Search Results (Searched for: )

- kbec

- kbec

21 Oct 2024 17:52

Help with probe/tool setter in qtdragon was created by kbec

Help with probe/tool setter in qtdragon

Category: Other User Interfaces

- martin2day

- martin2day

21 Oct 2024 17:46

- gardenweazel

21 Oct 2024 17:19

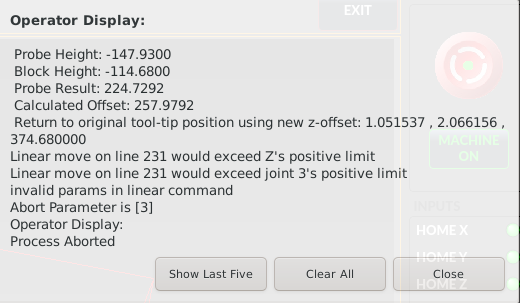

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- gardenweazel

21 Oct 2024 17:17

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- Grotius

21 Oct 2024 17:14

Replied by Grotius on topic c++ compiling error

c++ compiling error

Category: Advanced Configuration

- Grotius

21 Oct 2024 16:49

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- PCW

21 Oct 2024 16:47

Replied by PCW on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- vmihalca

- vmihalca

21 Oct 2024 16:23

Replied by vmihalca on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- Macwolf

- Macwolf

21 Oct 2024 16:15

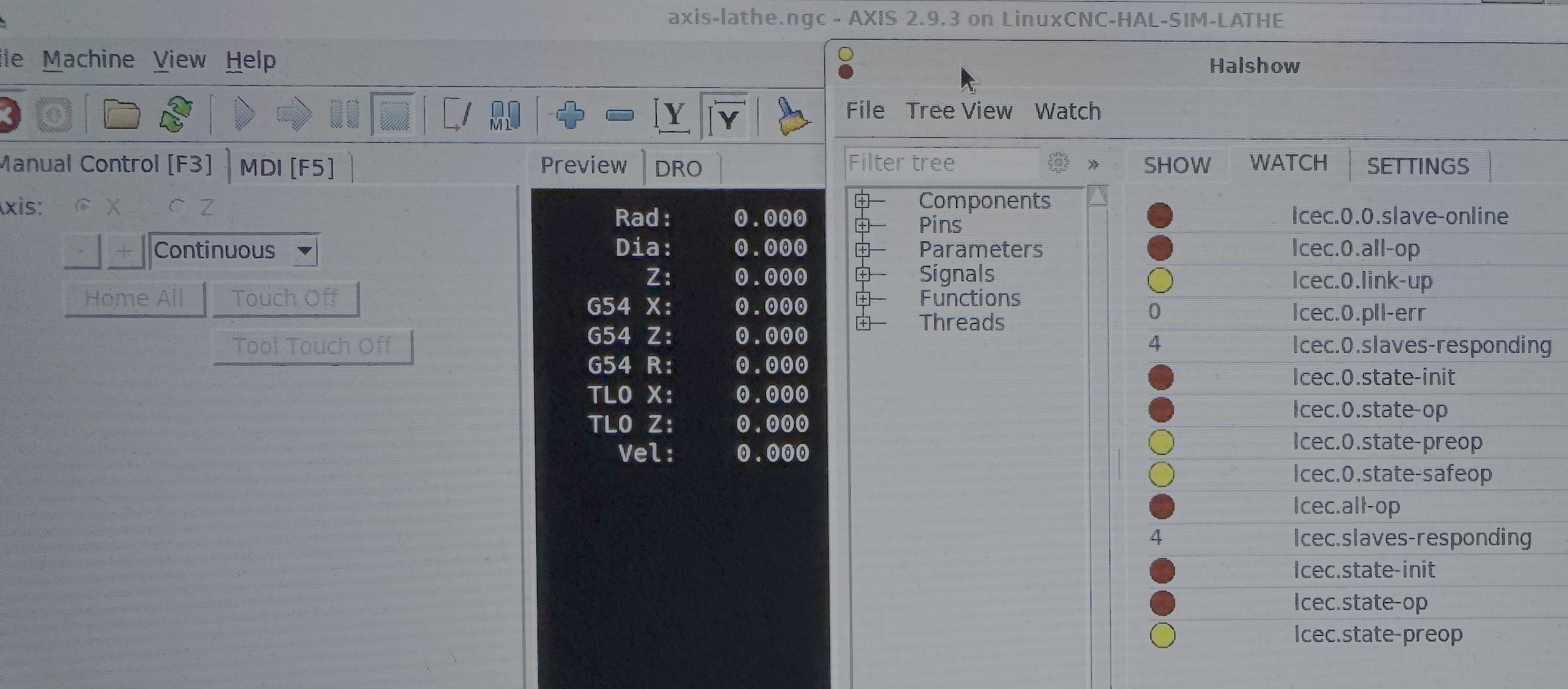

Replied by Macwolf on topic Beckhoff components crasht Linuxcnc

Beckhoff components crasht Linuxcnc

Category: EtherCAT

- Plasmanfm

- Plasmanfm

21 Oct 2024 16:10

Replied by Plasmanfm on topic G-Code Verarbeitung: Kurze Pausen zwischen Bewegungen - Wie beschleunigen?

G-Code Verarbeitung: Kurze Pausen zwischen Bewegungen - Wie beschleunigen?

Category: Deutsch

- PCW

21 Oct 2024 16:09

Replied by PCW on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- tommylight

21 Oct 2024 16:08

Replied by tommylight on topic Laser bleibt wegen M3 immer kurz stehen, wie kann man das beheben?

Laser bleibt wegen M3 immer kurz stehen, wie kann man das beheben?

Category: G&M Codes

- tommylight

21 Oct 2024 16:05

Replied by tommylight on topic Gecko 540 + Mesa 5i25 configuration.

Gecko 540 + Mesa 5i25 configuration.

Category: Basic Configuration

- tommylight

21 Oct 2024 15:53

Replied by tommylight on topic About lathe spindle encoder

About lathe spindle encoder

Category: General LinuxCNC Questions

- vmihalca

- vmihalca

21 Oct 2024 15:52

Replied by vmihalca on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

Time to create page: 0.694 seconds