Retrofitting a TOS FNG 32 NC

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

28 Jul 2022 13:39 - 28 Jul 2022 13:48 #248533

by Kevin_Pawlus

Thank you, this is my first milling machine.

I suspect that to. I also have two more motors i'm not sure about, the first one is mounted on the bottom base of the machine. I think this one could be the build-in pump for flood cooling. The previous owner used an external cooling pump that stood beside the machine and I will use the same pump.

Then there is a third motor that I don't have located yet. I can hear it starting when engage the contactor but i'm not sure where its coming from. This would be easier tomorrow when I'm not alone in the workshop

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Nice machine.

Could that motor run the central lube system pump?

Thank you, this is my first milling machine.

I suspect that to. I also have two more motors i'm not sure about, the first one is mounted on the bottom base of the machine. I think this one could be the build-in pump for flood cooling. The previous owner used an external cooling pump that stood beside the machine and I will use the same pump.

Then there is a third motor that I don't have located yet. I can hear it starting when engage the contactor but i'm not sure where its coming from. This would be easier tomorrow when I'm not alone in the workshop

Attachments:

Last edit: 28 Jul 2022 13:48 by Kevin_Pawlus.

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

29 Jul 2022 20:44 #248651

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

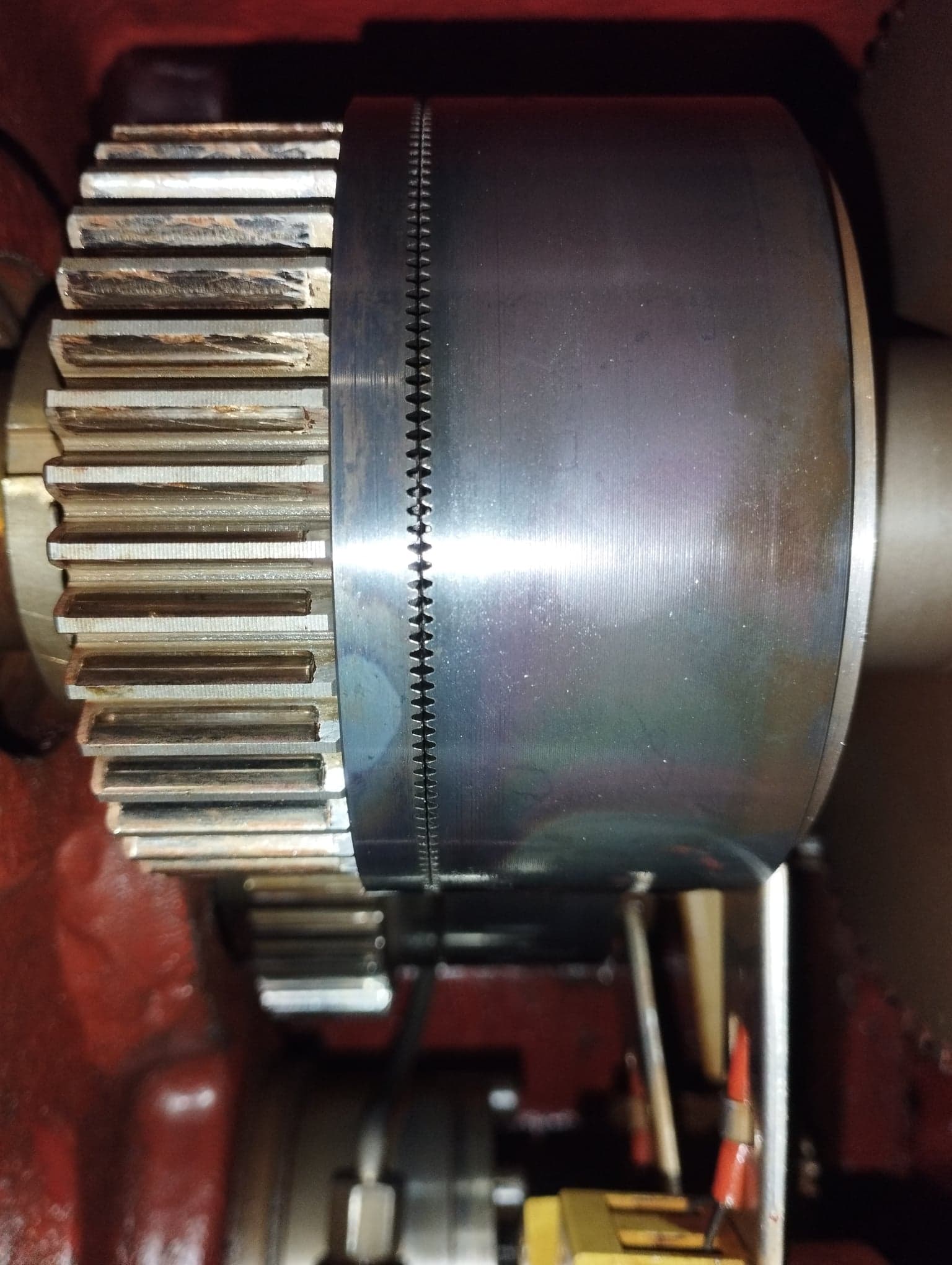

Ok, turns out that I had misunderstood how the gears work. They are not hydraulic at all, instead they are controlled by an electromagnetic tooth clutch, one for each gear so it makes it easy to control. I just give them 24V and they engage.

The hydraulics is used to automaticly release the tool but that function has been removed. It is also used to counter balance the table.

I tested all the limit switches and estop today, feels much better to have that. The main power to the spindel and drives is also controlled by estop now.

The hydraulics is used to automaticly release the tool but that function has been removed. It is also used to counter balance the table.

I tested all the limit switches and estop today, feels much better to have that. The main power to the spindel and drives is also controlled by estop now.

Attachments:

The following user(s) said Thank You: arvidb, tommylight

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

30 Jul 2022 19:09 #248688

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

I tried to run XYZ today but I have some problems.

When I press F2 in Axis, the machine immediately start to move down and to the right. Only about 10mm until I get joint following error.

I have checked the wiring 3 times. One time I unplugged X & Z and the same thing happend to Y after a couple of seconds. It makes a "jump" and I get joint error.

When I press F2 in Axis, the machine immediately start to move down and to the right. Only about 10mm until I get joint following error.

I have checked the wiring 3 times. One time I unplugged X & Z and the same thing happend to Y after a couple of seconds. It makes a "jump" and I get joint error.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5156

30 Jul 2022 19:24 #248690

by PCW

Replied by PCW on topic Retrofitting a TOS FNG 32 NC

Are you sure the feedback is in the correct direction?

A quick runaway and a following error is expected if the feedback is reversed

(the way to fix this is to change the sign of OUTPUT_SCALE in the ini file)

A quick runaway and a following error is expected if the feedback is reversed

(the way to fix this is to change the sign of OUTPUT_SCALE in the ini file)

The following user(s) said Thank You: Kevin_Pawlus

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

31 Jul 2022 09:50 #248709

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

I have changed the polarity of on of the pairs coming from my encodes, I had it backwards before.

I also changed inside the .ini file on one axis. So I believe every direction are correct now.

I only have 1 axis plugged in when testing and when I hit F2 the axis start to vibrate heavy. It's going 3mm forward, then 3mm backward very fast.

I get joint following erreor after 1 sec.

Same on all axis.

I also changed inside the .ini file on one axis. So I believe every direction are correct now.

I only have 1 axis plugged in when testing and when I hit F2 the axis start to vibrate heavy. It's going 3mm forward, then 3mm backward very fast.

I get joint following erreor after 1 sec.

Same on all axis.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21219

- Thank you received: 7246

31 Jul 2022 10:41 #248714

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

Ooen the "calibration" from the "machine" menu, set the P gain lower, click on test, then OK, then save to file after finding the right value.

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

The following user(s) said Thank You: Kevin_Pawlus

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

31 Jul 2022 11:14 #248716

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Thanks. I changed from 50 to 5. Now I can jog the machine.

Moving on to tuning the axis

Moving on to tuning the axis

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

31 Jul 2022 15:53 #248738

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

You are on the right track.

With your settings of output scale, min ans max output of 10....you will find that ff1 needs to be in the 0.1 - 0.2 range.

Set ff1 to 0, the increase P untill you get oscilation, decrwase p the by about 20%.

You should now see a following error symmetric around zero when jogging both ways.

The set ff1 to 0.1 and observe the following error. Change ff1 to 0.15 and check again. When you get close, reduce the increment of change to ff1. I normally tune ff1 to at least 3 significant digits.

With your settings of output scale, min ans max output of 10....you will find that ff1 needs to be in the 0.1 - 0.2 range.

Set ff1 to 0, the increase P untill you get oscilation, decrwase p the by about 20%.

You should now see a following error symmetric around zero when jogging both ways.

The set ff1 to 0.1 and observe the following error. Change ff1 to 0.15 and check again. When you get close, reduce the increment of change to ff1. I normally tune ff1 to at least 3 significant digits.

The following user(s) said Thank You: Kevin_Pawlus

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

02 Aug 2022 12:55 #248836

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

I have been tuning all axis now, they move really smooth and its a nice feeling to see that the machine is finally moving again.

I've been trying to get the spindle running. I see that there is some values you can change inside LinuxCNC calibration, similar to the XYZ. Don't know how to set those up correctly. I dont get the spindle to run at all. Is there something more then to press F9/F10 in Axis?

I have wired from pin 7 -> Enable on Mesa -> 63,64 & 80. My +-10V is beteween 56 & 14.

I've been trying to get the spindle running. I see that there is some values you can change inside LinuxCNC calibration, similar to the XYZ. Don't know how to set those up correctly. I dont get the spindle to run at all. Is there something more then to press F9/F10 in Axis?

I have wired from pin 7 -> Enable on Mesa -> 63,64 & 80. My +-10V is beteween 56 & 14.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21219

- Thank you received: 7246

02 Aug 2022 17:30 #248854

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

After F9/F10, F11 and F12 will raise or lower the speed.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.559 seconds