Search Results (Searched for: )

- R0ttencandy

- R0ttencandy

15 Jan 2025 17:22 - 15 Jan 2025 18:00

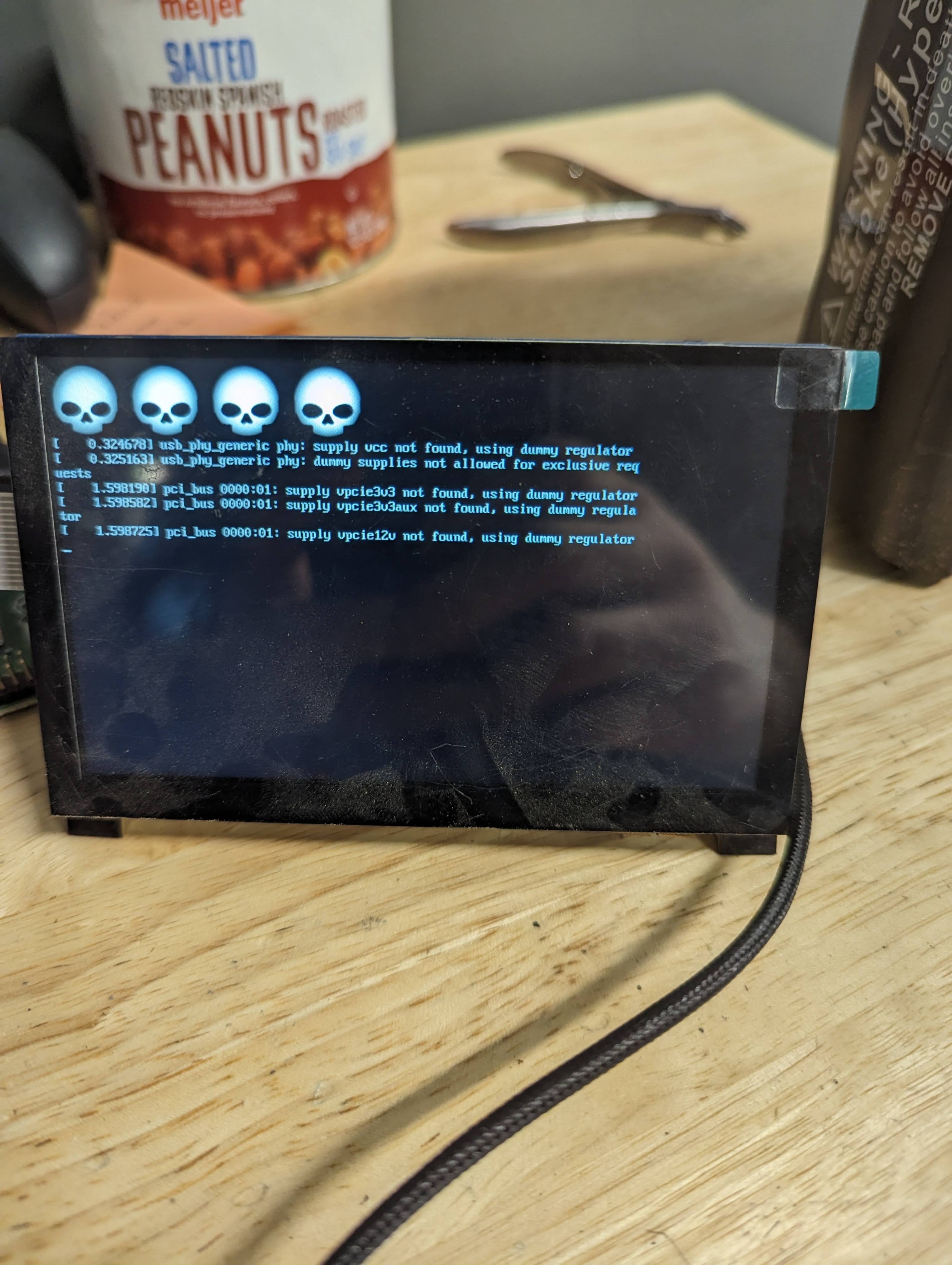

Replied by R0ttencandy on topic Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Category: Installing LinuxCNC

- Artur_1617

15 Jan 2025 16:33 - 15 Jan 2025 16:37

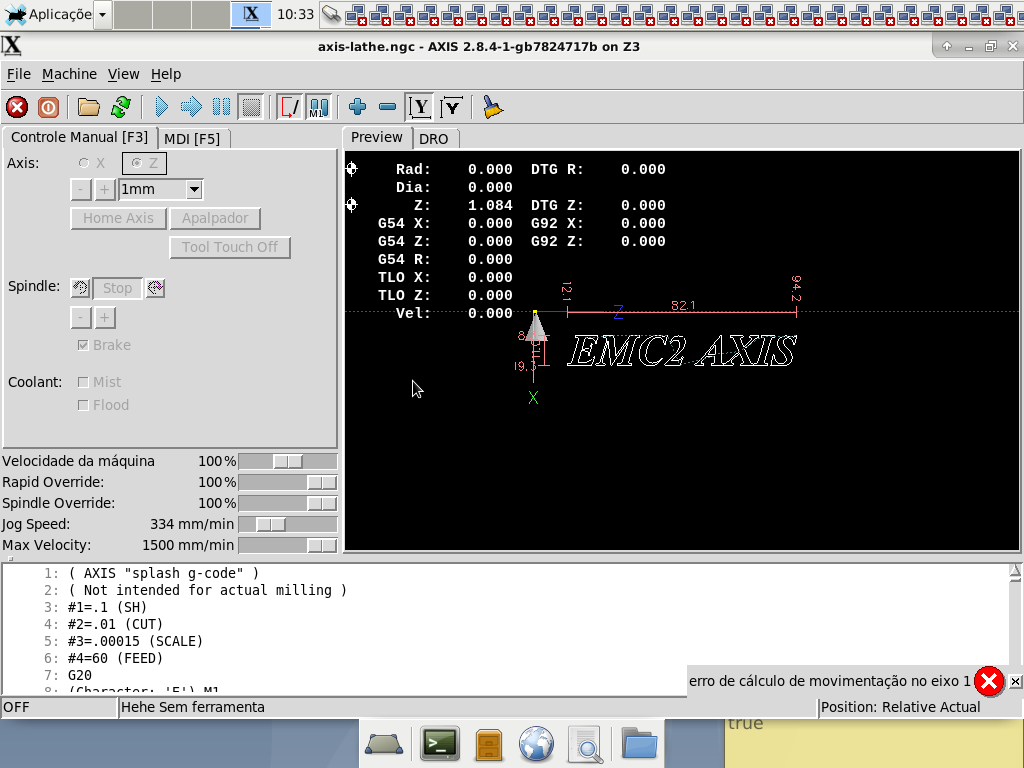

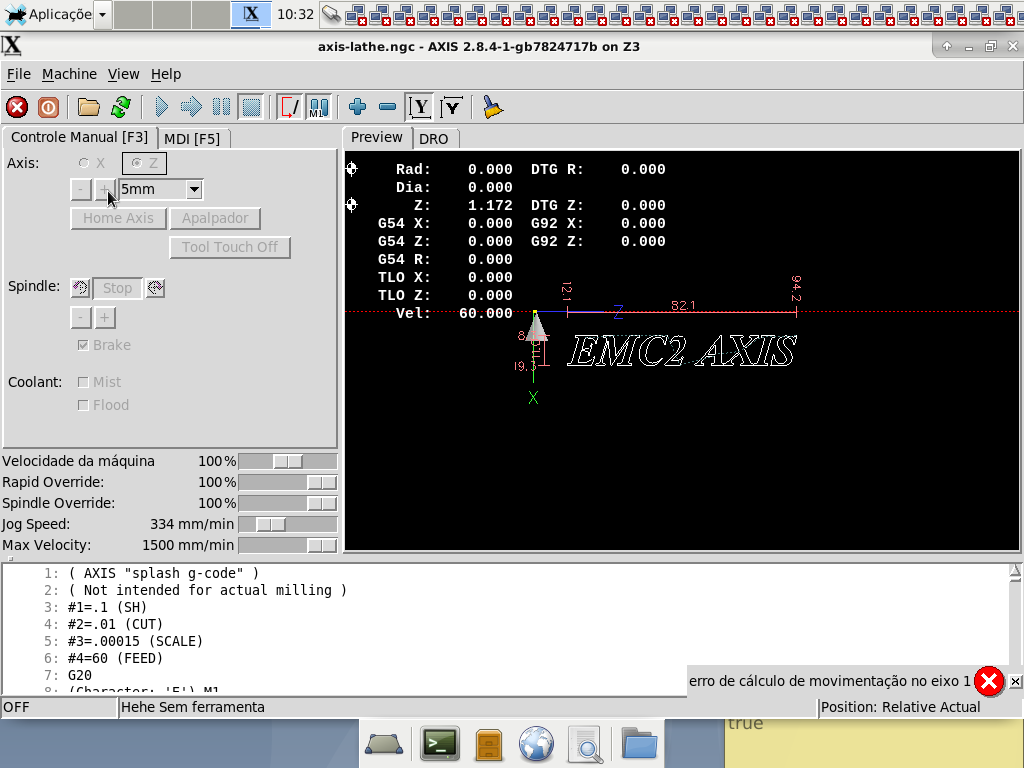

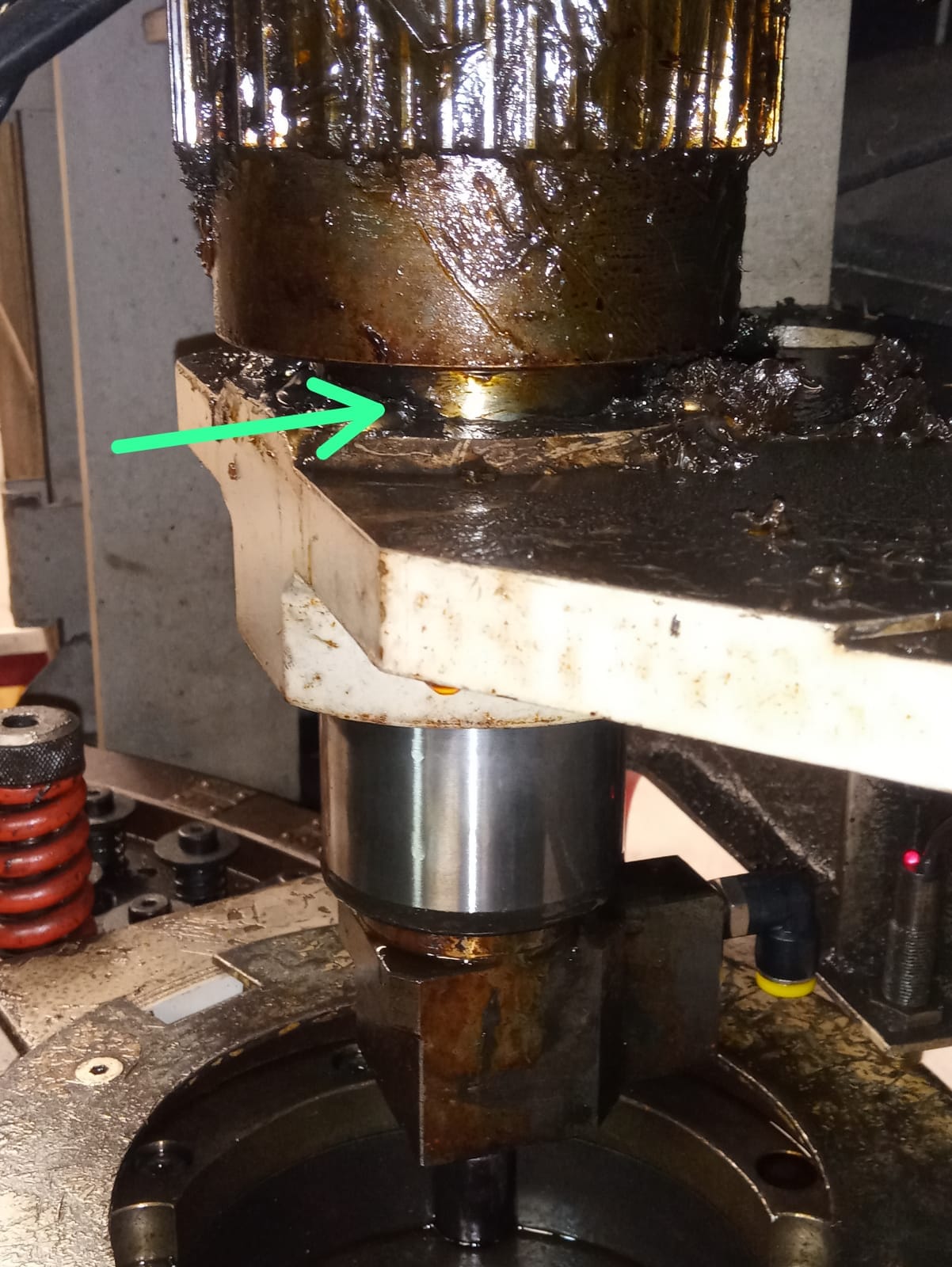

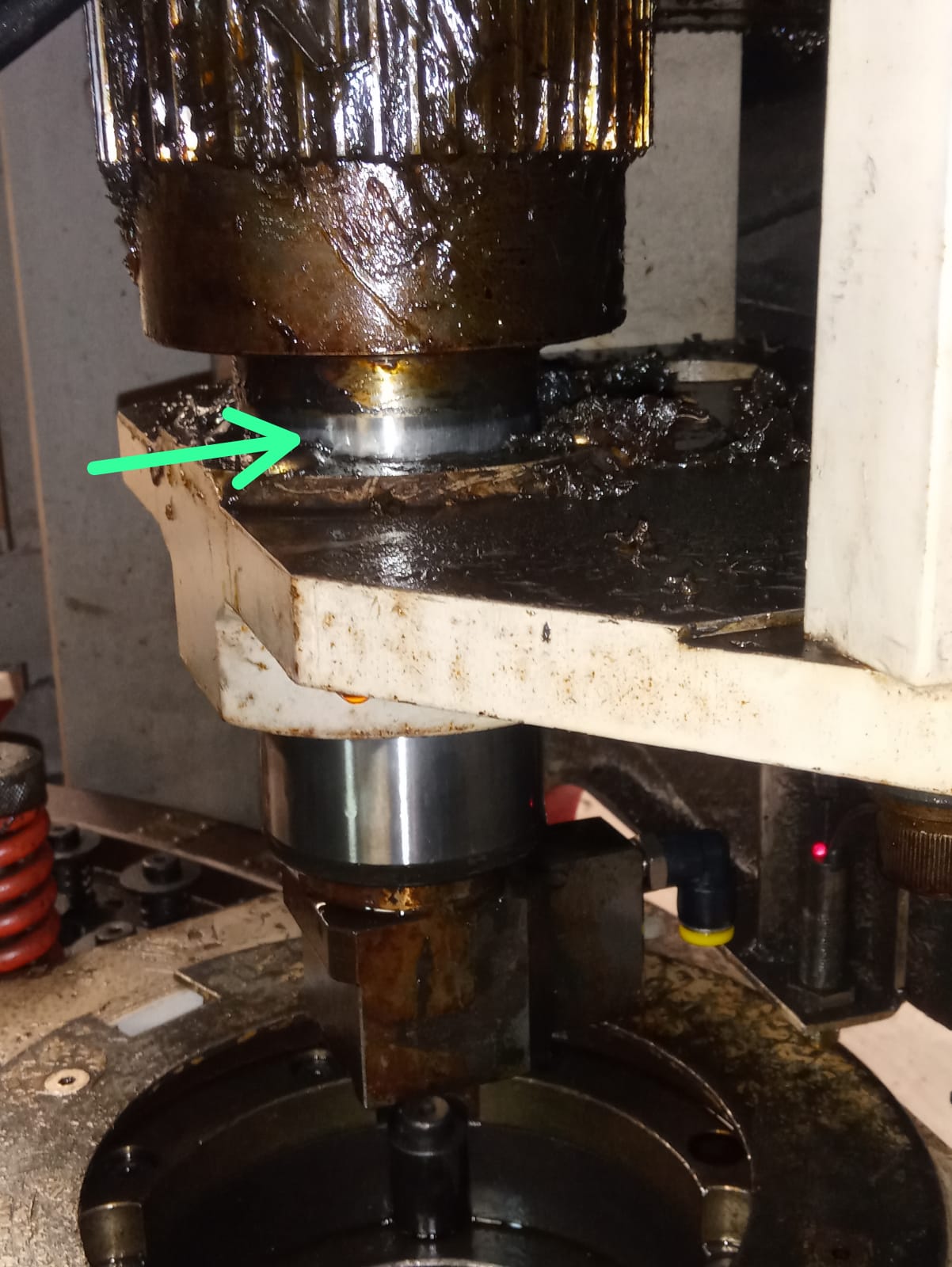

Replied by Artur_1617 on topic linuxcnc 2.9.2/2.9.3 toolchanger problem

linuxcnc 2.9.2/2.9.3 toolchanger problem

Category: Advanced Configuration

- Martin.L

- Martin.L

15 Jan 2025 16:27 - 15 Jan 2025 16:36

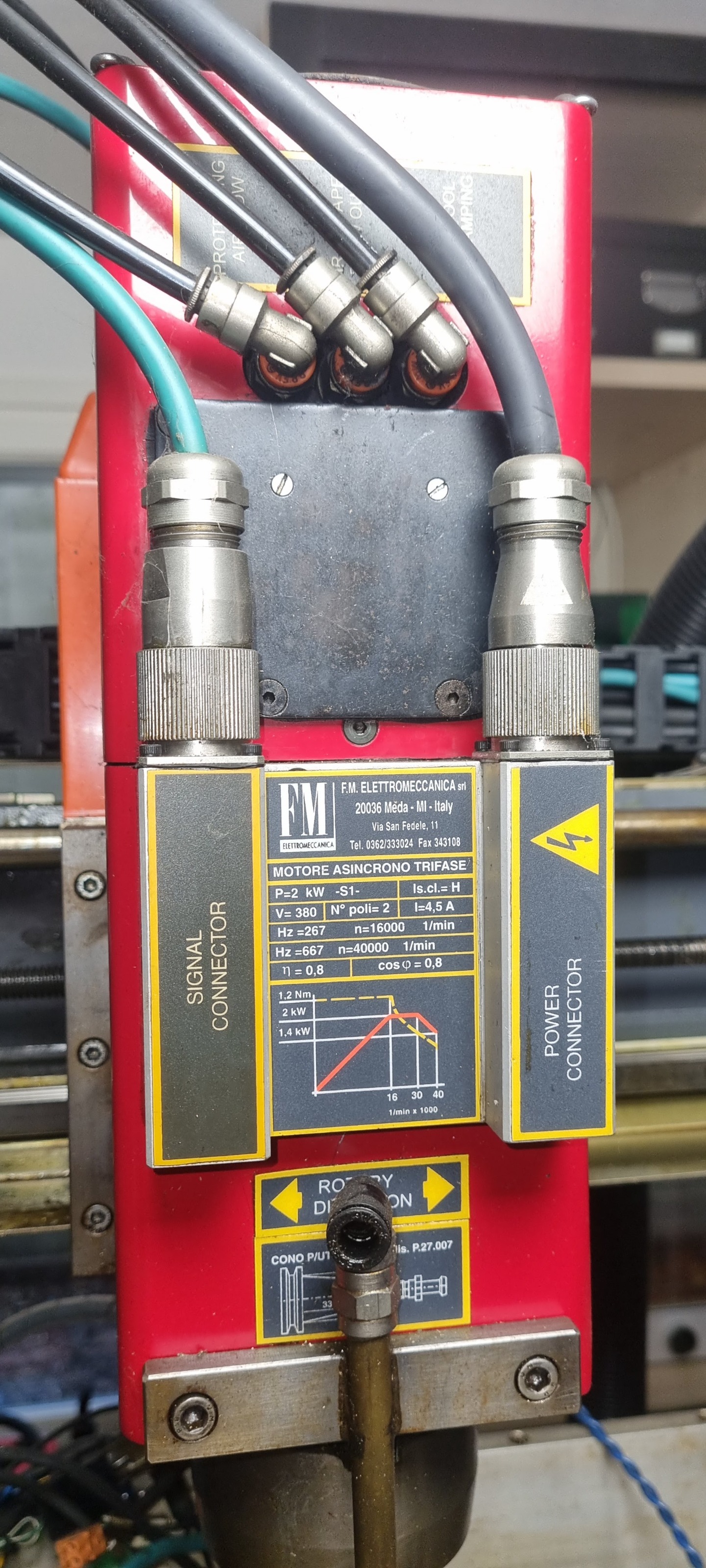

MS300 with CMM-EC02 to retrofit an existing electrospindle spindle was created by Martin.L

MS300 with CMM-EC02 to retrofit an existing electrospindle spindle

Category: EtherCAT

- KrisR

- KrisR

15 Jan 2025 16:24

- Plasmanfm

- Plasmanfm

15 Jan 2025 16:22 - 15 Jan 2025 16:28

Replied by Plasmanfm on topic Maus funktioniert nicht bei Spindel Start

Maus funktioniert nicht bei Spindel Start

Category: Deutsch

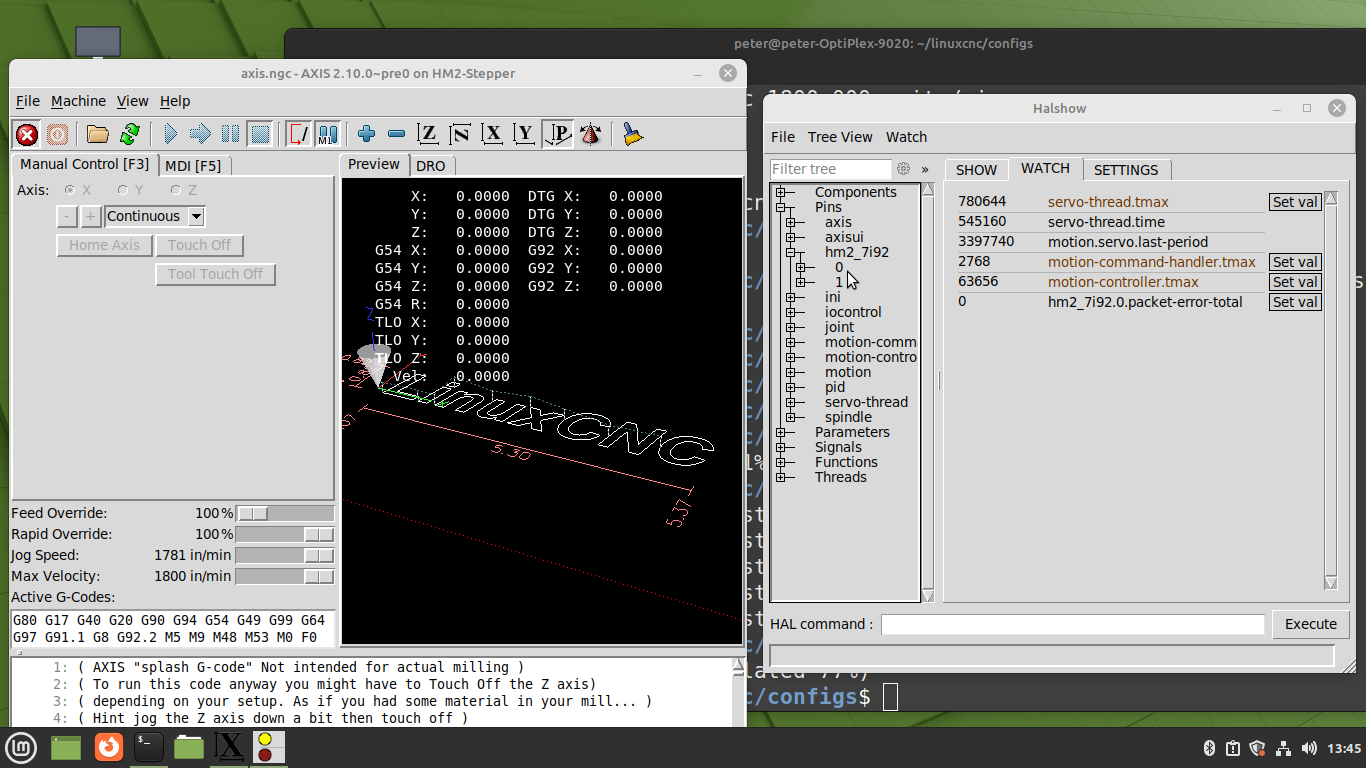

- PCW

15 Jan 2025 16:02 - 16 Jan 2025 00:22

- Aciera

15 Jan 2025 15:18 - 15 Jan 2025 15:22

Replied by Aciera on topic Using G64 with M66 for smooth robot control

Using G64 with M66 for smooth robot control

Category: General LinuxCNC Questions

- PCW

15 Jan 2025 15:13 - 15 Jan 2025 15:46

- Aciera

15 Jan 2025 15:07

Replied by Aciera on topic LinuxCNC with OKUMA OSP MX-55VA

LinuxCNC with OKUMA OSP MX-55VA

Category: Basic Configuration

- PCW

15 Jan 2025 15:02

- programador

15 Jan 2025 14:32

Replied by programador on topic How to use the velocity encoder signal as position feedback for the 7i77 board?

How to use the velocity encoder signal as position feedback for the 7i77 board?

Category: HAL

- programador

15 Jan 2025 14:22

- programador

15 Jan 2025 14:19 - 15 Jan 2025 14:22

- programador

15 Jan 2025 14:17

- hellvetica

- hellvetica

15 Jan 2025 14:09

Replied by hellvetica on topic Using G64 with M66 for smooth robot control

Using G64 with M66 for smooth robot control

Category: General LinuxCNC Questions

Time to create page: 0.612 seconds