Search Results (Searched for: )

- Cant do this anymore bye all

17 Jan 2025 07:58 - 17 Jan 2025 08:22

Replied by Cant do this anymore bye all on topic LinuxCNC on Intel Clear Linux

LinuxCNC on Intel Clear Linux

Category: Installing LinuxCNC

- hmnijp

- hmnijp

17 Jan 2025 07:56

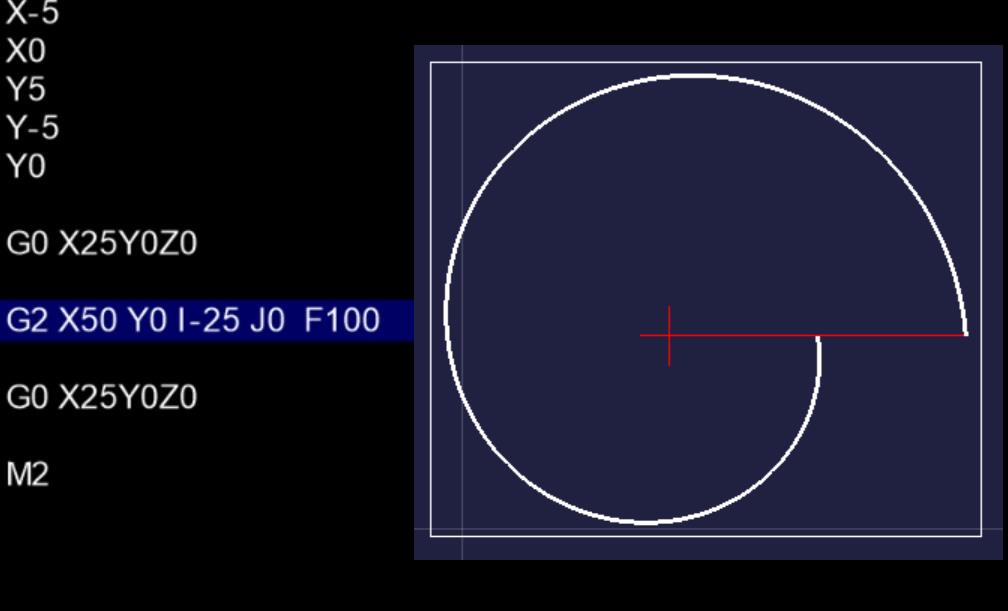

Replied by hmnijp on topic Error message "Radius to end of arc differs....etc etc"

Error message "Radius to end of arc differs....etc etc"

Category: General LinuxCNC Questions

- besriworld

- besriworld

17 Jan 2025 07:50

Replied by besriworld on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- Gautham

- Gautham

17 Jan 2025 06:30

Replied by Gautham on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- xenon-alien

17 Jan 2025 06:21 - 17 Jan 2025 07:02

Replied by xenon-alien on topic Carousel with step motor

Carousel with step motor

Category: Advanced Configuration

- rebelx

- rebelx

17 Jan 2025 05:54

Replied by rebelx on topic LinuxCNC on Intel Clear Linux

LinuxCNC on Intel Clear Linux

Category: Installing LinuxCNC

- tommylight

17 Jan 2025 02:38

Replied by tommylight on topic Path display glitching - QTPlasmaC - v1.235.265 QtVCP LinuxCNC v2.9.0

Path display glitching - QTPlasmaC - v1.235.265 QtVCP LinuxCNC v2.9.0

Category: Plasmac

- Thayloreing

- Thayloreing

17 Jan 2025 02:07

help to compensate for changes in the rack was created by Thayloreing

help to compensate for changes in the rack

Category: Advanced Configuration

- smc.collins

- smc.collins

17 Jan 2025 01:17

Replied by smc.collins on topic M6 Remap Lathe (Remap T & ignore M6)

M6 Remap Lathe (Remap T & ignore M6)

Category: General LinuxCNC Questions

- rodw

17 Jan 2025 01:16

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- phillc54

17 Jan 2025 00:48

Replied by phillc54 on topic Error message "Radius to end of arc differs....etc etc"

Error message "Radius to end of arc differs....etc etc"

Category: General LinuxCNC Questions

- rodw

17 Jan 2025 00:42

- Tntmold

- Tntmold

16 Jan 2025 22:48

Replied by Tntmold on topic Ethercat build from source - full instructions

Ethercat build from source - full instructions

Category: EtherCAT

- Yaroslav

- Yaroslav

16 Jan 2025 21:38

Replied by Yaroslav on topic M6 Remap Lathe (Remap T & ignore M6)

M6 Remap Lathe (Remap T & ignore M6)

Category: General LinuxCNC Questions

- spumco

- spumco

16 Jan 2025 21:08

Replied by spumco on topic Carousel with step motor

Carousel with step motor

Category: Advanced Configuration

Time to create page: 0.442 seconds