Search Results (Searched for: )

- Sandro

- Sandro

10 Feb 2025 17:32 - 10 Feb 2025 17:33

Replied by Sandro on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- unknown

- unknown

10 Feb 2025 17:05

Replied by unknown on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- NT4Boy

- NT4Boy

10 Feb 2025 16:59 - 10 Feb 2025 17:00

Replied by NT4Boy on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- Todd Zuercher

10 Feb 2025 16:46

- IB_CnC

- IB_CnC

10 Feb 2025 16:43 - 10 Feb 2025 16:52

Replied by IB_CnC on topic ProbeBasic and sidemount, retractable 3D Probe

ProbeBasic and sidemount, retractable 3D Probe

Category: QtPyVCP

- MaHa

- MaHa

10 Feb 2025 16:34

- tommylight

10 Feb 2025 16:15

Replied by tommylight on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- Hakan

- Hakan

10 Feb 2025 16:05

- Hakan

- Hakan

10 Feb 2025 16:01

Replied by Hakan on topic Ethercat + step/dir signals

Ethercat + step/dir signals

Category: EtherCAT

- Reddiamonduk

- Reddiamonduk

10 Feb 2025 15:59 - 10 Feb 2025 23:15

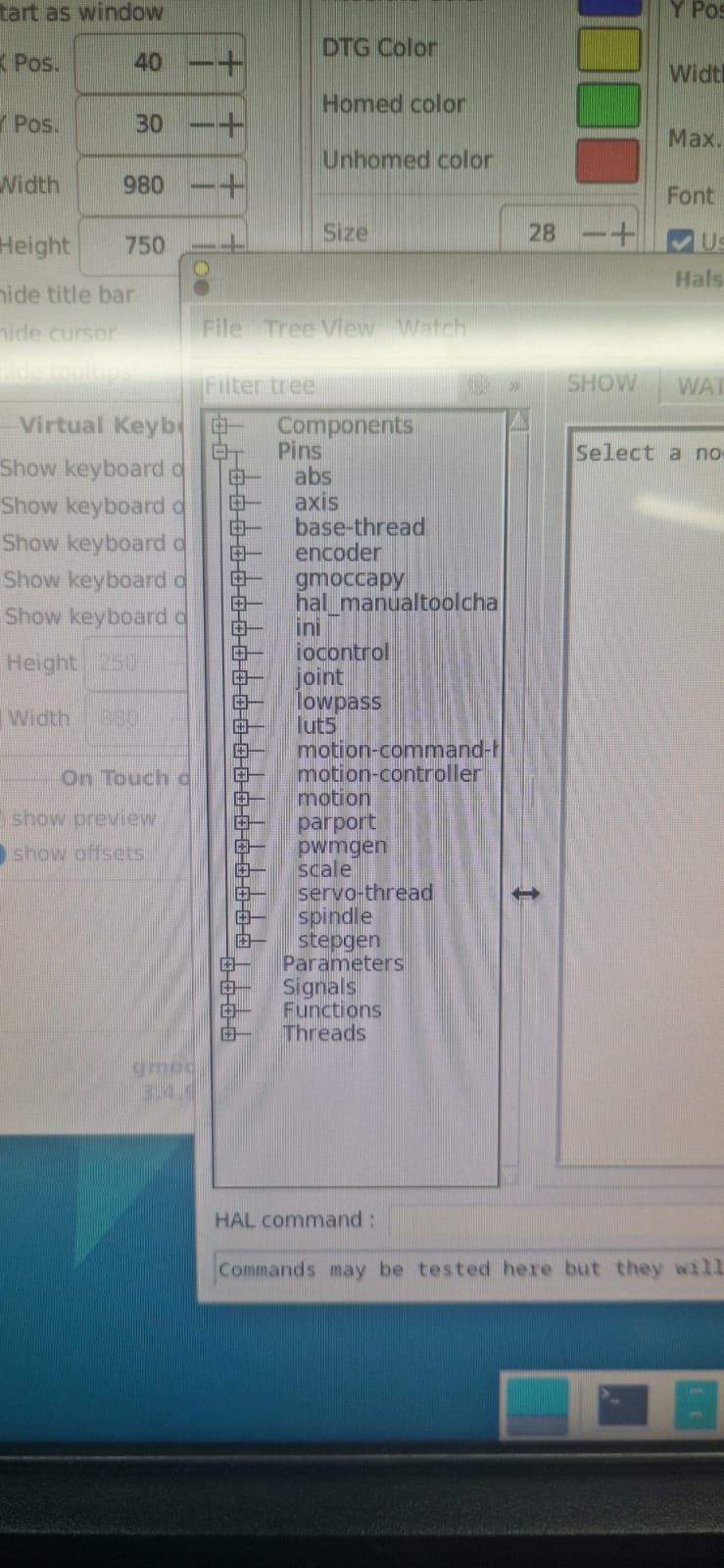

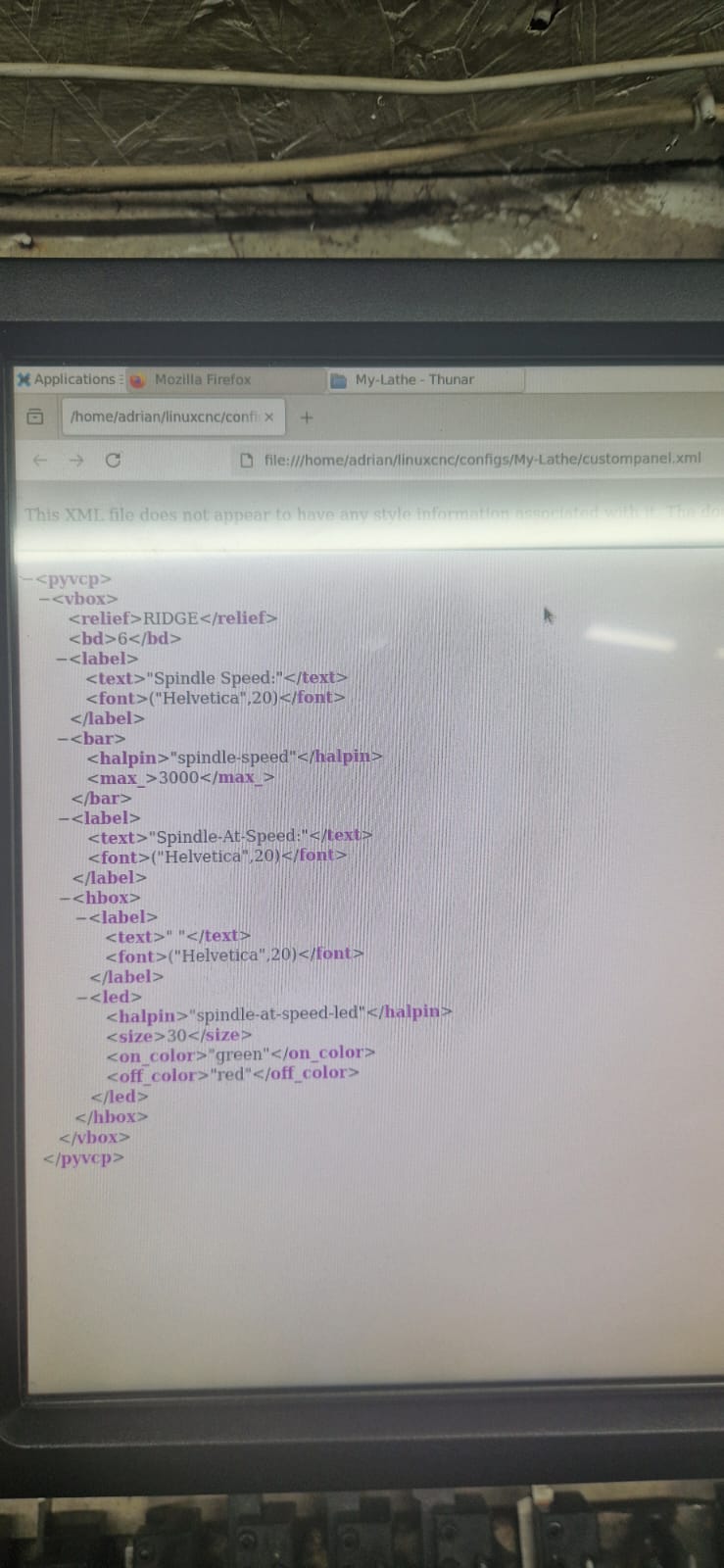

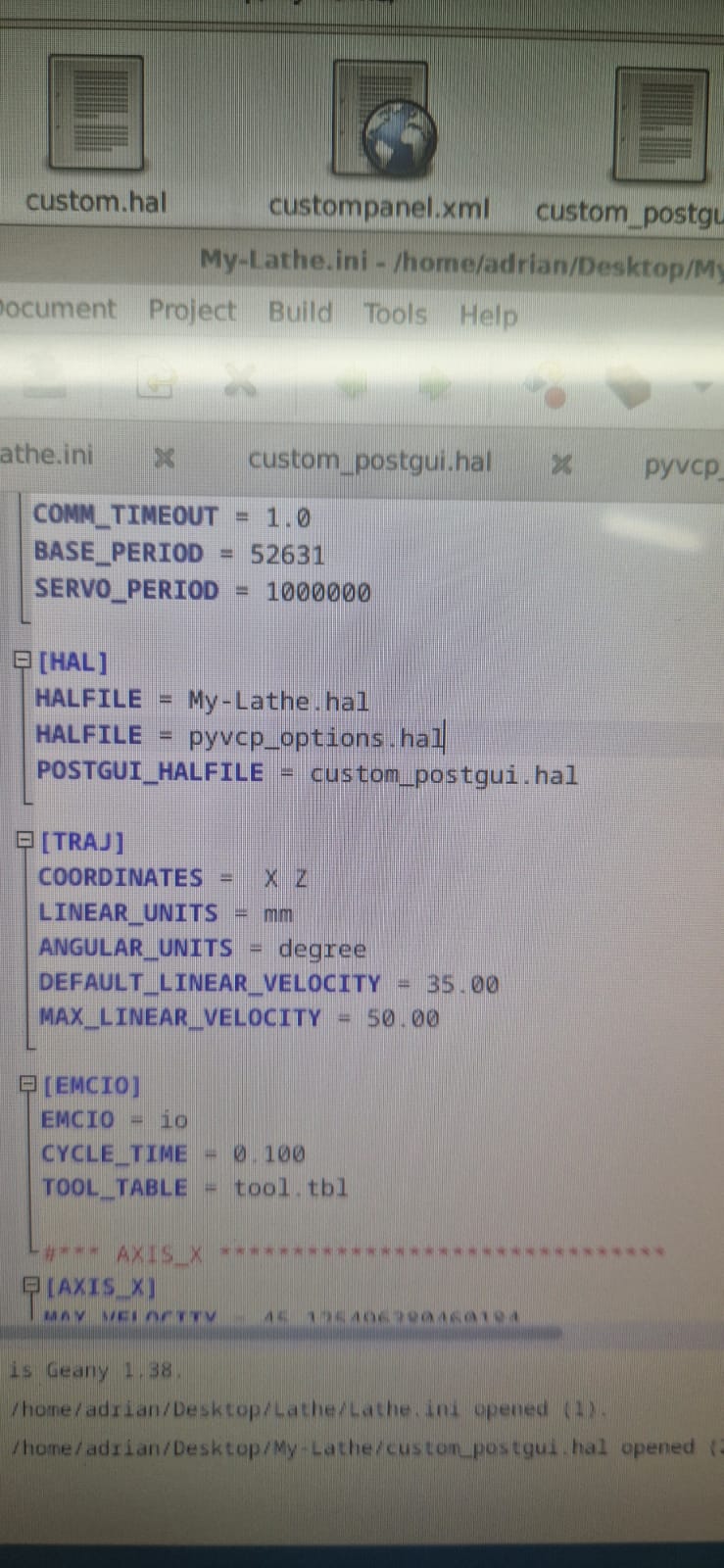

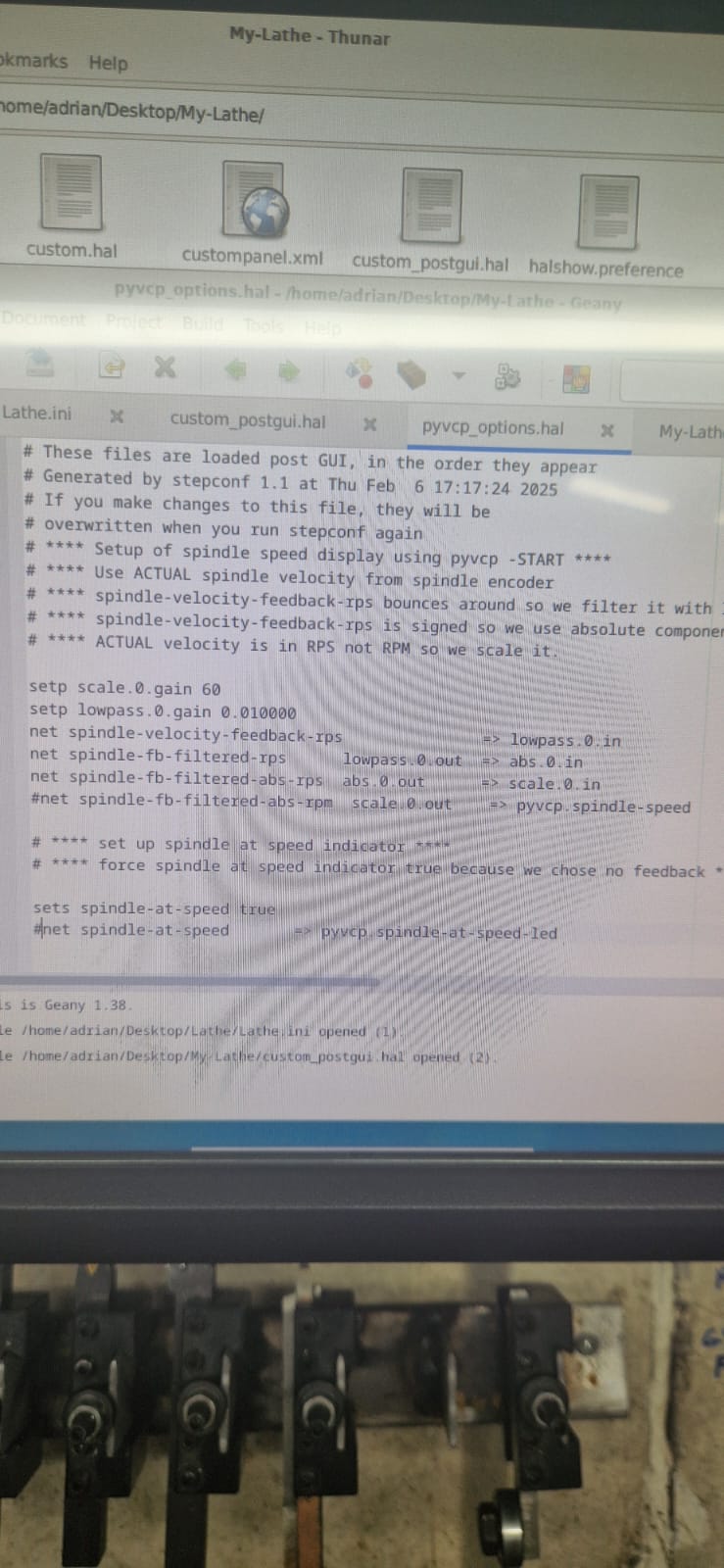

Replied by Reddiamonduk on topic Error starting gmoccapy with spindle speed display.

Error starting gmoccapy with spindle speed display.

Category: pyVCP

- CADdy

10 Feb 2025 15:34

Replied by CADdy on topic Ethercat + step/dir signals

Ethercat + step/dir signals

Category: EtherCAT

- spontarelliam

- spontarelliam

10 Feb 2025 15:24

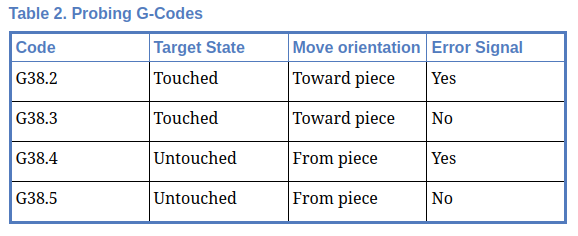

Z probing with G38.4 was created by spontarelliam

Z probing with G38.4

Category: Advanced Configuration

- PCW

10 Feb 2025 15:18

Replied by PCW on topic need help! mesa 7i95 connection problem

need help! mesa 7i95 connection problem

Category: Driver Boards

- Todd Zuercher

10 Feb 2025 14:58

- noqui

- noqui

10 Feb 2025 14:16

error running telnet using linuxcncrsh was created by noqui

error running telnet using linuxcncrsh

Category: General LinuxCNC Questions

Time to create page: 0.569 seconds