Schaublin 125-CNC retrofit.

- DoWerna

-

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 57

22 Nov 2021 08:00 #227279

by DoWerna

Replied by DoWerna on topic Schaublin 125-CNC retrofit.

great to see yout progress!

Now that everything is disassembled and clean the fun part of the retrofitt can begin

Now that everything is disassembled and clean the fun part of the retrofitt can begin

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

22 Nov 2021 11:18 #227291

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

I hope people do not have too much expection of this going fast. There is still a lot of work in the LinuxCNC retrofit which I need to do. All that wiring work takes ages.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

22 Nov 2021 15:02 #227301

by anfänger

Replied by anfänger on topic Schaublin 125-CNC retrofit.

I thin you make good progress.

My first Retrofit took me roughly four years. The second amount 9 months. It always needs more time than one thinks.

My first Retrofit took me roughly four years. The second amount 9 months. It always needs more time than one thinks.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

22 Nov 2021 15:57 #227306

by skunkworks

Replied by skunkworks on topic Schaublin 125-CNC retrofit.

It has become my sunday ritual.. Watch the latest RotarySMP video..

Keep them coming!

sam

Keep them coming!

sam

The following user(s) said Thank You: RotarySMP, DoWerna

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

28 Nov 2021 10:51 #227809

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

The following user(s) said Thank You: piasdom, arvidb, tommylight, anfänger

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

05 Dec 2021 13:36 #228385

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

The following user(s) said Thank You: arvidb, tommylight, anfänger, spumco

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21230

- Thank you received: 7249

05 Dec 2021 13:42 #228386

by tommylight

Replied by tommylight on topic Schaublin 125-CNC retrofit.

To late, i already watched it !

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

06 Dec 2021 05:24 - 06 Dec 2021 05:25 #228418

by spumco

Replied by spumco on topic Schaublin 125-CNC retrofit.

Mark,

Nice vid, thanks for posting.

[note - forgive me if I'm covering something you already know]

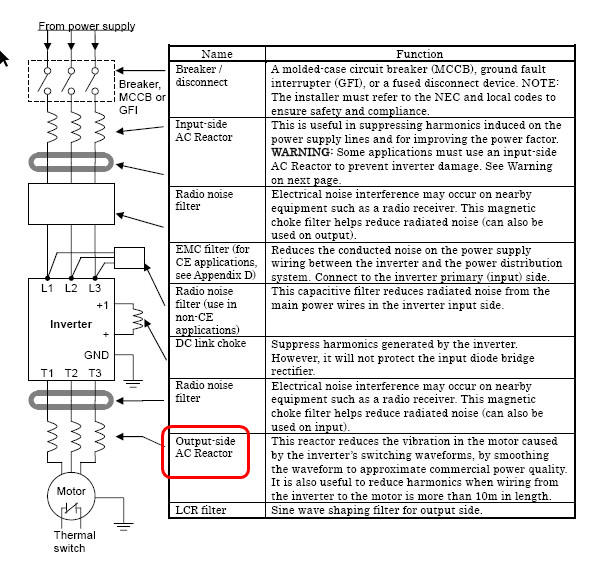

Noted a number of comments in the vid about 'filtering' the VFD to protect the motor, but none of them appeared to identify exactly what you might need/want.

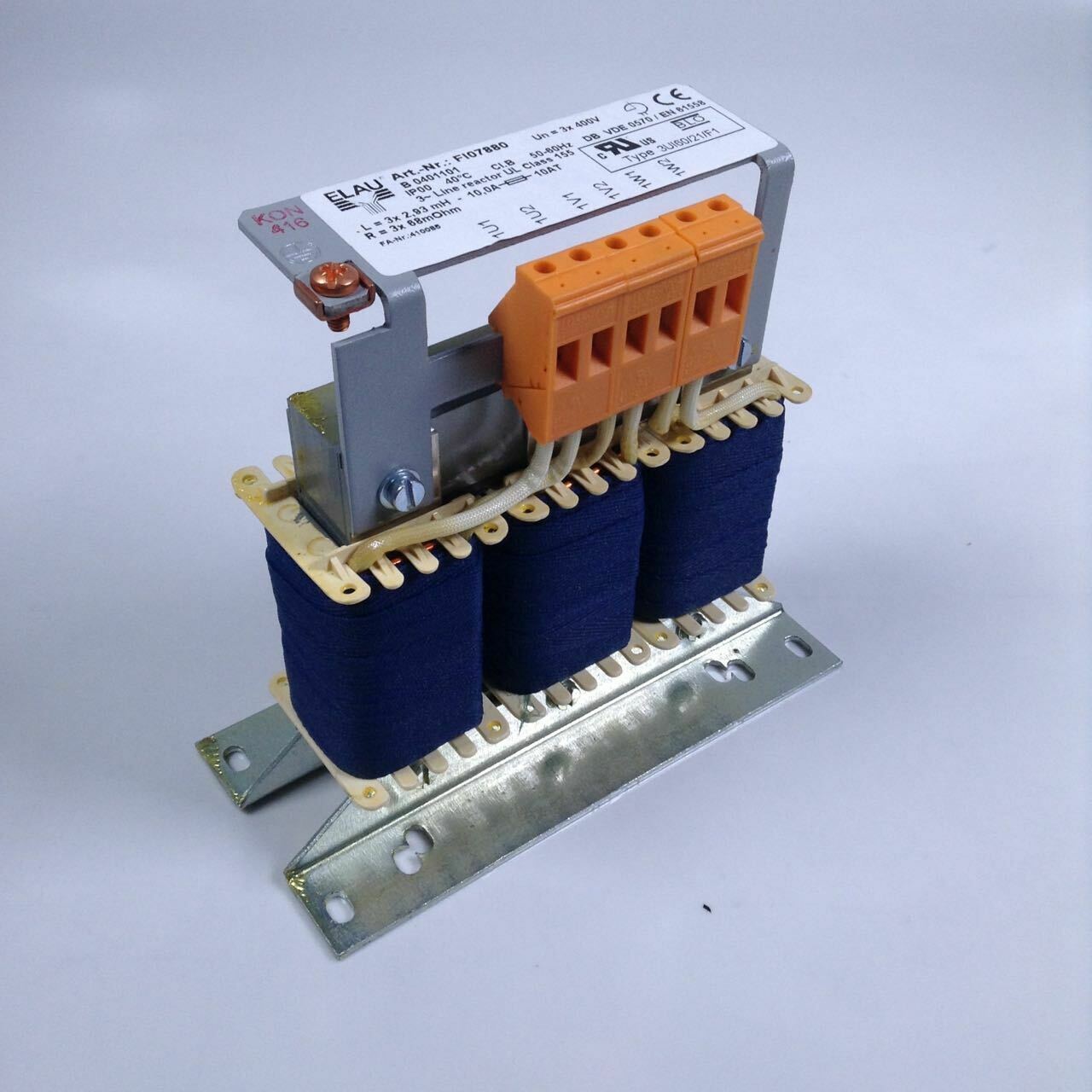

What you're looking for is a load reactor (pic below). This goes between the VFD and the motor and smooths out the harmonics produced by the VFD as it does its AC to DC to AC magic. Also reduces motor heating (helps quite a bit if you're operating a "non-VFD-rated" motor with a VFD).

If you have a decent VFD with a load reactor, you should have no issues running that motor.

They are fairly expensive new, but ebay is littered with them if you search for 'line reactor.' A line reactor is exactly the same thing, but is installed between the VFD and the incoming line voltage where it reduces noise than can be back-fed in to the mains wiring.

Assuming you're at 380VAC-3P and the motor is 3kw (from the vid), you should be able to find a 10a 600V line reactor pretty easily.

Ebay Austria (your location, no?) has 34 hits searching for 'line reactor' (in English), and plenty in the 7A-15A range. Ebay Germany has around 40.

Looks like Elau, Allen-Bradley, and Siemens are the top brands available.

Pro Tip - these things can be mislabeled as 'transformers'. They look similar to transformers - big coil of copper thing - to the uninitiated. So you might find one for scrap value if you've got a local machinery dealer/scrapper.

Something else to consider while you're deciding if you keep the varidrive... how much spindle torque do you need? You can estimate the required torque for anticipated cuts with a decent Feeds & Speeds program, and I bet you won't need as much as you think.

I suspect the massive gear reduction on that lathe was mostly to slow down the surface speed; the increased torque was a nice by-product. Coated carbide tooling wasn't as universal when it was built, and a large part with HSS tools would need the lower surface speed.

Keeping the vari-drive would simplify things mechanically right now... until something goes wrong or breaks or you have to replace that belt.

Food for thought.

Cheers,

Ralph

Nice vid, thanks for posting.

[note - forgive me if I'm covering something you already know]

Noted a number of comments in the vid about 'filtering' the VFD to protect the motor, but none of them appeared to identify exactly what you might need/want.

What you're looking for is a load reactor (pic below). This goes between the VFD and the motor and smooths out the harmonics produced by the VFD as it does its AC to DC to AC magic. Also reduces motor heating (helps quite a bit if you're operating a "non-VFD-rated" motor with a VFD).

If you have a decent VFD with a load reactor, you should have no issues running that motor.

They are fairly expensive new, but ebay is littered with them if you search for 'line reactor.' A line reactor is exactly the same thing, but is installed between the VFD and the incoming line voltage where it reduces noise than can be back-fed in to the mains wiring.

Assuming you're at 380VAC-3P and the motor is 3kw (from the vid), you should be able to find a 10a 600V line reactor pretty easily.

Ebay Austria (your location, no?) has 34 hits searching for 'line reactor' (in English), and plenty in the 7A-15A range. Ebay Germany has around 40.

Looks like Elau, Allen-Bradley, and Siemens are the top brands available.

Pro Tip - these things can be mislabeled as 'transformers'. They look similar to transformers - big coil of copper thing - to the uninitiated. So you might find one for scrap value if you've got a local machinery dealer/scrapper.

Something else to consider while you're deciding if you keep the varidrive... how much spindle torque do you need? You can estimate the required torque for anticipated cuts with a decent Feeds & Speeds program, and I bet you won't need as much as you think.

I suspect the massive gear reduction on that lathe was mostly to slow down the surface speed; the increased torque was a nice by-product. Coated carbide tooling wasn't as universal when it was built, and a large part with HSS tools would need the lower surface speed.

Keeping the vari-drive would simplify things mechanically right now... until something goes wrong or breaks or you have to replace that belt.

Food for thought.

Cheers,

Ralph

Attachments:

Last edit: 06 Dec 2021 05:25 by spumco. Reason: formatting

The following user(s) said Thank You: RotarySMP, arvidb, anfänger, DoWerna

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

06 Dec 2021 18:57 - 06 Dec 2021 19:00 #228457

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Wow, you answered all my thoughts about, what are these dL/dT filters, or whatever they are talking about. Thanks a lot Ralph.

Should the load reactor get mounted close to the VFD or close to the motor?

At this stage it is easier to just plop the motor back in and use it, as the Variator is there, whereas making a set of poly-Vee pulleys might be beyond the capacity of the Boley. It will be interesting whether i can come up with a sensible control logic for VFD + CVT + Back gear. If I only do VFD + Back gear, guys like Andy have already written the comp.

Mark

Should the load reactor get mounted close to the VFD or close to the motor?

At this stage it is easier to just plop the motor back in and use it, as the Variator is there, whereas making a set of poly-Vee pulleys might be beyond the capacity of the Boley. It will be interesting whether i can come up with a sensible control logic for VFD + CVT + Back gear. If I only do VFD + Back gear, guys like Andy have already written the comp.

Mark

Last edit: 06 Dec 2021 19:00 by RotarySMP.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

06 Dec 2021 21:24 #228466

by spumco

Replied by spumco on topic Schaublin 125-CNC retrofit.

Attachments:

The following user(s) said Thank You: RotarySMP, anfänger, DoWerna

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.154 seconds