Search Results (Searched for: )

- Artur_1617

15 Jan 2025 19:08 - 15 Jan 2025 19:09

Replied by Artur_1617 on topic linuxcnc 2.9.2/2.9.3 toolchanger problem

linuxcnc 2.9.2/2.9.3 toolchanger problem

Category: Advanced Configuration

- Aciera

15 Jan 2025 18:09 - 15 Jan 2025 18:11

Replied by Aciera on topic linuxcnc 2.9.2/2.9.3 toolchanger problem

linuxcnc 2.9.2/2.9.3 toolchanger problem

Category: Advanced Configuration

- programador

15 Jan 2025 18:07

- DieLimo

- DieLimo

15 Jan 2025 18:01

Replied by DieLimo on topic Coordinate system in GUI does not match machine

Coordinate system in GUI does not match machine

Category: Basic Configuration

- Aciera

15 Jan 2025 17:59

- R0ttencandy

- R0ttencandy

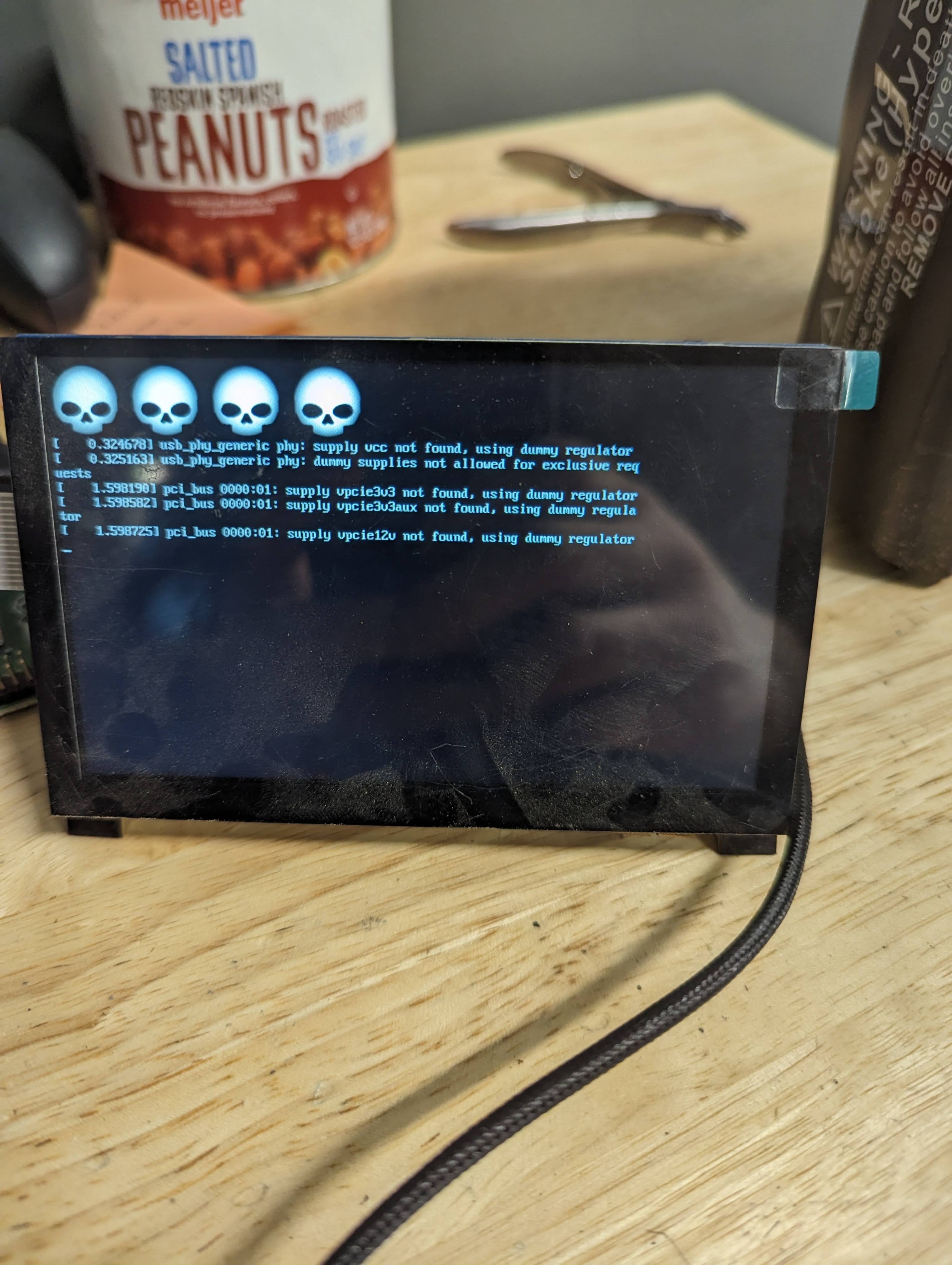

15 Jan 2025 17:22 - 15 Jan 2025 18:00

Replied by R0ttencandy on topic Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Category: Installing LinuxCNC

- Artur_1617

15 Jan 2025 16:33 - 15 Jan 2025 16:37

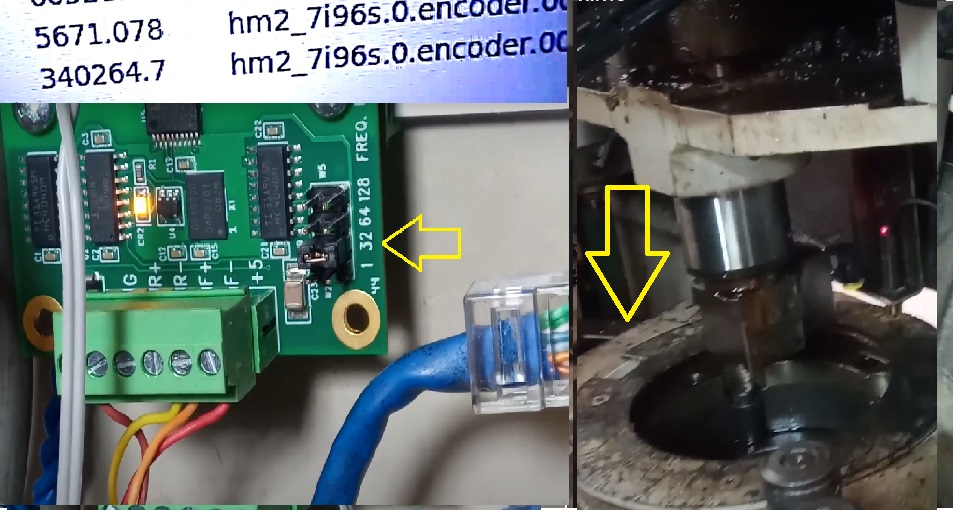

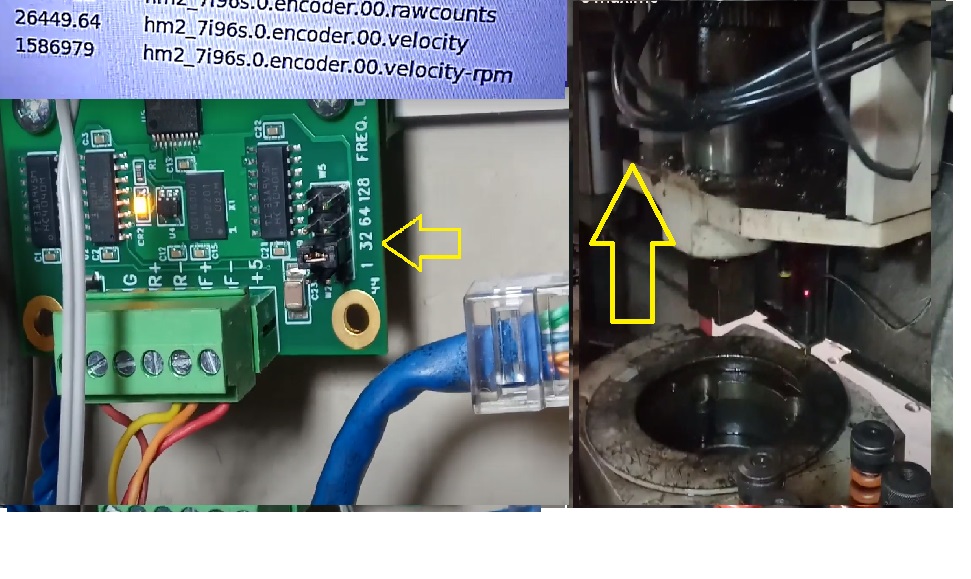

Replied by Artur_1617 on topic linuxcnc 2.9.2/2.9.3 toolchanger problem

linuxcnc 2.9.2/2.9.3 toolchanger problem

Category: Advanced Configuration

- Martin.L

- Martin.L

15 Jan 2025 16:27 - 15 Jan 2025 16:36

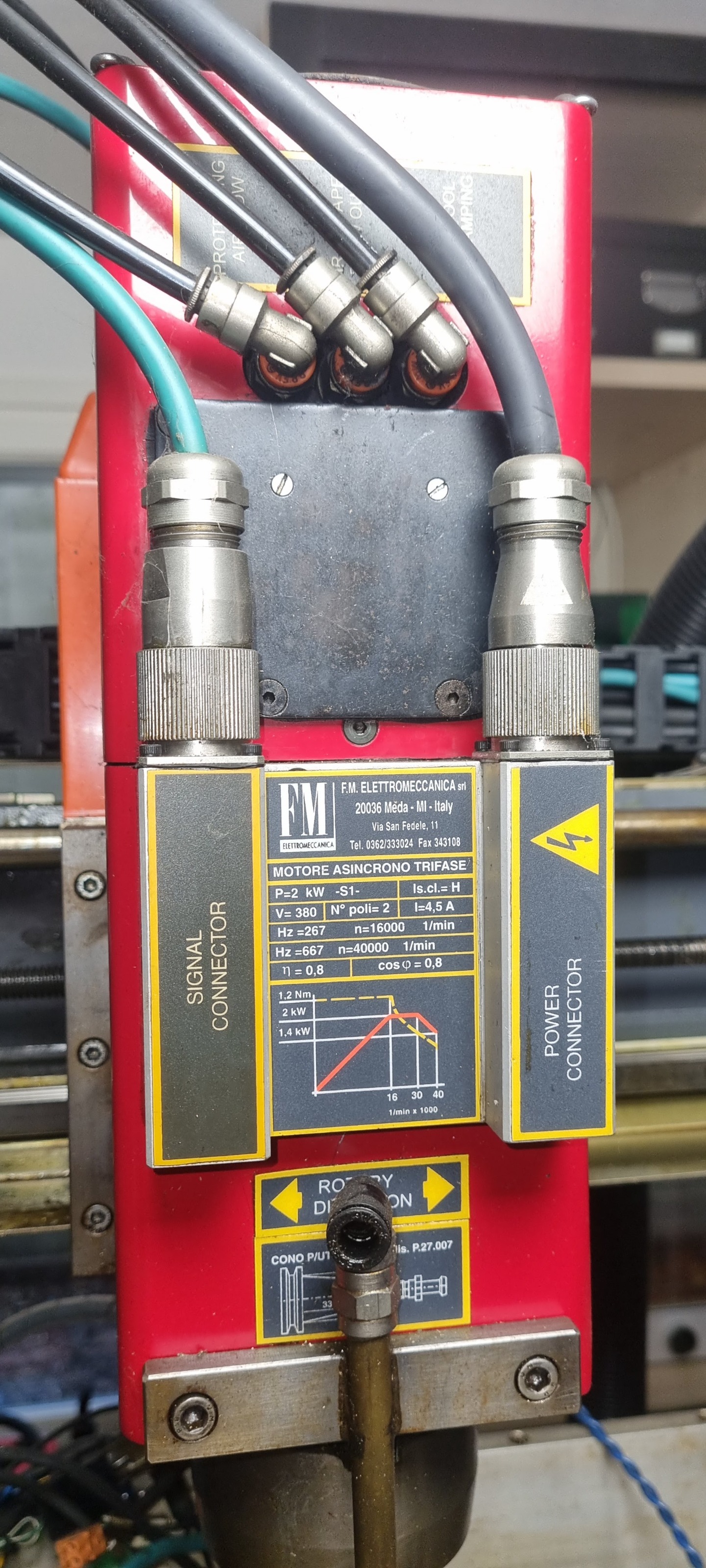

MS300 with CMM-EC02 to retrofit an existing electrospindle spindle was created by Martin.L

MS300 with CMM-EC02 to retrofit an existing electrospindle spindle

Category: EtherCAT

- KrisR

- KrisR

15 Jan 2025 16:24

- Plasmanfm

- Plasmanfm

15 Jan 2025 16:22 - 15 Jan 2025 16:28

Replied by Plasmanfm on topic Maus funktioniert nicht bei Spindel Start

Maus funktioniert nicht bei Spindel Start

Category: Deutsch

- PCW

15 Jan 2025 16:02 - 16 Jan 2025 00:22

- Aciera

15 Jan 2025 15:18 - 15 Jan 2025 15:22

Replied by Aciera on topic Using G64 with M66 for smooth robot control

Using G64 with M66 for smooth robot control

Category: General LinuxCNC Questions

- PCW

15 Jan 2025 15:13 - 15 Jan 2025 15:46

- Aciera

15 Jan 2025 15:07

Replied by Aciera on topic LinuxCNC with OKUMA OSP MX-55VA

LinuxCNC with OKUMA OSP MX-55VA

Category: Basic Configuration

- PCW

15 Jan 2025 15:02

Time to create page: 0.492 seconds