Search Results (Searched for: )

- Keincncnewbie

- Keincncnewbie

24 Mar 2025 02:47

Replied by Keincncnewbie on topic 5 axis configuration.

5 axis configuration.

Category: General LinuxCNC Questions

- ContinenteCNC

24 Mar 2025 02:03 - 24 Mar 2025 02:06

Replied by ContinenteCNC on topic Need help with CNC machine build up

Need help with CNC machine build up

Category: General LinuxCNC Questions

- ric812

- ric812

24 Mar 2025 02:00 - 24 Mar 2025 02:13

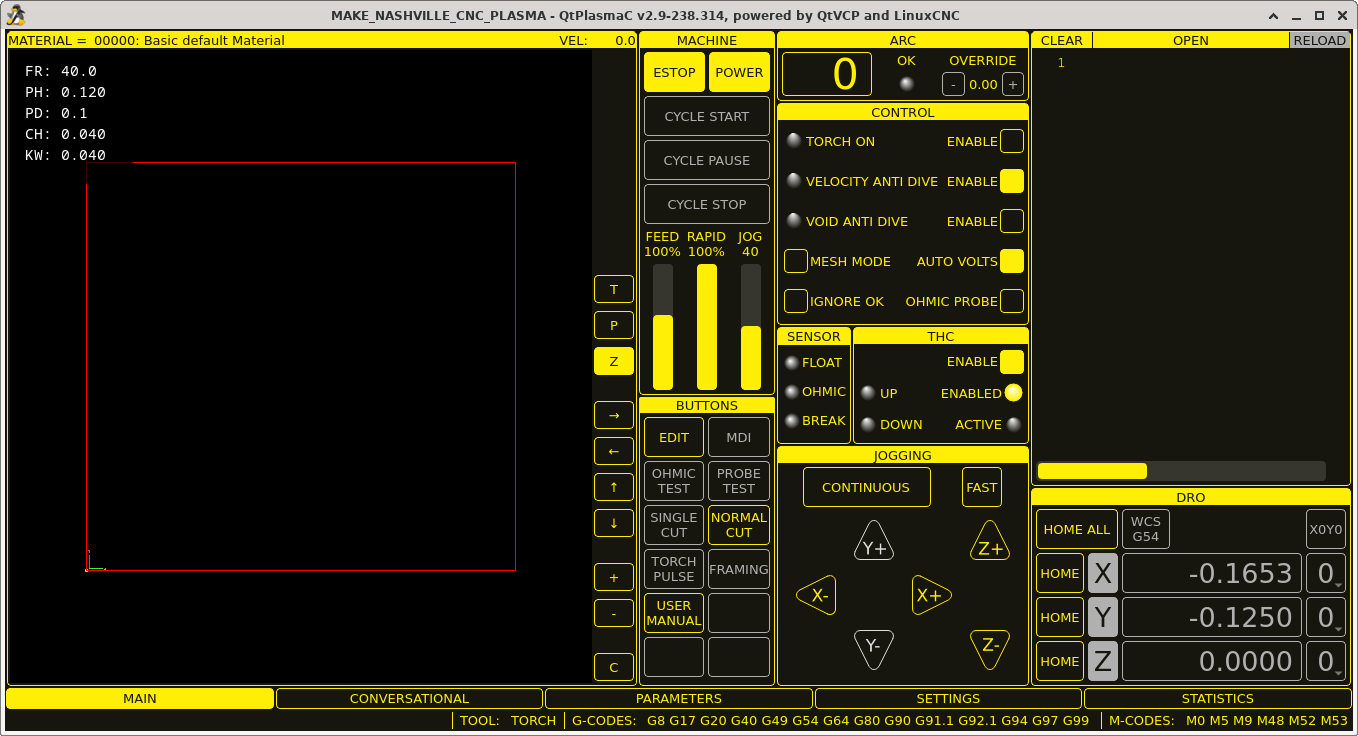

Y Axis not working in Plasmac screen was created by ric812

Y Axis not working in Plasmac screen

Category: Plasmac

- tommylight

24 Mar 2025 01:54

- ContinenteCNC

24 Mar 2025 01:44

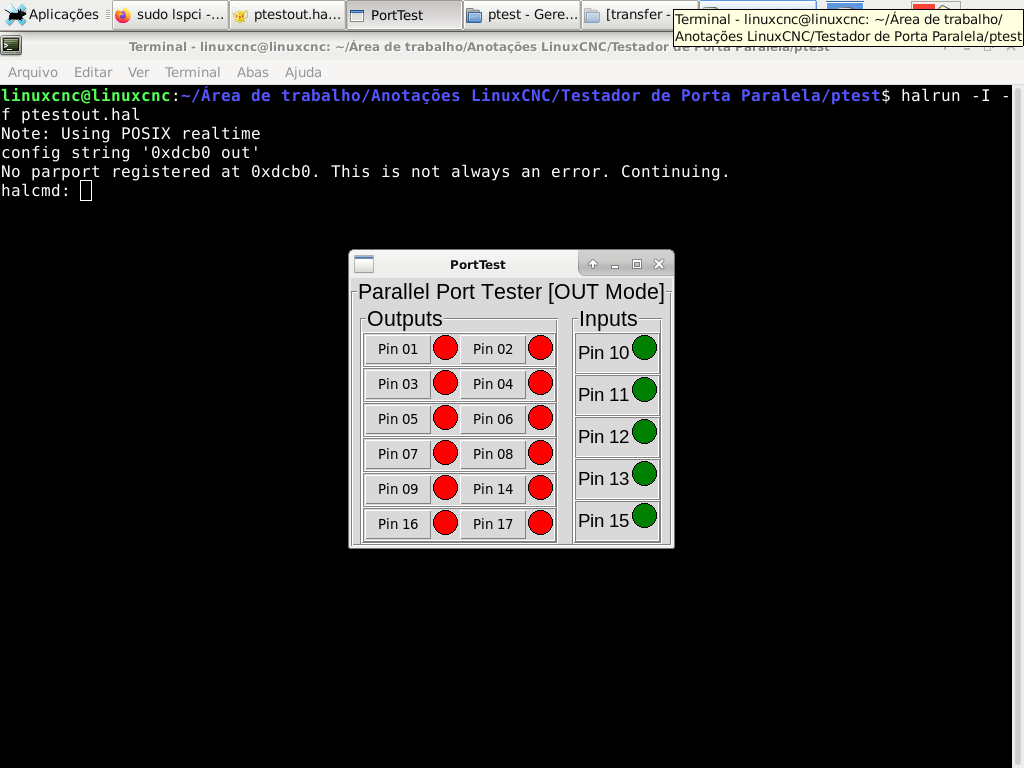

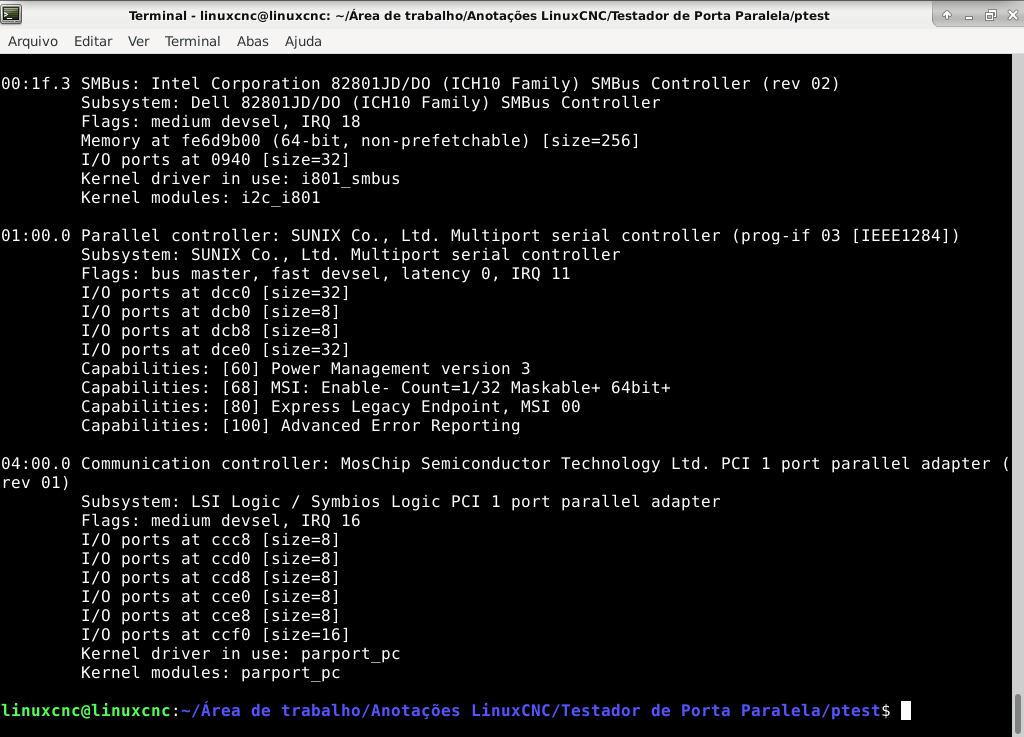

Replied by ContinenteCNC on topic PCIe - No parport registered at "0x " . This is not Always an error.Continuing.

PCIe - No parport registered at "0x " . This is not Always an error.Continuing.

Category: Advanced Configuration

- rodw

24 Mar 2025 01:39

Replied by rodw on topic Config will not open after Buildbot2 upgade from 2.9.4 to 2.10

Config will not open after Buildbot2 upgade from 2.9.4 to 2.10

Category: Plasmac

- SummerLotus

- SummerLotus

24 Mar 2025 01:37

Replied by SummerLotus on topic Regarding the question of following control on the assembly line

Regarding the question of following control on the assembly line

Category: General LinuxCNC Questions

- ContinenteCNC

24 Mar 2025 01:37

Replied by ContinenteCNC on topic PCIe - No parport registered at "0x " . This is not Always an error.Continuing.

PCIe - No parport registered at "0x " . This is not Always an error.Continuing.

Category: Advanced Configuration

- tommylight

24 Mar 2025 00:33

Replied by tommylight on topic Script to update 2.9.x ISO to use Linuxcnc Version 2.10 (master branch)

Script to update 2.9.x ISO to use Linuxcnc Version 2.10 (master branch)

Category: Installing LinuxCNC

- rodw

23 Mar 2025 23:57 - 31 Mar 2025 08:22

- tommylight

23 Mar 2025 23:30

Replied by tommylight on topic Linux_Mint_22.1_LinuxCNC_2.10.iso

Linux_Mint_22.1_LinuxCNC_2.10.iso

Category: Installing LinuxCNC

- tommylight

23 Mar 2025 22:41

Replied by tommylight on topic Send emails / txts notifications from gcode.

Send emails / txts notifications from gcode.

Category: PathPilot

- tommylight

23 Mar 2025 22:38

- chrisfischer

- chrisfischer

23 Mar 2025 22:35

Replied by chrisfischer on topic Send emails / txts notifications from gcode.

Send emails / txts notifications from gcode.

Category: PathPilot

- tommylight

23 Mar 2025 22:31

Replied by tommylight on topic Raspberry Pi 4 and bad latency.. SOLUTIONS?

Raspberry Pi 4 and bad latency.. SOLUTIONS?

Category: Installing LinuxCNC

Time to create page: 0.377 seconds