- Hardware & Machines

- Computers and Hardware

- LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

- mBender

- Offline

- Premium Member

-

- Posts: 133

- Thank you received: 15

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21352

- Thank you received: 7285

Are the probes reversed?

Please Log in or Create an account to join the conversation.

- mBender

- Offline

- Premium Member

-

- Posts: 133

- Thank you received: 15

Attachments:

Please Log in or Create an account to join the conversation.

- digiex_chris

- Offline

- Senior Member

-

- Posts: 40

- Thank you received: 11

Please Log in or Create an account to join the conversation.

- mBender

- Offline

- Premium Member

-

- Posts: 133

- Thank you received: 15

Please Log in or Create an account to join the conversation.

- mBender

- Offline

- Premium Member

-

- Posts: 133

- Thank you received: 15

I was also able to get a video of the problem of my Y axis.

I noticed a few things: The units in the display of LinuxCNC are sometimes jumping around a little bit. I think that was discussed somewhere earlier her. Will dig that out. Maybe that's the reason why I measured Step pulses and the motors shake even when I did not move an axis.

A few words to my machine. X and Z are are Nema 23 Motors (23HS30-2804S) with www.omc-stepperonline.com/digital-steppe...stepper-motor-dm332t DM332T driver. Z Axis has the highest resolution 5mm pitch ball screw and 3200 microsteps/round. Brings it to a scale in LinuxCNC of 800. As shown in the video I have no issues going up to 3600mm/min.

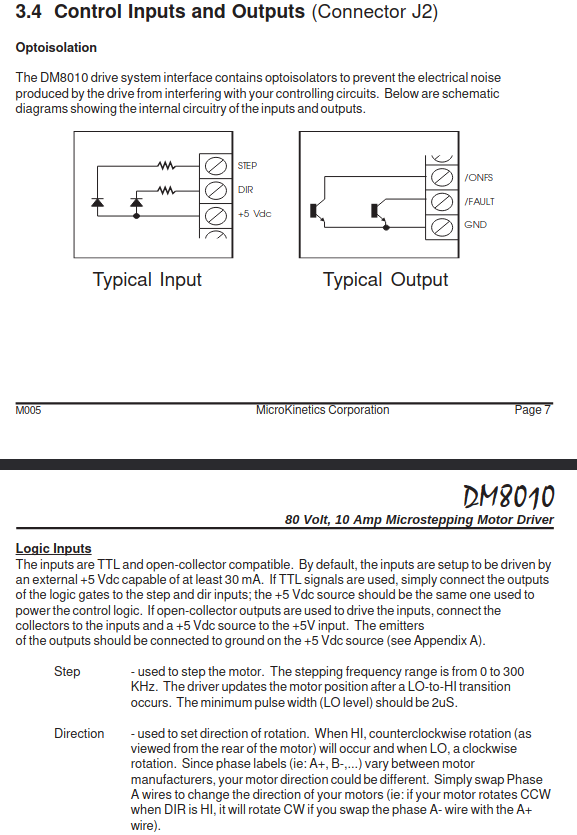

The Y Axis have 2x www.microkinetics.com/index.php?page=stepper_motors/34m450 34M450 Microkinetics Motors with www.microkinetics.com/pdfmanuals/DM8010.pdf DM8010 Driver.5mm pitch ball screw and 2000 microsteps/round. Scale 640 in Linuxcnc. I limited the axis to 1950mm/min, but it's still stalling.

All axis are connected over the same Breakout board with no level shifter.

I doubt that the problem has something to do with RIO, but I am not sure. Still a myth what the problem is.

Please Log in or Create an account to join the conversation.

- mBender

- Offline

- Premium Member

-

- Posts: 133

- Thank you received: 15

Anyway. I made some progress. I was curios why the Y axis motors making this weird sound when they are not moving and shaking a bit. I connected the oscilloscope to the Tang and depending on when I the movement I get the following signals on step and dir. The signals can look different which makes the motors sound different and sometimes i even stop at a point where no signal is produced. It feels like the tang is doing some sort of position holding or so.

Again, this is when the axis are not in a commanded move. It happens on X,Y,Y,and Z. X and Z just have different motors and I can't hear or feel it.

What could cause that?

DIR

Step

Attachments:

Please Log in or Create an account to join the conversation.

- mBender

- Offline

- Premium Member

-

- Posts: 133

- Thank you received: 15

Have you tried to set.....

Thinking about it more with your comment, I think maybe the machine is moving the correct amount, but the position reported back to LinuxCNC isn't correct or isn't stable, for some reason. How can I look into this further? If it were just floating point rounding error, once the iceshield had arrived at the correct position, shouldn't the reported position then be stable at the rounded value, instead of flicker? My X axis is very coarse, so I am comfortable with it not having high precision, but the flickering reported value (shown in the DRO) is very odd given that it's a stepper.

Do I need to re-flash with each change of scale, or is modifying it in the .ini sufficient?

For reference,

config: github.com/digiexchris/6x11-sg-grinder-l...reconfig/config.json

generated ini: github.com/digiexchris/6x11-sg-grinder-l...eld/LinuxCNC/rio.ini

but I have changed the scale to 11.64 (yes, very coarse) for the X axis but that's what was required to get 10mm of movement from G1 X10 with a surface grinder table driven off of the normal handwheel (it's quite a large movement per handwheel turn)

I think I'll change the microstepping up to 32k so I can get the scale number higher and see what effect that has on the stability of the reported position.

if i set the deadband to :

DEADBAND = 0.0001

my DRO shows the exact position like 10.000 or 0.000

POSITION_FEEDBACK = COMMANDEDPlease Log in or Create an account to join the conversation.

- meister

- Offline

- Platinum Member

-

- Posts: 703

- Thank you received: 430

It is at least due to the PID controller, but unfortunately I don't have a good solution at the moment

and please forgive me, I'm not a professional either and don't have an answer to every problem

Please Log in or Create an account to join the conversation.

- mBender

- Offline

- Premium Member

-

- Posts: 133

- Thank you received: 15

I increased the deadband to 0.01 and switched the position back to Actual. The jumping of the numbers stopped and the motors don't make that weird noise anymore. I will test it with the oscilloscope, but I am sure that brought me one step more where I want to be. I wanna say that the motors are not stalling as early anymore.

I played around with the PID settings and thought this would help with the problem, but no change so far.

Please Log in or Create an account to join the conversation.

- Hardware & Machines

- Computers and Hardware

- LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)