Retrofitting a TOS FNG 32 NC

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

18 Jul 2022 19:19 #247722

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Ok, sorry I was not aware of that  Will not happen again.

Will not happen again.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

19 Jul 2022 05:13 #247749

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

HI

Attached is part of my config for the maho i retrofitted last year.

It uses the same mesa config as your setup.

Note that the spindle in this config was not a variable speed spindle and i created a custom component to manage the gearbox. this was called "gearchange". i commented all that out of the files attached, but it is possible that there may be some remnants that will cause it to error when you launch this config, but it should be a good example. jumper the 7i94 for 10.10.10.10 ip adress

Anyway, not sure if it is going to be of any help.

You can create a config using pncconf with a 7i92 and 7i77, then find and replace "7i92" with "7i94"

Note that for your machine, you will not be able to create a config that covers all the aspects of your machine. there will be some hand editing of the hal file required. but you should be able to get a basic config that can control the axes, coolant and maybe the spindle if there is no gearbox

Attached is part of my config for the maho i retrofitted last year.

It uses the same mesa config as your setup.

Note that the spindle in this config was not a variable speed spindle and i created a custom component to manage the gearbox. this was called "gearchange". i commented all that out of the files attached, but it is possible that there may be some remnants that will cause it to error when you launch this config, but it should be a good example. jumper the 7i94 for 10.10.10.10 ip adress

Anyway, not sure if it is going to be of any help.

You can create a config using pncconf with a 7i92 and 7i77, then find and replace "7i92" with "7i94"

Note that for your machine, you will not be able to create a config that covers all the aspects of your machine. there will be some hand editing of the hal file required. but you should be able to get a basic config that can control the axes, coolant and maybe the spindle if there is no gearbox

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

19 Jul 2022 20:55 - 19 Jul 2022 21:02 #247789

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Thank you for your files, I really appreciate the help. How many gears did your maho have?

I have 3 controlled by hydraulic. Do I make some ladder program that controls the gears? Like if the rpm is set to 800rpm the machine atomatically changes to the right gear before the program start.

Today I connected the signals to X-Y-Z servos, I believe I can start the machine tomorrow and see if I get some movement. I have 1 EXE box to connect tomorrow and 2 more are coming soon.

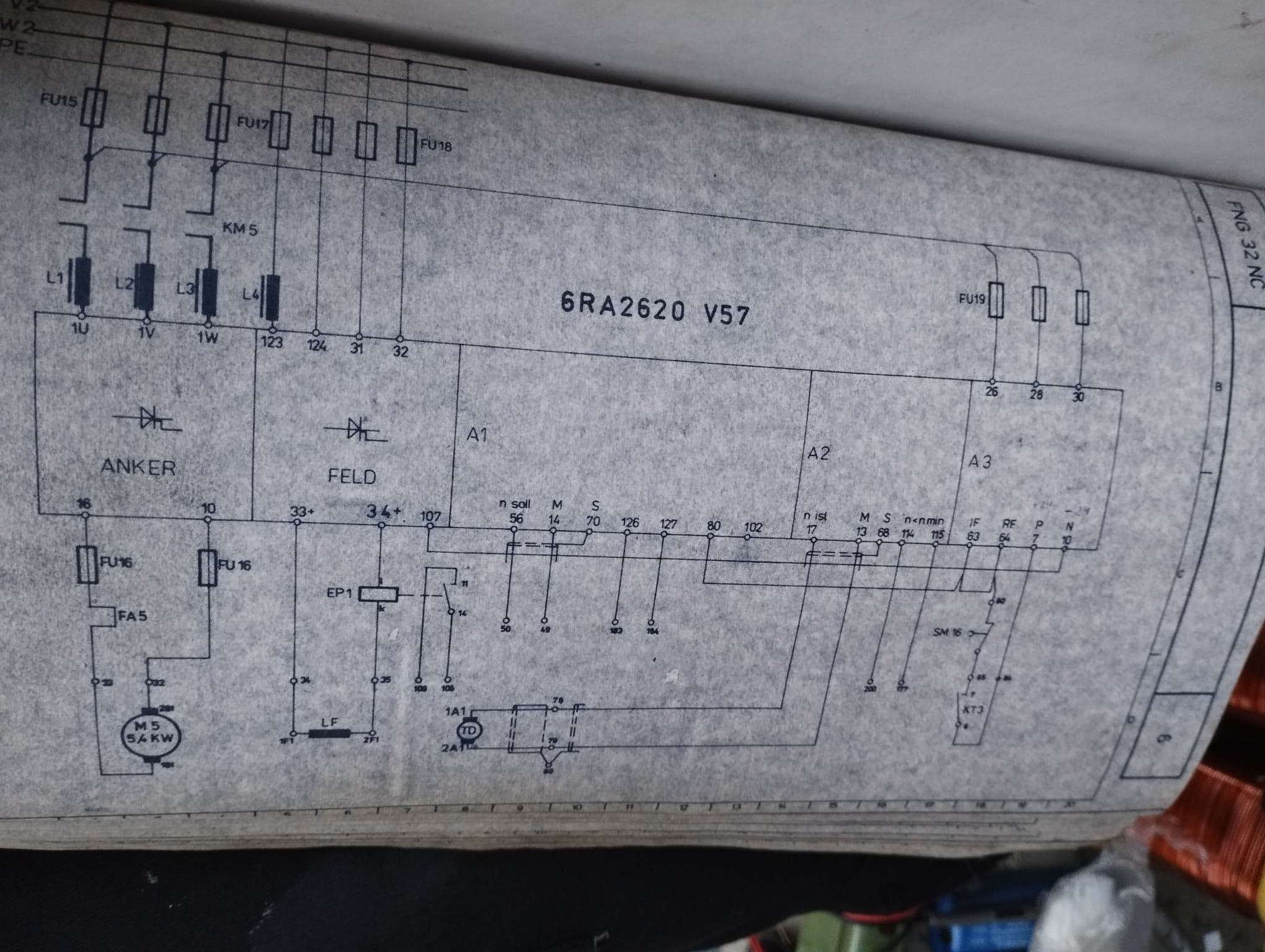

I started to take a look at the spindle driver. Does it work the same as the servo drivers, +-10V for speed control and how does the feedback for rpm work? I think enable is controlled by KT3 and +-10v is between 56 and 14, dont know which is 0V and which is +-10V.

Manual is here support.industry.siemens.com/forum/ww/en...dv57-0/43014/?page=0

I have 3 controlled by hydraulic. Do I make some ladder program that controls the gears? Like if the rpm is set to 800rpm the machine atomatically changes to the right gear before the program start.

Today I connected the signals to X-Y-Z servos, I believe I can start the machine tomorrow and see if I get some movement. I have 1 EXE box to connect tomorrow and 2 more are coming soon.

I started to take a look at the spindle driver. Does it work the same as the servo drivers, +-10V for speed control and how does the feedback for rpm work? I think enable is controlled by KT3 and +-10v is between 56 and 14, dont know which is 0V and which is +-10V.

Manual is here support.industry.siemens.com/forum/ww/en...dv57-0/43014/?page=0

Attachments:

Last edit: 19 Jul 2022 21:02 by Kevin_Pawlus.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

20 Jul 2022 07:39 #247823

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

HI

The Maho had 18 gear selections and a direst on line start 3 phase motor.

I normally use classicladder to control the spindle gearboxes if there isnt too many gear selections. 3 seems quite reasonable.

All my machines select the correct gear automatically based on the spindle speed commanded.

there are a couple of things to keep in mind though....

Linuxcnc has a "spindle-at-speed" input, that will stop the feed if the spindle is not running at the correct speed. It will only stop the next move though, if there is a current feed move in motion, it will not stop when the spindle at speed signal goes false....catastrophic when you fiddle the spindle override and initiate a gear change during cutting...

For this reason, i usually interlock the gear change and spindle at speed signals with "motion.feed-inhibit" look at the docs or type "man motion" in a terminal on your linuxcnc pc.

I doubt your machine is fitted with a spindle encoder. if it is, use this to generate the spindle at speed signal.

pin 56 on your spindle drive is + and 14 is the ref. It doesnt really matter what polarity you use, it will just change the direction since it is -10 to +10v differential input.

the tacho on the spindle motor gives speed feedback to the drive only. dont change the polarity of either the tacho or the armature connections.

The Maho had 18 gear selections and a direst on line start 3 phase motor.

I normally use classicladder to control the spindle gearboxes if there isnt too many gear selections. 3 seems quite reasonable.

All my machines select the correct gear automatically based on the spindle speed commanded.

there are a couple of things to keep in mind though....

Linuxcnc has a "spindle-at-speed" input, that will stop the feed if the spindle is not running at the correct speed. It will only stop the next move though, if there is a current feed move in motion, it will not stop when the spindle at speed signal goes false....catastrophic when you fiddle the spindle override and initiate a gear change during cutting...

For this reason, i usually interlock the gear change and spindle at speed signals with "motion.feed-inhibit" look at the docs or type "man motion" in a terminal on your linuxcnc pc.

I doubt your machine is fitted with a spindle encoder. if it is, use this to generate the spindle at speed signal.

pin 56 on your spindle drive is + and 14 is the ref. It doesnt really matter what polarity you use, it will just change the direction since it is -10 to +10v differential input.

the tacho on the spindle motor gives speed feedback to the drive only. dont change the polarity of either the tacho or the armature connections.

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

20 Jul 2022 20:13 #247872

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Tanks again for your replies Henk, it is very helpful.

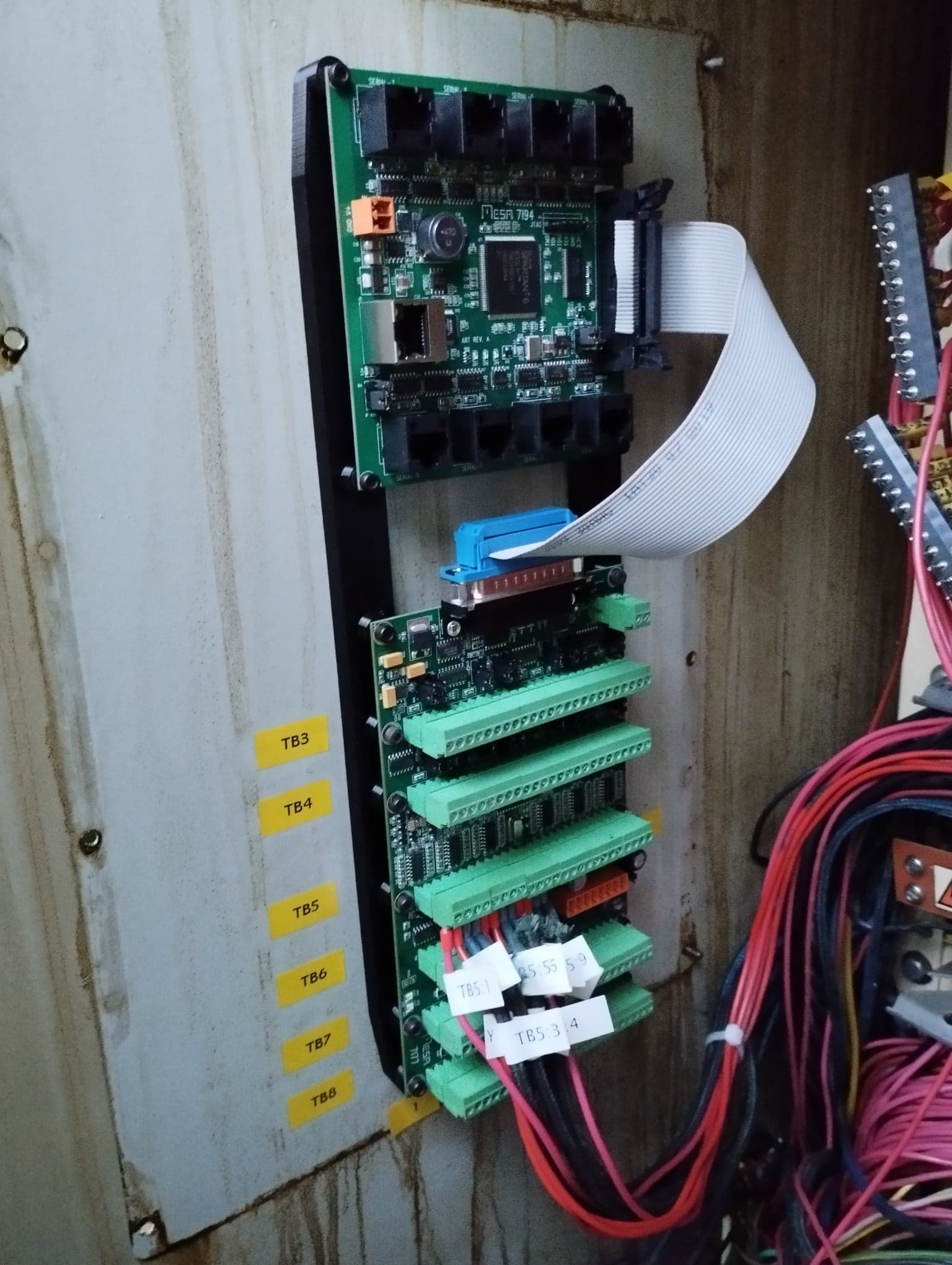

Today I installed the psu and powerd up the Mesa boards inside the cabinet. I used a computer psu, so I also have 5v for the EXE-boxes.

Todays plan was to get at least one axis to move, but I had some issues with 7i77. The led CR16 is red and that is intication for "Field I/O fault". In the manual it says

"At power-up, CR15

should be off and CR16 on. The red LED CR16 indicates a watchdog fault, which is

expected before host communications are established. Once running, CR16 should be off."

The ethernet connection to 7i94 is working, but im not sure how to check the connections between the 2 Mesa cards. I have doubled checked that all the jumpers is in the right place.

Today I installed the psu and powerd up the Mesa boards inside the cabinet. I used a computer psu, so I also have 5v for the EXE-boxes.

Todays plan was to get at least one axis to move, but I had some issues with 7i77. The led CR16 is red and that is intication for "Field I/O fault". In the manual it says

"At power-up, CR15

should be off and CR16 on. The red LED CR16 indicates a watchdog fault, which is

expected before host communications are established. Once running, CR16 should be off."

The ethernet connection to 7i94 is working, but im not sure how to check the connections between the 2 Mesa cards. I have doubled checked that all the jumpers is in the right place.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21147

- Thank you received: 7221

20 Jul 2022 20:18 #247874

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

CR16 is red until LinuxCNC is started and communicating with it.

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

20 Jul 2022 20:29 #247875

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Ah!

Yes, that is probably it.

Yes, that is probably it.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

21 Jul 2022 02:48 #247902

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

Assuming you have established the ethernet connection with the 7i94, you have to check that the FPGA is loaded with the correct bit file.

first, verify that you have a connection: in a terminal, type "ping 10.10.10.10". If it is jumpered for this IP address you should see the response timnes reported. if Ok, proceed

now, in a new terminal, type "sudo mesaflash --device 7i94 --addr 10.10.10.10 --readhmid"

you should see the following pin file details printed. for the P2 connector

IO Connections for P2

IO Connections for P2

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 0 IOPort SSerial 0 TXEn2 (Out)

14 1 IOPort SSerial 0 TXData2 (Out)

2 2 IOPort SSerial 0 RXData2 (In)

15 3 IOPort SSerial 0 TXData1 (Out)

3 4 IOPort SSerial 0 RXData1 (In)

16 5 IOPort SSerial 0 TXData0 (Out)

4 6 IOPort SSerial 0 RXData0 (In)

17 7 IOPort MuxedQCountSel 0 MuxSel0 (Out)

5 8 IOPort MuxedQCount 0 MuxQ-A (In)

6 9 IOPort MuxedQCount 0 MuxQ-B (In)

7 10 IOPort MuxedQCount 0 MuxQ-IDX (In)

8 11 IOPort MuxedQCount 1 MuxQ-A (In)

9 12 IOPort MuxedQCount 1 MuxQ-B (In)

10 13 IOPort MuxedQCount 1 MuxQ-IDX (In)

11 14 IOPort MuxedQCount 2 MuxQ-A (In)

12 15 IOPort MuxedQCount 2 MuxQ-B (In)

13 16 IOPort MuxedQCount 2 MuxQ-IDX (In)

there will be more printed but these are for the other SSerial connectiors and they should all show SSerial.....

If this is not the case, you have to load a new bit file on the 7i94. Download the software bit file from mesa's website for the 7i94, find this file "7i94ss_7i77d.bit" and copy it to your home folder on the linuxcnc pc.

now open a terminal and type "ls"

check that the bit file is shown in the list printed.

now write the fimrware to the 7i94

"sudo mesaflash --device 7i94 --addr 10.10.10.10 --write 7i94ss_7i77d.bit"

if this is succesfull, power cycle the 7i94 preferably by switching off the power supply input and not unplugging the 5v connector...

you should now be able to launch linuxcnc if your config is correct.

first, verify that you have a connection: in a terminal, type "ping 10.10.10.10". If it is jumpered for this IP address you should see the response timnes reported. if Ok, proceed

now, in a new terminal, type "sudo mesaflash --device 7i94 --addr 10.10.10.10 --readhmid"

you should see the following pin file details printed. for the P2 connector

IO Connections for P2

IO Connections for P2

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 0 IOPort SSerial 0 TXEn2 (Out)

14 1 IOPort SSerial 0 TXData2 (Out)

2 2 IOPort SSerial 0 RXData2 (In)

15 3 IOPort SSerial 0 TXData1 (Out)

3 4 IOPort SSerial 0 RXData1 (In)

16 5 IOPort SSerial 0 TXData0 (Out)

4 6 IOPort SSerial 0 RXData0 (In)

17 7 IOPort MuxedQCountSel 0 MuxSel0 (Out)

5 8 IOPort MuxedQCount 0 MuxQ-A (In)

6 9 IOPort MuxedQCount 0 MuxQ-B (In)

7 10 IOPort MuxedQCount 0 MuxQ-IDX (In)

8 11 IOPort MuxedQCount 1 MuxQ-A (In)

9 12 IOPort MuxedQCount 1 MuxQ-B (In)

10 13 IOPort MuxedQCount 1 MuxQ-IDX (In)

11 14 IOPort MuxedQCount 2 MuxQ-A (In)

12 15 IOPort MuxedQCount 2 MuxQ-B (In)

13 16 IOPort MuxedQCount 2 MuxQ-IDX (In)

there will be more printed but these are for the other SSerial connectiors and they should all show SSerial.....

If this is not the case, you have to load a new bit file on the 7i94. Download the software bit file from mesa's website for the 7i94, find this file "7i94ss_7i77d.bit" and copy it to your home folder on the linuxcnc pc.

now open a terminal and type "ls"

check that the bit file is shown in the list printed.

now write the fimrware to the 7i94

"sudo mesaflash --device 7i94 --addr 10.10.10.10 --write 7i94ss_7i77d.bit"

if this is succesfull, power cycle the 7i94 preferably by switching off the power supply input and not unplugging the 5v connector...

you should now be able to launch linuxcnc if your config is correct.

The following user(s) said Thank You: arvidb

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

21 Jul 2022 15:35 - 21 Jul 2022 15:38 #247954

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

I'm trying to launch LinuxCNC and move one axis. I use Pncconf and made the simpelst config possible using 7i92 and Firmware "7i77x2 with one 7i77". I have modified inside the .ini file to use 7i94. I cant launch the program.

It seems to me that I have configured the network properly. I can ping 10.10.10.10 and get response and if I write

"sudo mesaflash --device 7i94 --addr 10.10.10.10 --readhmid"

I get:

Configuration Name: HOSTMOT2

General configuration information:

BoardName : MESA7I94

FPGA Size: 9 KGates

FPGA Pins: 144

Number of IO Ports: 2

Width of one I/O port: 21

Clock Low frequency: 100.0000 MHz

Clock High frequency: 200.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

And so on.

Then I tried download 7i94ss_7i77d.bit. I write "ls" and I can see the file in the right place and the install was sucessful and I have restarted the board but I still cant launch. So I think I have some error in my config maybe.

I also tried using your .ini and .hal file Henk but no luck there either.

It seems to me that I have configured the network properly. I can ping 10.10.10.10 and get response and if I write

"sudo mesaflash --device 7i94 --addr 10.10.10.10 --readhmid"

I get:

Configuration Name: HOSTMOT2

General configuration information:

BoardName : MESA7I94

FPGA Size: 9 KGates

FPGA Pins: 144

Number of IO Ports: 2

Width of one I/O port: 21

Clock Low frequency: 100.0000 MHz

Clock High frequency: 200.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

And so on.

Then I tried download 7i94ss_7i77d.bit. I write "ls" and I can see the file in the right place and the install was sucessful and I have restarted the board but I still cant launch. So I think I have some error in my config maybe.

I also tried using your .ini and .hal file Henk but no luck there either.

Last edit: 21 Jul 2022 15:38 by Kevin_Pawlus.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

21 Jul 2022 16:07 #247958

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

can you post the error message that you get when you try to launch the config?

You can try running from the terminal just to see if all the comms and firmware is OK.

in a terminal, run the following commands one by one

halrun

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=000000" # sserial_port_1=000xxx"

If no error is reported, type:

show pin

you should now see all the available pins on the mesa card.

you should see 16 output pins and 32 input pins, 6 encoders, 6 enable and 6 analog outputs

Henk

You can try running from the terminal just to see if all the comms and firmware is OK.

in a terminal, run the following commands one by one

halrun

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=000000" # sserial_port_1=000xxx"

If no error is reported, type:

show pin

you should now see all the available pins on the mesa card.

you should see 16 output pins and 32 input pins, 6 encoders, 6 enable and 6 analog outputs

Henk

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.116 seconds