ubuntu 14.04.1 linuxcnc help

- Razor_keen

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- tjmarch

- Offline

- Premium Member

-

- Posts: 152

- Thank you received: 22

3.4-9-rtai-686-pae

Jason wrote

I will let the 64 bit os run a last test while i work on my truck, then afterwards ill use the same rt kernel with a 32 bit build to see how much gain is in the os vs the kernel.

Problem with that kernels are 32 bit and 64 bit specific unless you are patching it yourself then loading it.

If you are going to use a 32 bit Rt kernel you will need to edit setupRt.sh from post:

forum.linuxcnc.org/forum/9-installing-li...-help?start=80#66528

in section where all packages are installed look for and replace:

linux-image-rt-amd64

with

linux-image-rt-686-pae

and

linux-headers-rt-amd64

with

linux-headers-rt-686-pae

and lines

wget ftp.us.debian.org/debian/pool/main/b/boo...1.49.0-3.2_amd64.deb

sudo gdebi -n libboost-python1.49.0_1.49.0-3.2_amd64.deb

with

wget ftp.us.debian.org/debian/pool/main/b/boo..._1.49.0-3.2_i386.deb

sudo gdebi -n libboost-python1.49.0_1.49.0-3.2_i386.deb

and

rm -rf libboost-python1.49.0_1.49.0-3.2_amd64.deb

with

rm -rf libboost-python1.49.0_1.49.0-3.2_i386.deb

everything else should be ok in script

To give Rtai kernel same test I reset histogram before I came to work so it will run for 11 hours also

My desktop dose have 8GB of Ram

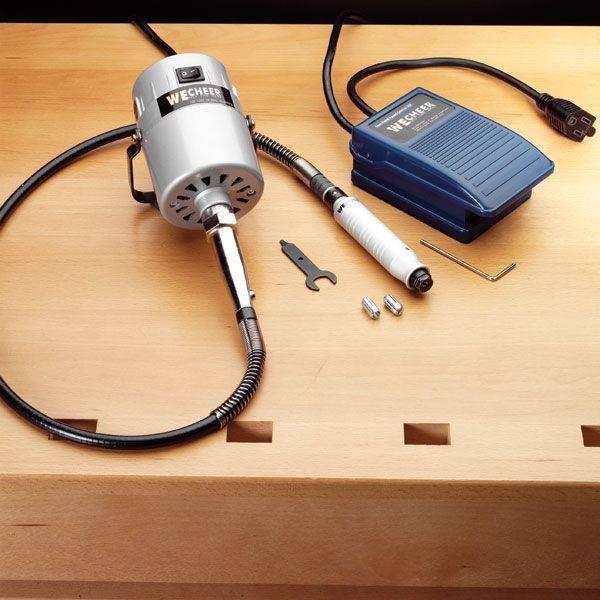

You posted earlier about using a RC motor for spindle. I did check into it. Looked like a cool project, I do own a small lathe and will consider making one down the road, would probable be able to cut aluminum if I did. As of now I have already purchased one of these it has a 1/4" collet needed for my drag knife:

Will be setup similar as this but CNC is totally different:

Please Log in or Create an account to join the conversation.

- Razor_keen

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

the biggest problem is the power supply. the solution is modded server supplies plus the lipo batteries that are for the motors. the batteries keep the power supplies from cutting out if accidentally u make way to deep of a cut... (it happens sometimes..)

kinda like caps in car stereos.

they last a pretty good while and the occational bearing replacement and even motor replacement is really easy on the budget.

collet costed me about 12 motor 40. bad ass controller was 80. (may never replace that) power supply 50, 50 fot the pillow block machined at a shop. bearings are either 1.00 a peice or there are some awsome ones at about 8 a piece. you need two axial and one radial at min.

Please Log in or Create an account to join the conversation.

- tjmarch

- Offline

- Premium Member

-

- Posts: 152

- Thank you received: 22

My personal conclusion for results of histogram for 32 Rtai (post 66614) & 64 Rt (post 66562), bit systems on my computer. On both 32 & 64 bit systems the worst latency spikes occurred during reset and start of test. If you eliminate these spikes it leaves 20 or so spikes above 1E4, (10000us) in bin ct areas + and - during the rest of the eleven hours tested. Off chart bin ct + and - had no recorded hits over 1E4. Both 32 & 64 bit max latency were in the 60000us range. 32 bit system had less CPU load CPU1 40%, CPU2 0% than 64 bit system CPU1 90%+ CPU2 0% which resulted in lower temps for 32 bit system. 32 bit system latency was a little erratic but in low region most of the time, not as constant as 64 bit system. 64 bit system dropped pulse audio where 32 bit system did not.

The hits in latency over 30000us during 11 hour period are something to be concerned about for 32 or 64 bit system. I will just have to setup step pulse and direction control to be a little slower, I am in no hurry anyway. The materials that I will be cutting are low cost, balsa wood, hobby grade aircraft plywood, 4mm thick foam board from Dollar Tree and building grade foam insulation board. As far as 3D printer plastic that is cheap and can be recycled for other uses. If machine makes a incorrect radius cut due to latency spike I will not be out of much money. Plus here is a quote from LinuxCNC V2.7.3-5-g99ffe2d, 2015-11-30 documentation "Worst case latencies might only happen a few times a minute, and the odds of bad latency happening just as the motor is changing direction are low. So you can get very rare errors that ruin a part every once in a while and are impossible to troubleshoot."

Now for me it is important to be able to use windozes in a VM. I could go 32 bit and do a daul boot system but I have done that in the past and it is a pain to setup. Windozes requires drivers to be loaded, windozes in VM dose not only a ISO of OS instalation disk. Plus you do not have access to files on linux partition while using windozes system with a dual boot system. Then there is the grub loader which with a dual boot system at some time is bound to get buggered up and will prohibit access to windoze or linux system until fixed. Been there done that. VM also has the ability to take snap shots of VM hard drive so reverting back to a previous state of VM OS is a snap.

Could run VM on 32 bit system but VM software only allows you to dedicate half available ram of OS to VM not the 4GB allowance that pae kernel could use for a single process if available in swap area. So the results are a sluggish VM with only 2GB of ram available.

64 bit system will be the way for me to go on this computer and there will be few ram restrictions with my 8GB system. As far as audio dropping I do not need tunes the sound of this machine running will be music to my ears.

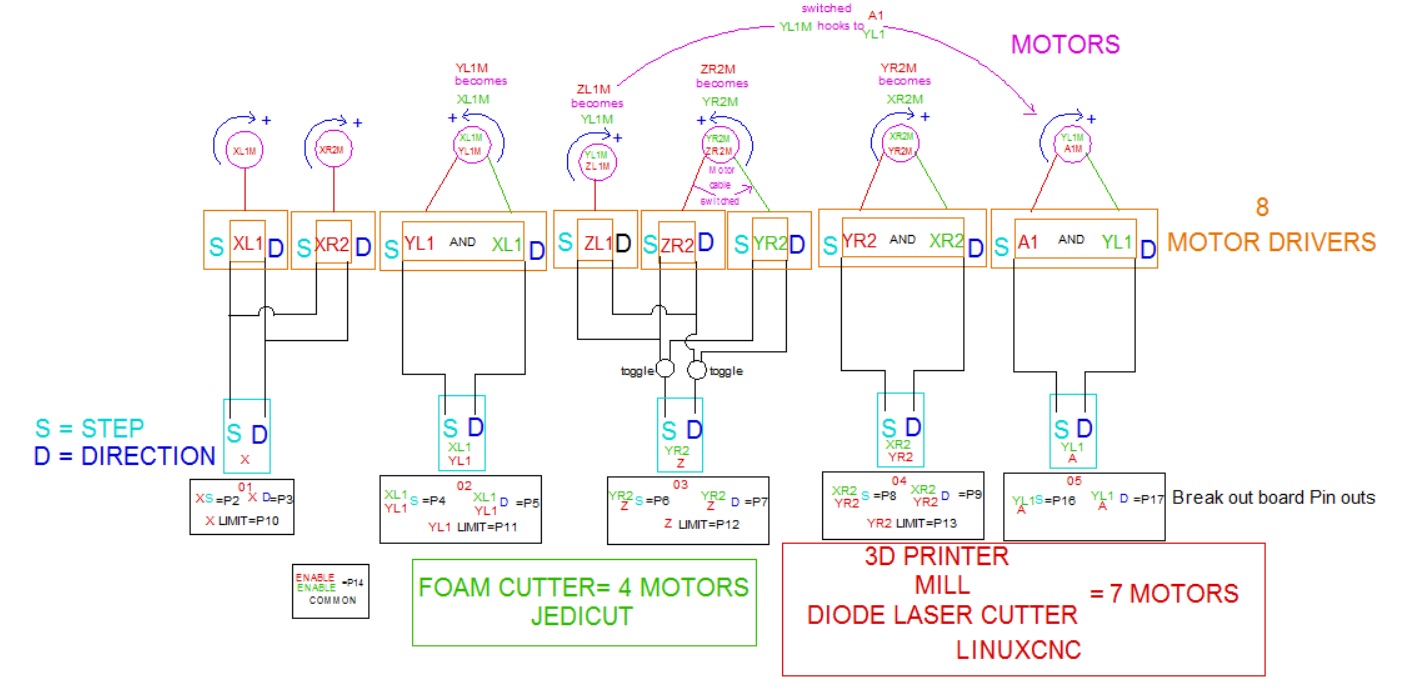

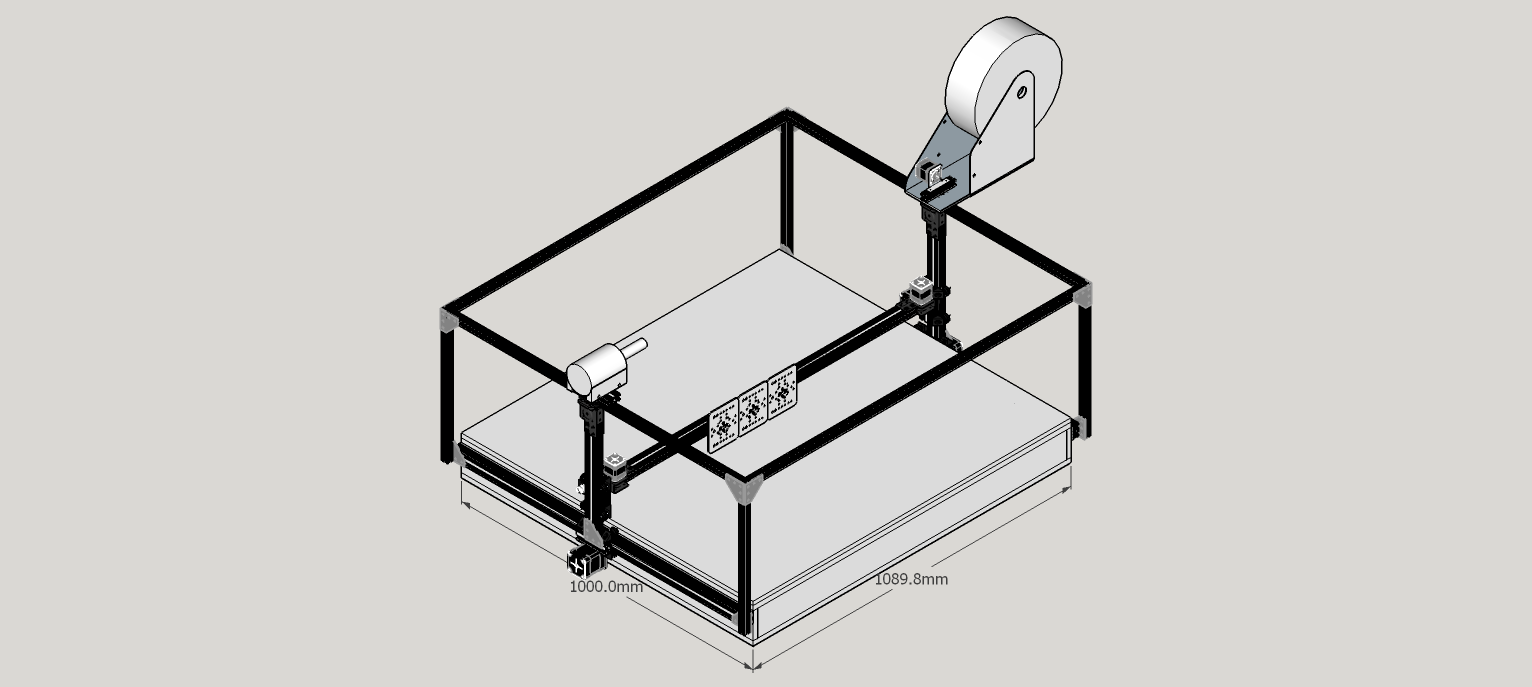

The reason for the use of windozes on my CNC is because my machine will be a multi-purpose gantry machine. I will be able to do vacuum forming on base of machine and Linuxcnc will be setup as Gantrykins, (gantry-hs) and used for 3D printing, Mill work, drag knife work and Diode Laser cutting. Gantry beam will be removable so CNC can be used as 4 axis foam cutting CNC. Foam cutting can be done with Linuxcnc but I want to use a windozes program called Jedicut, (freeware}. Jedicut dose not use gcode dose not require limit switches and will work over USB using a homemade USB to parallel port dongle that off loads timeing to arduino in dongle. VM has USB support so dongle will work. The advantage of Jedicut is there is no need for CAM software you go from drawing straight to CNC. The disadvantage of 64 bit system will be the CPU draw while running linuxcnc and heat created. I figure my CNC will not be a production machine, use will be low volume as a hobby project system with short runs. I plan to use CNC to help make RC airplane parts.

My advice to you Jason because you are using a laptop if you get the same type of results from test is to go with 32 bit Rtai system. Your Robot arm is for hobby use not much concern for the few latency spikes, accuracy is not that important and might make it more of a challenge for your kids and act like a real arcade claw machine, lol. The problem would be the heat and from my test if you get the same results 32 bit Rtai would be better choice. The 32 bit Rt kernel might also work latency would be a little higher than the Rtai.

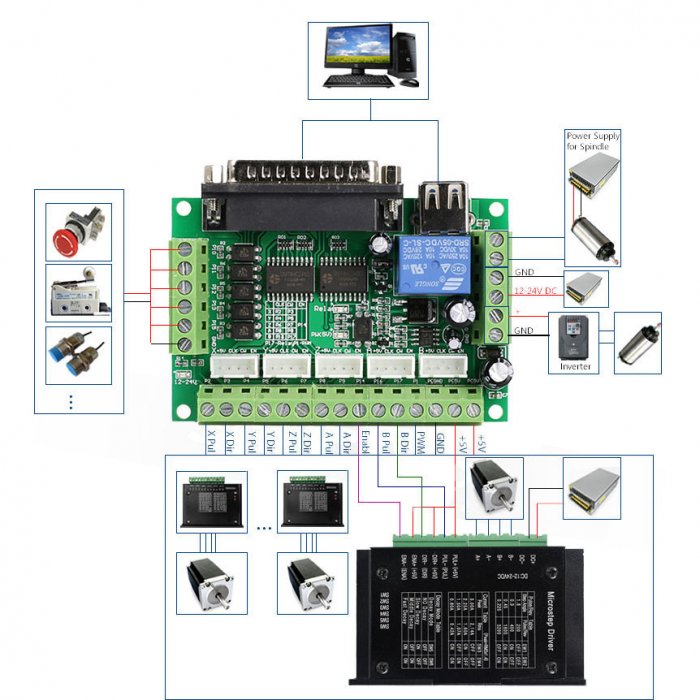

For others reading this any input would be appreciated. I have also attached a wiring schematic I drew up for my CNC and pic of B.O.B.

The following is the way I set it up in sim as Gantrykins seems to work as Mill have not tried 3D print gcode yet.

INI file

axis 5

0 X= 2 nema 17's

1 Y1= nema 23

2 Z= 2 nema 17's

3 Y2= nema 23

4 A= nema 17 (extruder)

hal file

coordinates=XYYZA

Also added extra axis nets as needed

If one of the Moderators or old time CNCers here would take a look at schematic and let me know if what I have planned will work. I know the Jedicut part will work but would like someone to give it a once over for the Linuxcnc part before I start doing the wiring. I would be grateful if someone with knowledge of linuxcnc did this for me because this is not a kit build but my own design.

Tim

Ps I have also attached schematic as PDF if one would like to to view with different program.

Please Log in or Create an account to join the conversation.

- tjmarch

- Offline

- Premium Member

-

- Posts: 152

- Thank you received: 22

I guess I should have been more direct about my concern of schematic. Not looking for someone to check my work just wondering if it is ok to use same Step and direction output from BOB to drive two separate motor drivers such as the way I have X axis setup in schematic. And is this the correct way to set up gantry-hs and adding the extra axis of A as motor 04. In sim while in joint mode I see four axis in display which are not labeled, I was thinking I should see five X, Y1, Y2, Z, A

Tim

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19797

- Thank you received: 4606

just wondering if it is ok to use same Step and direction output from BOB to drive two separate motor drivers such as the way I have X axis setup in schematic. And is this the correct way to set up gantry-hs

If it works for you, then it is correct.

There are many ways to make this work. Starting at the motor:

Both sides can be driven by one motor, via a shaft.

Both motors can be driven by the same driver, in series or parallel. (serial is probably better, but you need double the voltage)

Both Drivers can be driven by the same step-dir signal

into software----

Both step-dir signals can be drive by the same stepgen

Both stepgens can be driven by the same joint position

Both joint positions can be driven by the same axis position.

Which do you prefer? We can tell you how.

Please Log in or Create an account to join the conversation.

- tjmarch

- Offline

- Premium Member

-

- Posts: 152

- Thank you received: 22

Thanks for the quick reply

Starting at the motors for Y axis:

Not one of the choices you gave me but I would like if possible:

Each joint Y1 and Y2 to have separate motor drivers with separate step-dir signals to each motor driver

If that is not possible I would go with

Two Drivers that can be driven by the same step-dir signal

Y1 and Y2 will both have separate belt and pinion drives with nema 23 motors like this

into software----

1. I would like Y1 and Y2 to work together in world jog mode and to run gcode

2. And independently in joint jog mode for squaring up gantry

Out of the choices that you gave me not sure what would be best to achieve above needs but thinking

Both step-dir signals can be drive by the same stepgen

Tim

Please Log in or Create an account to join the conversation.

- Razor_keen

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

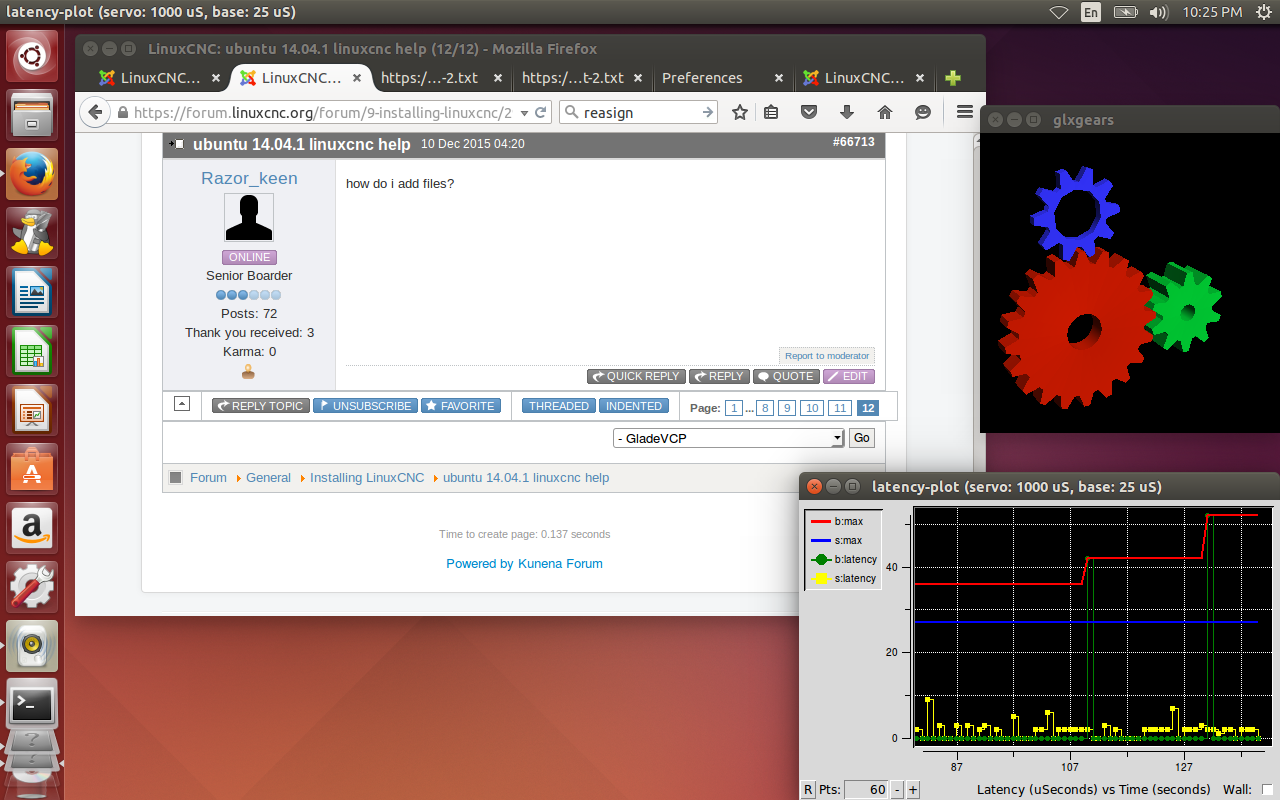

Latency is much more irradic and even reassigning process priorities dos not fix these spikes.

64 bit system shows a bit of instability in its audio processing capabilities with no process changes but changing the nice value from "very high" in both hd audio and pulse audio seems to fix this.

tim

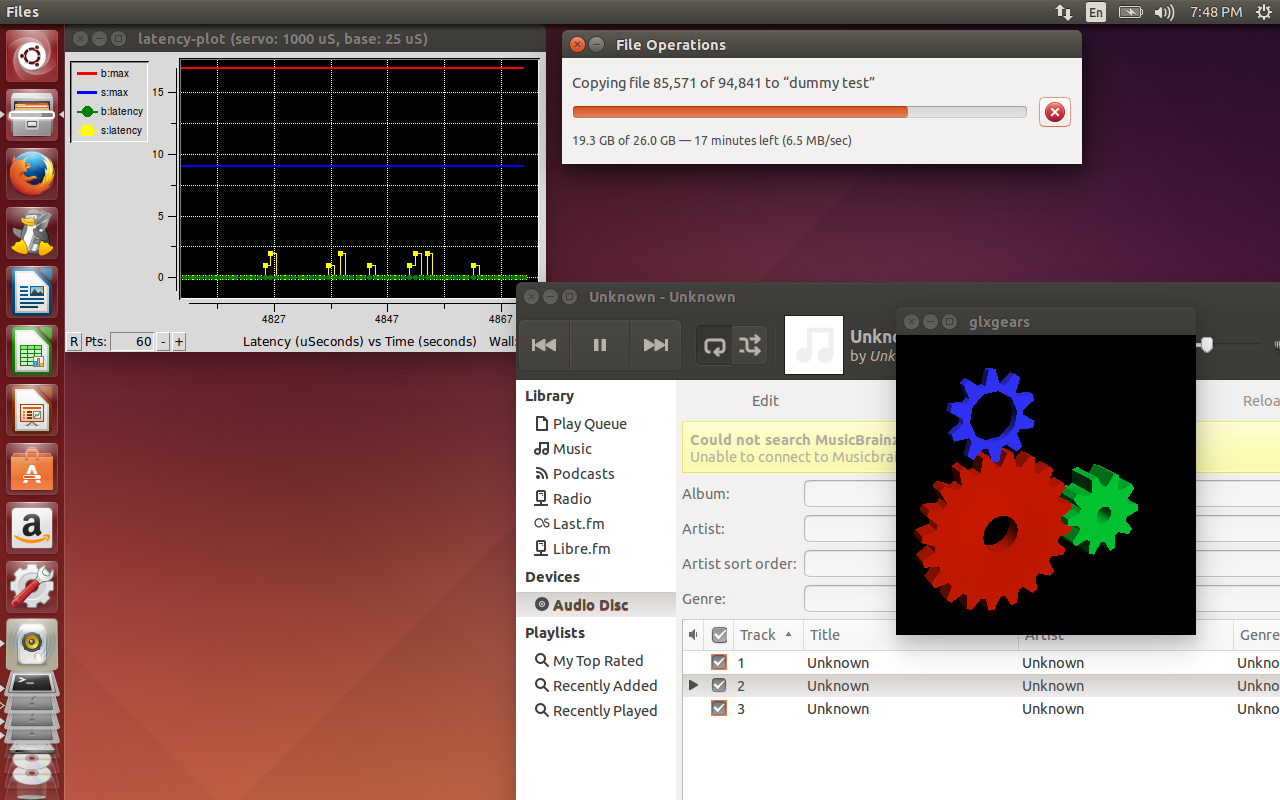

view the screen shot i listed as personal reference and not that i did not suffer the initial spike like you saw on your system. this is in part due to process tweaks i made and opening the plot in a clean environment. i then opened all the other operations one by one till the cpu ramped up.

this may or may not be defeating the purpose of the test but i was able to run glxgears, massive file copies and music playing full blast with those results after an hour. it may not be as conclusive as 11 hours but for the first time i have a consistent result .

Also the performance of the 32 bit os is noticeably more sluggish than the 64 bit. i will attach the amended 32 bit .sh file for anyone else to test the diff. we would love to here others results to help prove/disprove these results, or if i fat fingered something let me know.

thanks

jason

Please Log in or Create an account to join the conversation.

- Razor_keen

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Razor_keen

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

Tests of rtai kernels on both kernels ubuntu,

Tests of linux mint, half the testing has already been performed by tim.

figuring out how to permanently change niceness value for specific processes,

turning on fan full speed through grub,Future possibilities may include modifying of configuration for 3.18.24 rt kernel layered with ubuntu patches for a fully functional ubuntu os.. (Yes its true app armor does not work with the kernel we are testing. )

there are instructions on linuxcnc wiki to make the grub configurations only load with a specific kernel. this would be very useful if the 3.18.24 kernel is a bust...

if the 3.18.24 kernel is successful, i can be made into an iso, with the included changes i previously mentioned?

Any thoughts? Is this a bad idea?

Please Log in or Create an account to join the conversation.