I know Mesa was even saying way back that the little mini ITX boards with the embedded atom chips would work with their hardware and not be a issue... and even could use the slow little Intel Atom D525 boards.

Personally I like the EtherCAT setup for the bus speed & resolution, just don't have support. My second choice would be Mesa or Pico and still staying with analog for servo thread. Tom (Tommylight) or Pete Wallace (PCW) will be able to advise on what hardware would give you the least problems with latency and issues when using Mesa. Just for the record, Pete Wallace is Mesa.. so if you go with Mesa and when you get info from (PCW) your getting it directly from the main man.. Jon Elson is Pico and nothing wrong with Pico.

I am pretty tired, so I believe I have everything worded right so I don't get you miss informed, if not Tom can correct me.... I have got to get in bed.. exhausted. I have a long day tomorrow, but will be back along and along to try and add some more comments from the pics you posted.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

And, are there any issues with LinuxCNC managing heterogeneous servo paths? The two existing paths are analog with I think 200 clicks per turn encoders. A new(er) servo is likely to be step/dir and a finer encoder.

This is not a problem for each axis as in the INI file you will have separate sections for each axis/joint that can be configured for the type of equipment you have. Just as an example, (and I would not do this at all) but you could technically keep the X and Z as they are existing with servo motors. Then change the Y to a NEMA 42 stepper motor and simply configure in INI. So yes you can mix up hardware as it is no different than having a small sherline CNC lathe with steppers on each axis, but changing the DC spindle motor to a servo motor with encoder to get spindle feedback for threading.... same concept. For a short period I ran a parallel port card (base thread) along with EtherCAT driver (servo thread), so yeah no issue. LinuxCNC is super versatile and there are fixes and work around's for all types of problems. Can do ladder logic and there is basically a HAL component for practically any problem.

The only problem with step/dir is that you are adding the "base thread" back into your code to get the step generators. The only drawback to using the "Base Thread" is that latency will show up worse. So it would be more critical for getting a motherboard from the list with proven low latency if you did go the step/dir route. When you are using an analog setup only without step/direction then you can use the "servo thread" only and latency becomes way less of a factor. I know Mesa was even saying way back that the little mini ITX boards with the embedded atom chips would work with their hardware and not be a issue... and even could use the slow little Intel Atom D525 boards.

Personally I like the EtherCAT setup for the bus speed & resolution, just don't have support. My second choice would be Mesa or Pico and still staying with analog for servo thread. Tom (Tommylight) or Pete Wallace (PCW) will be able to advise on what hardware would give you the least problems with latency and issues when using Mesa. Just for the record, Pete Wallace is Mesa.. so if you go with Mesa and when you get info from (PCW) your getting it directly from the main man.. Jon Elson is Pico and nothing wrong with Pico.

I am pretty tired, so I believe I have everything worded right so I don't get you miss informed, if not Tom can correct me.... I have got to get in bed.. exhausted. I have a long day tomorrow, but will be back along and along to try and add some more comments from the pics you posted.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

26 Aug 2020 03:06 - 26 Aug 2020 03:09 #179488

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

I just saw the post where you have the armature video. I haven't watched it yet, but just the pic is enough... LOL

EDIT: But yeah I would try it to get by and get it working for a bit. You are right, nothing to loose...

I will catch you tomorrow, will have more info to hopefully help you with.

Robert

I just saw the post where you have the armature video. I haven't watched it yet, but just the pic is enough... LOL

EDIT: But yeah I would try it to get by and get it working for a bit. You are right, nothing to loose...

I will catch you tomorrow, will have more info to hopefully help you with.

Robert

Last edit: 26 Aug 2020 03:09 by CORBETT.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

26 Aug 2020 11:32 #179513

by tommylight

Replied by tommylight on topic Hurco KMB-IS CNC update

That would be a nice exercise in patience, but i would not bother with it, try to find something that fits, frame and shaft wise, with near enough characteristics.

The following user(s) said Thank You: CORBETT

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17590

- Thank you received: 5145

26 Aug 2020 14:51 #179550

by PCW

This is only true if you are using a parallel port for step/dir, if you are using a hardware

stepgen (Pico, Mesa etc) you only need a servo thread

Replied by PCW on topic Hurco KMB-IS CNC update

The only problem with step/dir is that you are adding the "base thread"

This is only true if you are using a parallel port for step/dir, if you are using a hardware

stepgen (Pico, Mesa etc) you only need a servo thread

The following user(s) said Thank You: CORBETT, _big_

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

26 Aug 2020 17:15 #179558

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Pete is totally correct, I was referring to the parallel port driver and messed up about the Mesa hardware driver. That is why I am glad Tom and Pete check behind in case I screw up.

I have to run to a jobsite, but will be back later... have to go out of town tomorrow, but will try to get more info for you tonight.

Robert

Pete is totally correct, I was referring to the parallel port driver and messed up about the Mesa hardware driver. That is why I am glad Tom and Pete check behind in case I screw up.

I have to run to a jobsite, but will be back later... have to go out of town tomorrow, but will try to get more info for you tonight.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

27 Aug 2020 02:36 #179628

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

I couldn't get on until now.. have been busy, plus some rough lighting again. I have to cut it short unfortunately and get in the bed. I will be back tomorrow night as I will be out of town during the day...

Definitely have replies to make on things I saw... I believe your MPU is different from my original board from what I remember. I have it boxed up, but going to find it so we can compare the two... pretty sure mine had 2 or 3 connectors. Not the AMTS board, but the original Hurco OEM board.... plus I should be able to fine the part number on the board to see if they match.

Also, I would try making a offer to some of the people on Ebay for a used servo that matches up. There was some on there the other day that were exact. That would be the easiest for bolting right in, and stay cheap for the fix.... well that is if they took a cheaper offer. But if you wanted to move on with new setup, then you could keep the Max 430 as a backup for the other 2 still in use.

Also, no on RS-232... going to backtrack after seeing and say its the indexer output. Will get with you... after seeing it makes more sense what you were describing... I was thinking it was like my plug but with the Opto22 cut into the wiring. But no that is Hurco all the way.

Anyway, will catch you tomorrow night... sorry couldn't keep going, not enough time in the day...

Robert

I couldn't get on until now.. have been busy, plus some rough lighting again. I have to cut it short unfortunately and get in the bed. I will be back tomorrow night as I will be out of town during the day...

Definitely have replies to make on things I saw... I believe your MPU is different from my original board from what I remember. I have it boxed up, but going to find it so we can compare the two... pretty sure mine had 2 or 3 connectors. Not the AMTS board, but the original Hurco OEM board.... plus I should be able to fine the part number on the board to see if they match.

Also, I would try making a offer to some of the people on Ebay for a used servo that matches up. There was some on there the other day that were exact. That would be the easiest for bolting right in, and stay cheap for the fix.... well that is if they took a cheaper offer. But if you wanted to move on with new setup, then you could keep the Max 430 as a backup for the other 2 still in use.

Also, no on RS-232... going to backtrack after seeing and say its the indexer output. Will get with you... after seeing it makes more sense what you were describing... I was thinking it was like my plug but with the Opto22 cut into the wiring. But no that is Hurco all the way.

Anyway, will catch you tomorrow night... sorry couldn't keep going, not enough time in the day...

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

27 Aug 2020 15:07 - 27 Aug 2020 15:07 #179694

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

The broken motor is Electro Craft part number 0703-02-089.

There are currently three similar motors on Ebay. Part numbers are 0703-02-039 and 0703-02-049.

www.ebay.com/itm/Electro-Craft-0703-02-0...b:g:oboAAOSwhvpdxwcK

I suspect all these motors are very similar. But I don't know what the -089, -039 and -049 suffixes mean.

The good news is, my -089 is just a motor generator. The encoder for this axis is on the screw. The Ebay motors include encoders. These can either be removed or simply left unconnected in my application.

So the big question is, does anybody have a 40 year old secret decoder ring for Electro Craft motor part numbers?

There are currently three similar motors on Ebay. Part numbers are 0703-02-039 and 0703-02-049.

www.ebay.com/itm/Electro-Craft-0703-02-0...b:g:oboAAOSwhvpdxwcK

I suspect all these motors are very similar. But I don't know what the -089, -039 and -049 suffixes mean.

The good news is, my -089 is just a motor generator. The encoder for this axis is on the screw. The Ebay motors include encoders. These can either be removed or simply left unconnected in my application.

So the big question is, does anybody have a 40 year old secret decoder ring for Electro Craft motor part numbers?

Last edit: 27 Aug 2020 15:07 by _big_.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.129 seconds