Retrofitting a TOS FNG 32 NC

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

08 Jul 2022 18:40 - 08 Jul 2022 18:47 #246893

by Kevin_Pawlus

Retrofitting a TOS FNG 32 NC was created by Kevin_Pawlus

Hello

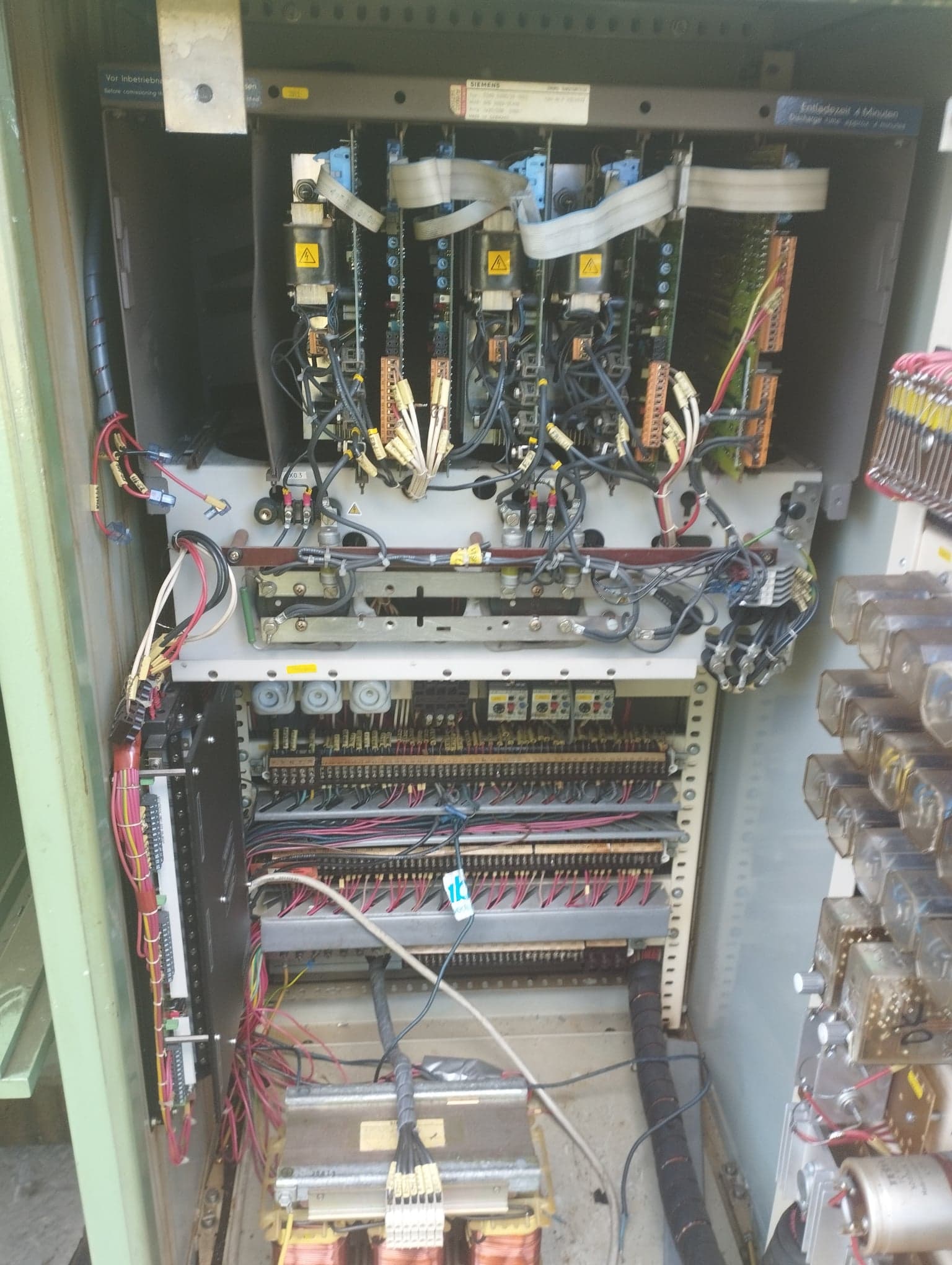

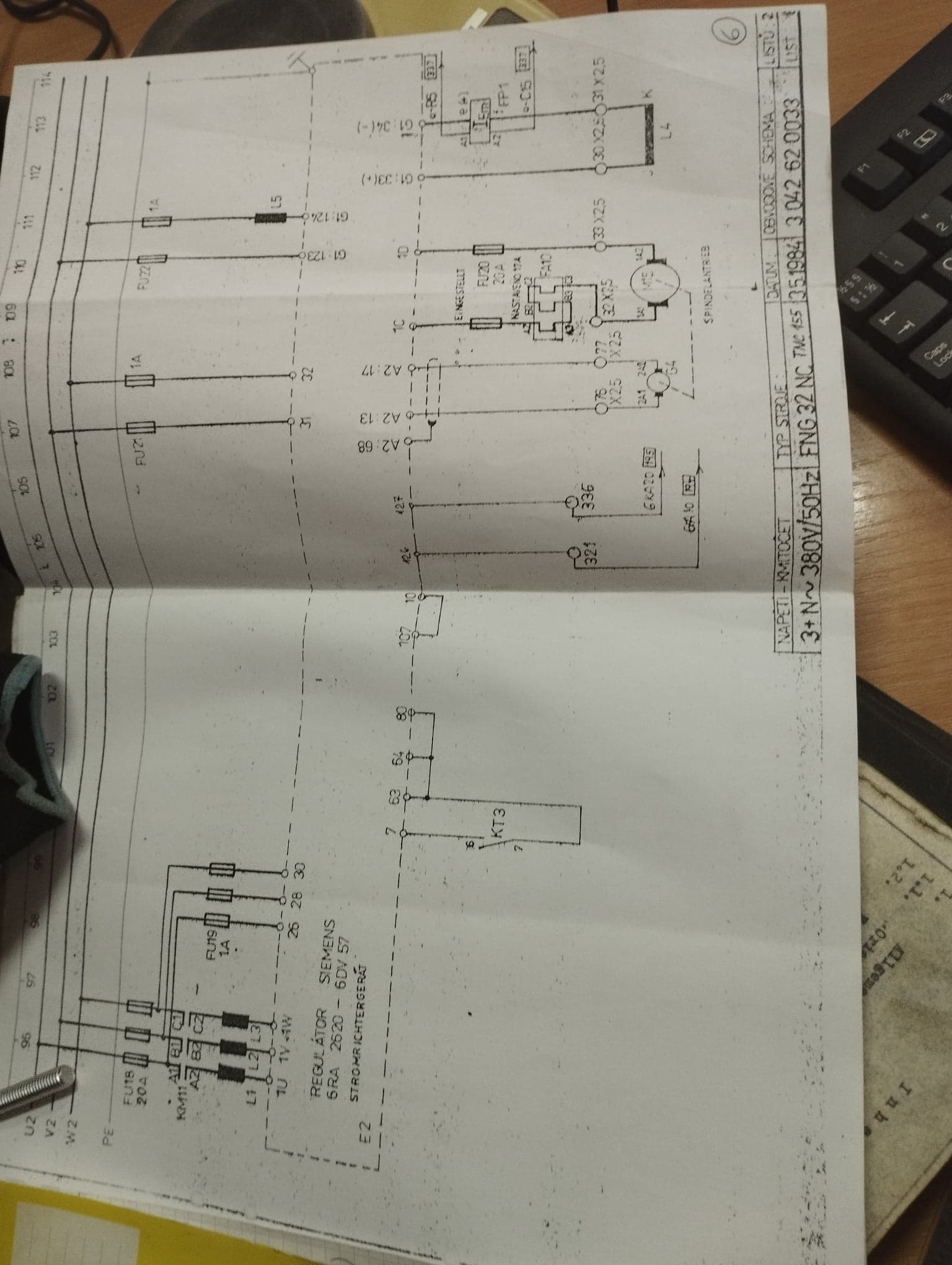

I recently started my own company here in Sweden to manufacture bottle filling machines. To do that I would need a milling machine and I bought a TOS FNG 32 NC with a Heidenhain TNC 150. The plan was to use to the existing control system which was fully working when i bought the machine, unfortunately it seems like something in the old electronics broke during transport. I cant find anyone to come here and repair my machine either, not many people that can repair TNC 150 are around.

Plan B is to change the control system to LinuxCNC. I really hope I can use as much as possible of the old electronics. Servo drives and spindle driver especially.I dont know today how to control the servos and spindle drive. Is 0-10V the most common?It uses a Siemens 6RA 2620-6DV 57 for the spindle.I believe its a DC motor. The servos is controlled by 6RB 2025-3EA01.

I still have some reading to do before I order any parts. I will probably use some Mesa board. I dont know how the positioning works, it seems like my machine has both linear scales and an encoder on the servo. Should I use both also?Best regards

I recently started my own company here in Sweden to manufacture bottle filling machines. To do that I would need a milling machine and I bought a TOS FNG 32 NC with a Heidenhain TNC 150. The plan was to use to the existing control system which was fully working when i bought the machine, unfortunately it seems like something in the old electronics broke during transport. I cant find anyone to come here and repair my machine either, not many people that can repair TNC 150 are around.

Plan B is to change the control system to LinuxCNC. I really hope I can use as much as possible of the old electronics. Servo drives and spindle driver especially.I dont know today how to control the servos and spindle drive. Is 0-10V the most common?It uses a Siemens 6RA 2620-6DV 57 for the spindle.I believe its a DC motor. The servos is controlled by 6RB 2025-3EA01.

I still have some reading to do before I order any parts. I will probably use some Mesa board. I dont know how the positioning works, it seems like my machine has both linear scales and an encoder on the servo. Should I use both also?Best regards

Last edit: 08 Jul 2022 18:47 by Kevin_Pawlus.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

08 Jul 2022 19:05 #246897

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

Do you have all the schematics for it?

If yes, first thing is to scan them and make a copy for yourself so you can write what you are wiring where and what is changing, makes maintenance later very comfortable.

Then upload those here or on you google drive and make them public so we can have a look at them, we can figure out pretty much everything from them, granted checks have to be done all the time during retrofitting to make sure the schematics reflect whats on the machine, there are almost always some minor errors there.

Also take a lot of pictures now, connectors, wiring, switches, everything, it makes it easier to find where that dangling connector came out off.

If yes, first thing is to scan them and make a copy for yourself so you can write what you are wiring where and what is changing, makes maintenance later very comfortable.

Then upload those here or on you google drive and make them public so we can have a look at them, we can figure out pretty much everything from them, granted checks have to be done all the time during retrofitting to make sure the schematics reflect whats on the machine, there are almost always some minor errors there.

Also take a lot of pictures now, connectors, wiring, switches, everything, it makes it easier to find where that dangling connector came out off.

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

08 Jul 2022 21:21 #246912

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

Yes I have all of the schematics.

Upload them on Drive and make them public is a goof idea, I will do that.

And lots of pictures

I think I will remove almost everything in the electrical cabinets except for the drives and only keep what I need on the machine.

The plan is to make completely new schematics.

There is also a hydraulic unit on this machine that shifts gear for the spindle and lift the table.

Upload them on Drive and make them public is a goof idea, I will do that.

And lots of pictures

I think I will remove almost everything in the electrical cabinets except for the drives and only keep what I need on the machine.

The plan is to make completely new schematics.

There is also a hydraulic unit on this machine that shifts gear for the spindle and lift the table.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

08 Jul 2022 21:51 #246916

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

Hold that off for a while, something might prove very useful later.I think I will remove almost everything in the electrical cabinets except for the drives and only keep what I need on the machine.

The following user(s) said Thank You: RotarySMP, Joeymcc

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 405

- Thank you received: 92

09 Jul 2022 04:27 #246928

by Henk

Replied by Henk on topic Retrofitting a TOS FNG 32 NC

I agree with Tommy, dont remove anything yet untill you decide how you want to do the retrofit.

I have used those same siemens drives for a recent retrofit of a 5 axis K+T machine.

Yes, they are DC, and Yes, they are +/- 10v analog control. Perfectly useable with a Mesa 7i77.

in my opinion, there are two ways to go about this retrofit.

Henk

I have used those same siemens drives for a recent retrofit of a 5 axis K+T machine.

Yes, they are DC, and Yes, they are +/- 10v analog control. Perfectly useable with a Mesa 7i77.

in my opinion, there are two ways to go about this retrofit.

- Remove only the old controller, screen and some parts of the old control, like the keypad for example. the control will have cables plugged into it for the digital input and output signals, encoder feedback and so on. you need to make sure you can identify these cables and their pinout. Then remove the control, and install the Mesa kit, and wire these cables to that. the rest can most probably stay the same.

- if you decide to replace everything electrical besides the drives, then a complete strip down of the panel is the best way, but if you have not retrofitted or designed/wired a panel like this i would not reccomend it

Henk

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

09 Jul 2022 18:55 #246971

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

After thinking about it, I think your nr 1 is the best way forward.

I have some experience from my previous job where I did build electrical stuff for industrial robots, but I believe this will be a difficult project for me.

I have all the schematics so I should be able to identify every cable coming out from the control system and put on a new lable. The original labeling was written by hand with a sharpie and has faded so its difficult to read.

After some reading, I believe this kit could suit me:

store.mesanet.com/index.php?route=produc...69_73&product_id=214

I have some experience from my previous job where I did build electrical stuff for industrial robots, but I believe this will be a difficult project for me.

I have all the schematics so I should be able to identify every cable coming out from the control system and put on a new lable. The original labeling was written by hand with a sharpie and has faded so its difficult to read.

After some reading, I believe this kit could suit me:

store.mesanet.com/index.php?route=produc...69_73&product_id=214

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

09 Jul 2022 19:54 #246975

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

See if there are any Mesa 7i97, that is all you might need.

And if you do need more IO, a Mesa 7i84 will add 32 inputs and 16 outputs, can be placed anywhere as it connects with a single UTP cable to Mesa 7i97 ... i think !

I know 7i77 has an sserial port, 7i76 and 7i76E also have 1, 7i95 has 2 as i have one on the table, so i will conclude the 7i97 has at least 1!

And if you do need more IO, a Mesa 7i84 will add 32 inputs and 16 outputs, can be placed anywhere as it connects with a single UTP cable to Mesa 7i97 ... i think !

I know 7i77 has an sserial port, 7i76 and 7i76E also have 1, 7i95 has 2 as i have one on the table, so i will conclude the 7i97 has at least 1!

Please Log in or Create an account to join the conversation.

- Kevin_Pawlus

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 6

09 Jul 2022 20:24 - 09 Jul 2022 20:35 #246978

by Kevin_Pawlus

Replied by Kevin_Pawlus on topic Retrofitting a TOS FNG 32 NC

I was looking at the 7i97 first and I like it but it only has 8 outputs, not sure that is enough .

Or is there some advantage to the 7i97 compared to the 7i77?

Price is very similar

Or is there some advantage to the 7i97 compared to the 7i77?

Price is very similar

Last edit: 09 Jul 2022 20:35 by Kevin_Pawlus.

Please Log in or Create an account to join the conversation.

- arvidb

-

- Offline

- Platinum Member

-

Less

More

- Posts: 459

- Thank you received: 158

09 Jul 2022 20:57 - 09 Jul 2022 21:08 #246979

by arvidb

Replied by arvidb on topic Retrofitting a TOS FNG 32 NC

The parallel cable and connectors are a bit clumsy, and the cable length is limited. Ethernet should give you galvanic isolation between control computer and machine cabinet which I consider a big plus. Also you have a wider choice of computers using Ethernet since 5i25/6i25 requires a PCI or a PCIe slot, respectively. So you can't use a small ("mini/micro") desktop computer with them.

On the other hand it seems Ethernet is a little bit more finicky to get working well - parallel seems to "just work" while there are some people that seem to have to tweak Ethernet driver and/or PLL settings to get things working (and obviously you need to configure the IP settings on the host). If you want to run your servo loop at faster than normal speed then parallel is probably the way to go - I believe Ethernet is closer to its limits at 1 kHz servo loop? Also Ethernet takes up the Ethernet port of the computer so you need either a motherboard with multiple Ethernet ports, WiFi, or to use an USB-to-Ethernet dongle for the network connection to the outside world (the Mesa card should run on its own net unconnected to anything else).

Overall, unless I had some special requirements, and everything else being equal, I would choose Ethernet over parallel. If you know from the start that you need >6 outputs (note 6 plus drive enables, not 8) however perhaps the 7i77 is better. Then again, as tommylight says, there are expansion cards. In the end, both options should work.

On the other hand it seems Ethernet is a little bit more finicky to get working well - parallel seems to "just work" while there are some people that seem to have to tweak Ethernet driver and/or PLL settings to get things working (and obviously you need to configure the IP settings on the host). If you want to run your servo loop at faster than normal speed then parallel is probably the way to go - I believe Ethernet is closer to its limits at 1 kHz servo loop? Also Ethernet takes up the Ethernet port of the computer so you need either a motherboard with multiple Ethernet ports, WiFi, or to use an USB-to-Ethernet dongle for the network connection to the outside world (the Mesa card should run on its own net unconnected to anything else).

Overall, unless I had some special requirements, and everything else being equal, I would choose Ethernet over parallel. If you know from the start that you need >6 outputs (note 6 plus drive enables, not 8) however perhaps the 7i77 is better. Then again, as tommylight says, there are expansion cards. In the end, both options should work.

Last edit: 09 Jul 2022 21:08 by arvidb.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

09 Jul 2022 22:47 #246987

by tommylight

Replied by tommylight on topic Retrofitting a TOS FNG 32 NC

If you can get the 7i92M (notice the M) that would be best as it does not need a clunky cable, it just plugs directly to 7i77.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.238 seconds