Planning - Bridgeport Interact 1 linuxCNC Retrofit

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

18 Mar 2016 15:28 #71870

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

csbrady,

You Sir, are awesome! Thank you! I have been going through the code inside and out. I can read and basically understand the code in HAL but so far my understanding is not enough to create full expressions. However, I'm getting there thanks to you guys.

Thanks again!

You Sir, are awesome! Thank you! I have been going through the code inside and out. I can read and basically understand the code in HAL but so far my understanding is not enough to create full expressions. However, I'm getting there thanks to you guys.

Thanks again!

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

20 Mar 2016 00:30 - 20 Mar 2016 00:45 #71922

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

OK! I have most of my test panel working. I decided to use the jog buttons on the panel anyway since I already had it wired. I had to figure out how to use or2. The exercise was good for my understanding of HAL.

Im starting to see how things fit. I had to separate the code for my tiny brain to handle.

I do have a issue now that Im not sure where to look to fix it. Below is the section of my HAL with overrides. Im using a cheap Chinese VFD with their MODBUS. The spindle override is where Im having issues.

At 5% override I am at 30 hz on my spindle, the lowest allowed setting in my parameters in the VFD.

at 19% override I am at 65 hz the highest setting allowed by my parameters in the VFD.

The scale of my override in halui continues from 19% to 100% with the pot adjustment as expected, however this has no effect otherwise. I have tried to change scale and other factors and still nothing has changed this behavior.

csbrady was kind enough to give me his hal which this is part of. He is using analog voltage to his VFD for control. I do not know if this matters. My spindle scale is up to 100% max in the INI.

Any ideas?

EDIT: Figured it out. My spindle is being commanded to go to 10K rpms. Looks like I have some reading to do.

Im starting to see how things fit. I had to separate the code for my tiny brain to handle.

I do have a issue now that Im not sure where to look to fix it. Below is the section of my HAL with overrides. Im using a cheap Chinese VFD with their MODBUS. The spindle override is where Im having issues.

At 5% override I am at 30 hz on my spindle, the lowest allowed setting in my parameters in the VFD.

at 19% override I am at 65 hz the highest setting allowed by my parameters in the VFD.

The scale of my override in halui continues from 19% to 100% with the pot adjustment as expected, however this has no effect otherwise. I have tried to change scale and other factors and still nothing has changed this behavior.

csbrady was kind enough to give me his hal which this is part of. He is using analog voltage to his VFD for control. I do not know if this matters. My spindle scale is up to 100% max in the INI.

Any ideas?

###################################################################

# "Overrides" #

###################################################################

# "Read analog inputs from the override knobs. Full scale will be"#

# "approximately 24v. Scale the input accordingly. 1.0 = 100%" #

# #

# "Scale up the raw values 100x so that when converted to" #

# "integers we have good resolution." #

# "The results will be between 0 and 2400." #

###################################################################

################"--- Feed Override ---"##################

# Convert from float to S32 #

#########################################################

# "Read in analog input and send to halui.feed-override"

# "Enable direct count input"

net scale_ovr => scale-fo.gain scale-ro.gain scale-so.gain

sets scale_ovr 100.0

#600

net fo-ena halui.feed-override.count-enable halui.feed-override.direct-value

sets fo-ena 1

# "Scale down the value to a percentage"

net scf-scale => halui.feed-override.scale

sets scf-scale 0.000852

net scf-raw scale-fo.in <= hm2_5i25.0.7i77.0.0.analogin0

net scf-raw-adj cnvf.in <= scale-fo.out

net scf-s halui.feed-override.counts <= cnvf.out

################"--- Rapid Override ---"#################

# Convert from float to S32 #

#########################################################

# "Read in analog input and send to halui.rapid-override"

# "Enable direct count input"

net ro-ena halui.rapid-override.count-enable halui.rapid-override.direct-value

sets ro-ena 1

# "Scale down the value to a percentage"

net scr-scale => halui.rapid-override.scale

sets scr-scale 0.00044

net scr-raw scale-ro.in <= hm2_5i25.0.7i77.0.0.analogin1

net scr-raw-adj cnvr.in <= scale-ro.out

net scr-s halui.rapid-override.counts <= cnvr.out

###############"--- Spindle Override ---"################

# Convert from float to S32 #

#########################################################

# "Read in analog input and send to halui.spindle-override"

# "Enable direct count input"

net so-ena halui.spindle-override.count-enable halui.spindle-override.direct-value

sets so-ena 1

# "Scale down the value to a percentage"

net scs-scale => halui.spindle-override.scale

sets scs-scale 0.0004

#0.0005

# "Add an offest so that we have a minimum override of 30%"

net scs-offset => scale-so.offset

sets scs-offset 100

net scs-raw scale-so.in <= hm2_5i25.0.7i77.0.0.analogin2

net scs-raw-adj cnvs.in <= scale-so.out

net scs-s halui.spindle-override.counts <= cnvs.outEDIT: Figured it out. My spindle is being commanded to go to 10K rpms. Looks like I have some reading to do.

Last edit: 20 Mar 2016 00:45 by cncnoob1979.

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

23 Mar 2016 14:04 #72061

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

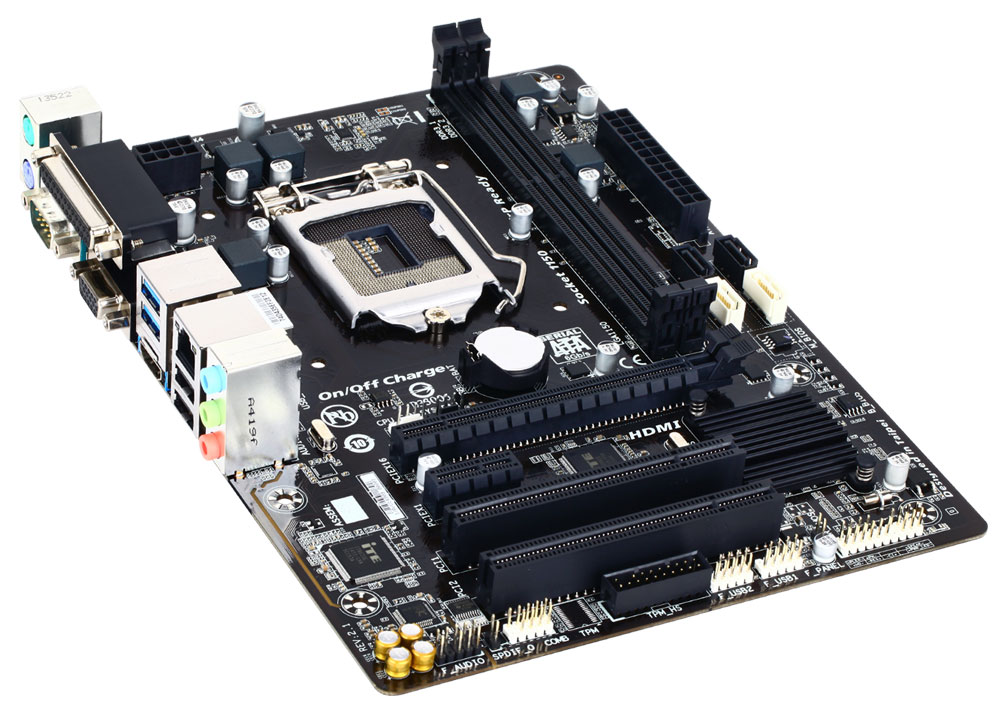

This past weekend I had 3 complete freezes of linuxcnc. I have decided to replace the motherboard and related components. This will allow me to upgrade to Linux Mint LMDE. The processor and hardware will be much more powerful. After reading about it in this

thread

,

I decided to go with this hardware.

I am still having issues in Gmoccapy frontend, listed in this thread , any ideas on a solution? I am having strage behavior with de-activating my software E-stop in Gmoccapy.

GIGABYTE GA-H81M-S2PH LGA 1150 Intel H81 74$

G.SKILL Ripjaws X Series 8GB $38.00

Kingston SSDNow V300 Series 2.5" 60GB $43.00

Intel G3260 3MB Haswell Dual-Core 3.3 GHz $60.00

Came to $215.00 shipped. Same microATX formfactor.

I decided to go with this hardware.

I am still having issues in Gmoccapy frontend, listed in this thread , any ideas on a solution? I am having strage behavior with de-activating my software E-stop in Gmoccapy.

GIGABYTE GA-H81M-S2PH LGA 1150 Intel H81 74$

G.SKILL Ripjaws X Series 8GB $38.00

Kingston SSDNow V300 Series 2.5" 60GB $43.00

Intel G3260 3MB Haswell Dual-Core 3.3 GHz $60.00

Came to $215.00 shipped. Same microATX formfactor.

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

24 Mar 2016 00:31 #72074

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Hey!

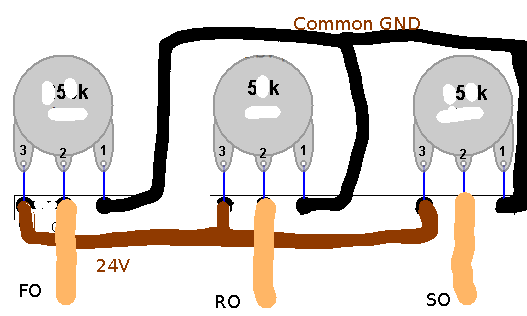

One of my pots just started smoking and shorted out. (the power surge shut down the 24v system) I have them wired with all sharing a common 24v source and all sharing the same common GND.

I have posted a quick and crude wiring diagram of how its wired. Is the an acceptable way to wire these, or am I missing something?

The GND is the same ground I'm using in the entire machine. This connection point is shared with the 12v power-supply, and the 24v source is the same that is powering my panel buttons and connects to my field power. The overrides(pot pin 2) are going to the 0,1,2 pins of the 7i77. Should I run another ground wire (star config) back to the grounding plane? Or did I have bad pot to begin with?

One of my pots just started smoking and shorted out. (the power surge shut down the 24v system) I have them wired with all sharing a common 24v source and all sharing the same common GND.

I have posted a quick and crude wiring diagram of how its wired. Is the an acceptable way to wire these, or am I missing something?

The GND is the same ground I'm using in the entire machine. This connection point is shared with the 12v power-supply, and the 24v source is the same that is powering my panel buttons and connects to my field power. The overrides(pot pin 2) are going to the 0,1,2 pins of the 7i77. Should I run another ground wire (star config) back to the grounding plane? Or did I have bad pot to begin with?

Please Log in or Create an account to join the conversation.

- csbrady

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 10

25 Mar 2016 13:31 #72130

by csbrady

Replied by csbrady on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Your wiring diagram appears to be correct as is your description for how they are wired. No need to do star wiring for the ground. Either a bad pot or it not really wired like you think.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

26 Mar 2016 20:43 #72191

by andypugh

Is there any load on the output? (I assume it goes to a Mesa analog input, in which case it ought to be "no")

Replied by andypugh on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Hey!

One of my pots just started smoking and shorted out. (the power surge shut down the 24v system)

Is there any load on the output? (I assume it goes to a Mesa analog input, in which case it ought to be "no")

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

26 Mar 2016 21:08 #72194

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Thanks for the response guys.

No there is no load on them. Just going to the 7i77 analogs. PCW said the load from the 7i77 would be around 22k.

I'm fairly certain I had a bad pot. Guess we will see.

No there is no load on them. Just going to the 7i77 analogs. PCW said the load from the 7i77 would be around 22k.

I'm fairly certain I had a bad pot. Guess we will see.

Please Log in or Create an account to join the conversation.

- bogie6040

-

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 10

01 Apr 2016 15:30 #72527

by bogie6040

Replied by bogie6040 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Do you know the specs for the pots?? With a 5K value you are only dissipating 4.8 mA but multiply that by 24V for wattage and you get 115 milli-watts If your power supply varied by just 1 volt to 25V you would be at 120 mW which is very close to the common 1/8 Watt rated pots. You may want to consider switching to 1/4 or even 1/2 watt pots or changing the value to 10K for some extra operational safety margin.

Bogie

Bogie

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

02 Apr 2016 03:07 - 02 Apr 2016 03:25 #72551

by cncnoob1979

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Hey bogie6040!

Yes the pots are 5k @ 1/2 watt.

I do believe I found my particular issue. The pots have a "nib" extended from the mounting base to prevent it from rotating when properly secured.

However since I was just temporary mounting these to a "test" panel I did not bother to cut out for the extrusion "nib" on the pot. So I snug down the pot, not real tight but apparently tight enough to have "warped" the pot's base enough to cause a direct short.

At least that is my conclusion... so user error yet again

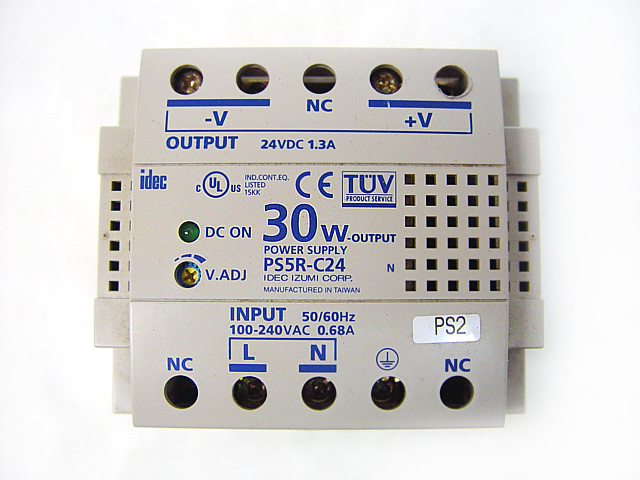

Also, just for my piece of mind I installed a 30w regulated 1.3A / 24v DIN mounted power-supply [PS5R-C24]. So now my 24v system is regulated, I feel much better about that.

Also for those interested:

I’m finally up on Linux mint 17.3 Mate Desktop. I built from source LinuxCNC and installed Glade 3.8.5

LMDE 2 Gave my processor's GPU hangups and Jessie required a lot more "work" to become a full desktop. Wheezy truthfully was the best suited to run just as a controller for this mill. But you know hobbyist!

The hardware listed in this thread for this build has turned out to be AWESOME! Im around 5-7 in latency and its wicked fast, I would highly recommend this build to anyone wanting a stable platform for LinuxCNC. [comes with paraport too! V2 and up]

Im around 5-7 in latency and its wicked fast, I would highly recommend this build to anyone wanting a stable platform for LinuxCNC. [comes with paraport too! V2 and up]

Yes the pots are 5k @ 1/2 watt.

I do believe I found my particular issue. The pots have a "nib" extended from the mounting base to prevent it from rotating when properly secured.

However since I was just temporary mounting these to a "test" panel I did not bother to cut out for the extrusion "nib" on the pot. So I snug down the pot, not real tight but apparently tight enough to have "warped" the pot's base enough to cause a direct short.

At least that is my conclusion... so user error yet again

Also, just for my piece of mind I installed a 30w regulated 1.3A / 24v DIN mounted power-supply [PS5R-C24]. So now my 24v system is regulated, I feel much better about that.

Also for those interested:

I’m finally up on Linux mint 17.3 Mate Desktop. I built from source LinuxCNC and installed Glade 3.8.5

LMDE 2 Gave my processor's GPU hangups and Jessie required a lot more "work" to become a full desktop. Wheezy truthfully was the best suited to run just as a controller for this mill. But you know hobbyist!

The hardware listed in this thread for this build has turned out to be AWESOME!

Last edit: 02 Apr 2016 03:25 by cncnoob1979.

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

14 Apr 2016 02:41 #73266

by cncnoob1979

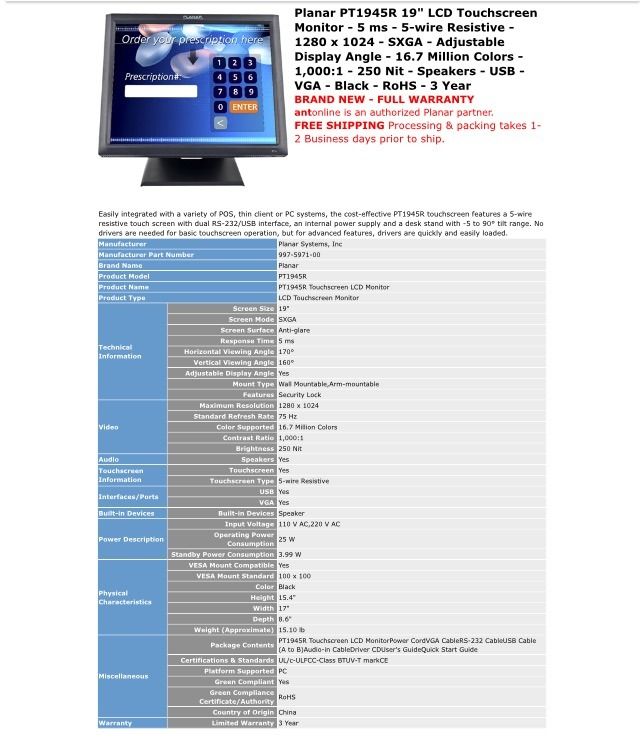

Planar PT1945R 19" LCD Touchscreen

Just picked up this used touch screen. It was a steal at 62.00$ shipped!!

I was wondering how difficult it would be to create a screen in axis just for gremlin view? And force it on a seperate monitor.

Has anyone tried this? I belive I can just create a VCP screen with just gremlin. Any thoughts on where to read up on that task? I'm reading the docs at the moment.

Replied by cncnoob1979 on topic Planning - Bridgeport Interact 1 linuxCNC Retrofit

Planar PT1945R 19" LCD Touchscreen

Just picked up this used touch screen. It was a steal at 62.00$ shipped!!

I was wondering how difficult it would be to create a screen in axis just for gremlin view? And force it on a seperate monitor.

Has anyone tried this? I belive I can just create a VCP screen with just gremlin. Any thoughts on where to read up on that task? I'm reading the docs at the moment.

Please Log in or Create an account to join the conversation.

Time to create page: 0.198 seconds