Search Results (Searched for: stepper spindle)

- richcolvin

08 Oct 2025 19:20

Replied by richcolvin on topic Stepper Motor Speed is too slow

Stepper Motor Speed is too slow

Category: Basic Configuration

These are the files. The .INC files were renamed to be .INI so that they could be attached.

I've attached one spindle file: that one and the one for Spindle1 all work exactly as expected.

I also attached only two of the axis files: U & Y (due to the file limit).

I've attached one spindle file: that one and the one for Spindle1 all work exactly as expected.

I also attached only two of the axis files: U & Y (due to the file limit).

- richcolvin

25 Sep 2025 19:04

Stepper Motor Speed does not match MaxVel was created by richcolvin

Stepper Motor Speed does not match MaxVel

Category: Basic Configuration

I am finding that

When I run LinuxCNC based on this configuration, the value for the parameter, hm2_yi92.0.stepgen.02.maxvel = 1.

Regardless, the stepper motor does NOT run at 1 rev / sec.

Attached are the HAL, INI, and include files for

Help would be GREATLY appreciated!

Thank you and kind regards,

Rich

- the stepper motors for the two spindles work as expected, however

- the stepper motors for the axes (B, U, V, X, &, & Z) run at a VERY slow speed.

- Servo Thread

- Max Interval = 1,013,089nS

- Max Jitter = 13,089nS

- Base Thread

- Max Interval = 46,407nS

- Max Jitter = 24,074nS

- Step Length = 2.5µS

- Step Space = 2.5µS

- Direction Setup = 5µS

- Direction Hold = 5µS

When I run LinuxCNC based on this configuration, the value for the parameter, hm2_yi92.0.stepgen.02.maxvel = 1.

Regardless, the stepper motor does NOT run at 1 rev / sec.

Attached are the HAL, INI, and include files for

- Spindle0 (Spindle1 is the same)

- Axis X (axes Y, Z, B, U, & V are the same)

Help would be GREATLY appreciated!

Thank you and kind regards,

Rich

- ozntyr

- ozntyr

25 Sep 2025 09:04

5-Axis CNC Setup with LinuxCNC + Mesa Boards was created by ozntyr

5-Axis CNC Setup with LinuxCNC + Mesa Boards

Category: General LinuxCNC Questions

Hi everyone,I’ve been working on a CNC project for a while and I’d like some advice before committing to hardware. Here’s my situation:

- I originally built a 3-axis CNC router running on GRBL (ESP32) + a custom PCB. I used that setup for a long time and gained good experience with it.

- Later, I decided to upgrade to 5-axis by adding A and C axes to the same GRBL-based system. While it functions, I quickly discovered a limitation: ESP32 GRBL doesn’t support TCP, so the machine can’t act as a proper 5-axis system.

- Because of this, I started looking into LinuxCNC. At first I wanted to use my Raspberry Pi 5, but I read that the Pi version of LinuxCNC can’t really handle full 5-axis control.

- I then tried installing LinuxCNC on an old laptop, but since it has no parallel port, I searched for hardware solutions that use Ethernet. That’s how I found Mesa boards.

- The 7i76 series supports 5 axes and spindle control, but its encoder inputs are only for the spindle, not for axes.

- The 7i95 series seems more suitable because it supports encoder inputs for the axes as well. My thinking was that even though steppers usually work fine, it would be good to have encoder feedback to check for missed steps.

- When testing LinuxCNC setup, I couldn’t find any 7i95 options in PNCconf, which left me confused.

- My current hardware: 2.2 Nm NEMA 23 steppers with DM556 drivers on all axes (6 motors total, since Y has dual rails).

- I don’t have encoders yet, I was waiting to see which types are actually supported by the mesa boards.

- As another option, I do have a couple of 400 W Delta B3 servos, but not enough to equip all axes. I’ve considered using them if steppers turn out too weak, but that would mean buying more servos.

- My main goal with encoders is simply to check for missed steps on the steppers.

- Am I on the right track with the 7i95 + LinuxCNC setup for a 5-axis machine with encoder feedback?

- Would you recommend a different Mesa board or configuration for this?

- Are there any guides/resources for setting up a 4+ axis machine with Mesa boards and LinuxCNC?

- phew

- phew

21 Sep 2025 12:21

LCNC 2.9.5 - How to jog with a wireless xbox bt controller was created by phew

LCNC 2.9.5 - How to jog with a wireless xbox bt controller

Category: Basic Configuration

Hey,

I am trying to set up my xbox controller to jog a three axis machine (y-gantry). Using a bluetooth dongle I had to fiddle around a bit (and install xpadneo) to get the controller to connect to the system but I eventually got there and do see input when pressing buttons/moving the joysticks.

I was digging into LinuxCNC a few years ago but then life happened and I had to put the project on ice up until now. This is my first home-built CNC (wood router) and I am very new to all of this.

My goal is to be able to move the X, Y (gantry) and Z axis using the gaming controller when there is no gcode being executed.

Currently this is a parport setup and the stepper motors are not actually installed on ball screws so I do not mess up anything while testing. I am planning on switching to a mesa card in the near future.

xyyz.ini (machine basic setup)

xyyz.hal:

xbox.hal

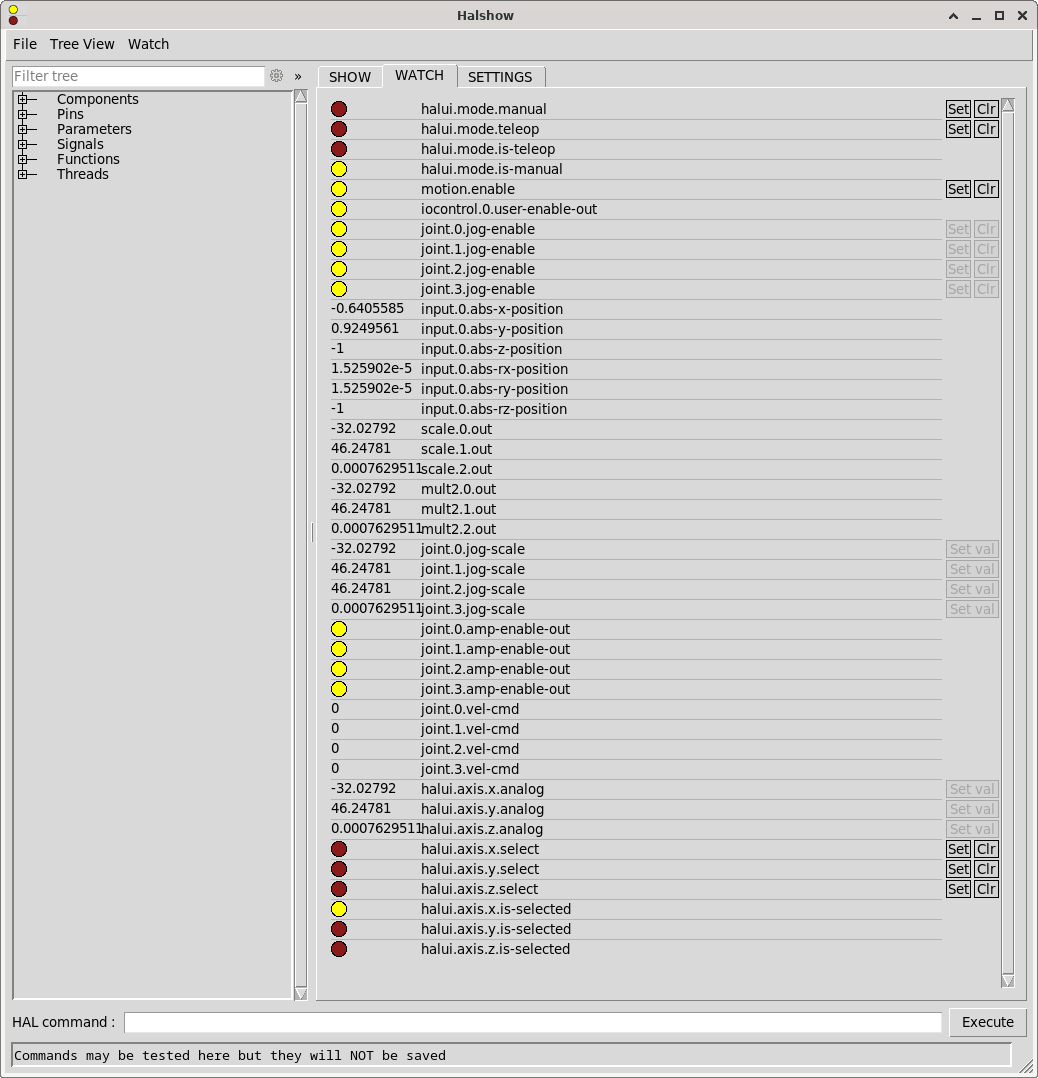

With this setup I can see input from the controller in halshow:

However, joint.*.vel-cmd always stays 0 and obviously the stepper motors are not spinning. Also I am not sure what mode I have to use, but I also tried setting halui.mode.manual and halui.mode.teleop using the [Set] button in halshow, but this did not change anything.

Setting it up like this will not allow the machine to start when the Xbox Controller is not connected as it expects the controller to be found. The controller will shut itself off if not being used for a certain period of time and this will also result in an error popping up in axis ui.

I think my current approach is way more complicated and clumsy than it actually needs to be, but the learning curve seems to be pretty steep for me and therefore I probably resorted to using way more AI generated code than I should have.

How do I

I am trying to set up my xbox controller to jog a three axis machine (y-gantry). Using a bluetooth dongle I had to fiddle around a bit (and install xpadneo) to get the controller to connect to the system but I eventually got there and do see input when pressing buttons/moving the joysticks.

I was digging into LinuxCNC a few years ago but then life happened and I had to put the project on ice up until now. This is my first home-built CNC (wood router) and I am very new to all of this.

My goal is to be able to move the X, Y (gantry) and Z axis using the gaming controller when there is no gcode being executed.

Currently this is a parport setup and the stepper motors are not actually installed on ball screws so I do not mess up anything while testing. I am planning on switching to a mesa card in the near future.

phew@linuxcnc:~$ sudo lsusb

Bus 001 Device 002: ID 2357:0604 TP-Link TP-Link Bluetooth USB Adapter

phew@linuxcnc:~$ sudo dkms status

hid-xpadneo/v0.9-226-ga16acb0, 6.1.0-39-rt-amd64, x86_64: installed

phew@linuxcnc:~$ sudo dmesg | grep -i xbox

[ 41.033957] input: Xbox Wireless Controller as /devices/virtual/misc/uhid/0005:045E:0B13.0007/input/input16

[ 41.034076] hid-generic 0005:045E:0B13.0007: input,hidraw6: BLUETOOTH HID v5.23 Gamepad [Xbox Wireless Controller] on 98:03:8e:4f:32:fd

[ 41.094172] input: Xbox Wireless Controller as /devices/virtual/misc/uhid/0005:045E:0B13.0007/input/input17

[ 41.094277] xpadneo 0005:045E:0B13.0007: input,hidraw6: BLUETOOTH HID v11.30 Gamepad [Xbox Wireless Controller] on 98:03:8e:4f:32:fd

[ 41.094307] input: Xbox Wireless Controller Consumer Control as /devices/virtual/misc/uhid/0005:045E:0B13.0007/input/input18

[ 41.094367] input: Xbox Wireless Controller Keyboard as /devices/virtual/misc/uhid/0005:045E:0B13.0007/input/input19

[ 42.076531] xpadneo 0005:045E:0B13.0007: Xbox Wireless Controller [14:cb:65:c7:03:1e] connected

[ 42.206305] input: Xbox Wireless Controller as /devices/virtual/misc/uhid/0005:045E:0B13.0007/input/input20

[ 42.206585] xpadneo 0005:045E:0B13.0007: input,hidraw6: BLUETOOTH HID v11.30 Gamepad [Xbox Wireless Controller] on 98:03:8e:4f:32:fd

[ 42.206615] input: Xbox Wireless Controller Consumer Control as /devices/virtual/misc/uhid/0005:045E:0B13.0007/input/input21

[ 42.206743] input: Xbox Wireless Controller Keyboard as /devices/virtual/misc/uhid/0005:045E:0B13.0007/input/input22

[ 43.189177] xpadneo 0005:045E:0B13.0007: Xbox Wireless Controller [14:cb:65:c7:03:1e] connectedxyyz.ini (machine basic setup)

# Generated by stepconf 1.1 at Thu Sep 11 20:35:55 2025

# If you make changes to this file, they will be

# overwritten when you run stepconf again

[EMC]

MACHINE = xyyz

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

EDITOR = gedit

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

ARCDIVISION = 64

GRIDS = 10mm 20mm 50mm 100mm 1in 2in 5in 10in

MAX_FEED_OVERRIDE = 1.2

MIN_SPINDLE_OVERRIDE = 0.5

MAX_SPINDLE_OVERRIDE = 1.2

DEFAULT_LINEAR_VELOCITY = 10.0

MIN_LINEAR_VELOCITY = 0

MAX_LINEAR_VELOCITY = 50.0

CYCLE_TIME = 0.100

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/phew/linuxcnc/nc_files

INCREMENTS = 20mm 10mm 5mm 1mm .5mm .1mm .05mm .01mm .005mm

[KINS]

JOINTS = 4

KINEMATICS = trivkins coordinates=XYYZ kinstype=both

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

PROGRAM_EXTENSION = .nc,.tap G-Code File

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

BASE_PERIOD = 50000

SERVO_PERIOD = 1000000

[HAL]

HALUI = halui

HALFILE = xyyz.hal

HALFILE = custom.hal

HALFILE = xbox.hal

POSTGUI_HALFILE = postgui_call_list.hal

MDI_COMMAND = G0 X0

MDI_COMMAND = G0 Y0

MDI_COMMAND = G0 Z0

JOINT_0 = X

JOINT_1 = Y

JOINT_2 = Y

JOINT_3 = Z

[TRAJ]

COORDINATES = X Y Y Z

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 2.50

MAX_LINEAR_VELOCITY = 25.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[AXIS_X]

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 25.0

MIN_LIMIT = -0.001

MAX_LIMIT = 800.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 800.0

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 1875.0

STEPGEN_MAXACCEL = 1875

SCALE = 160

FERROR = 1

MIN_FERROR = .25

HOME_SEQUENCE = 0

HOME_SEARCH_VEL = -20.0

HOME_LATCH_VEL = 2.0

HOME_OFFSET = -1.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

[AXIS_Y]

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 25.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1000.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1000.0

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 1875.0

STEPGEN_MAXACCEL = 1875

SCALE = 160

FERROR = 1

MIN_FERROR = .25

HOME_SEQUENCE = 1

HOME_SEARCH_VEL = -20.0

HOME_LATCH_VEL = 2.0

HOME_OFFSET = -1.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1000.0

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 1875.0

STEPGEN_MAXACCEL = 1875

SCALE = 160

FERROR = 1

MIN_FERROR = .25

HOME_SEQUENCE = 1

HOME_SEARCH_VEL = -20.0

HOME_LATCH_VEL = 2.0

HOME_OFFSET = -1.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

[AXIS_Z]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 10.0

MIN_LIMIT = -150.0

MAX_LIMIT = 0.001

[JOINT_3]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -150.0

MAX_LIMIT = 0.001

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 1000.0

STEPGEN_MAXACCEL = 1875

SCALE = 160

FERROR = 1

MIN_FERROR = .25

HOME_SEQUENCE = 2

HOME_SEARCH_VEL = 20.0

HOME_LATCH_VEL = -2.0

HOME_OFFSET = 1.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YESxyyz.hal:

loadrt [KINS]KINEMATICS kinstype=both

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hal_parport cfg="1 out+in"

setp parport.0.reset-time 5000

loadrt stepgen step_type=0,0,0,0

loadrt pwmgen output_type=1

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf pwmgen.make-pulses base-thread

addf parport.0.write base-thread

addf parport.0.reset base-thread

addf stepgen.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread

addf pwmgen.update servo-thread

net x-home-raw parport.0.pin-11-in

net x-home-raw => joint.0.home-sw-in

#net x-home-raw => joint.0.neg-lim-sw-in

# net x-home-raw => joint.0.pos-lim-sw-in # optional

net y0-home-raw parport.0.pin-12-in

net y0-home-raw => joint.1.home-sw-in

#net y0-home-raw => joint.1.neg-lim-sw-in

net y1-home-raw parport.0.pin-13-in

net y1-home-raw => joint.2.home-sw-in

#net y1-home-raw => joint.2.neg-lim-sw-in

net z-home-raw parport.0.pin-15-in

net z-home-raw => joint.3.home-sw-in

#net z-home-raw => joint.3.neg-lim-sw-in

setp stepgen.0.position-scale [JOINT_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 0

setp stepgen.0.dirhold 40000

setp stepgen.0.dirsetup 40000

setp stepgen.0.maxaccel [JOINT_0]STEPGEN_MAXACCEL

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.position-cmd

net xpos-fb stepgen.0.position-fb => joint.0.motor-pos-fb

net xstep stepgen.0.step => parport.0.pin-02-out

net xdir stepgen.0.dir => parport.0.pin-03-out

net xenable joint.0.amp-enable-out => stepgen.0.enable

net y-enable joint.1.amp-enable-out

net y-enable => stepgen.1.enable

net y-enable => stepgen.2.enable

setp stepgen.1.position-scale [JOINT_1]SCALE

setp stepgen.1.steplen 1

setp stepgen.1.stepspace 0

setp stepgen.1.dirhold 40000

setp stepgen.1.dirsetup 40000

setp stepgen.1.maxaccel [JOINT_1]STEPGEN_MAXACCEL

net ypos-cmd joint.1.motor-pos-cmd => stepgen.1.position-cmd

net ypos-fb stepgen.1.position-fb => joint.1.motor-pos-fb

net y0step stepgen.1.step => parport.0.pin-04-out

net y0dir stepgen.1.dir => parport.0.pin-05-out

setp stepgen.2.position-scale [JOINT_2]SCALE

setp stepgen.2.steplen 1

setp stepgen.2.stepspace 0

setp stepgen.2.dirhold 40000

setp stepgen.2.dirsetup 40000

setp stepgen.2.maxaccel [JOINT_2]STEPGEN_MAXACCEL

net y1pos-cmd joint.2.motor-pos-cmd => stepgen.2.position-cmd

net y1pos-fb stepgen.2.position-fb => joint.2.motor-pos-fb

net y1step stepgen.2.step => parport.0.pin-06-out

net y1dir stepgen.2.dir => parport.0.pin-07-out

setp stepgen.3.position-scale [JOINT_3]SCALE

setp stepgen.3.steplen 1

setp stepgen.3.stepspace 0

setp stepgen.3.dirhold 40000

setp stepgen.3.dirsetup 40000

setp stepgen.3.maxaccel [JOINT_3]STEPGEN_MAXACCEL

net zpos-cmd joint.3.motor-pos-cmd => stepgen.3.position-cmd

net zpos-fb stepgen.3.position-fb => joint.3.motor-pos-fb

net zstep stepgen.3.step => parport.0.pin-08-out

net zdir stepgen.3.dir => parport.0.pin-09-out

net zenable joint.3.amp-enable-out => stepgen.3.enable

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-inxbox.hal

loadusr -W hal_input -KRAL Xbox

loadrt scale count=3

addf scale.0 servo-thread

addf scale.1 servo-thread

addf scale.2 servo-thread

setp scale.0.gain 50.0 # X

setp scale.1.gain 50.0 # Y

setp scale.2.gain 50.0 # Z

loadrt mult2 count=3

addf mult2.0 servo-thread

addf mult2.1 servo-thread

addf mult2.2 servo-thread

loadrt conv_bit_float

addf conv-bit-float.0 servo-thread

net xbox-x-raw input.0.abs-x-position => scale.0.in

net xbox-y-raw input.0.abs-y-position => scale.1.in

net xbox-z-raw input.0.abs-ry-position => scale.2.in

net xbox-x-scaled scale.0.out => mult2.0.in0

net xbox-y-scaled scale.1.out => mult2.1.in0

net xbox-z-scaled scale.2.out => mult2.2.in0

net xbox-jog-bit input.0.btn-a => conv-bit-float.0.in

net xbox-jog-float conv-bit-float.0.out => mult2.0.in1

net xbox-jog-float => mult2.1.in1

net xbox-jog-float => mult2.2.in1

net xbox-x-vel mult2.0.out => joint.0.jog-scale # X

net xbox-y-vel mult2.1.out => joint.1.jog-scale # Y (Y0)

net xbox-y-vel => joint.2.jog-scale # Y (Y1)

net xbox-z-vel mult2.2.out => joint.3.jog-scale # Z

# Press [A]-button to enable joints

net xbox-jog-bit => joint.0.jog-enable

net xbox-jog-bit => joint.1.jog-enable

net xbox-jog-bit => joint.2.jog-enable

net xbox-jog-bit => joint.3.jog-enable

setp joint.0.jog-vel-mode TRUE

setp joint.1.jog-vel-mode TRUE

setp joint.2.jog-vel-mode TRUE

setp joint.3.jog-vel-mode TRUE

net xbox-x-vel => halui.axis.x.analog

net xbox-y-vel => halui.axis.y.analog

net xbox-z-vel => halui.axis.z.analogWith this setup I can see input from the controller in halshow:

However, joint.*.vel-cmd always stays 0 and obviously the stepper motors are not spinning. Also I am not sure what mode I have to use, but I also tried setting halui.mode.manual and halui.mode.teleop using the [Set] button in halshow, but this did not change anything.

Setting it up like this will not allow the machine to start when the Xbox Controller is not connected as it expects the controller to be found. The controller will shut itself off if not being used for a certain period of time and this will also result in an error popping up in axis ui.

I think my current approach is way more complicated and clumsy than it actually needs to be, but the learning curve seems to be pretty steep for me and therefore I probably resorted to using way more AI generated code than I should have.

How do I

- set this up correctly so the Xbox Controller input can actually controll the X, Y and Z axis?

- set this up in a way so the controller does not need to be connected in order for the machine to start and won't result in an error when the controller disconnects for some reason

- farmer_mike

- farmer_mike

12 Sep 2025 13:35 - 13 Sep 2025 01:36

Replied by farmer_mike on topic Getting (hopefully) close to an Rtelligent build

Getting (hopefully) close to an Rtelligent build

Category: EtherCAT

I have made some big progress lately. I have the limit switches and homing switches working. I also have the E stop working.

My issue is the RS750E AC servos shake quite a bit. Without the drive belts installed, the servos will sit and shake after completing a move. With the drive belts on, the system moves in the correct direction, but does so in a shaky manner.

My hypothesis is too much integral gain. I believe the problem is because I started with the stepper motor examples. Maybe there are some PID gains inside the drive that I need to configure.

I think what I need are the drive gains set with the SDO parameters inside the XML file.

Thanks for all the help

[/code]

[/code]

[/code]

My issue is the RS750E AC servos shake quite a bit. Without the drive belts installed, the servos will sit and shake after completing a move. With the drive belts on, the system moves in the correct direction, but does so in a shaky manner.

My hypothesis is too much integral gain. I believe the problem is because I started with the stepper motor examples. Maybe there are some PID gains inside the drive that I need to configure.

I think what I need are the drive gains set with the SDO parameters inside the XML file.

Thanks for all the help

###########################################################

#

# CIA 402 example snippet Hal

#

###########################################################

###########################################################

# Setup

###########################################################

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadusr -W lcec_conf ethercat-conf.xml

#loadusr -W /home/cnc/linuxcnc/configs/linuxcnc-cia402-single/python_control.py

loadrt lcec

loadrt cia402 count=3

loadrt pid names=0-pid,1-pid,2-pid

loadrt bitslice count=6 personality=32,32,32,32,32,32

addf bitslice.0 servo-thread

addf bitslice.1 servo-thread

addf bitslice.2 servo-thread

addf bitslice.3 servo-thread

addf bitslice.4 servo-thread

addf bitslice.5 servo-thread

loadrt conv_s32_u32 count=6

addf conv-s32-u32.0 servo-thread

addf conv-s32-u32.1 servo-thread

addf conv-s32-u32.2 servo-thread

addf conv-s32-u32.3 servo-thread

addf conv-s32-u32.4 servo-thread

addf conv-s32-u32.5 servo-thread

###########################################################

# Functions servo-thread

###########################################################

addf lcec.read-all servo-thread

addf cia402.0.read-all servo-thread

addf cia402.1.read-all servo-thread

addf cia402.2.read-all servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf 0-pid.do-pid-calcs servo-thread

addf 1-pid.do-pid-calcs servo-thread

addf 2-pid.do-pid-calcs servo-thread

addf cia402.0.write-all servo-thread

addf cia402.1.write-all servo-thread

addf cia402.2.write-all servo-thread

addf lcec.write-all servo-thread

#########################################

#nets

#########################################

net emc-enable => iocontrol.0.emc-enable-in

sets emc-enable 1

#config

#

# Joint 0

#

setp cia402.0.csp-mode 1

setp cia402.0.pos-scale 786432

#from servo(ethercat) to cia402

net 0-statusword lcec.0.0.cia-statusword => cia402.0.statusword

net 0-opmode-display lcec.0.0.opmode-display => cia402.0.opmode-display

net 0-drv-act-pos lcec.0.0.actual-position => cia402.0.drv-actual-position

net 0-drv-act-velo lcec.0.0.actual-velocity => cia402.0.drv-actual-velocity

#from motion to cia

net 0-enable <= joint.0.amp-enable-out => cia402.0.enable

net 0-amp-fault => joint.0.amp-fault-in <= cia402.0.drv-fault

net 0-pos-cmd <= joint.0.motor-pos-cmd => cia402.0.pos-cmd

net 0-pos-fb => joint.0.motor-pos-fb <= cia402.0.pos-fb

#from cia402 to servo(ethercat)

net 0-controlword cia402.0.controlword => lcec.0.0.cia-controlword

net 0-modes-of-operation cia402.0.opmode => lcec.0.0.opmode

net 0-drv-target-pos cia402.0.drv-target-position => lcec.0.0.target-position

net 0-drv-target-velo cia402.0.drv-target-velocity => lcec.0.0.target-velocity

net my-out-0 conv-s32-u32.0.in <= lcec.0.0.digitalinputs

net my-in-0 conv-s32-u32.0.out => bitslice.0.in

net my-bit-0 bitslice.0.out-00 joint.0.neg-lim-sw-in

net my-out-0 conv-s32-u32.1.in <= lcec.0.0.digitalinputs

net my-in-1 conv-s32-u32.1.out => bitslice.1.in

net my-bit-1 bitslice.1.out-01 joint.0.pos-lim-sw-in

net my-out-0 conv-s32-u32.2.in <= lcec.0.0.digitalinputs

net my-in-2 conv-s32-u32.2.out => bitslice.2.in

net my-bit-2 bitslice.2.out-02 joint.0.home-sw-in

#

# Joint 1

#

setp cia402.1.csp-mode 1

setp cia402.1.pos-scale -786432

#from servo(ethercat) to cia402

net 1-statusword lcec.0.1.cia-statusword => cia402.1.statusword

net 1-opmode-display lcec.0.1.opmode-display => cia402.1.opmode-display

net 1-drv-act-pos lcec.0.1.actual-position => cia402.1.drv-actual-position

net 1-drv-act-velo lcec.0.1.actual-velocity => cia402.1.drv-actual-velocity

#from cia402 to servo(ethercat)

net 1-controlword cia402.1.controlword => lcec.0.1.cia-controlword

net 1-modes-of-operation cia402.1.opmode => lcec.0.1.opmode

net 1-drv-target-pos cia402.1.drv-target-position => lcec.0.1.target-position

net 1-drv-target-velo cia402.1.drv-target-velocity => lcec.0.1.target-velocity

#from motion to cia

net 1-enable <= joint.1.amp-enable-out => cia402.1.enable

net 1-amp-fault => joint.1.amp-fault-in <= cia402.1.drv-fault

net 1-pos-cmd <= joint.1.motor-pos-cmd => cia402.1.pos-cmd

net 1-pos-fb => joint.1.motor-pos-fb <= cia402.1.pos-fb

net my-out-1 conv-s32-u32.3.in <= lcec.0.1.digitalinputs

net my-in-3 conv-s32-u32.3.out => bitslice.3.in

net my-bit-3 bitslice.3.out-00 joint.1.pos-lim-sw-in

net my-out-1 conv-s32-u32.4.in <= lcec.0.1.digitalinputs

net my-in-4 conv-s32-u32.4.out => bitslice.4.in

net my-bit-4 bitslice.4.out-01 joint.1.neg-lim-sw-in

net my-out-1 conv-s32-u32.5.in <= lcec.0.1.digitalinputs

net my-in-5 conv-s32-u32.5.out => bitslice.5.in

net my-bit-5 bitslice.5.out-02 joint.1.home-sw-in

#

# Joint 2

#

setp cia402.2.csp-mode 1

setp cia402.2.pos-scale 96000

#from servo(ethercat) to cia402

net 2-statusword lcec.0.2.cia-statusword => cia402.2.statusword

net 2-opmode-display lcec.0.2.opmode-display => cia402.2.opmode-display

net 2-drv-act-pos lcec.0.2.actual-position => cia402.2.drv-actual-position

net 2-drv-act-velo lcec.0.2.actual-velocity => cia402.2.drv-actual-velocity

#from cia402 to servo(ethercat)

net 2-controlword cia402.2.controlword => lcec.0.2.cia-controlword

net 2-modes-of-operation cia402.2.opmode => lcec.0.2.opmode

net 2-drv-target-pos cia402.2.drv-target-position => lcec.0.2.target-position

net 2-drv-target-velo cia402.2.drv-target-velocity => lcec.0.2.target-velocity

#from motion to cia

net 2-enable <= joint.2.amp-enable-out => cia402.2.enable

net 2-amp-fault => joint.2.amp-fault-in <= cia402.2.drv-fault

net 2-pos-cmd <= joint.2.motor-pos-cmd => cia402.2.pos-cmd

net 2-pos-fb => joint.2.motor-pos-fb <= cia402.2.pos-fb

net 2-CCW-limit lcec.0.2.in-3 => joint.2.neg-lim-sw-in

net 2-CW-limit lcec.0.2.in-4 => joint.2.pos-lim-sw-in

net 2-in-home lcec.0.2.in-5 => joint.2.home-sw-in

net 2-in-6 lcec.0.2.in-6 => halui.estop.activate

#net spindle_speed spindle.0.speed-out => python_control.rpm_in

[code]# This config file was created 2020-08-14 17:19:37.621705 by the update_ini script

# The original config files may be found in the /home/demo/linuxcnc/configs/et-3ax/et_3ax_CIA402.old directory

[EMC]

# The version string for this INI file.

VERSION = 1.1

MACHINE = EtherCAT Machine

DEBUG = 1

[DISPLAY]

DISPLAY = axis

EDITOR = gedit

#PYVCP = pyvcp_panel.xml

# places the pyvcp panel at the bottom of the Axis window

PYVCP_POSITION = RIGHT

# Cycle time, in seconds, that display will sleep between polls

CYCLE_TIME = 0.100

# Path to help file

HELP_FILE = doc/help.txt

# Initial display setting for position, RELATIVE or MACHINE

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 1

# Prefix to be used

PROGRAM_PREFIX = /home/demo/linuxcnc/nc_files

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 0

INCREMENTS = 1in .5in .25in .125in .0625in .025in .05in

#INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

nc = /usr/bin/axis

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

BASE_PERIOD = 0

SERVO_PERIOD = 1000000

[TASK]

TASK = milltask

CYCLE_TIME = 0.005

[HAL]

HALFILE = cia402.hal

#SHUTDOWN = shutdown.hal

HALUI = halui

[HALUI]

[TRAJ]

HOME = 16 12 7

COORDINATES = XYZ

LINEAR_UNITS = in

ANGULAR_UNITS = deg

DEFAULT_LINEAR_VELOCITY = .25

MAX_LINEAR_VELOCITY = .5

MIN_LINEAR_VELOCITY = .01

DEFAULT_ANGULAR_VELOCITY = 360

MAX_ANGULAR_VELOCITY = 720

POSITION_FILE = position.txt

[EMCIO]

# Name of IO controller program, e.g., iov2 has tool changer stuff

EMCIO = iov2

CYCLE_TIME = 0.100

# tool table file

TOOL_TABLE = cia402.tbl

TOOL_CHANGE_POSITION = 0 0 50.8

#RANDOM_TOOLCHANGER = 1

[KINS]

JOINTS = 3

KINEMATICS = trivkins kinstype=both coordinates=xyz

[AXIS_X]

MIN_LIMIT = 0.1

MAX_LIMIT = 17.9

MAX_VELOCITY = .5

MAX_ACCELERATION = 10

BACKLASH = 0.0000

[JOINT_0]

TYPE = LINEAR

MAX_VELOCITY = .5

MAX_ACCELERATION = 10

DEADBAND = 0.01

P=1

I=0

D=0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

# is this applicable for ethercat????

#STEPGEN_MAXVEL = 1.25

#STEPGEN_MAXACCEL = 1.25

SCALE = 1

FERROR = 200

MIN_FERROR = 50

MIN_LIMIT = 0

MAX_LIMIT = 18

HOME = 16

HOME_OFFSET = 16

HOME_SEQUENCE = 0

HOME_SEARCH_VEL = -.125

HOME_LATCH_VEL = -.125

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

[AXIS_Y]

MIN_LIMIT = 0.1

MAX_LIMIT = 12.9

MAX_VELOCITY = .5

MAX_ACCELERATION = 10

BACKLASH = 0.0000

[JOINT_1]

TYPE = LINEAR

MAX_VELOCITY = .5

MAX_ACCELERATION = 10

DEADBAND = 0.01

P=1

I=0

D=0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

# is this applicable for ethercat????

#STEPGEN_MAXVEL = 1.25

#STEPGEN_MAXACCEL = 1.25

STEP_SCALE = 1

FERROR = 2

MIN_FERROR = 20

MIN_LIMIT = 0

MAX_LIMIT = 13

HOME = 12

HOME_OFFSET = 12

HOME_SEQUENCE = 1

HOME_SEARCH_VEL = .125

HOME_LATCH_VEL = .125

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

[JOINT_2]

TYPE = LINEAR

MAX_VELOCITY = .5

MAX_ACCELERATION = 10

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

# is this applicable for ethercat????

STEPGEN_MAXVEL = 1.25

STEPGEN_MAXACCEL = 1.25

STEP_SCALE = 1

FERROR = 200

MIN_FERROR = 20

MIN_LIMIT = 3.4

MAX_LIMIT = 8.1

HOME = 7

HOME_OFFSET = 7

HOME_SEQUENCE = 2

HOME_SEARCH_VEL = .125

HOME_LATCH_VEL = .125

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

[AXIS_Z]

MIN_LIMIT = 3.5

MAX_LIMIT = 8

MAX_VELOCITY = .5

MAX_ACCELERATION = 10

BACKLASH = 0.0000[/code]

[code][code]<masters>

<master idx="0" appTimePeriod="1000000" refClockSyncCycles="1">

<slave idx="0" type="generic" vid="00000A88" pid="0a880013" configPdos="true">

<!-- Joint 0 -->

<syncManager idx="0" dir="out"> </syncManager>

<syncManager idx="1" dir="out"> </syncManager>

<syncManager idx="2" dir="out">

<pdo idx="1600">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="607a" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

<pdoEntry idx="60b8" subIdx="00" bitLen="16" halPin="touchprobefunction0" halType="bit"/>

</pdo>

<pdo idx="1601">

<pdoEntry idx="6081" subIdx="00" bitLen="32" halPin="profile-velocity" halType="u32"/>

<pdoEntry idx="6083" subIdx="00" bitLen="32" halPin="target-accel" halType="u32"/>

<pdoEntry idx="6084" subIdx="00" bitLen="32" halPin="target-decel" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

</pdo>

<pdo idx="1602">

<pdoEntry idx="60ff" subIdx="00" bitLen="32" halPin="target-velocity" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="603f" subIdx="00" bitLen="16" halPin="errorcode" halType="bit"/>

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="60b9" subIdx="00" bitLen="16" halPin="touchprobestat" halType="bit"/>

<pdoEntry idx="60ba" subIdx="00" bitLen="32" halPin="touchprobe1pos" halType="s32"/>

<pdoEntry idx="60fd" subIdx="00" bitLen="32" halPin="digitalinputs" halType="s32"/>

</pdo>

<pdo idx="1a01">

<pdoEntry idx="606c" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

</pdo>

</syncManager>

<dcConf assignActivate="300" sync0Cycle="1000000"/>

</slave>

<slave idx="1" type="generic" vid="00000A88" pid="0a880013" configPdos="true">

<!-- Joint 1 -->

<syncManager idx="0" dir="out"> </syncManager>

<syncManager idx="1" dir="out"> </syncManager>

<syncManager idx="2" dir="out">

<pdo idx="1600">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="607a" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

<pdoEntry idx="60b8" subIdx="00" bitLen="16" halPin="touchprobefunction0" halType="bit"/>

</pdo>

<pdo idx="1601">

<pdoEntry idx="6081" subIdx="00" bitLen="32" halPin="profile-velocity" halType="u32"/>

<pdoEntry idx="6083" subIdx="00" bitLen="32" halPin="target-accel" halType="u32"/>

<pdoEntry idx="6084" subIdx="00" bitLen="32" halPin="target-decel" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

</pdo>

<pdo idx="1602">

<pdoEntry idx="60ff" subIdx="00" bitLen="32" halPin="target-velocity" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="603f" subIdx="00" bitLen="16" halPin="errorcode" halType="bit"/>

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="60b9" subIdx="00" bitLen="16" halPin="touchprobestat" halType="bit"/>

<pdoEntry idx="60ba" subIdx="00" bitLen="32" halPin="touchprobe1pos" halType="s32"/>

<pdoEntry idx="60fd" subIdx="00" bitLen="32" halPin="digitalinputs" halType="s32"/>

</pdo>

<pdo idx="1a01">

<pdoEntry idx="606c" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

</pdo>

</syncManager>

<dcConf assignActivate="300" sync0Cycle="1000000"/>

</slave>

<!-- Joint 2 -->

<slave idx="2" type="generic" vid="00000a88" pid="0a880002" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<sdoConfig idx="2000" subIdx="0"><sdoDataRaw data ="88 13"/></sdoConfig> <!-- Max motor current (5.0) -->

<sdoConfig idx="2007" subIdx="3"><sdoDataRaw data ="01"/></sdoConfig> <!-- Input 3 - CCW Limit -->

<sdoConfig idx="2007" subIdx="4"><sdoDataRaw data ="02"/></sdoConfig> <!-- Input 4 - CW Limit -->

<sdoConfig idx="2007" subIdx="5"><sdoDataRaw data ="03"/></sdoConfig> <!-- Input 5 - Home Function -->

<sdoConfig idx="2007" subIdx="6"><sdoDataRaw data ="05"/></sdoConfig> <!-- Input 6 - Emergency Stop -->

<sdoConfig idx="2011" subIdx="0"><sdoDataRaw data ="01 00"/></sdoConfig> <!-- Closed loop -->

<sdoConfig idx="6098" subIdx="0"><sdoDataRaw data ="11 00"/></sdoConfig> <!-- Home mode 17 -->

<sdoConfig idx="607C" subIdx="0"><sdoDataRaw data ="00 00"/></sdoConfig> <!-- Home offset 0 -->

<sdoConfig idx="609A" subIdx="0"><sdoDataRaw data ="F4 01"/></sdoConfig> <!-- Home accelleration 500 -->

<sdoConfig idx="6099" subIdx="01"><sdoDataRaw data ="C4 09"/></sdoConfig> <!-- Home fast speed 2500-->

<sdoConfig idx="6099" subIdx="02"><sdoDataRaw data ="F4 01"/></sdoConfig> <!-- Home slow speed 500 -->

<syncManager idx="2" dir="out">

<pdo idx="1600">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<!-- Target Position -->

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

<!-- Target Velocity -->

<pdoEntry idx="60FF" subIdx="00" bitLen="32" halPin="target-velocity" halType="s32"/>

<!-- Digtial Outputs (manufacturer's extension ECT86/ECT60)-->

<pdoEntry idx="204A" subIdx="0" bitLen="16" halType="complex">

<complexEntry bitLen="1" halPin="out-1" halType="bit"/>

<complexEntry bitLen="1" halPin="out-2" halType="bit"/>

<complexEntry bitLen="14"/>

</pdoEntry>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="32" halPin="actual-torque" halType="s32"/>

<!-- Digtial_inputs (cia402 compatible) -->

<pdoEntry idx="60FD" subIdx="0" bitLen="32" halType="complex">

<complexEntry bitLen="1" halPin="CW-limit" halType="bit"/>

<complexEntry bitLen="1" halPin="CCW-limit" halType="bit"/>

<complexEntry bitLen="1" halPin="in-home" halType="bit"/>

<complexEntry bitLen="13"/>

<complexEntry bitLen="1" halPin="in-1" halType="bit"/>

<complexEntry bitLen="1" halPin="in-2" halType="bit"/>

<complexEntry bitLen="1" halPin="in-3" halType="bit"/>

<complexEntry bitLen="1" halPin="in-4" halType="bit"/>

<complexEntry bitLen="1" halPin="in-5" halType="bit"/>

<complexEntry bitLen="1" halPin="in-6" halType="bit"/>

<complexEntry bitLen="10"/>

</pdoEntry>

</pdo>

</syncManager>

</slave>

</master>

</masters>[/code]

- Martin.L

- Martin.L

06 Sep 2025 12:18

Replied by Martin.L on topic Stepperonline A6-1000EC driver

Stepperonline A6-1000EC driver

Category: EtherCAT

replace x with your servo/spindle index

net s-vel-cmd <= spindle.0.speed-out

net s-vel-cmd => cia402.x.velocity-cmd

You will need csp mode 0 :

setp cia402.5.csp-mode 0

setp cia402.5.pos-scale 1

net s-vel-cmd <= spindle.0.speed-out

net s-vel-cmd => cia402.x.velocity-cmd

You will need csp mode 0 :

setp cia402.5.csp-mode 0

setp cia402.5.pos-scale 1

- Rookie0

- Rookie0

01 Sep 2025 11:44

hope it helps.

Replied by Rookie0 on topic Stepperonline A6-1000EC driver

Stepperonline A6-1000EC driver

Category: EtherCAT

# spindle.hal

# use cia402 comp. link: https://github.com/dbraun1981/hal-cia402

loadrt cia402 names=cia-s

addf cia-s.read-all servo-thread

addf cia-s.write-all servo-thread

# value = resolution_servo_encoder ÷ 60

# if gearbox exists, then * reduction_ratio(input:ouput)

setp cia-s.velo-scale 800

net s-statusword <= lcec.0.N.cia-statusword => cia-s.statusword

net s-opmode-display <= lcec.0.N.opmode-display => cia-s.opmode-display

net s-drv-act-velo <= lcec.0.N.actual-velocity => cia-s.drv-actual-velocity

net s-controlword <= cia-s.controlword => lcec.0.N.cia-controlword

net s-opmode <= cia-s.opmode => lcec.0.N.opmode

net s-drv-target-velo <= cia-s.drv-target-velocity => lcec.0.N.target-velocity

net s-enable <= spindle.0.on => cia-s.enable

net s-velo-fb <= cia-s.velocity-fb => spindle.0.speed-in

net s-velo-cmd <= spindle.0.speed-out => cia-s.velocity-cmd

hope it helps.

- russkinch

01 Sep 2025 11:14

Stepperonline A6-1000EC driver was created by russkinch

Stepperonline A6-1000EC driver

Category: EtherCAT

Hi again. I have sorted the power issue (manual was no help at all). Now, I have it set to Linuxcnc using ethercat. It is all communication etc. I want to run the servo as a spindle motor so just have the target-velocity (60FE). How do I create the 'pins' to tell the drive to turn at say 1000rpm with an M3 command is given. I have done the many times using a VFD (much easier but space and weight limits force me to use a servo).

I am soooo out of my depth here, any help is always hugely appreciated. (I have already looked through the various threads and found no help after hours of scrolling)

I am soooo out of my depth here, any help is always hugely appreciated. (I have already looked through the various threads and found no help after hours of scrolling)

- Gautham

- Gautham

29 Aug 2025 02:43

Replied by Gautham on topic Connecting my 7i96s to the VFD

Connecting my 7i96s to the VFD

Category: Driver Boards

Omg it worked!!! Thank you so much PCW not only did you spoon feed me on how to get my 7i96s to run my spindle but you also helped me get all my steppers working with the BoB. Thank you so much

- russkinch

28 Aug 2025 09:07

Stepperonline A6-1000EC driver was created by russkinch

Stepperonline A6-1000EC driver

Category: EtherCAT

Hi, I am creating a custom machine for work and really really need help. I am using the above driver with a 1000w servo motor for the spindle. I have installed ethercat and configured. I have downloaded the xml file for the drive from stepperonline. I have created a hal file that loads lcec and the xml file. But when I start linuxcnc is stops with an error saying lcec exited. How can I use this to drive the spindle. I don't need limits or probes or anything, Just speed.

I am really out of my depth here as I normally use a 3ph and vfd but space and weight does not permit this on the machine I am making.

Thanks

Russell

I am really out of my depth here as I normally use a 3ph and vfd but space and weight does not permit this on the machine I am making.

Thanks

Russell

- lj

- lj

26 Aug 2025 06:05

Replied by lj on topic ESP32 HAL2UDP setup for linux CNC noob.

ESP32 HAL2UDP setup for linux CNC noob.

Category: Computers and Hardware

Hello, I just started working on the linuxcnc esp32 W5500 setup and I ran into some issues.

1. Hardware: Rpi4 8gb with linuxcnc 2.8.4, W5500, Esp32 Wroom

2. Esp firmware: hal2udp pwm

3. Motion: open loop stepper with TB6600 Driver

Issues

1. activation of spindle or flood no voltage change on esp32 pins 4 or 25.

2. joint follow error all axis3. My stepper is enable without the enable pin connection (I'm not even sure what pin to use for enable/disable on the esp32-the pin out from the read file doesn't show what pin to use.

3. udp.stepgen.1.enable (error doesn't exsist) (My assumption is that because the udp.comp file doesnt show the param or pin) maybe I'm missing something

4. is the Pid function only used for closed loop steppers to accurately determine movement

I attached my hal and ini files

thanks for the help

1. Hardware: Rpi4 8gb with linuxcnc 2.8.4, W5500, Esp32 Wroom

2. Esp firmware: hal2udp pwm

3. Motion: open loop stepper with TB6600 Driver

Issues

1. activation of spindle or flood no voltage change on esp32 pins 4 or 25.

2. joint follow error all axis3. My stepper is enable without the enable pin connection (I'm not even sure what pin to use for enable/disable on the esp32-the pin out from the read file doesn't show what pin to use.

3. udp.stepgen.1.enable (error doesn't exsist) (My assumption is that because the udp.comp file doesnt show the param or pin) maybe I'm missing something

4. is the Pid function only used for closed loop steppers to accurately determine movement

I attached my hal and ini files

thanks for the help

- rhscdn

- rhscdn

14 Aug 2025 03:07 - 14 Aug 2025 03:13

Axyz retrofit - spindle wiring 7i96 was created by rhscdn

Axyz retrofit - spindle wiring 7i96

Category: CNC Machines

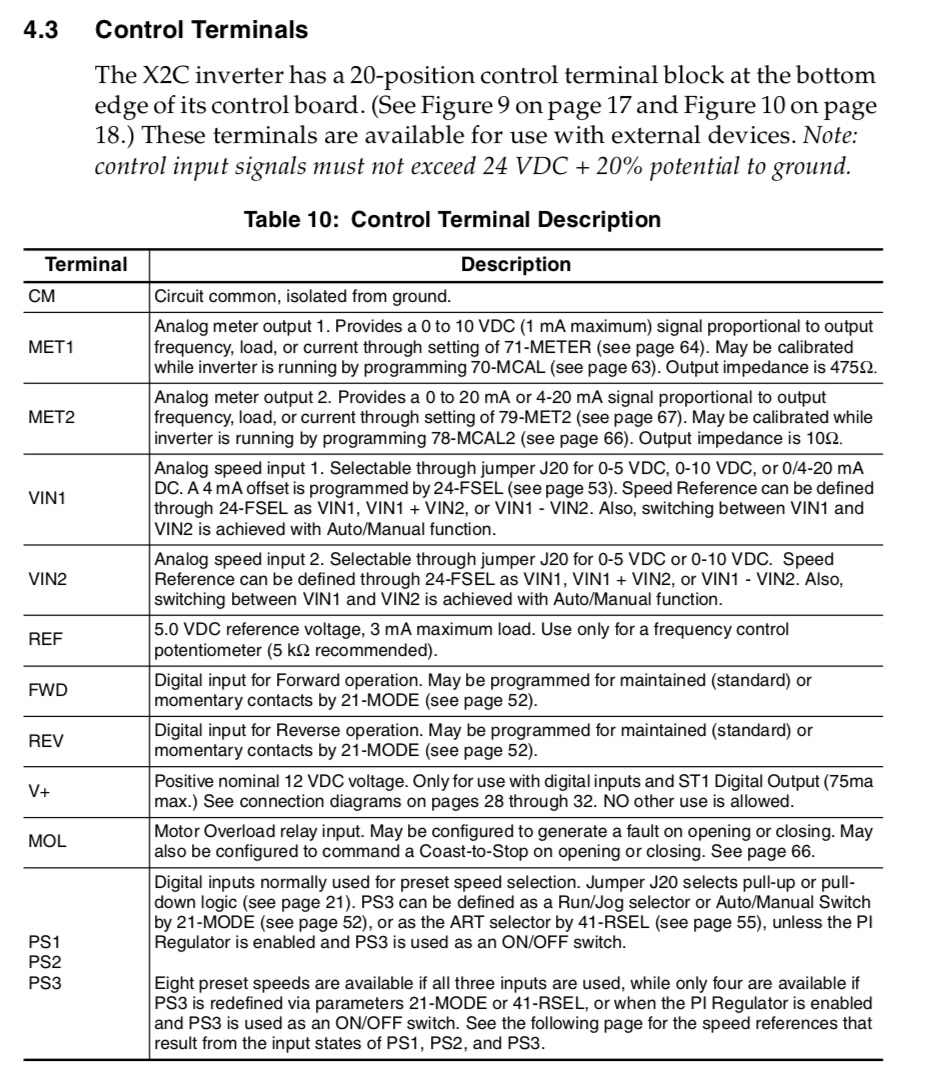

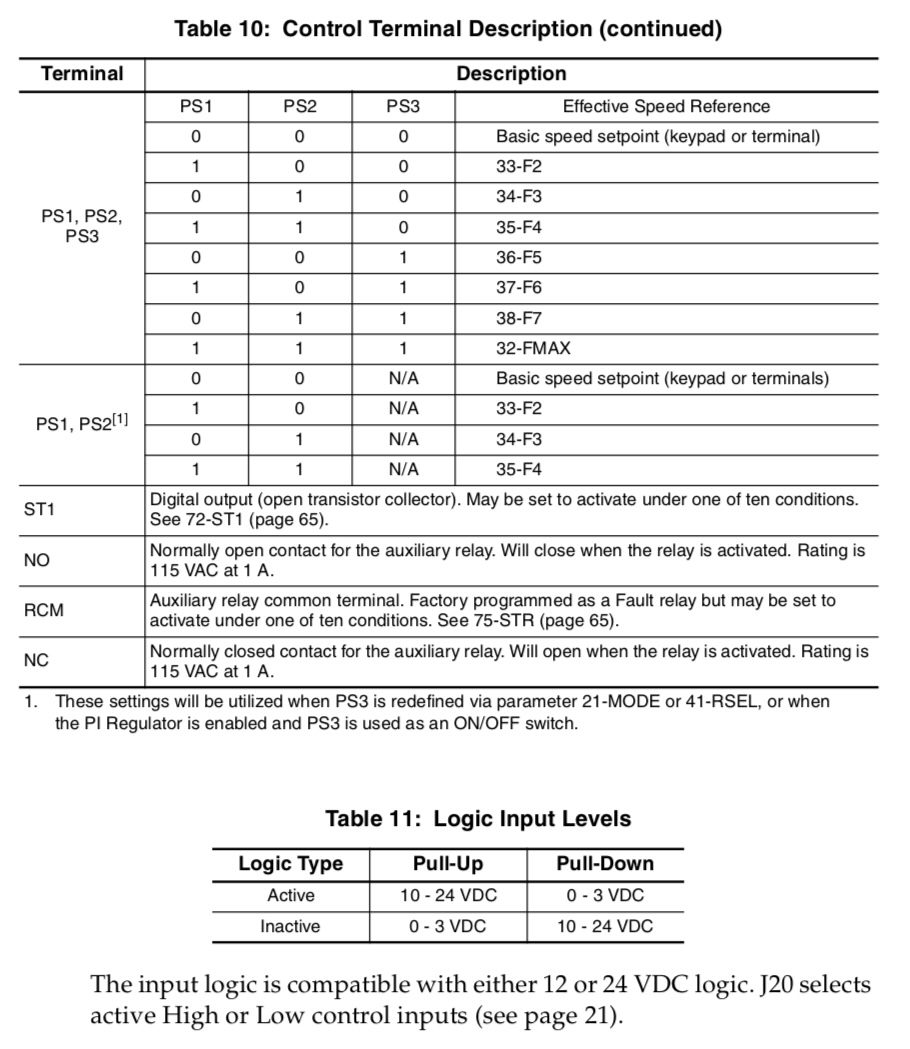

I think I have wrapped my head around my stepper motor and limit switch wiring. Regarding the spindle, I have a few questions:

The inverter is a woods eTrac x2c and the manual offers a nearly overwhelming number of options. I was never able to see the spindle working with the stock

AMC controller. I have attached the relevant table from the inverter manual and it seems like I should be able to use the analog spindle interface to provide 0-5vdc signal for speed control (vin). Do I simply use inputs on the 7i96 to conteol fwd/rev and a ground connected to the inverter common? Is that all there is to it?

The original wiring from the AMC controller to the inverter is somewhat different and it isn’t obvious that the AMC was actually able to control the spindle speed. It is connected to use 4 preset spindle speeds and the AMC has wires indicating an acceleration/deceleration signal, as well as some connections to NO and RCM.

The inverter is a woods eTrac x2c and the manual offers a nearly overwhelming number of options. I was never able to see the spindle working with the stock

AMC controller. I have attached the relevant table from the inverter manual and it seems like I should be able to use the analog spindle interface to provide 0-5vdc signal for speed control (vin). Do I simply use inputs on the 7i96 to conteol fwd/rev and a ground connected to the inverter common? Is that all there is to it?

The original wiring from the AMC controller to the inverter is somewhat different and it isn’t obvious that the AMC was actually able to control the spindle speed. It is connected to use 4 preset spindle speeds and the AMC has wires indicating an acceleration/deceleration signal, as well as some connections to NO and RCM.

- hitchhiker

- hitchhiker

13 Aug 2025 15:35

Replied by hitchhiker on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

ECMO VMC100 Retrofit with Carousel/Toolchanger

Category: Milling Machines

sry for delay.

i have now the whole machine running with the original controller.

all works.. steppers,maindrive, all sensors and the spindleencoder.

in the next days i link up my raspberry pi 4 with a 7i92.

why the rasp? its easier for me instead a notebook.. i have the machine in my garage not in my basement...

if all works and linked to the mesa and is in my linuxcnc i came back.

parallel i would build a small model for the toolchanger to play in the apartment with the toolchanger carousel stuff.

thanks

i have now the whole machine running with the original controller.

all works.. steppers,maindrive, all sensors and the spindleencoder.

in the next days i link up my raspberry pi 4 with a 7i92.

why the rasp? its easier for me instead a notebook.. i have the machine in my garage not in my basement...

if all works and linked to the mesa and is in my linuxcnc i came back.

parallel i would build a small model for the toolchanger to play in the apartment with the toolchanger carousel stuff.

thanks

- juergen-home

- juergen-home

13 Aug 2025 09:37 - 13 Aug 2025 09:40

Replied by juergen-home on topic "pwm/dir" (Out1) switches for spindle CCW

"pwm/dir" (Out1) switches for spindle CCW

Category: Basic Configuration

At the end it was easier for me to compile a new bit file without the pwm/dir (I/O 07 PIN 17) and use it as a GPIO. It is working now.

Many thanks to you Peter!

Another question is about my "26 HDR" internal port of the 6i25 , I wanted to do my own encoder pcb but now I found a used 7I52S.

How to modify my vhd-file to do so and how should the cable from 26 HDR 6i25 to the 50 HDR 7I52S look like?

I don't now if I can use all functionality of the 7I52S but at least the 6 encoders and the rest filled with (stepper)outputs?

Should I open a new thread for this?

Many thanks to you Peter!

Another question is about my "26 HDR" internal port of the 6i25 , I wanted to do my own encoder pcb but now I found a used 7I52S.

How to modify my vhd-file to do so and how should the cable from 26 HDR 6i25 to the 50 HDR 7I52S look like?

I don't now if I can use all functionality of the 7I52S but at least the 6 encoders and the rest filled with (stepper)outputs?

Should I open a new thread for this?

- konrad

- konrad

05 Aug 2025 15:24

Replied by konrad on topic prevent jog limit error

prevent jog limit error

Category: General LinuxCNC Questions

I made the config with PnCconf and only slightly changed to to account for probe basic interface.

the inductive endstops are mounted on the traveling part of the axis and there are metal stops at each end of the travel.

the machine has the following specs:

Machine Specs:

X460, Y750mm, Z160

20mm linear rails

10mm pitch ballscrews, 20mm diameter

Construction: aluminum profiles bolted to 12mm steel plates, welded gantry sides

Motors: Y-axis 6.8Nm stepper, Z + X-axis 3Nm stepper

Drives: DM556 V1 48v

Spindle: 24K RPM 2.2kW ER20

inductive endstops

good latency values mostly sub 3000ns servo

the inductive endstops are mounted on the traveling part of the axis and there are metal stops at each end of the travel.

the machine has the following specs:

Machine Specs:

X460, Y750mm, Z160

20mm linear rails

10mm pitch ballscrews, 20mm diameter

Construction: aluminum profiles bolted to 12mm steel plates, welded gantry sides

Motors: Y-axis 6.8Nm stepper, Z + X-axis 3Nm stepper

Drives: DM556 V1 48v

Spindle: 24K RPM 2.2kW ER20

inductive endstops

good latency values mostly sub 3000ns servo

Time to create page: 0.580 seconds