Time to setup my lathe with 7i76e

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Dec 2017 19:33 #103568

by tecno

Replied by tecno on topic Time to setup my lathe with 7i76e - Need help!

Both are 1e9

Well we know that the 7i76e has faults = spindle encoder inputs ( this have been discussed before and maybe some other too)

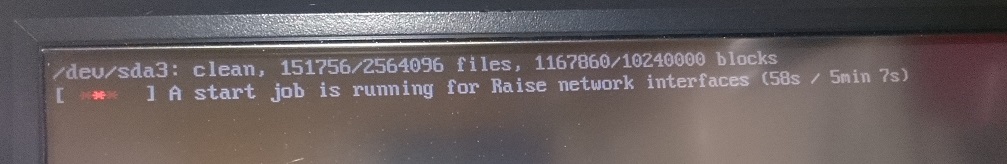

I am about to do a new install and skip that WiFi fix in grub as it slows down the boot.

Before this screen it takes few minutes and this part takes 1½minute = in total SLOOOOOOW

Well we know that the 7i76e has faults = spindle encoder inputs ( this have been discussed before and maybe some other too)

I am about to do a new install and skip that WiFi fix in grub as it slows down the boot.

Before this screen it takes few minutes and this part takes 1½minute = in total SLOOOOOOW

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17657

- Thank you received: 5164

24 Dec 2017 19:42 #103569

by PCW

Replied by PCW on topic Time to setup my lathe with 7i76e - Need help!

The index fault most likely reflects damage to the RS-422 receiver from excessive input voltage

It has nothing to do with the step generators

There is something very basic wrong with your setup

Might be a PC issue

Might be a corner case driver issue

Might be FPGA card related

Really hard to tell at this point

I will try your hal/ini files and seen if anything odd shows up

It has nothing to do with the step generators

There is something very basic wrong with your setup

Might be a PC issue

Might be a corner case driver issue

Might be FPGA card related

Really hard to tell at this point

I will try your hal/ini files and seen if anything odd shows up

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Dec 2017 19:46 #103570

by tecno

Replied by tecno on topic Time to setup my lathe with 7i76e - Need help!

I will do a reinstall of LinuxCNC tomorrow so that part is back to basics.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Dec 2017 20:28 #103572

by tecno

Replied by tecno on topic Time to setup my lathe with 7i76e - Need help!

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17657

- Thank you received: 5164

24 Dec 2017 21:08 - 24 Dec 2017 21:37 #103573

by PCW

Replied by PCW on topic Time to setup my lathe with 7i76e - Need help!

OK the main problem is in your hal file, you commented out all the stepgen feedback parts for the x axis...

To be clear, this part was commented out:

# ---closedloop stepper signals---

# net x-pos-cmd <= axis.0.motor-pos-cmd

# net x-vel-cmd <= axis.0.joint-vel-cmd

# net x-output <= hm2_7i76e.0.stepgen.00.velocity-cmd

# net x-pos-fb <= hm2_7i76e.0.stepgen.00.position-fb

# net x-pos-fb => axis.0.motor-pos-fb

# net x-enable <= axis.0.amp-enable-out

# net x-enable => hm2_7i76e.0.stepgen.00.enable

and should be

# ---closedloop stepper signals---

net x-pos-cmd <= axis.0.motor-pos-cmd

net x-vel-cmd <= axis.0.joint-vel-cmd

net x-output <= hm2_7i76e.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i76e.0.stepgen.00.position-fb

net x-pos-fb => axis.0.motor-pos-fb

net x-enable <= axis.0.amp-enable-out

net x-enable => hm2_7i76e.0.stepgen.00.enable

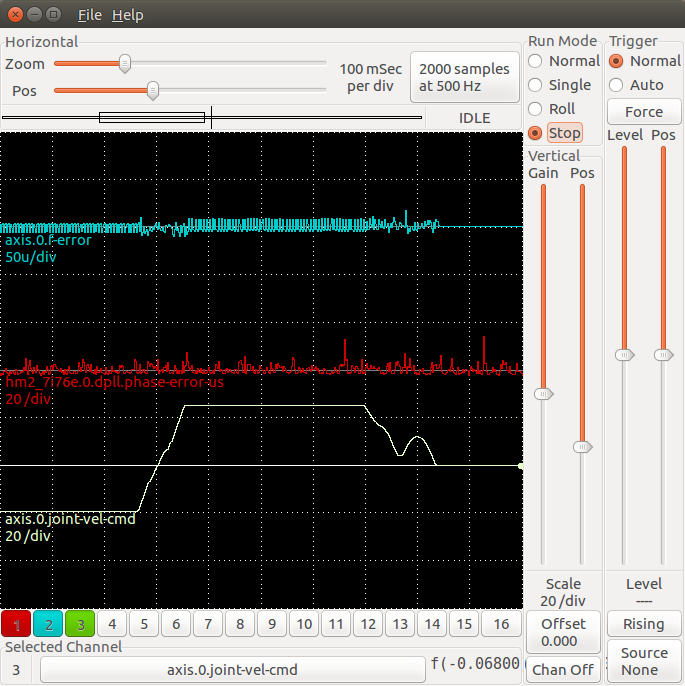

Here is the xaxis ferror with your config files (with a small tweak to FF2)

(50 u/div is not 50 microns/div but rather 50 nM/div since the machine scale is mm not Meters )

Also note that you had an error in the CNC3000enc.ini file, it pointed to the CNC3000.hal file, _not_ the CNC3000enc.hal file

To be clear, this part was commented out:

# ---closedloop stepper signals---

# net x-pos-cmd <= axis.0.motor-pos-cmd

# net x-vel-cmd <= axis.0.joint-vel-cmd

# net x-output <= hm2_7i76e.0.stepgen.00.velocity-cmd

# net x-pos-fb <= hm2_7i76e.0.stepgen.00.position-fb

# net x-pos-fb => axis.0.motor-pos-fb

# net x-enable <= axis.0.amp-enable-out

# net x-enable => hm2_7i76e.0.stepgen.00.enable

and should be

# ---closedloop stepper signals---

net x-pos-cmd <= axis.0.motor-pos-cmd

net x-vel-cmd <= axis.0.joint-vel-cmd

net x-output <= hm2_7i76e.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i76e.0.stepgen.00.position-fb

net x-pos-fb => axis.0.motor-pos-fb

net x-enable <= axis.0.amp-enable-out

net x-enable => hm2_7i76e.0.stepgen.00.enable

Here is the xaxis ferror with your config files (with a small tweak to FF2)

(50 u/div is not 50 microns/div but rather 50 nM/div since the machine scale is mm not Meters )

Also note that you had an error in the CNC3000enc.ini file, it pointed to the CNC3000.hal file, _not_ the CNC3000enc.hal file

Last edit: 24 Dec 2017 21:37 by PCW.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Dec 2017 21:14 #103574

by tecno

Replied by tecno on topic Time to setup my lathe with 7i76e - Need help!

Well that was something I have missed totally, been comparing hal files and did not see that one. Thanks will retry tomorrow and report back.

But I still think a reinstall is in place, where can I find latest NETINSTALL ISO. Have no CD and I do not have any big USB memory sticks to take full ISO.

Thanks again Peter for checking what was wrong, much appreciated.

But I still think a reinstall is in place, where can I find latest NETINSTALL ISO. Have no CD and I do not have any big USB memory sticks to take full ISO.

Thanks again Peter for checking what was wrong, much appreciated.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17657

- Thank you received: 5164

24 Dec 2017 21:38 #103575

by PCW

Replied by PCW on topic Time to setup my lathe with 7i76e - Need help!

Not really sure a re-install is needed, just fixing the hal file issues

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Dec 2017 21:40 #103576

by tecno

Replied by tecno on topic Time to setup my lathe with 7i76e - Need help!

OK, I will go from there and see what happens. The slow boot up is really annoying.

Will report back tomorrow how all works.

Will report back tomorrow how all works.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

25 Dec 2017 12:57 - 25 Dec 2017 12:57 #103590

by tecno

Replied by tecno on topic Time to setup my lathe with 7i76e - Need help!

Now both axis are working and NO stuttering = very smooth.

Tested pawn.ngc and it works OK, file says S1000 but in reality 610rpm == Where do I adjust this?

How can I verify G76 function? With sample files I get nowhere as there is something wrong in gcode.

Can somebody please share a small sample G76 threading with tool table that works so I can verify that threading is working.

Tested pawn.ngc and it works OK, file says S1000 but in reality 610rpm == Where do I adjust this?

How can I verify G76 function? With sample files I get nowhere as there is something wrong in gcode.

Can somebody please share a small sample G76 threading with tool table that works so I can verify that threading is working.

Last edit: 25 Dec 2017 12:57 by tecno.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

25 Dec 2017 14:07 #103591

by tecno

Replied by tecno on topic Time to setup my lathe with 7i76e - Need help!

Is it perhaps in this section of HAL where I change scale?

# ---Spindle synchronized motion

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.spindle.gain 60 >>>>>>>>>>>>>>>>>>>>>>>>>>>> change this line to 100 ?

setp lowpass.spindle.gain 1.000000

net spindle-vel-fb-rps => scale.spindle.in

net spindle-fb-rpm scale.spindle.out => abs.spindle.in

net spindle-fb-rpm-abs abs.spindle.out => lowpass.spindle.in

net spindle-fb-rpm-abs-filtered lowpass.spindle.out

# ---Spindle synchronized motion

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.spindle.gain 60 >>>>>>>>>>>>>>>>>>>>>>>>>>>> change this line to 100 ?

setp lowpass.spindle.gain 1.000000

net spindle-vel-fb-rps => scale.spindle.in

net spindle-fb-rpm scale.spindle.out => abs.spindle.in

net spindle-fb-rpm-abs abs.spindle.out => lowpass.spindle.in

net spindle-fb-rpm-abs-filtered lowpass.spindle.out

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 1.197 seconds