7i96S card arrived what setup is recomended

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17732

- Thank you received: 5187

04 Sep 2022 22:57 #251191

by PCW

Replied by PCW on topic 7i96S card arrived what setup is recomended

OK if there is a flyback diode on the contactor coil, the noise is likely coming

from the contact side of the contactor

If you cannot isolate the control wiring from the power wiring you

may need to either shield the control wiring or add arc suppression

to the contactor contacts (commonly a R/C snubber is used here)

from the contact side of the contactor

If you cannot isolate the control wiring from the power wiring you

may need to either shield the control wiring or add arc suppression

to the contactor contacts (commonly a R/C snubber is used here)

The following user(s) said Thank You: xenon-alien

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

05 Sep 2022 06:29 #251205

by xenon-alien

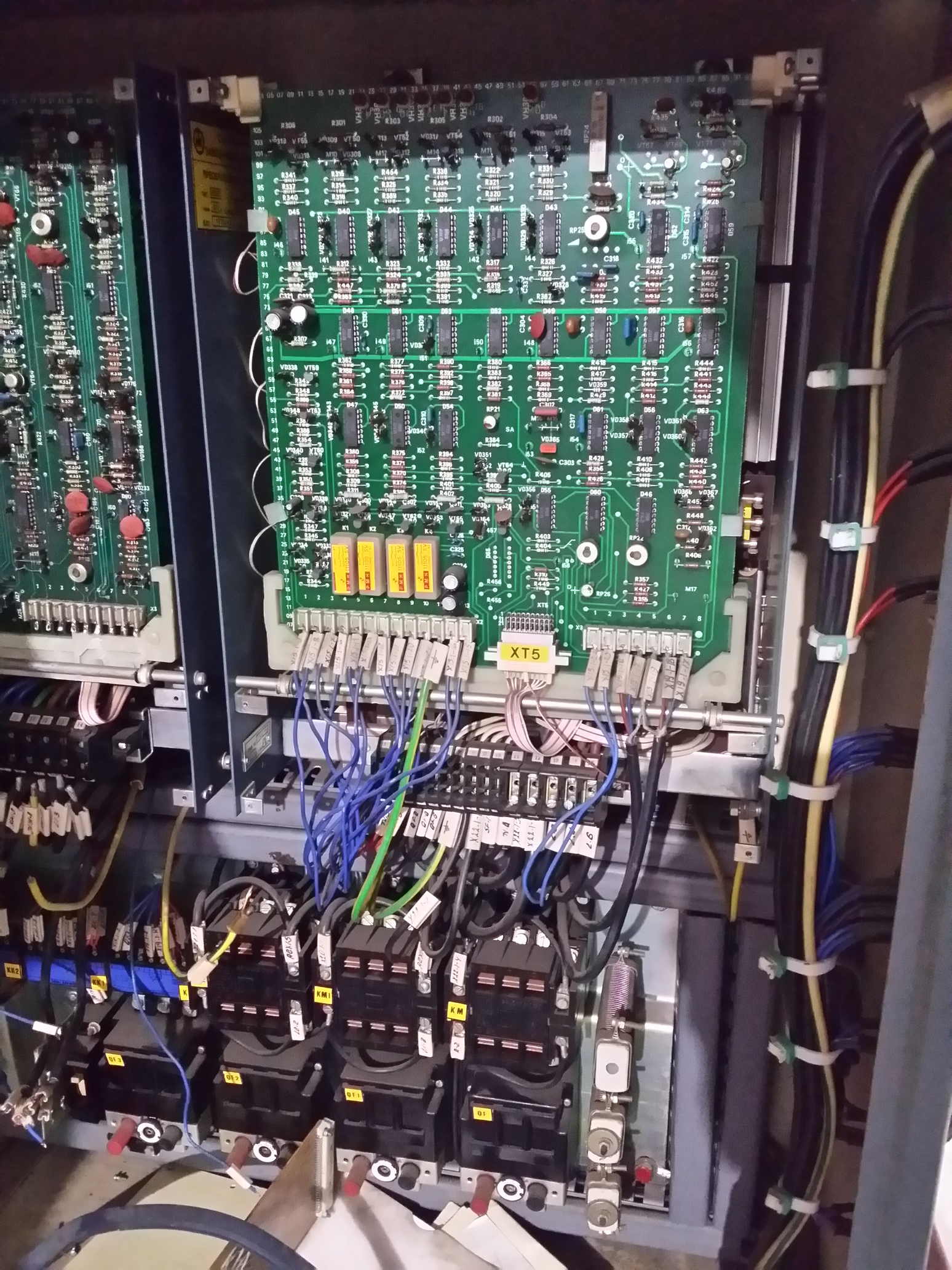

But in my case the flyback diode and the coil are not working, because I switching ON/OFF the contactor by my hand (without 24v power supply) and the input LEDs are blinking.

I will try to shield it and somehow separate them.

The arc suppression looks like this? What resistance resistor and what capacity capacitor should I use? (if the manipulation wont be success)

Replied by xenon-alien on topic 7i96S card arrived what setup is recomended

Thanks for your advices!OK if there is a flyback diode on the contactor coil, the noise is likely coming

from the contact side of the contactor

If you cannot isolate the control wiring from the power wiring you

may need to either shield the control wiring or add arc suppression

to the contactor contacts (commonly a R/C snubber is used here)

But in my case the flyback diode and the coil are not working, because I switching ON/OFF the contactor by my hand (without 24v power supply) and the input LEDs are blinking.

I will try to shield it and somehow separate them.

The arc suppression looks like this? What resistance resistor and what capacity capacitor should I use? (if the manipulation wont be success)

Attachments:

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

05 Sep 2022 06:30 #251206

by xenon-alien

But in my case the flyback diode and the coil are not working, because I switching ON/OFF the contactor by my hand (without 24v power supply) and the input LEDs are blinking.

I will try to shield it and somehow separate them.

The arc suppression looks like this? What resistance resistor and what capacity capacitor should I use? (if the manipulation wont be success)

We also bought 3 ph SSR...

Replied by xenon-alien on topic 7i96S card arrived what setup is recomended

Thanks for your advices!OK if there is a flyback diode on the contactor coil, the noise is likely coming

from the contact side of the contactor

If you cannot isolate the control wiring from the power wiring you

may need to either shield the control wiring or add arc suppression

to the contactor contacts (commonly a R/C snubber is used here)

But in my case the flyback diode and the coil are not working, because I switching ON/OFF the contactor by my hand (without 24v power supply) and the input LEDs are blinking.

I will try to shield it and somehow separate them.

The arc suppression looks like this? What resistance resistor and what capacity capacitor should I use? (if the manipulation wont be success)

We also bought 3 ph SSR...

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

05 Sep 2022 07:18 - 05 Sep 2022 07:19 #251208

by xenon-alien

Replied by xenon-alien on topic 7i96S card arrived what setup is recomended

Here are the conf files.2) The Spindle Close-Loop

There is a simple 3 ph AC motor and inverter. They are connected and turning the Spindle CW/CCW.

The Lathe has 3 speeds. On the first speed when I command to turn 200 rpm (almost 1:1 ratio), it's turning with 275 ±2rpm.

The scaling not correct yet. I will do it soon.

Is it possible to use the Close-Loop to use all speeds automatically, without using any other hal component.

(the lathe config will upload on monday.)

Attachments:

Last edit: 05 Sep 2022 07:19 by xenon-alien.

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

05 Sep 2022 09:03 - 05 Sep 2022 09:39 #251218

by xenon-alien

Replied by xenon-alien on topic 7i96S card arrived what setup is recomended

We received 3 ph SSR (i think they are used) - D53TP50D Relay; SSR; Zero-Switching; Cur-Rtg 50A; Ctrl-V 3-32DC; Vol-Rtg 48-530AC; Pnl-Mnt.

But not really understand, are they OK?

Without load I see 220V.

When I plug a load (soldering iron) I see 114v. (but the load not turns ON) With a 25W lamp the voltage is 0v.

When I turn on the SSR with 24v I see 220v and the load is turns on. (With a 25W lamp the voltage is 220v.)

So the question is, Can I use them for Turret CW/CCW switching 2 wires?

The output will look like (A2toA2) (B2toC2) (C2toB2) and goes to the turret 3 ph AC motor.

Wont it blow up (with those measurements)?

But not really understand, are they OK?

Without load I see 220V.

When I plug a load (soldering iron) I see 114v. (but the load not turns ON) With a 25W lamp the voltage is 0v.

When I turn on the SSR with 24v I see 220v and the load is turns on. (With a 25W lamp the voltage is 220v.)

So the question is, Can I use them for Turret CW/CCW switching 2 wires?

The output will look like (A2toA2) (B2toC2) (C2toB2) and goes to the turret 3 ph AC motor.

Wont it blow up (with those measurements)?

Last edit: 05 Sep 2022 09:39 by xenon-alien.

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

07 Sep 2022 09:16 #251393

by xenon-alien

setp hm2_7i96s.0.pwmgen.00.scale [SPINDLE_0]MAX_RPM (in the hal)

I have 275 ±2rpm, when I command to turn 200 rpm.

But when I change the MAX_RPM = 2800 (2700) It should change the pwm.scale, but no effect.

Then I command to turn 300 rpm I have 310 ±2rpm

Then I command to turn 400 rpm I have 425 ±2rpm

So I'm not really understand how to use the 7i96s functionality...

Or I have problems with the 10v output from the VFD - 10.67v

200 rpm (Enc 270) - 0.75v

300 rpm (Enc 310) - 1.13v

400 rpm (Enc 420) - 1.51v

500 rpm (Enc 530) - 1.89v

Encoder showing correct numbers (270 rpm), I've tested it with an optical tachometer (270± rpm on the spindle).

Replied by xenon-alien on topic 7i96S card arrived what setup is recomended

Hello.In the MAX_RPM = 2900 (in the ini - the motor speed, but there are some ratio)

2) The Spindle Close-LoopThere is a simple 3 ph AC motor and inverter. They are connected and turning the Spindle CW/CCW.The Lathe has 3 speeds. On the first speed when I command to turn 200 rpm (almost 1:1 ratio), it's turning with 275 ±2rpm.The scaling not correct yet. I will do it soon.Is it possible to use the Close-Loop to use all speeds automatically, without using any other hal component.(the lathe config will upload on monday.) Here are the conf files.

setp hm2_7i96s.0.pwmgen.00.scale [SPINDLE_0]MAX_RPM (in the hal)

I have 275 ±2rpm, when I command to turn 200 rpm.

But when I change the MAX_RPM = 2800 (2700) It should change the pwm.scale, but no effect.

Then I command to turn 300 rpm I have 310 ±2rpm

Then I command to turn 400 rpm I have 425 ±2rpm

So I'm not really understand how to use the 7i96s functionality...

Or I have problems with the 10v output from the VFD - 10.67v

200 rpm (Enc 270) - 0.75v

300 rpm (Enc 310) - 1.13v

400 rpm (Enc 420) - 1.51v

500 rpm (Enc 530) - 1.89v

Encoder showing correct numbers (270 rpm), I've tested it with an optical tachometer (270± rpm on the spindle).

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17732

- Thank you received: 5187

07 Sep 2022 15:28 #251411

by PCW

Replied by PCW on topic 7i96S card arrived what setup is recomended

The voltages look scaled correctly (200/2900 *10.67 = 0.735862069V so 0.75V is very close)

but its likely the VFD is not terribly linear at low speeds. MAX_RPM will change the PWM scaling

but if you need it to be more linear you may need to use some compensation like the lincurve

component (or run closed loop)

but its likely the VFD is not terribly linear at low speeds. MAX_RPM will change the PWM scaling

but if you need it to be more linear you may need to use some compensation like the lincurve

component (or run closed loop)

The following user(s) said Thank You: xenon-alien

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

07 Sep 2022 16:00 #251415

by xenon-alien

About lincurve component I will read.

Better is the closed loop, but i have no idea, how to make it work. (We have 3 speeds, but i think we will use only one)

Can you help me out with the closed loop?

Replied by xenon-alien on topic 7i96S card arrived what setup is recomended

Tomorrow I will try to change the scale from 2900 to 2000 to see some difference. (if it will be)The voltages look scaled correctly (200/2900 *10.67 = 0.735862069V so 0.75V is very close)

but its likely the VFD is not terribly linear at low speeds. MAX_RPM will change the PWM scaling

but if you need it to be more linear you may need to use some compensation like the lincurve

component (or run closed loop)

About lincurve component I will read.

Better is the closed loop, but i have no idea, how to make it work. (We have 3 speeds, but i think we will use only one)

Can you help me out with the closed loop?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

17 Sep 2022 09:27 #252152

by andypugh

I found this wiki.linuxcnc.org/cgi-bin/wiki.pl?Closed...pindle_Speed_Control

But it is rather outdated, as it has all the old spindle pins (motion.spindle rather than spindle.0. A global change to the latter should help). Also it is using a software encoder, rather than a Mesa one.

Replied by andypugh on topic 7i96S card arrived what setup is recomended

[/quote]Can you help me out with the closed loop?

I found this wiki.linuxcnc.org/cgi-bin/wiki.pl?Closed...pindle_Speed_Control

But it is rather outdated, as it has all the old spindle pins (motion.spindle rather than spindle.0. A global change to the latter should help). Also it is using a software encoder, rather than a Mesa one.

The following user(s) said Thank You: xenon-alien

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

26 Dec 2022 12:44 #260320

by xenon-alien

Replied by xenon-alien on topic 7i96S card arrived what setup is recomended

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.201 seconds