Search Results (Searched for: )

- PCW

07 Feb 2025 15:31

Replied by PCW on topic 7i96s Replacement Needed

7i96s Replacement Needed

Category: General LinuxCNC Questions

- tommy

- tommy

07 Feb 2025 15:15

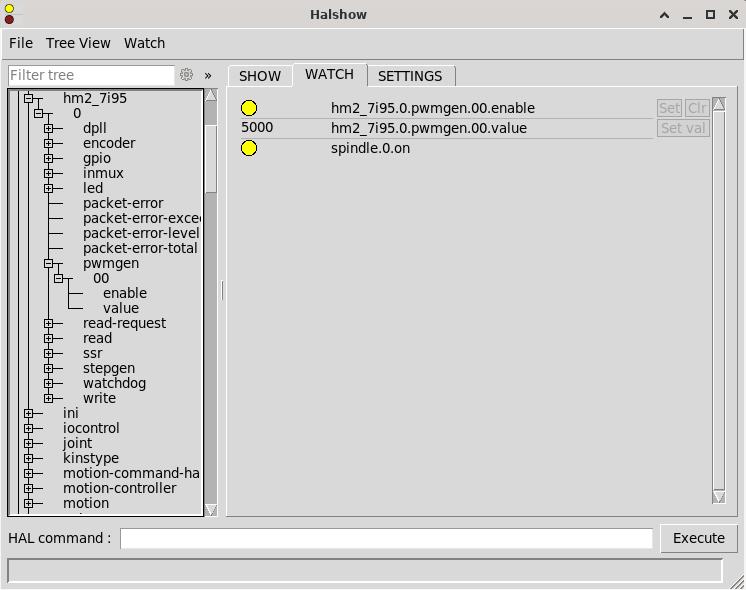

Replied by tommy on topic 7i95T + 7i78 spindle configuration

7i95T + 7i78 spindle configuration

Category: Basic Configuration

- Sandro

- Sandro

07 Feb 2025 15:02 - 07 Feb 2025 15:08

- slowpoke

- slowpoke

07 Feb 2025 14:31

Replied by slowpoke on topic Indivudual home buttons - EMC2-Axis

Indivudual home buttons - EMC2-Axis

Category: General LinuxCNC Questions

- cakeslob

- cakeslob

07 Feb 2025 14:21

Replied by cakeslob on topic Indivudual home buttons - EMC2-Axis

Indivudual home buttons - EMC2-Axis

Category: General LinuxCNC Questions

- tommylight

07 Feb 2025 13:10

Replied by tommylight on topic 7i96s Replacement Needed

7i96s Replacement Needed

Category: General LinuxCNC Questions

- beauxnez

- beauxnez

07 Feb 2025 13:09

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- tommylight

07 Feb 2025 13:05

Replied by tommylight on topic Tandem Motor Free to Turn - Mesa 7i96s

Tandem Motor Free to Turn - Mesa 7i96s

Category: Basic Configuration

- unknown

- unknown

07 Feb 2025 12:31

Replied by unknown on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- Grotius

07 Feb 2025 12:20

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- jhandel

- jhandel

07 Feb 2025 12:17

Replied by jhandel on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- Grad

- Grad

07 Feb 2025 11:20

Replied by Grad on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- GeckoWorks

- GeckoWorks

07 Feb 2025 10:24

Replied by GeckoWorks on topic Index homing Mesa 7i96s

Index homing Mesa 7i96s

Category: PnCConf Wizard

- babinda01

- babinda01

07 Feb 2025 10:24

Replied by babinda01 on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- unknown

- unknown

07 Feb 2025 10:16

Replied by unknown on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

Time to create page: 0.463 seconds