15m Industrial Plasma Cutter

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11574

- Thank you received: 3888

23 Aug 2019 20:18 - 23 Aug 2019 20:19 #143004

by rodw

You will definitely need ohmic sensing on such thin material as it will warp a tremendous amount.

Ohmic sensing is covered in the Plasma Primer which is part of the main Linuxcnc 2.8 & 2.9 docs.

But you also need home and limit sensors. With Mesa hardware if you use PNP proximity sensors it is pretty easy and you can keep all the wiring located on the moving gantry. My build thread shows the simple method I came up with on the first post. Just make sure the max limit sensor plate is mounted so the high side is on the inside of the limit otherwise if the home sensor is at that end it will think it is near home and move the wrong way and crash!

forum.linuxcnc.org/show-your-stuff/32029...a-cutter-build#84551

So back to material height sensing. Ohmic will be your primary method but you will need to also make a float switch on the Z axis in case it does not activate. This thread which predated my build thread shows some close ups of my Z axis design.

forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

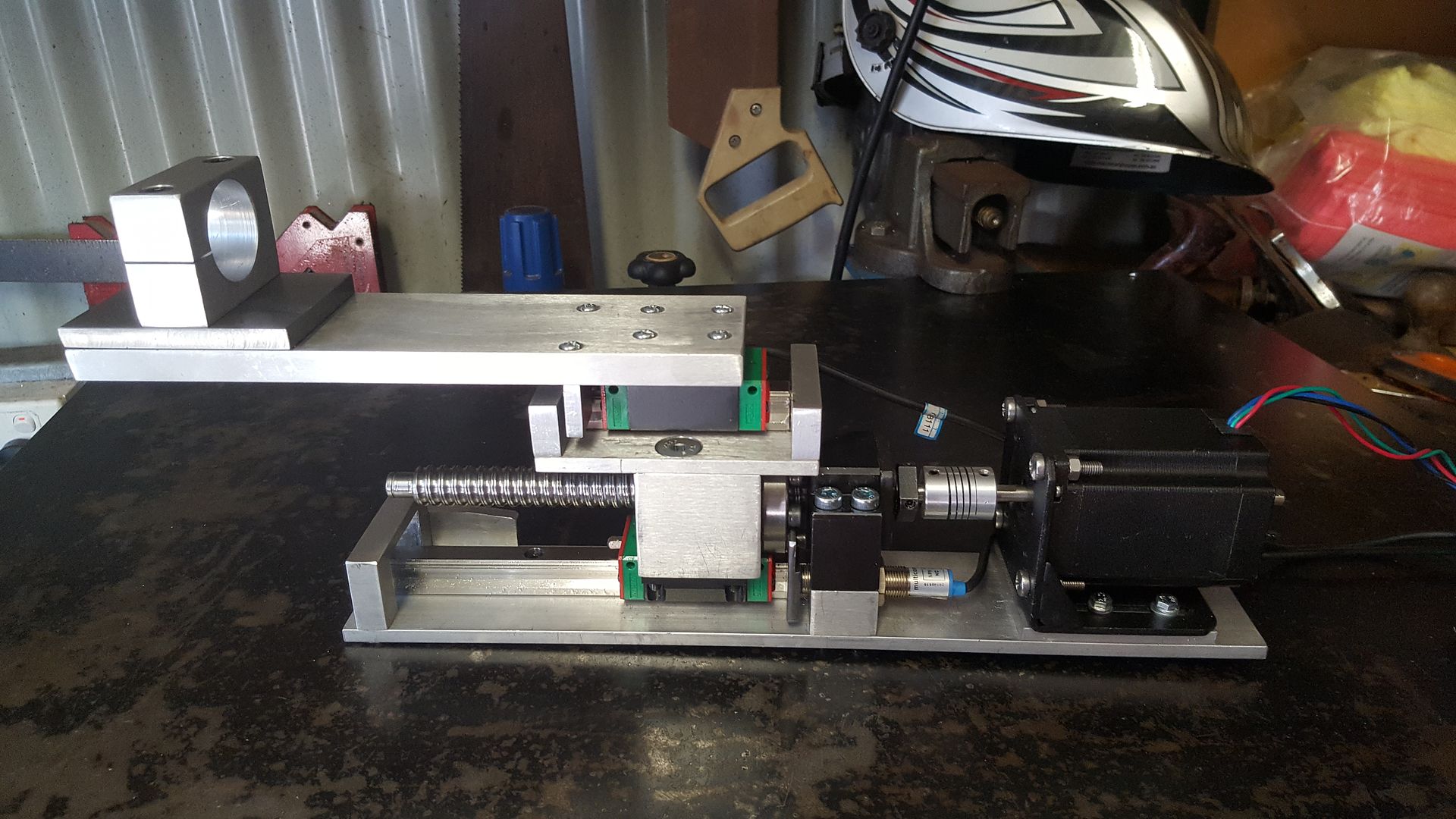

The advice from the guys on this thread was really invaluable and this is an excellent design. By purchasing a prebuilt stage, all you need to build is the parts secured to the collar around the ballscrew nut in this photo

eg. the assembly held on by the large black screw.

The only other thing I would say is to be really generous with the Z axis travel. I used a 150mm long ball screw which gave me about 85mm of travel. I think I would use a 300mm long stage and make sure you have a minimum of 200 mm of travel to handle material warpage on thin stock

Replied by rodw on topic 15m Industrial Plasma Cutter

Do I need anything when it comes to sensing?

I saw that Rod said he used ohmic sensing on another thread.

You will definitely need ohmic sensing on such thin material as it will warp a tremendous amount.

Ohmic sensing is covered in the Plasma Primer which is part of the main Linuxcnc 2.8 & 2.9 docs.

But you also need home and limit sensors. With Mesa hardware if you use PNP proximity sensors it is pretty easy and you can keep all the wiring located on the moving gantry. My build thread shows the simple method I came up with on the first post. Just make sure the max limit sensor plate is mounted so the high side is on the inside of the limit otherwise if the home sensor is at that end it will think it is near home and move the wrong way and crash!

forum.linuxcnc.org/show-your-stuff/32029...a-cutter-build#84551

So back to material height sensing. Ohmic will be your primary method but you will need to also make a float switch on the Z axis in case it does not activate. This thread which predated my build thread shows some close ups of my Z axis design.

forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

The advice from the guys on this thread was really invaluable and this is an excellent design. By purchasing a prebuilt stage, all you need to build is the parts secured to the collar around the ballscrew nut in this photo

eg. the assembly held on by the large black screw.

The only other thing I would say is to be really generous with the Z axis travel. I used a 150mm long ball screw which gave me about 85mm of travel. I think I would use a 300mm long stage and make sure you have a minimum of 200 mm of travel to handle material warpage on thin stock

Last edit: 23 Aug 2019 20:19 by rodw.

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11574

- Thank you received: 3888

23 Aug 2019 20:37 #143007

by rodw

Replied by rodw on topic 15m Industrial Plasma Cutter

Also, these NEMA 34 reduction mounts will save you a lot of time for the Y axis. They come with a drive belt and have worked well for me with a 1.25 mod helical rack. Much better than the straight rack I used on the X axis

www.aliexpress.com/item/33038138992.html...0.0.0.c16c2e0e8i97dg

www.aliexpress.com/item/33038138992.html...0.0.0.c16c2e0e8i97dg

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- Jarman

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 8

28 Aug 2019 15:07 #143449

by Jarman

Replied by Jarman on topic 15m Industrial Plasma Cutter

Thanks everyone.

I'm leaning towards steppers now (only because I'm pressed for time and I'm trying to keep it simple). I'm not sure that I fully understand what the advantages of servos are.

Is there a good way of navigating this forum/ finding resources? How did you guys find out how things like the z axis worked for your first build? For example, I see pictures of people's designs but I don't really see how they work or what the necessary parts are. Sorry to bug you guys about the boring stuff, normally I'd just trawl through the Internet and figure it out myself but I'm really trying to get into a position where I can place some orders on Friday.

I'm leaning towards steppers now (only because I'm pressed for time and I'm trying to keep it simple). I'm not sure that I fully understand what the advantages of servos are.

Is there a good way of navigating this forum/ finding resources? How did you guys find out how things like the z axis worked for your first build? For example, I see pictures of people's designs but I don't really see how they work or what the necessary parts are. Sorry to bug you guys about the boring stuff, normally I'd just trawl through the Internet and figure it out myself but I'm really trying to get into a position where I can place some orders on Friday.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21103

- Thank you received: 7205

28 Aug 2019 15:24 #143452

by tommylight

Replied by tommylight on topic 15m Industrial Plasma Cutter

Use google hacking, that is a thing and google teaches you how to do that, just search for it.

Example:

to search for anything related to DIY, plasma, cnc, only on the Linuxcnc.org site you type

diy plasma cnc site:linuxcnc.org

results:

To search for the exact sentence use

"diy plasma" site:linuxcnc.org

results:

Same goes for files, like

diy plasma cnc filetype:pdf

etc.

Example:

to search for anything related to DIY, plasma, cnc, only on the Linuxcnc.org site you type

diy plasma cnc site:linuxcnc.org

results:

To search for the exact sentence use

"diy plasma" site:linuxcnc.org

results:

Same goes for files, like

diy plasma cnc filetype:pdf

etc.

Attachments:

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- Jarman

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 8

29 Aug 2019 14:24 #143558

by Jarman

Replied by Jarman on topic 15m Industrial Plasma Cutter

Thanks for that.

If I'm using tommy's stepper idea and going with a 7i76E + THCAD do I need an additional breakout board? I saw a thread about using a 7i76E and 7i43?

If I'm using tommy's stepper idea and going with a 7i76E + THCAD do I need an additional breakout board? I saw a thread about using a 7i76E and 7i43?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

29 Aug 2019 15:25 #143563

by andypugh

Replied by andypugh on topic 15m Industrial Plasma Cutter

I don't think you _can_ use the 7i43 with a 7i76E. Maybe it was a 7i73?

(the Mesa names are definitely confusing, but they do Google well)

(the Mesa names are definitely confusing, but they do Google well)

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- Jarman

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 8

29 Aug 2019 15:28 #143564

by Jarman

Replied by Jarman on topic 15m Industrial Plasma Cutter

but a 7i76E and THCAD are sufficient aren't they?

They don't need anything else?

They don't need anything else?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

29 Aug 2019 15:55 #143568

by andypugh

I would think so, yes.

Replied by andypugh on topic 15m Industrial Plasma Cutter

but a 7i76E and THCAD are sufficient aren't they?

I would think so, yes.

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21103

- Thank you received: 7205

29 Aug 2019 16:12 #143573

by tommylight

Replied by tommylight on topic 15m Industrial Plasma Cutter

They do need other things, like, power supply, wires, drives, motors, someone to put all that together and a lot of coffee !but a 7i76E and THCAD are sufficient aren't they?

They don't need anything else?

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- Jarman

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 8

29 Aug 2019 16:58 #143578

by Jarman

Replied by Jarman on topic 15m Industrial Plasma Cutter

I just wish they came with more time!

I'm struggling to see how I can feasibly make the z axis myself in the time frame. I've been looking at some prebuilt z axis stages but they are all from China and most have a 2 week lead time. Does anyone have experience ordering from these chinese cnc companies? Do they tend to deliver when they say? From previous experience with even local manufacturing companies I doubt it.

I'm not too concerned about the complicated stuff like electronics, software and motors. It's the lead times and basic machining that's got me worried. I have to stop in 4 weeks no matter how far I've got so I'm wondering if it's worth investing all this money in a gamble that I can get it built.

I'm also wondering if I can throw together an extremely simplified version eg. no variable z axis height/magnetic breakaway or any of that. And just accept that the quality won't be fantastic, but at least it will get done.

I'm struggling to see how I can feasibly make the z axis myself in the time frame. I've been looking at some prebuilt z axis stages but they are all from China and most have a 2 week lead time. Does anyone have experience ordering from these chinese cnc companies? Do they tend to deliver when they say? From previous experience with even local manufacturing companies I doubt it.

I'm not too concerned about the complicated stuff like electronics, software and motors. It's the lead times and basic machining that's got me worried. I have to stop in 4 weeks no matter how far I've got so I'm wondering if it's worth investing all this money in a gamble that I can get it built.

I'm also wondering if I can throw together an extremely simplified version eg. no variable z axis height/magnetic breakaway or any of that. And just accept that the quality won't be fantastic, but at least it will get done.

Please Log in or Create an account to join the conversation.

Time to create page: 0.320 seconds