Search Results (Searched for: )

- Bari

07 Jul 2024 20:34

- PCW

07 Jul 2024 20:28

- Aciera

07 Jul 2024 20:26

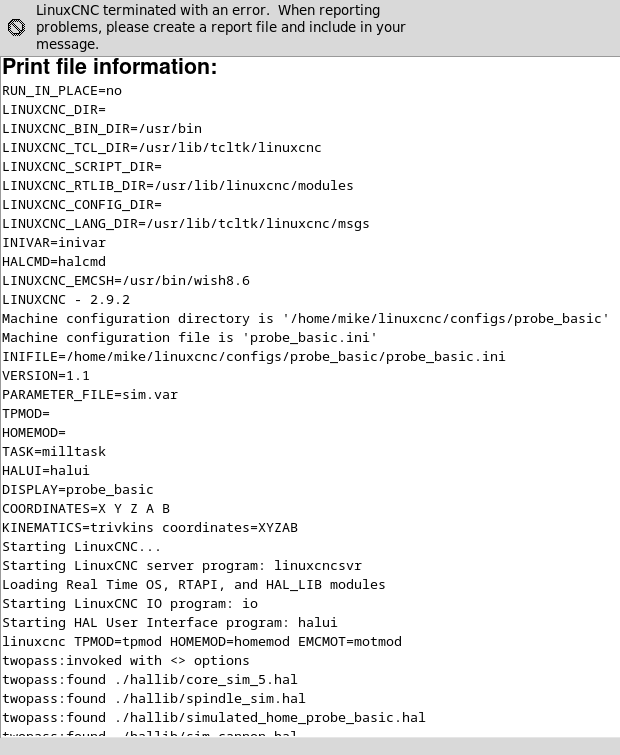

Replied by Aciera on topic Router Will not run

Router Will not run

Category: General LinuxCNC Questions

- slowpoke

- slowpoke

07 Jul 2024 20:26 - 07 Jul 2024 20:33

Replied by slowpoke on topic Data transfer LinuxCNC to / from custom board - Solved

Data transfer LinuxCNC to / from custom board - Solved

Category: Advanced Configuration

- meister

- meister

07 Jul 2024 20:24 - 07 Jul 2024 20:24

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Bari

07 Jul 2024 20:19

- Aciera

07 Jul 2024 20:11

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Bari

07 Jul 2024 20:11 - 18 Jul 2024 19:57

New and Working RTAI debs for 2.9 was created by Bari

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- Catch22

07 Jul 2024 20:03

- Ricoch3T

- Ricoch3T

07 Jul 2024 19:56

Replied by Ricoch3T on topic Newb retrofit question

Newb retrofit question

Category: General LinuxCNC Questions

- Aciera

07 Jul 2024 19:40 - 07 Jul 2024 20:17

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Aciera

07 Jul 2024 19:31 - 07 Jul 2024 20:15

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Irritant

- Irritant

07 Jul 2024 19:21

Replied by Irritant on topic Router Will not run

Router Will not run

Category: General LinuxCNC Questions

- B.Reilly01

- B.Reilly01

07 Jul 2024 19:03

- endian

07 Jul 2024 19:00 - 07 Jul 2024 19:44

Time to create page: 1.311 seconds