PNCconf 7i92H and 7i76

- stonebite

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 10

27 May 2024 13:31 - 27 May 2024 13:32 #301587

by stonebite

Replied by stonebite on topic PNCconf 7i92H and 7i76

Is that an APU? Does this mean that the processor has the graphics card inside it?

Yes, exactly (ASUS Barbone AMI Prozessor an Radeon Grafic), I thought I had explained this in previous posts?

The temperature of the processor is 89 degrees, the graphics card is 70 degrees, and that indicates that the cooler is not sitting properly on the processor.

Ok, I could understand that if I didn't know that I completely disassembled the PC and posted the facts and ordered and freshly applied thermal paste. Please see the post

forum.linuxcnc.org/39-pncconf/52373-pncc...7i76?start=40#299252

Yes, exactly (ASUS Barbone AMI Prozessor an Radeon Grafic), I thought I had explained this in previous posts?

The temperature of the processor is 89 degrees, the graphics card is 70 degrees, and that indicates that the cooler is not sitting properly on the processor.

Ok, I could understand that if I didn't know that I completely disassembled the PC and posted the facts and ordered and freshly applied thermal paste. Please see the post

forum.linuxcnc.org/39-pncconf/52373-pncc...7i76?start=40#299252

Last edit: 27 May 2024 13:32 by stonebite.

Please Log in or Create an account to join the conversation.

- stonebite

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 10

04 Jun 2024 08:32 #302299

by stonebite

Replied by stonebite on topic PNCconf 7i92H and 7i76

Hello, I am back from many attempts. Thanks to the support of a colleague, I have now got to the point where I can see that the servos are moving on all axles.

How can I send you a donation?

How can I send you a donation?

Please Log in or Create an account to join the conversation.

- stonebite

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 10

04 Jun 2024 09:29 - 04 Jun 2024 09:37 #302303

by stonebite

Replied by stonebite on topic PNCconf 7i92H and 7i76

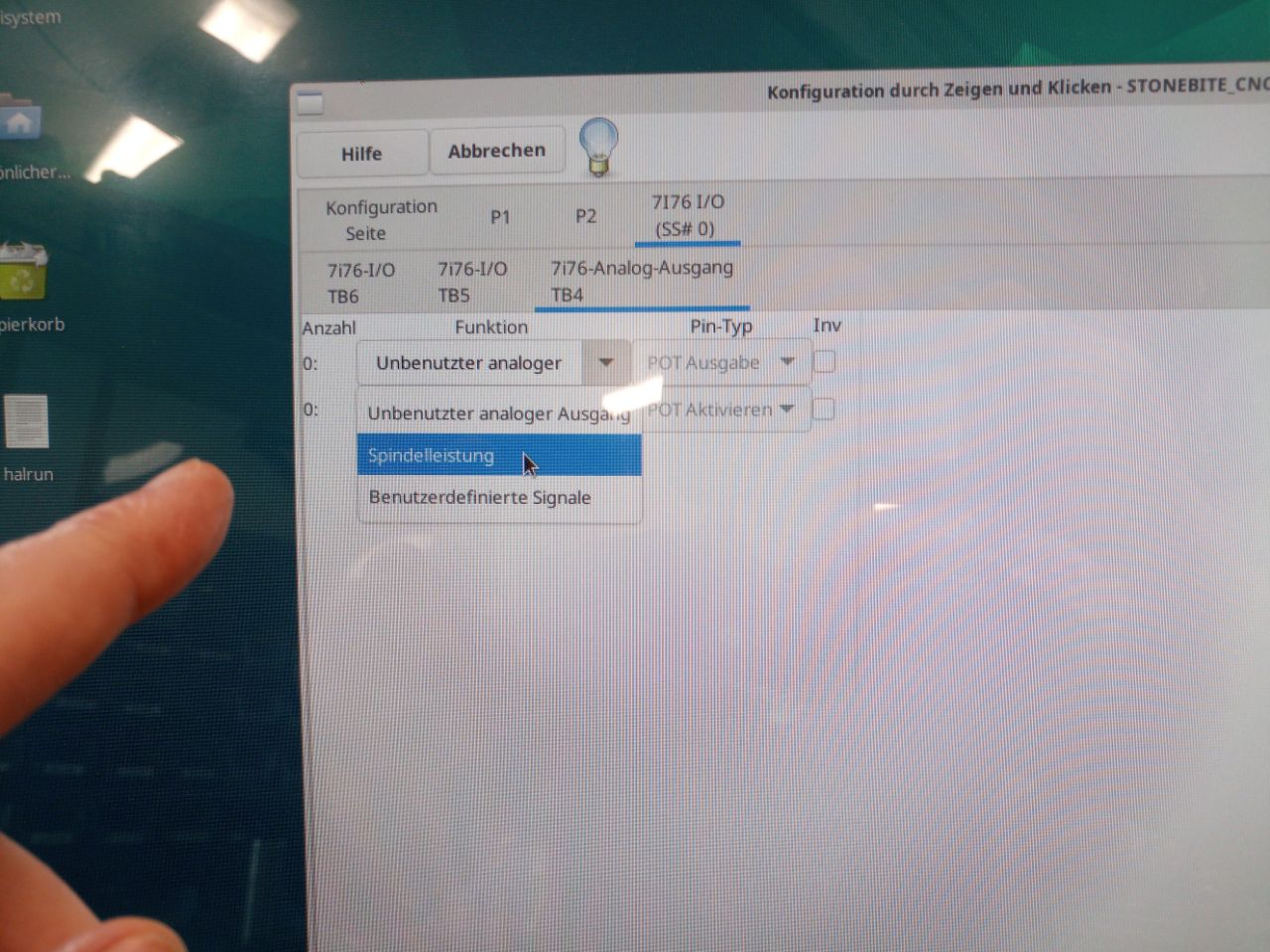

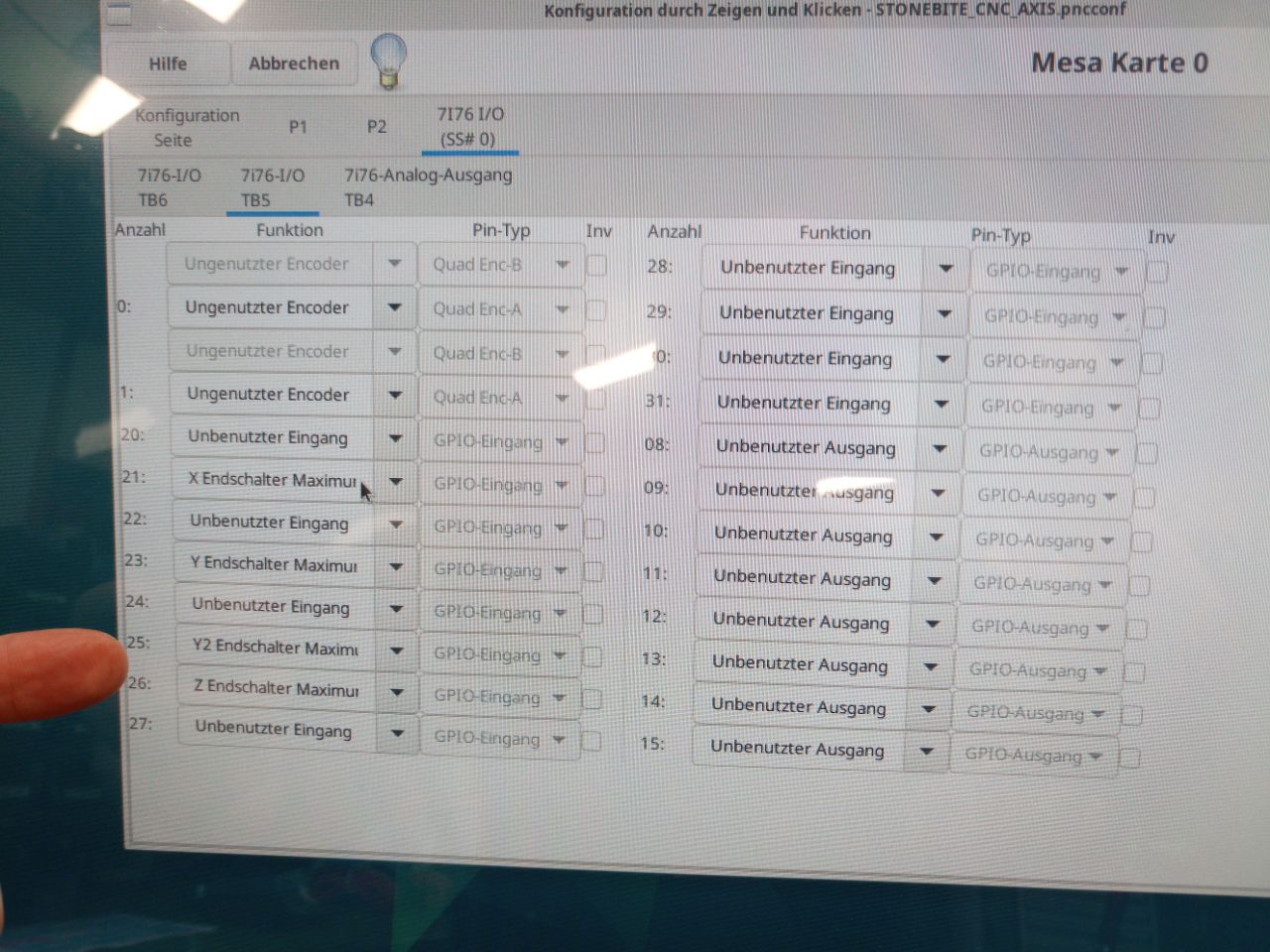

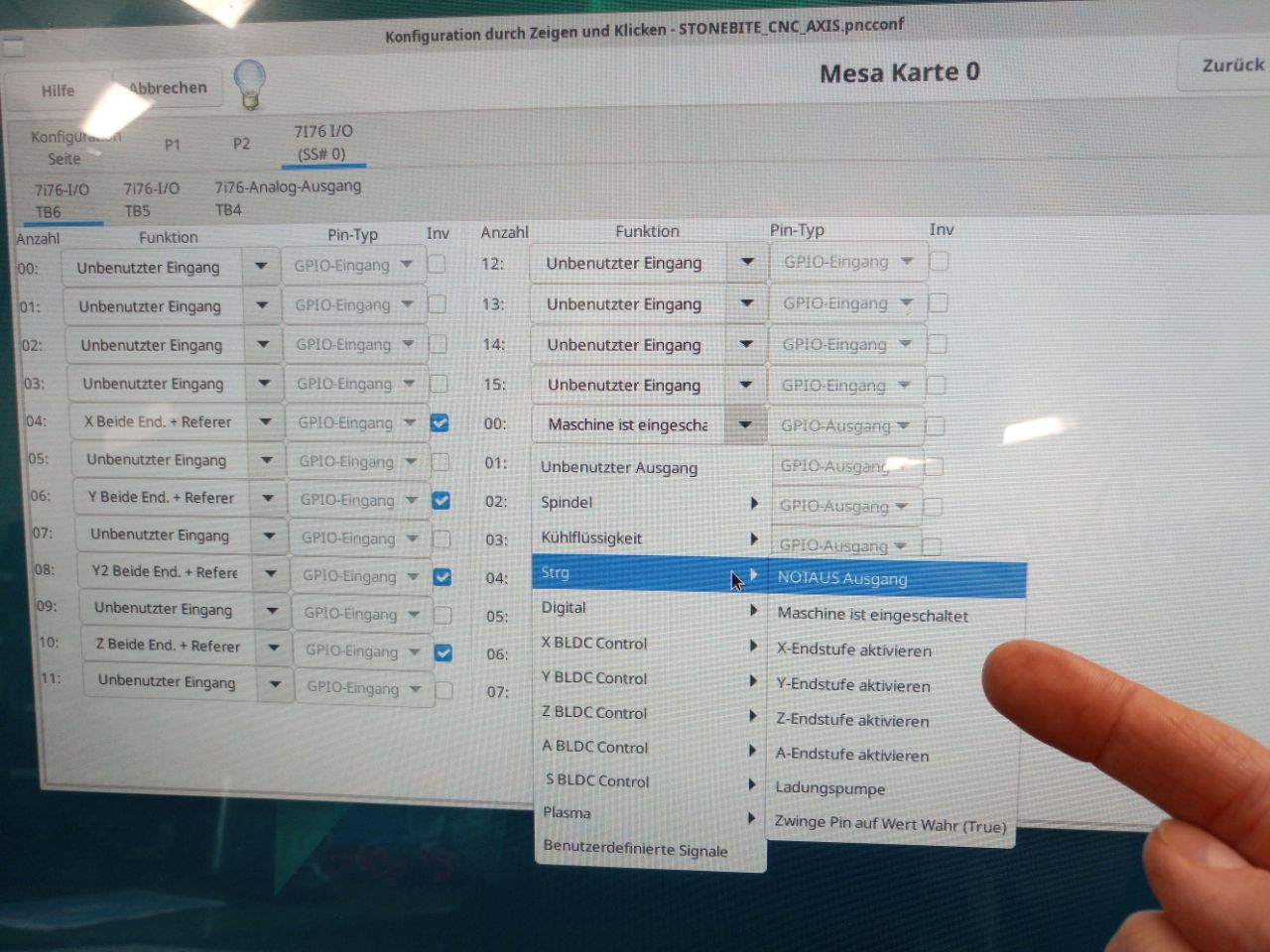

I would like to thank you once again for your support up to this point!As mentioned above, I can move the servos on the axles.At the moment I would like to ignore the previous topic with the current PC and concentrate on creating a basic HAL/INI with the PncConf, with the 7i92 and 7i76 installed in my system.I would like to be able to use PncConf to assign the properties from the pull-down menus to the occupied contacts of the 7i76. I have not found any posts in the forum that help me?I have created an Excel sheet (please see attached), which shows the created contacts.Since I could not find any detailed information or examples in the LinuxCNC manual for the individual properties that can be assigned, I would like to ask if there is any information available?Please provide a picture below of what I mean.Based on the use of PncConf.A voltage safety circuit must be enabled for the servos to run. To enable this via the 7i76 I have to assign the correct property from the pull-down menu, which is the correct property? At the moment I have to bridge this voltage circuit. There are two safety circuits, one each at TB6 output 0 and output 1 (please see Excel sheet)

Attachments:

Last edit: 04 Jun 2024 09:37 by stonebite.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

04 Jun 2024 13:25 #302311

by PCW

Replied by PCW on topic PNCconf 7i92H and 7i76

For a general enable output, "Control" --> "Machine Is Enabled"

is a good choice

is a good choice

Please Log in or Create an account to join the conversation.

- stonebite

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 10

04 Jun 2024 14:26 #302316

by stonebite

Replied by stonebite on topic PNCconf 7i92H and 7i76

Thank you.

i have a basic question - are my questions incomprehensible, inappropriate, not detailed enough, written way too much, boring to answer ...?

i am an absolute beginner in the field of LinuxCNC and the interfaces it creates. i am happy to receive advice and have no problem admitting my own mistakes.

i know that i am certainly not the only one who asks questions here, but i try very hard to describe my topics, the information i can give from my perspective i share as far as my knowledge allows me and form concerns and/or questions from this.

As already mentioned, I am and was very grateful for any help.

I have no ambition or claim to get my topic solved within a certain time here in the forum, but I imagine that a topic, especially for me as a beginner, will result in an in-depth conversation.

I have the uneasiness with your answer that my concern is not understood or does not want to be understood.

I think it's a pity that a topic can drag on for such a long time as the one on the previous pages of this thread. I would like to avoid this and don't want to waste your time unnecessarily and receive answers that frankly don't get me anywhere.

I would be very grateful if you would write if you are not interested, or ask if my question or information is too unclear.

Thank you for your understanding.

i have a basic question - are my questions incomprehensible, inappropriate, not detailed enough, written way too much, boring to answer ...?

i am an absolute beginner in the field of LinuxCNC and the interfaces it creates. i am happy to receive advice and have no problem admitting my own mistakes.

i know that i am certainly not the only one who asks questions here, but i try very hard to describe my topics, the information i can give from my perspective i share as far as my knowledge allows me and form concerns and/or questions from this.

As already mentioned, I am and was very grateful for any help.

I have no ambition or claim to get my topic solved within a certain time here in the forum, but I imagine that a topic, especially for me as a beginner, will result in an in-depth conversation.

I have the uneasiness with your answer that my concern is not understood or does not want to be understood.

I think it's a pity that a topic can drag on for such a long time as the one on the previous pages of this thread. I would like to avoid this and don't want to waste your time unnecessarily and receive answers that frankly don't get me anywhere.

I would be very grateful if you would write if you are not interested, or ask if my question or information is too unclear.

Thank you for your understanding.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21158

- Thank you received: 7224

05 Jun 2024 00:24 #302351

by tommylight

The only reason i started helping here was to get better at asking and answering questions, i was bad at both.

There are times that i can not reply to anything for weeks, but at least i check and remove spam, and there are times when i post here 10 times a day despite working all the time.

We are all volunteers, we were all young and had to go through rough times when we had no one to help us (no internet back then)

And yes, sometimes answers here might seem absolutely weird, but with a bit of digging you always find out those are good answers.

You asked : To enable this via the 7i76 I have to assign the correct property from the pull-down menu, which is the correct property?

You got the answer : For a general enable output, "Control" --> "Machine Is Enabled"

is a good choice

That is the exact answer to that question, on the output pins pull down menu, choose "control" and select "machine is enabled".

That is the pin that will enable the machine when F2 is pressed on the keyboard or screen/GUI.

That is also the pin that will disable the drives in case of joint errors or pressing E-stop.

For more info about PncConf or anything related to LinuxCNC, start by using you Linux menu, in the CNC section together with LinuxCNC, there are also links to documentation, there is way to much there, so try just finding what you need at any moment in time, it is easier to absorb.

Replied by tommylight on topic PNCconf 7i92H and 7i76

No, no, no, no and no !i have a basic question - are my questions incomprehensible, inappropriate, not detailed enough, written way too much, boring to answer ...?

The only reason i started helping here was to get better at asking and answering questions, i was bad at both.

We were all beginners at one point in time.i am an absolute beginner in the field of LinuxCNC and the interfaces it creates. i am happy to receive advice and have no problem admitting my own mistakes.

And you are welcomed to ask for help always, you are also welcomed to try to help others with stuff you are good at, many topics on this forum, so we keep an eye on "recent topics" most of the time.As already mentioned, I am and was very grateful for any help.

This is a bit harder to explain, but i know for sure there is no need for concern, it is just that all we who try to help here have a life, and that life takes it's time, so the very little spare time we have we try to help others here.I have the uneasiness with your answer that my concern is not understood or does not want to be understood.

I think it's a pity that a topic can drag on for such a long time as the one on the previous pages of this thread. I would like to avoid this and don't want to waste your time unnecessarily and receive answers that frankly don't get me anywhere.

There are times that i can not reply to anything for weeks, but at least i check and remove spam, and there are times when i post here 10 times a day despite working all the time.

We are all volunteers, we were all young and had to go through rough times when we had no one to help us (no internet back then)

And yes, sometimes answers here might seem absolutely weird, but with a bit of digging you always find out those are good answers.

You asked : To enable this via the 7i76 I have to assign the correct property from the pull-down menu, which is the correct property?

You got the answer : For a general enable output, "Control" --> "Machine Is Enabled"

is a good choice

That is the exact answer to that question, on the output pins pull down menu, choose "control" and select "machine is enabled".

That is the pin that will enable the machine when F2 is pressed on the keyboard or screen/GUI.

That is also the pin that will disable the drives in case of joint errors or pressing E-stop.

For more info about PncConf or anything related to LinuxCNC, start by using you Linux menu, in the CNC section together with LinuxCNC, there are also links to documentation, there is way to much there, so try just finding what you need at any moment in time, it is easier to absorb.

Please Log in or Create an account to join the conversation.

- stonebite

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 10

05 Jun 2024 06:07 - 05 Jun 2024 06:47 #302361

by stonebite

Replied by stonebite on topic PNCconf 7i92H and 7i76

Thank you very much for your explanation.

I can very well understand what you mean by your privacy and I didn't imagine it any differently.

that's why i wrote that i have no ambitions and/or expectations that my issues have to be resolved in a certain amount of time. i feel the same way about my clientele as you do.

english is not my mother tongue, so of course a question i have written can be understood differently by you.

The answer I received is ok, but it's not what I was hoping for. It only takes me a very small step forward

I therefore conclude from this conversation that my question was too imprecise. What I usually miss in my answers is some background information.

I don't want to hold you up with my anecdotes, but perhaps point out what is important to me ...

A small example - I compare my situation with LinuxCNC and my CNC machine with the situation in 1997, when I was working professionally in rally car racing and completely built my own static engine test bench for combustion engines up to 1200hp. At that time I used a PC with Windows NT4, the special control software Rhothron, an industrial PC for real-time control and the engine sensors that had to be connected to the industrial PC.

At that time, the manual was more difficult for me to understand than the LinuxCNC manual. What I did have, however, were basic and schematic example templates from the software manufacturer on how to connect an internal combustion engine to the industrial PC. So it was clear to me that the connections of the sensors had to be placed on certain pins. The pins were intended for a specific function. So I didn't have to do anything other than solder the sensor contacts to the corresponding DB connectors. I then had to set up the graphical control software on NT4 graphically.

So I can see certain parallels there. What I didn't know with LinuxCNC was whether Linux itself recognised certain things or whether I had to configure everything manually. The decisive factor for me was your realisation that the polarity of the ribbon cable from the 7i76 to the 7i92 was reversed. This shows me that Linux recognises certain things itself.

So I didn't answer correctly or not completely enough and would like to try again but differently ...

Can you please help me to find the correct categorisations?

The PNP limit switches (work on halshow). The servos are running. The Excel sheet shows where I have created which contacts, what I don't know and can't read anywhere (manual) or look up (videos) is which assignment is correct.

The Excel sheet shows where I have created which contacts. What I don't know and can't read about anywhere (manual) or see (videos) is which assignment term is to be assigned to which GPIO, etc. I don't have a clear idea of this and I can only test, test, test, but I don't know whether I'll destroy anything in the process. I want to counteract this.

And I like to ask questions here in the forum when I don't know what to do next - it's not because I'm too lazy.

I can very well understand what you mean by your privacy and I didn't imagine it any differently.

that's why i wrote that i have no ambitions and/or expectations that my issues have to be resolved in a certain amount of time. i feel the same way about my clientele as you do.

english is not my mother tongue, so of course a question i have written can be understood differently by you.

The answer I received is ok, but it's not what I was hoping for. It only takes me a very small step forward

I therefore conclude from this conversation that my question was too imprecise. What I usually miss in my answers is some background information.

I don't want to hold you up with my anecdotes, but perhaps point out what is important to me ...

A small example - I compare my situation with LinuxCNC and my CNC machine with the situation in 1997, when I was working professionally in rally car racing and completely built my own static engine test bench for combustion engines up to 1200hp. At that time I used a PC with Windows NT4, the special control software Rhothron, an industrial PC for real-time control and the engine sensors that had to be connected to the industrial PC.

At that time, the manual was more difficult for me to understand than the LinuxCNC manual. What I did have, however, were basic and schematic example templates from the software manufacturer on how to connect an internal combustion engine to the industrial PC. So it was clear to me that the connections of the sensors had to be placed on certain pins. The pins were intended for a specific function. So I didn't have to do anything other than solder the sensor contacts to the corresponding DB connectors. I then had to set up the graphical control software on NT4 graphically.

So I can see certain parallels there. What I didn't know with LinuxCNC was whether Linux itself recognised certain things or whether I had to configure everything manually. The decisive factor for me was your realisation that the polarity of the ribbon cable from the 7i76 to the 7i92 was reversed. This shows me that Linux recognises certain things itself.

So I didn't answer correctly or not completely enough and would like to try again but differently ...

Can you please help me to find the correct categorisations?

The PNP limit switches (work on halshow). The servos are running. The Excel sheet shows where I have created which contacts, what I don't know and can't read anywhere (manual) or look up (videos) is which assignment is correct.

The Excel sheet shows where I have created which contacts. What I don't know and can't read about anywhere (manual) or see (videos) is which assignment term is to be assigned to which GPIO, etc. I don't have a clear idea of this and I can only test, test, test, but I don't know whether I'll destroy anything in the process. I want to counteract this.

And I like to ask questions here in the forum when I don't know what to do next - it's not because I'm too lazy.

Last edit: 05 Jun 2024 06:47 by stonebite.

Please Log in or Create an account to join the conversation.

- stonebite

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 10

06 Jun 2024 09:54 #302454

by stonebite

Replied by stonebite on topic PNCconf 7i92H and 7i76

I would now like to ask specific questions.

Would anyone like to help me ...

to write the basic HAL/INI files for my Gantry CNC machine if I provide all information about the machine and its components like the 7i92 with 7i76?

or

would someone like to help me ...

to write me with the PncConf with the Excel file "7i76 Contact Assignment" listed above, which "selection criteria" from the pulldown menus of the PncConf I should/must select for the corresponding pins, so that I get at least all actuators on the 7i76 assigned for LinuxCNC?

I realise that I learn the most by testing and trying things out. At the moment I'm at a point where I realise that it's no use spending nights on end and not making any progress.

If I had at least the basic HAL/INI file, I could learn from it.

As already mentioned, I am willing to donate to the LinuxCNC community or to cover the costs of the HAL/INI files.

Thank you for your understanding

Would anyone like to help me ...

to write the basic HAL/INI files for my Gantry CNC machine if I provide all information about the machine and its components like the 7i92 with 7i76?

or

would someone like to help me ...

to write me with the PncConf with the Excel file "7i76 Contact Assignment" listed above, which "selection criteria" from the pulldown menus of the PncConf I should/must select for the corresponding pins, so that I get at least all actuators on the 7i76 assigned for LinuxCNC?

I realise that I learn the most by testing and trying things out. At the moment I'm at a point where I realise that it's no use spending nights on end and not making any progress.

If I had at least the basic HAL/INI file, I could learn from it.

As already mentioned, I am willing to donate to the LinuxCNC community or to cover the costs of the HAL/INI files.

Thank you for your understanding

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

06 Jun 2024 12:41 #302465

by PCW

Replied by PCW on topic PNCconf 7i92H and 7i76

The typical way this would be done is to use pncconf

or mesact (GUI configurator programs) to create a basic

hal/ini file set. Then if there are more complex details

not handeled by the GUI configurator programs, the hal /ini

files are edited by hand to add the needed features.

Do you have a basic working hal/ini file set?

if not , what is the specific issue?

or mesact (GUI configurator programs) to create a basic

hal/ini file set. Then if there are more complex details

not handeled by the GUI configurator programs, the hal /ini

files are edited by hand to add the needed features.

Do you have a basic working hal/ini file set?

if not , what is the specific issue?

Please Log in or Create an account to join the conversation.

- stonebite

- Offline

- Premium Member

-

Less

More

- Posts: 116

- Thank you received: 10

07 Jun 2024 10:25 #302526

by stonebite

Replied by stonebite on topic PNCconf 7i92H and 7i76

=:o( I'm sorry, but your explanation is not the answer that could help me. Or I am misunderstanding and misinterpreting your answer ...

I don't think I'm asking the right question, or my questions are interpreted?

So again ...

To help me:

Can and or do you want to write a HAL/INI file for me and my CNC portal milling machine?

If so, what informations do you need?

If not,

the second possibility to help me:

Can and/or do you want to write me which terms I need to assign to the pins from the pulldown menus of the PncConf. Please watch my video per Link

www.dropbox.com/scl/fi/j62sg1yh12hca8g03...dbu&st=cnasz00z&dl=0

I need the correct assignment terms from the pull-down menus in PncConf that match my data sheet for the contact assignment.

To respond to your answer, if I understand it correctly.

I am using Visual Studio Code to create, read, emulate an save HAL and INI files.

Are you referring to this or a similar programm?

I don't think I'm asking the right question, or my questions are interpreted?

So again ...

To help me:

Can and or do you want to write a HAL/INI file for me and my CNC portal milling machine?

If so, what informations do you need?

If not,

the second possibility to help me:

Can and/or do you want to write me which terms I need to assign to the pins from the pulldown menus of the PncConf. Please watch my video per Link

www.dropbox.com/scl/fi/j62sg1yh12hca8g03...dbu&st=cnasz00z&dl=0

I need the correct assignment terms from the pull-down menus in PncConf that match my data sheet for the contact assignment.

To respond to your answer, if I understand it correctly.

I am using Visual Studio Code to create, read, emulate an save HAL and INI files.

Are you referring to this or a similar programm?

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.139 seconds