Search Results (Searched for: )

- gbestwick

- gbestwick

11 Dec 2024 22:53 - 11 Dec 2024 22:55

Issue with halcmd show pin not showing pins. was created by gbestwick

Issue with halcmd show pin not showing pins.

Category: EtherCAT

- Masterdrive

- Masterdrive

11 Dec 2024 21:41

Replied by Masterdrive on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- gardenweazel

11 Dec 2024 21:27

- gardenweazel

11 Dec 2024 21:23

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- cmorley

- cmorley

11 Dec 2024 20:47

- schnellmued

- schnellmued

11 Dec 2024 19:51

Replied by schnellmued on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- fully_defined

11 Dec 2024 18:10

Replied by fully_defined on topic Rotary Selector Switches & Resistors

Rotary Selector Switches & Resistors

Category: General LinuxCNC Questions

- gardenweazel

11 Dec 2024 17:48 - 11 Dec 2024 17:58

- macrimarco001

- macrimarco001

11 Dec 2024 17:18 - 11 Dec 2024 19:06

Replied by macrimarco001 on topic Newbie looking for a hardware configuration based on Raspberry Pi

Newbie looking for a hardware configuration based on Raspberry Pi

Category: Computers and Hardware

- gilesclement

- gilesclement

11 Dec 2024 16:18

Replied by gilesclement on topic Mill Single Point Spline Broaching - Spindle Orient?

Mill Single Point Spline Broaching - Spindle Orient?

Category: Advanced Configuration

- PCW

11 Dec 2024 15:23

Replied by PCW on topic Changing stepgen position-scale parameter dynamically

Changing stepgen position-scale parameter dynamically

Category: Basic Configuration

- Lcvette

11 Dec 2024 15:15 - 11 Dec 2024 15:44

- Lcvette

11 Dec 2024 14:58

- Lcvette

11 Dec 2024 14:54

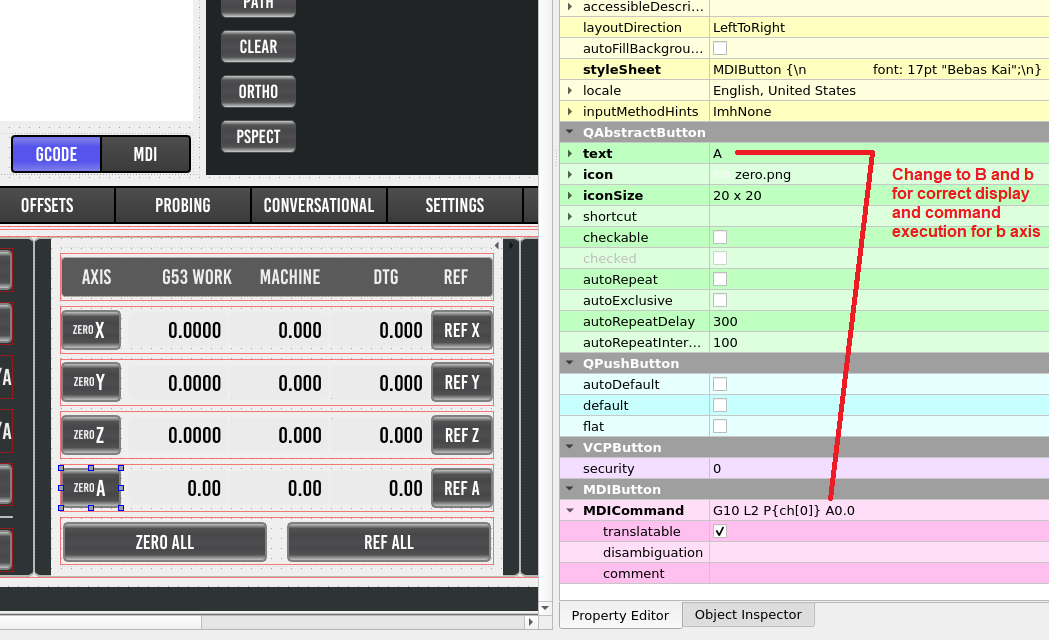

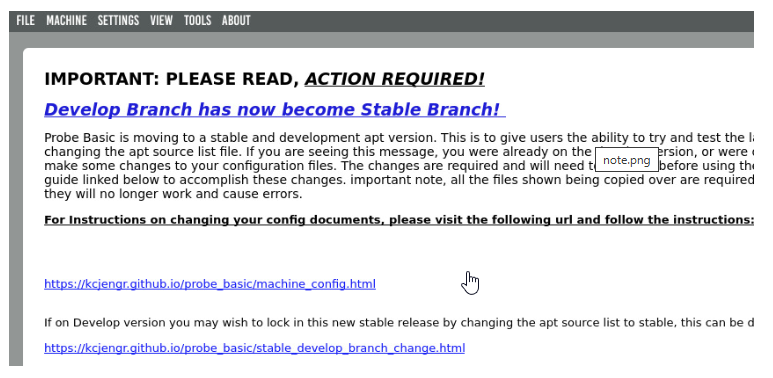

Replied by Lcvette on topic Probe Basic is splitting into Stable and Develop apt branch

Probe Basic is splitting into Stable and Develop apt branch

Category: QtPyVCP

Time to create page: 0.699 seconds