Search Results (Searched for: )

- Sternfox

- Sternfox

16 Jan 2025 12:06

- programador

16 Jan 2025 11:59

- spumco

- spumco

16 Jan 2025 11:42

Replied by spumco on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- rodw

16 Jan 2025 11:10

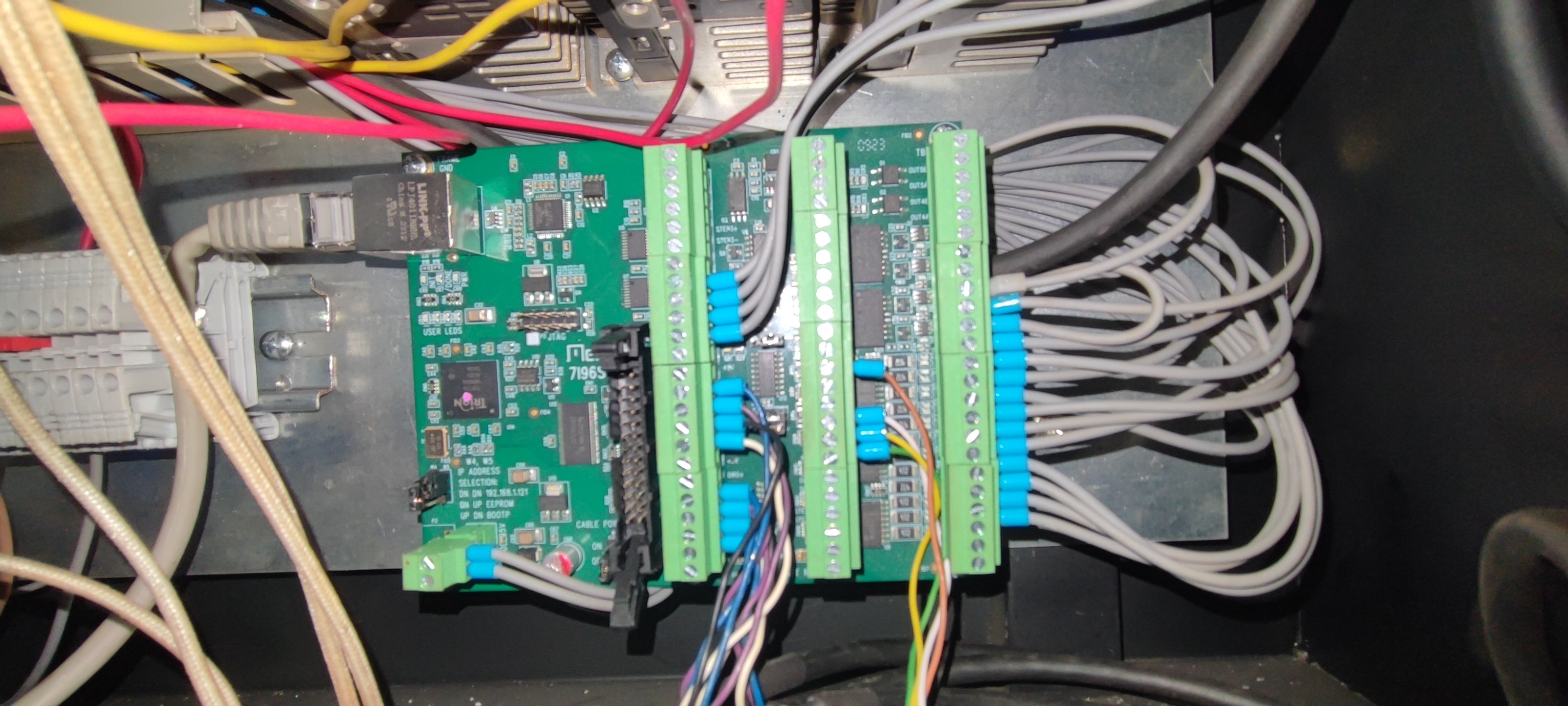

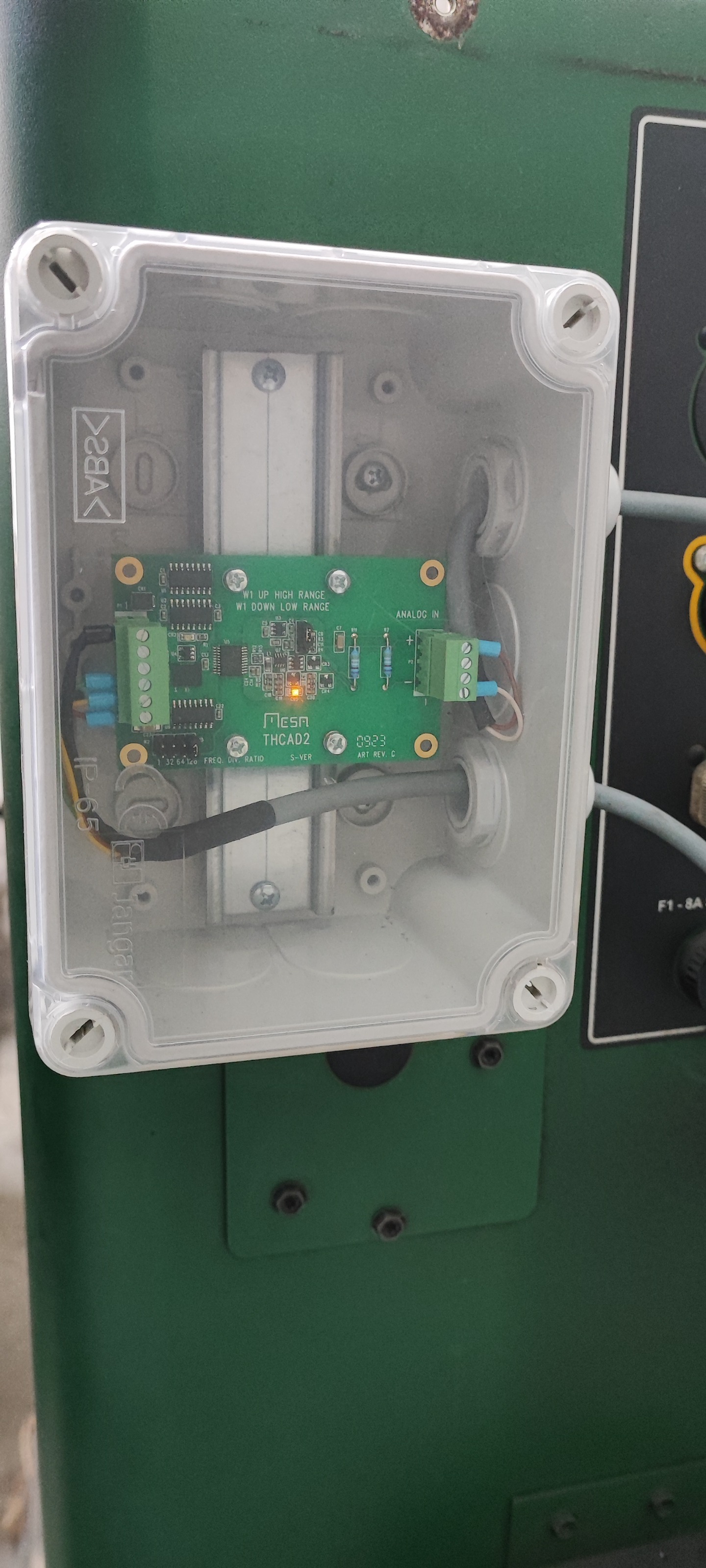

Replied by rodw on topic 7i96s Arc Voltage + Encoder Fault

7i96s Arc Voltage + Encoder Fault

Category: Plasma & Laser

- timo

- timo

16 Jan 2025 11:04 - 16 Jan 2025 11:09

- KrisR

- KrisR

16 Jan 2025 10:22

- Gautham

- Gautham

16 Jan 2025 09:39

Replied by Gautham on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- hellvetica

- hellvetica

16 Jan 2025 09:38

Replied by hellvetica on topic Using G64 with M66 for smooth robot control

Using G64 with M66 for smooth robot control

Category: General LinuxCNC Questions

- Gautham

- Gautham

16 Jan 2025 09:37

Replied by Gautham on topic Ballscrew articulation, has anybody had success?

Ballscrew articulation, has anybody had success?

Category: General LinuxCNC Questions

- sharp_reaper

- sharp_reaper

16 Jan 2025 09:23

Replied by sharp_reaper on topic 7i96s Arc Voltage + Encoder Fault

7i96s Arc Voltage + Encoder Fault

Category: Plasma & Laser

- gekonko

16 Jan 2025 09:14

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

Error message "Radius to end of arc differs....etc etc"

Category: General LinuxCNC Questions

- Gautham

- Gautham

16 Jan 2025 09:12

Replied by Gautham on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- besriworld

- besriworld

16 Jan 2025 08:35

Replied by besriworld on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- chrischan

- chrischan

16 Jan 2025 08:26

Replied by chrischan on topic Maus funktioniert nicht bei Spindel Start

Maus funktioniert nicht bei Spindel Start

Category: Deutsch

- Gautham

- Gautham

16 Jan 2025 08:16

Rotating Axis Controlled by a Ballscrew was created by Gautham

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

Time to create page: 0.490 seconds