2nd stage of Crusader II retrofit

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

17 May 2018 23:38 - 17 May 2018 23:39 #110827

by jamby

2nd stage of Crusader II retrofit was created by jamby

Hi

People that helped with the first stage

Punking: this is like your machine.

OT-cnc

BigJohnT

PCW

My old mill was converted to use Linuxcnc to control the drives two years ago, mostly thanks to the members here, and now I hope to finish the conversion and completely remove the old controller.

Machine: Alliant V42 knee mill (bridgeport clone)

Control: Anilam Crusader II (the one without a screen)

Year: 1986 (picture below)

Currently the old control has the Power On, E-stop, Reset Button, and Limit Switches connected to it. There is a power on rocker switch on the back of the control that starts up the transformer in the controller supplying 5vdc and 24 vdc power. Then the reset button on the back of the control is pressed and the servo box is enabled. The limit switches and E-stop button shut down the servo box when activated. The same reset button restarts it.

Linuxcnc, enables the drives with the power on button, feeds position information, and reads the scales for feedback on postioning.

Now I want to remove the card rack from the control box and install the 7i77 in it with the power supply driving the 7i77 card. How do I connect the 7i77 to the servo cabinet to enable it? One person told me he removed the K4 and K3 IC's from the PCB801 board and connected the 24 vdc to the P3 connector pins 1 and 2. Those are the only connections he kept to the P1 socket. However his is a much newer model of the PCB801 than mine which only has two IC's K1 and K3.

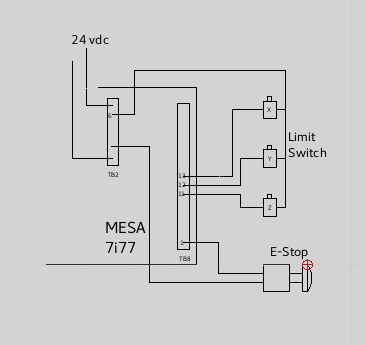

Limit Switches and E-stop will be connected as shown in the sketch below. One leg of the switch circuit will carry power to each switch then the other leg will connect to TB8's IO terminals using (3) different ones with definitions in the hal file as shown in BigJohnT's examples.

Also I plan to connect the 5i25 to the 7i77 using the current cable from my desktop computer to the back of the old controller with the 7i77 in it. Unless someone can recommend a computer MB that could me mounted inside the controller box running on 5vdc or 24vdc??

I am trying to picture how the machine will operate once this conversion is done. My best guess: rocker switch on back of control box will power up the 7i77, reset switch on back of control will enable servo box. I just can see how the connections will be made between the servo and 7i77??

I have drawings of both the controller and servo box cards showing the board layouts and the circuits. Problem is my machine is from 1986 and the drawings are a mix of dates. Most being later then my machine with features not on mine.

Thanks

Jim

People that helped with the first stage

Punking: this is like your machine.

OT-cnc

BigJohnT

PCW

My old mill was converted to use Linuxcnc to control the drives two years ago, mostly thanks to the members here, and now I hope to finish the conversion and completely remove the old controller.

Machine: Alliant V42 knee mill (bridgeport clone)

Control: Anilam Crusader II (the one without a screen)

Year: 1986 (picture below)

Currently the old control has the Power On, E-stop, Reset Button, and Limit Switches connected to it. There is a power on rocker switch on the back of the control that starts up the transformer in the controller supplying 5vdc and 24 vdc power. Then the reset button on the back of the control is pressed and the servo box is enabled. The limit switches and E-stop button shut down the servo box when activated. The same reset button restarts it.

Linuxcnc, enables the drives with the power on button, feeds position information, and reads the scales for feedback on postioning.

Now I want to remove the card rack from the control box and install the 7i77 in it with the power supply driving the 7i77 card. How do I connect the 7i77 to the servo cabinet to enable it? One person told me he removed the K4 and K3 IC's from the PCB801 board and connected the 24 vdc to the P3 connector pins 1 and 2. Those are the only connections he kept to the P1 socket. However his is a much newer model of the PCB801 than mine which only has two IC's K1 and K3.

Limit Switches and E-stop will be connected as shown in the sketch below. One leg of the switch circuit will carry power to each switch then the other leg will connect to TB8's IO terminals using (3) different ones with definitions in the hal file as shown in BigJohnT's examples.

Also I plan to connect the 5i25 to the 7i77 using the current cable from my desktop computer to the back of the old controller with the 7i77 in it. Unless someone can recommend a computer MB that could me mounted inside the controller box running on 5vdc or 24vdc??

I am trying to picture how the machine will operate once this conversion is done. My best guess: rocker switch on back of control box will power up the 7i77, reset switch on back of control will enable servo box. I just can see how the connections will be made between the servo and 7i77??

I have drawings of both the controller and servo box cards showing the board layouts and the circuits. Problem is my machine is from 1986 and the drawings are a mix of dates. Most being later then my machine with features not on mine.

Thanks

Jim

Last edit: 17 May 2018 23:39 by jamby.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

19 May 2018 12:39 #110881

by BigJohnT

Replied by BigJohnT on topic 2nd stage of Crusader II retrofit

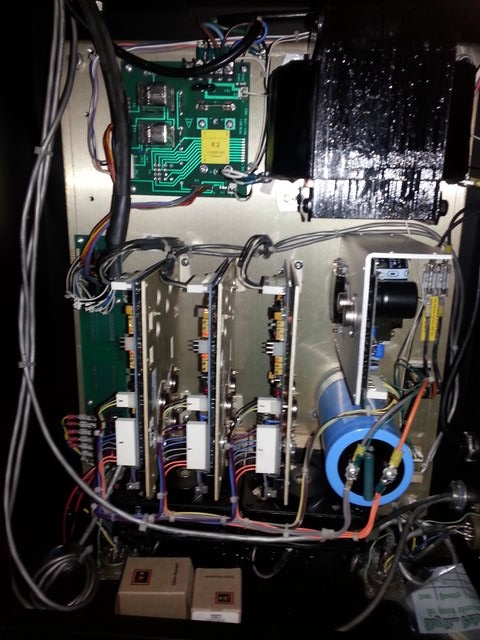

My BP knee mill had an Anilam 1100M control. I removed everything except the power supply for the drives and the driver cards. Then connected the drive analog to the 7i77 and also the limit switches and encoders. I'm not familiar with the Crusader. A photo of the drives might help.

JT

JT

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

19 May 2018 14:40 - 19 May 2018 14:41 #110885

by jamby

Replied by jamby on topic 2nd stage of Crusader II retrofit

Last edit: 19 May 2018 14:41 by jamby.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

19 May 2018 15:30 #110886

by BigJohnT

Replied by BigJohnT on topic 2nd stage of Crusader II retrofit

That looks like my drives except mine are mounted the other way around. Is there a red and black wire on the top plug? On mine the black is in the rear hole and the red the next to front hole. If so then that is the velocity input to the drive. I mounted the 7i77 where the green board is now in your cabinet.

JT

JT

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

19 May 2018 17:43 - 19 May 2018 17:52 #110891

by jamby

Replied by jamby on topic 2nd stage of Crusader II retrofit

John

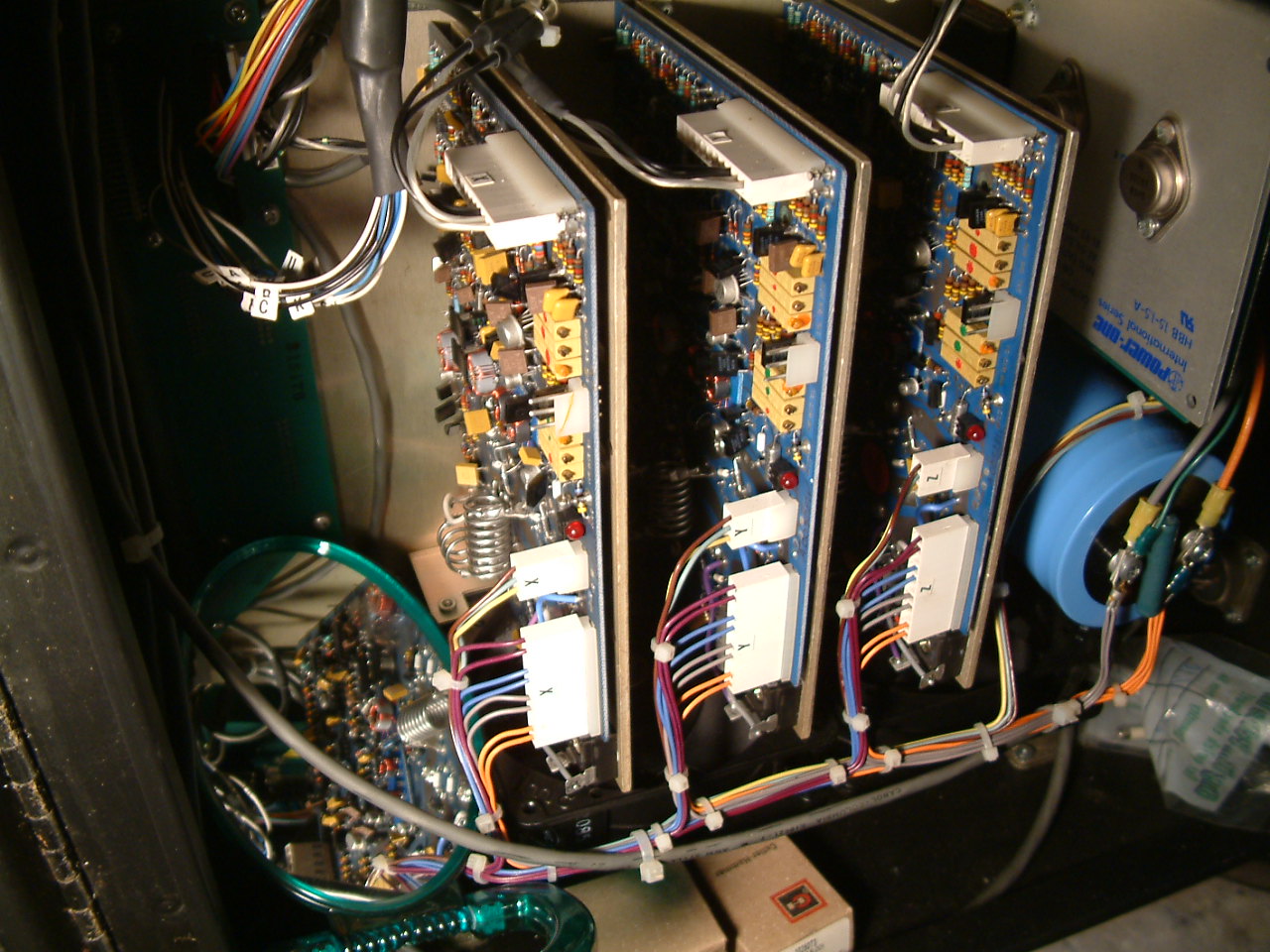

Does this answer your question or am I looking in the wrong place? These are the Westamp boards.

Problem is a lot of the conversion I been reading are like your M100 "newer" and they have the same boards but with different connectors and addition plugs and IC's. But the board numbers are the same, and the drawings I have are all kinds of rev letters and show connections from later models.

Thanks

Jim

Does this answer your question or am I looking in the wrong place? These are the Westamp boards.

Problem is a lot of the conversion I been reading are like your M100 "newer" and they have the same boards but with different connectors and addition plugs and IC's. But the board numbers are the same, and the drawings I have are all kinds of rev letters and show connections from later models.

Thanks

Jim

Last edit: 19 May 2018 17:52 by jamby.

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

19 May 2018 17:58 #110894

by OT-CNC

Replied by OT-CNC on topic 2nd stage of Crusader II retrofit

Hi Jim,

On mine I reused the upper hmi control box body and added a stainless face with buttons and monitor cutout. I also added a keyboard mount and mouse tray. A small form factor pc fits inside that box. I have added a small separate enclosure to the back of the lower power cabinet. This is where the 7i77 resides. I didn't feel there was enough room in the hmi box to fit everything. The 25 pin cable is routed outside the arm to the pc. I had to redo the old anilam arm to add a pivot for better positioning and increased it's height. I wish the steel tubing I used was big enough to fit the 25pin connector for a cleaner install. I kept the toggle switch on the back of the power box to switch between automatic and manual. In manual mode, the spindle contactor is energized so you can turn on the spindle and move the x y manually without having to power up the pc if you just want to do a quick op. I went through great lengths to to modify the Z axis so I can disconnect it from the ball nut which was not stock on that older design. So you may not benefit much from the manual switch if the z is locked.

I also added a power disconnect switch to the power box on the 110v line. Not really needed. PC is always connected to the 110. I hacked the pc on switch to the power on momentary button on the HMI panel. This turns on the PC. Once linuxcnc is started, the enable drives/power button turns on the drives via the relay inside the old anilam power box. Estop or disable drives button shuts down the drives.

You don't need the reset button from the old setup or the power switch in the back of the hmi if that makes sense?The 7i77 enable out will go to the drive enable relay on that upper relay board. I think the board you have uses the same enable we talked about prior. Someone else may want to confirm the wiring on that.

I would also suggest adding a remote connection for usb on your panel if you plan on burying your pc. Also, I suggest adding homing switches so after power up you home the machine and don't run the risk of crashing into a hard stop.

On mine I reused the upper hmi control box body and added a stainless face with buttons and monitor cutout. I also added a keyboard mount and mouse tray. A small form factor pc fits inside that box. I have added a small separate enclosure to the back of the lower power cabinet. This is where the 7i77 resides. I didn't feel there was enough room in the hmi box to fit everything. The 25 pin cable is routed outside the arm to the pc. I had to redo the old anilam arm to add a pivot for better positioning and increased it's height. I wish the steel tubing I used was big enough to fit the 25pin connector for a cleaner install. I kept the toggle switch on the back of the power box to switch between automatic and manual. In manual mode, the spindle contactor is energized so you can turn on the spindle and move the x y manually without having to power up the pc if you just want to do a quick op. I went through great lengths to to modify the Z axis so I can disconnect it from the ball nut which was not stock on that older design. So you may not benefit much from the manual switch if the z is locked.

I also added a power disconnect switch to the power box on the 110v line. Not really needed. PC is always connected to the 110. I hacked the pc on switch to the power on momentary button on the HMI panel. This turns on the PC. Once linuxcnc is started, the enable drives/power button turns on the drives via the relay inside the old anilam power box. Estop or disable drives button shuts down the drives.

You don't need the reset button from the old setup or the power switch in the back of the hmi if that makes sense?The 7i77 enable out will go to the drive enable relay on that upper relay board. I think the board you have uses the same enable we talked about prior. Someone else may want to confirm the wiring on that.

I would also suggest adding a remote connection for usb on your panel if you plan on burying your pc. Also, I suggest adding homing switches so after power up you home the machine and don't run the risk of crashing into a hard stop.

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

19 May 2018 19:32 #110896

by jamby

Replied by jamby on topic 2nd stage of Crusader II retrofit

OT-CNC

Good to here from you again. I am thinking of gutting my control box (hmi) except for the power supply. The original Anilam power supply has both 5vdc and 24vdc to power the 7i77 with and I'd like to have the PS, 7i77, and a small computer inside that old control box. I like the control panel front you added to yours.

What type of small form computer did you use? does it have its own power supply in the box and did you have to add vents for heat?

Thanks

Jim

Good to here from you again. I am thinking of gutting my control box (hmi) except for the power supply. The original Anilam power supply has both 5vdc and 24vdc to power the 7i77 with and I'd like to have the PS, 7i77, and a small computer inside that old control box. I like the control panel front you added to yours.

What type of small form computer did you use? does it have its own power supply in the box and did you have to add vents for heat?

Thanks

Jim

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

Less

More

- Posts: 235

- Thank you received: 6

19 May 2018 19:45 #110897

by jamby

Replied by jamby on topic 2nd stage of Crusader II retrofit

OT-CNC

Another question. When you trip your limit or e-stop do the drives in the servo box shut down or is it just the drive enable that drops?

Thanks again

Jim

Another question. When you trip your limit or e-stop do the drives in the servo box shut down or is it just the drive enable that drops?

Thanks again

Jim

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

19 May 2018 19:59 #110898

by OT-CNC

Replied by OT-CNC on topic 2nd stage of Crusader II retrofit

Hi Jim,

I ditched the power supply in the HMI (Human Machine Interface) as well as the old 24 volt one inside the power box. You can get some nice new ones that fit din rail from meanwell and others or use what you have if it has life left in it. The PC I'm using is a dell optiplex that apparently is not well suited for linuxcnc. It has its own built in ps. I did add vents to the back. I may add an addition fan if things get hot in the summer. The enclosed box does warm up considerably.

With the type of older anilam power boxes you and I have, there is not much additional room for anything. The later used a much bigger enclosure. I was faced with the same problem of where to put the 7i77. Wherever you put it, consider enough room to get to the connectors so you can add to the i/o s if you want to expand and I assume not mount it next to a transformer /switching ps or hf drive in case they output noise.

I ditched the power supply in the HMI (Human Machine Interface) as well as the old 24 volt one inside the power box. You can get some nice new ones that fit din rail from meanwell and others or use what you have if it has life left in it. The PC I'm using is a dell optiplex that apparently is not well suited for linuxcnc. It has its own built in ps. I did add vents to the back. I may add an addition fan if things get hot in the summer. The enclosed box does warm up considerably.

With the type of older anilam power boxes you and I have, there is not much additional room for anything. The later used a much bigger enclosure. I was faced with the same problem of where to put the 7i77. Wherever you put it, consider enough room to get to the connectors so you can add to the i/o s if you want to expand and I assume not mount it next to a transformer /switching ps or hf drive in case they output noise.

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

19 May 2018 20:08 #110899

by OT-CNC

Replied by OT-CNC on topic 2nd stage of Crusader II retrofit

Yes, the drives shut down both with the estop, the limits and drive enable/disable button. It's all handled through linuxcnc and the enable out pin from the 7i77 going to the relay board. I wired the limits to the 7i77 inputs.

Please Log in or Create an account to join the conversation.

Time to create page: 0.254 seconds