Planning - Bridgeport Interact 1 linuxCNC Retrofit

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

19 Jan 2016 00:43 - 19 Jan 2016 01:17 #68731

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

I got this error:

This is listed under jog-speed in the "show hal configuration menu"

I commented out a line in hal that had one thing to do with jog-speed. Now I can set it, look like 100 is what I would like.

I replaced the commented line above with "setp halui.jog-speed 100"

Its working now. Once I get familiar with the hal layout I'll clean it up.

setting parameter 'halui.jog-speed' to '10'

pin 'halui.jog-speed' is connected to a signal

setting parameter 'halui.jog-speed' to '10'

pin 'halui.jog-speed' is connected to a signal

while executing

"hal setp halui.jog-speed 10"

("eval" body line 1)

invoked from within

"eval hal $what"

(procedure "showEx" line 2)

invoked from within

"showEx $halcommand"

invoked from within

".main.note.fps.f2.b.execute invoke"

("uplevel" body line 1)

invoked from within

"uplevel #0 [list $w invoke]"

(procedure "tk::ButtonUp" line 22)

invoked from within

"tk::ButtonUp .main.note.fps.f2.b.execute"

(command bound to event)This is listed under jog-speed in the "show hal configuration menu"

owner type dir value name

7 float in 0 halui.jog-speed <======= jog-speedI commented out a line in hal that had one thing to do with jog-speed. Now I can set it, look like 100 is what I would like.

net machine-is-on halui.machine.is-on

#net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdiI replaced the commented line above with "setp halui.jog-speed 100"

Its working now. Once I get familiar with the hal layout I'll clean it up.

Last edit: 19 Jan 2016 01:17 by cncnoob1979.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

19 Jan 2016 01:16 #68732

by andypugh

Replied by andypugh on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Sorry, it looks like i didn't read the HAL carefully enough.

The pin is connected to a signal, is there anything writing to that signal anywhere?

The pin is connected to a signal, is there anything writing to that signal anywhere?

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

19 Jan 2016 01:18 - 19 Jan 2016 01:21 #68733

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

No there was nothing listed in my INI file for it, or in the HAL. I just did a quick and dirty fix for it. I would like to know how it should have went. I guess the Pnc Wizard left something out, or I messed something up!

Thanks Andy! You came to the rescue... Now just have to finish wiring up the z axis.

Thanks Andy! You came to the rescue... Now just have to finish wiring up the z axis.

Last edit: 19 Jan 2016 01:21 by cncnoob1979.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

19 Jan 2016 10:35 #68748

by andypugh

Replied by andypugh on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

In this case, rather than disconnecting the pin from the signal, you could have added a line to the HAL file "sets jog-speed 100" or, if you prefer to keep the numbers in the INI file, create an entry and "sets jog-speed [RANDOM_SECTION]JOG_SPEED"

The "sets" command sets the value of a HAL signal and thus any connected pins. It won't work if the net has an output pin connected.

The problem here is that you don't have a source for the jog speed.

When I was using a USB joypad I configured it so that the rear buttons controlled speed. No buttons pressed was zero speed, for safety. Top button was super-slow, bottom button was medium, both buttons was fast.

So, once you have decided how you want to set the joystick jog speed, we can tell you how to do it.

I was expecting the UI jog-speed slider value to be available to use, but it doesn't seem to be.

The "sets" command sets the value of a HAL signal and thus any connected pins. It won't work if the net has an output pin connected.

The problem here is that you don't have a source for the jog speed.

When I was using a USB joypad I configured it so that the rear buttons controlled speed. No buttons pressed was zero speed, for safety. Top button was super-slow, bottom button was medium, both buttons was fast.

So, once you have decided how you want to set the joystick jog speed, we can tell you how to do it.

I was expecting the UI jog-speed slider value to be available to use, but it doesn't seem to be.

Please Log in or Create an account to join the conversation.

- csbrady

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 10

20 Jan 2016 05:37 #68798

by csbrady

Replied by csbrady on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Tonight I experimented with inverse deadband. It clearly makes things worse. Looking at the servo output I could see that it was doing what it was suppose to do, create a bump at the start of movement, but the result was worse following errors. I tried very small (0.001) to moderate amount values (0.1) and the amount of error just got smaller as I reduced the amount value and 0 was the best.

While I was at it I made another pass at tuning the servos. I had been tuning with velocities between 40-60 IPM. It was interesting and telling to tune using 10-15 IPM. The following error is smaller and it was easier to see what was going on. In particular the effect of FF1 was easier to see. I was able to get considerably smaller following errors at low speed and just as good at higher speeds. Since most machining is going to be done near 15 IPM it makes sense to tune for that speed. I still get fairly big spikes (about 0.0005") at the begin and end of movement. But during movement I am now staying within 0.0001. I wish there was a solution for the spikes.

While I was at it I made another pass at tuning the servos. I had been tuning with velocities between 40-60 IPM. It was interesting and telling to tune using 10-15 IPM. The following error is smaller and it was easier to see what was going on. In particular the effect of FF1 was easier to see. I was able to get considerably smaller following errors at low speed and just as good at higher speeds. Since most machining is going to be done near 15 IPM it makes sense to tune for that speed. I still get fairly big spikes (about 0.0005") at the begin and end of movement. But during movement I am now staying within 0.0001. I wish there was a solution for the spikes.

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

20 Jan 2016 14:48 - 20 Jan 2016 14:54 #68827

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Thanks for the explanation Andy,

Concerning the HAL and INI settings. I did try to "clean it up" but I must be doing it incorrectly. So I will have to try once I get this machine buttoned up, and can wrap my head around the HAL and INI syntax.

csbrady,

I have around 0.0005 [up to 0.00078] spikes as well. However, I am around .0002/3 or so following error during movement. I still have some tuning to do.

I wonder what the factory settings are for this machine? I think around 300ipm was the design of the machine. [Fast JOG speed??] I think around 60-80IPM is sufficient for the milling capabilities. Anyone want to chime in as to what they believe would be acceptable for max speed? To be clear, I only want to set the machine up to factory capabilities.

I also wonder what others are achieving for their max following errors, and start movement / stop movement errors. Just wanting to know what is achievable with others. I have given thought to replacing with 750w AC servos and changing the AMPS but that will be down the road if I go that route. Selling the existing servo's and amps would finance the purchase of the AC system - at least, it would make a huge dent, I'm thinking.

Thanks for posting your result in reverse deadband. You saved me some time again! Too bad it wont help our situation.

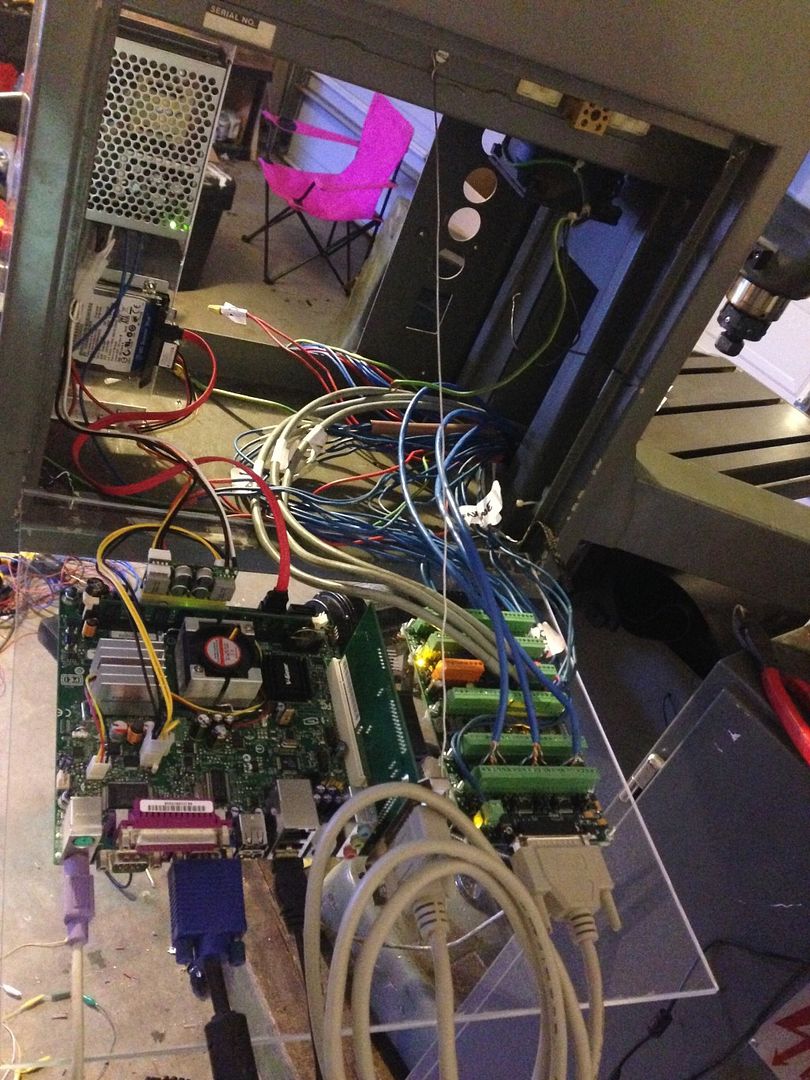

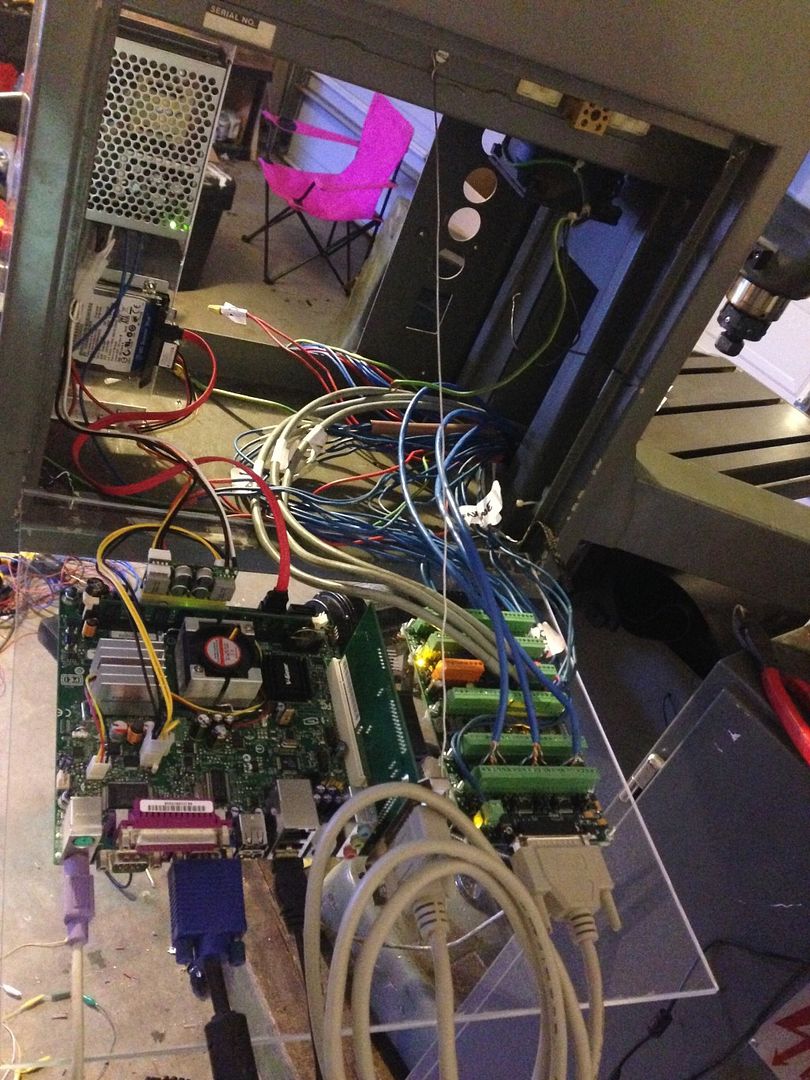

Here is my current state of the machine:

Concerning the HAL and INI settings. I did try to "clean it up" but I must be doing it incorrectly. So I will have to try once I get this machine buttoned up, and can wrap my head around the HAL and INI syntax.

csbrady,

I have around 0.0005 [up to 0.00078] spikes as well. However, I am around .0002/3 or so following error during movement. I still have some tuning to do.

I wonder what the factory settings are for this machine? I think around 300ipm was the design of the machine. [Fast JOG speed??] I think around 60-80IPM is sufficient for the milling capabilities. Anyone want to chime in as to what they believe would be acceptable for max speed? To be clear, I only want to set the machine up to factory capabilities.

I also wonder what others are achieving for their max following errors, and start movement / stop movement errors. Just wanting to know what is achievable with others. I have given thought to replacing with 750w AC servos and changing the AMPS but that will be down the road if I go that route. Selling the existing servo's and amps would finance the purchase of the AC system - at least, it would make a huge dent, I'm thinking.

Thanks for posting your result in reverse deadband. You saved me some time again! Too bad it wont help our situation.

Here is my current state of the machine:

Last edit: 20 Jan 2016 14:54 by cncnoob1979.

Please Log in or Create an account to join the conversation.

- csbrady

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 10

20 Jan 2016 16:27 #68835

by csbrady

Replied by csbrady on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

I have the original velocity parameters for the Machine that were set in the TNC 151.

Rapid Trav X,Y 197

Rapid Trav Z 157

Man Feed XYZ 20

I set my max velocity a little less than these, 190 and 150. No need to stress the machine. I could not find any indication of what the original max acceleration was. Having used the machine a lot I suspect that it was around 8. My setting of 4 is clearly more sluggish. The default of 20 was much higher than the original and made the machine jerky and sounded bad.

Here are a few more parameters that you may find useful:

Backlash Comp X 0.000472

Backlash Comp Y 00.00098

Backlash Comp Z 0

X Range + -17.75587

Y Range + -11.708638

Z Range + -4.665345

X Range - 0.240157

Y Range - 0.303149

Z Range - 0.259842

I readjusted all of these but it was nice to have a starting place.

Rapid Trav X,Y 197

Rapid Trav Z 157

Man Feed XYZ 20

I set my max velocity a little less than these, 190 and 150. No need to stress the machine. I could not find any indication of what the original max acceleration was. Having used the machine a lot I suspect that it was around 8. My setting of 4 is clearly more sluggish. The default of 20 was much higher than the original and made the machine jerky and sounded bad.

Here are a few more parameters that you may find useful:

Backlash Comp X 0.000472

Backlash Comp Y 00.00098

Backlash Comp Z 0

X Range + -17.75587

Y Range + -11.708638

Z Range + -4.665345

X Range - 0.240157

Y Range - 0.303149

Z Range - 0.259842

I readjusted all of these but it was nice to have a starting place.

The following user(s) said Thank You: cncnoob1979

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

20 Jan 2016 16:28 #68836

by Todd Zuercher

Replied by Todd Zuercher on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

I doubt the factory precision of the machine was much if any better than that.

Please Log in or Create an account to join the conversation.

- csbrady

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 10

20 Jan 2016 19:00 - 20 Jan 2016 19:01 #68845

by csbrady

Replied by csbrady on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Todd, I agree this is probably as good and possibly better than the factory precision. It's also better than I actually need since neither my skills or projects are "high precision". But that does not keep me from a neurotic quest to make it better. I am a hobbyist after all.

Last edit: 20 Jan 2016 19:01 by csbrady.

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

21 Jan 2016 21:53 #68899

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

csbrady,

Would you mind posting your final INI and HAL files for me to look at? I would like to see how you linked everything together with your panel ect.

Reading yours helps me understand the links between each file/pin.

Also I like comparing yours to mine.

Would you mind posting your final INI and HAL files for me to look at? I would like to see how you linked everything together with your panel ect.

Reading yours helps me understand the links between each file/pin.

Also I like comparing yours to mine.

Please Log in or Create an account to join the conversation.

Time to create page: 0.437 seconds