Retrofitting a TOS FNG 32 NC

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

03 Aug 2022 19:47 #248967

by Kevin_Pawlus

[SPINDLE_0]

P = 15

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000

OUTPUT_SCALE = 2000

OUTPUT_MIN_LIMIT = -2000

OUTPUT_MAX_LIMIT = 2000

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

This is the values for the spindel in .iniChek your .ini file settings to make sure you have it set for + and - control and not 0 to some positive value.

[SPINDLE_0]

P = 15

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000

OUTPUT_SCALE = 2000

OUTPUT_MIN_LIMIT = -2000

OUTPUT_MAX_LIMIT = 2000

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4604

03 Aug 2022 22:53 #248983

by andypugh

Replied by andypugh on topic Retrofitting a TOS FNG 32 NC

Can you attach the HAL file?

(You need to be linking spindle.0.speed-out and not speed-out-abs, for example.

linuxcnc.org/docs/stable/html/man/man9/m....html#SPINDLE%20PINS

(You need to be linking spindle.0.speed-out and not speed-out-abs, for example.

linuxcnc.org/docs/stable/html/man/man9/m....html#SPINDLE%20PINS

The following user(s) said Thank You: Kevin_Pawlus

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

04 Aug 2022 12:12 - 04 Aug 2022 12:57 #249026

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Yes.

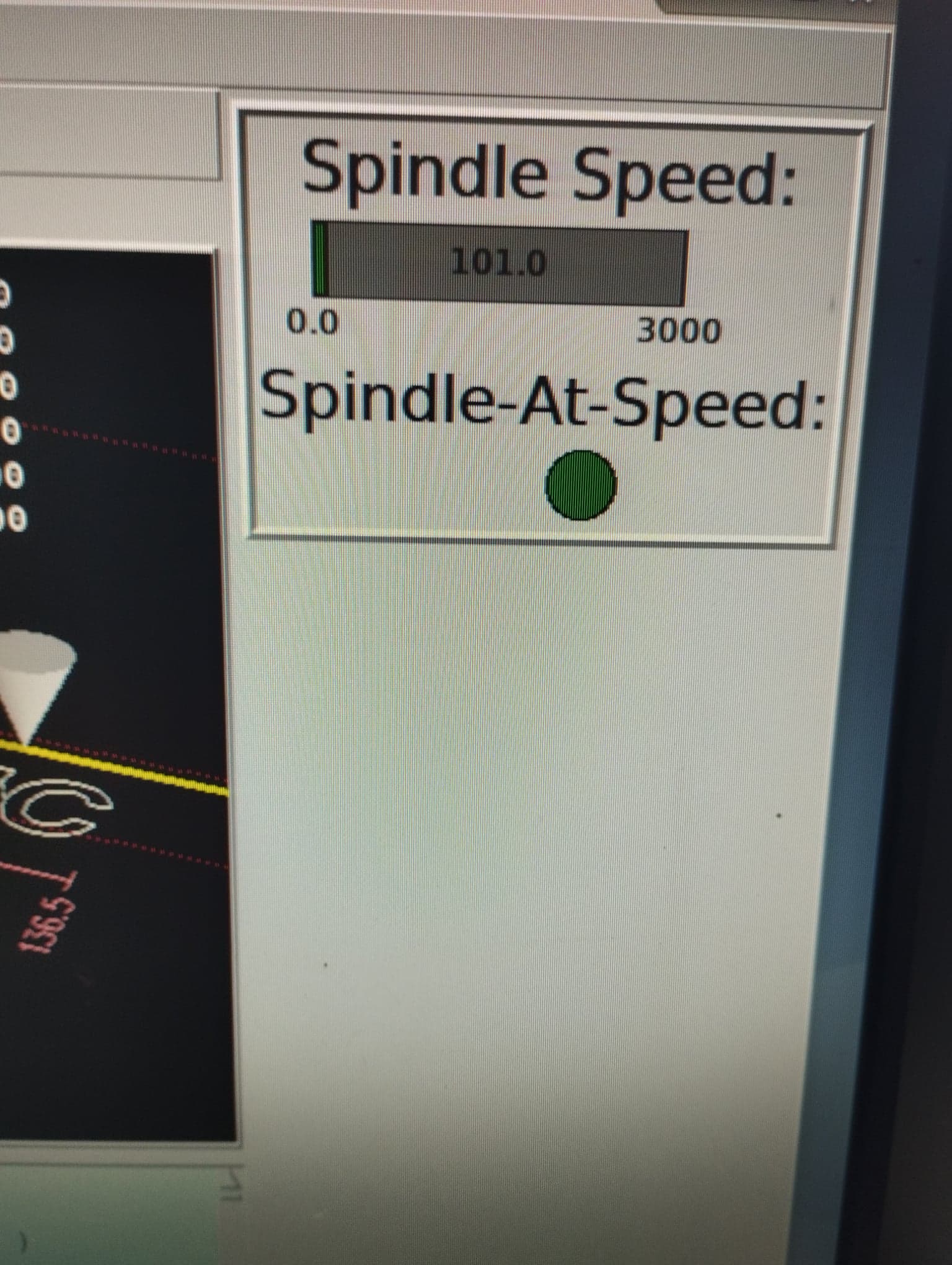

It seems like if I run the spindle at the lowest speed it will slowly ramp up and run very fast in about 10 seconds. I think some setting is making my Mesaboard output 10v.

I also started to work with Classicladder. Having trouble to save and open previous files. When I start LinuxCNC with CL I only see a blank space in "Sections Manager" and dont know how to acces my ladder program I just created and saved.

It seems like if I run the spindle at the lowest speed it will slowly ramp up and run very fast in about 10 seconds. I think some setting is making my Mesaboard output 10v.

I also started to work with Classicladder. Having trouble to save and open previous files. When I start LinuxCNC with CL I only see a blank space in "Sections Manager" and dont know how to acces my ladder program I just created and saved.

Last edit: 04 Aug 2022 12:57 by Kevin_Pawlus.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

04 Aug 2022 12:51 #249029

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

In your .ini file, make the spindle P zero. I doubt that you have a spindle encoder set up at this moment, so it will be zero and the PID will increase the output to try and reach the speed setpoint. With P=0 and FF1=1, the PID does nothing, just passes the input to the output, which is what you want if there is no feedback set up.

Then play with the OUPUT_SCALE value to calibrate the actual speed if you have something at hand to measure the actual speed. Otherwise measure the tacho feedback voltage from the motor. It should be 20V/1000RPM but could be something else.

When LCNC is running, switch on the spindle, then open a terminal and type "setp [HMOT](CARD0).7i77.0.1.analogout5-scalemax xxxx"

where xxxx is the new value you want to test. you may have to replace the "[HMOT](CARD0)" with the actual card description as it appears in hal configuration.

Then play with the OUPUT_SCALE value to calibrate the actual speed if you have something at hand to measure the actual speed. Otherwise measure the tacho feedback voltage from the motor. It should be 20V/1000RPM but could be something else.

When LCNC is running, switch on the spindle, then open a terminal and type "setp [HMOT](CARD0).7i77.0.1.analogout5-scalemax xxxx"

where xxxx is the new value you want to test. you may have to replace the "[HMOT](CARD0)" with the actual card description as it appears in hal configuration.

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

04 Aug 2022 13:09 #249034

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Right, there is no encoder feedback.

It's working now. With P=0 and FF0=1

Thanks.

It's working now. With P=0 and FF0=1

Thanks.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

04 Aug 2022 16:15 #249049

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

Forgot to mention above, once you figured out the output scale value using the halcmd approach, ypu need to updatw your .ini file manually with the correct value and save it.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21185

- Thank you received: 7240

04 Aug 2022 16:44 #249051

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

Output scale can also be tuned in "calibration" menu, and settings saved without restarting LinuxCNC.

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

04 Aug 2022 22:58 #249078

by scotth

Replied by scotth on topic Retrofitting a TOS FNG 32 NC

I would put "EP1" relay in the spindle enable string to avoid this problem. Lack of field on spindle startup will draw max current and not start. Field loss at speed is even worse, it will get you a runaway condition. DC motors will throw windings at over speed.

The following user(s) said Thank You: Kevin_Pawlus

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

05 Aug 2022 09:39 #249105

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

I tried to cut some chips today. It works really good.

Still some things to do of course like programing the buttons. Everything is plugged in and I can see that I get the signal when I push the button.

I did about 2 hours of milling and noticed that Y-motor is getting really hot. So hot that the paint is melting so that's something that needs to be fixed. There is some backlash in Y so you can hear the motor always going back and forth all the time, I don't know if this is the reason. X motor is also quite hot, I don't think its too hot though. Z is only a bit warm.

Still some things to do of course like programing the buttons. Everything is plugged in and I can see that I get the signal when I push the button.

I did about 2 hours of milling and noticed that Y-motor is getting really hot. So hot that the paint is melting so that's something that needs to be fixed. There is some backlash in Y so you can hear the motor always going back and forth all the time, I don't know if this is the reason. X motor is also quite hot, I don't think its too hot though. Z is only a bit warm.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4604

05 Aug 2022 22:03 #249164

by andypugh

Replied by andypugh on topic Retrofitting a TOS FNG 32 NC

If it was dithering inside the backlash it would be under no load, so probably wouldn't make much heat.

Can you move the axis with the motor unpowered? Try to feel if something is unusually stiff (thrust bearings are a likely culprit)

Can you move the axis with the motor unpowered? Try to feel if something is unusually stiff (thrust bearings are a likely culprit)

The following user(s) said Thank You: Kevin_Pawlus

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.131 seconds