Search Results (Searched for: )

- slowpoke

- slowpoke

01 Jan 2025 22:03 - 01 Jan 2025 22:17

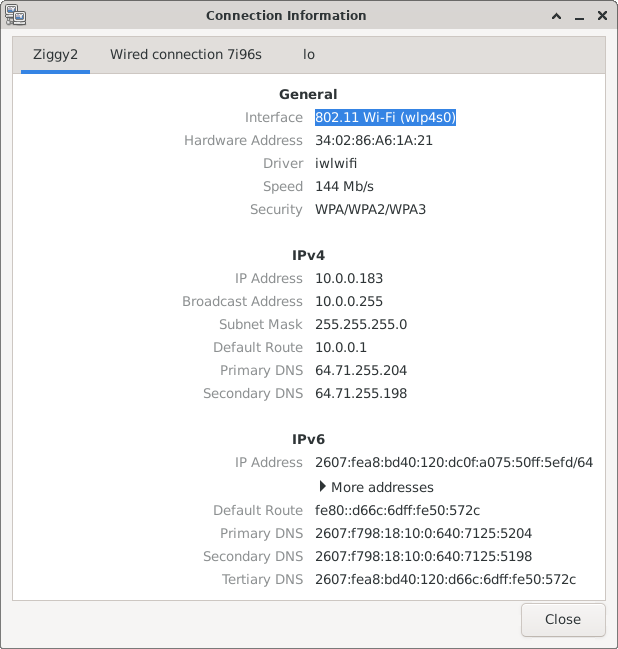

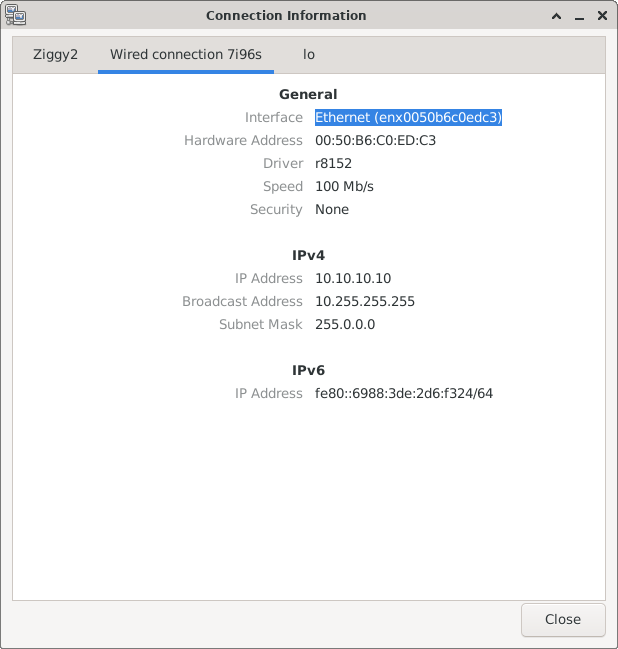

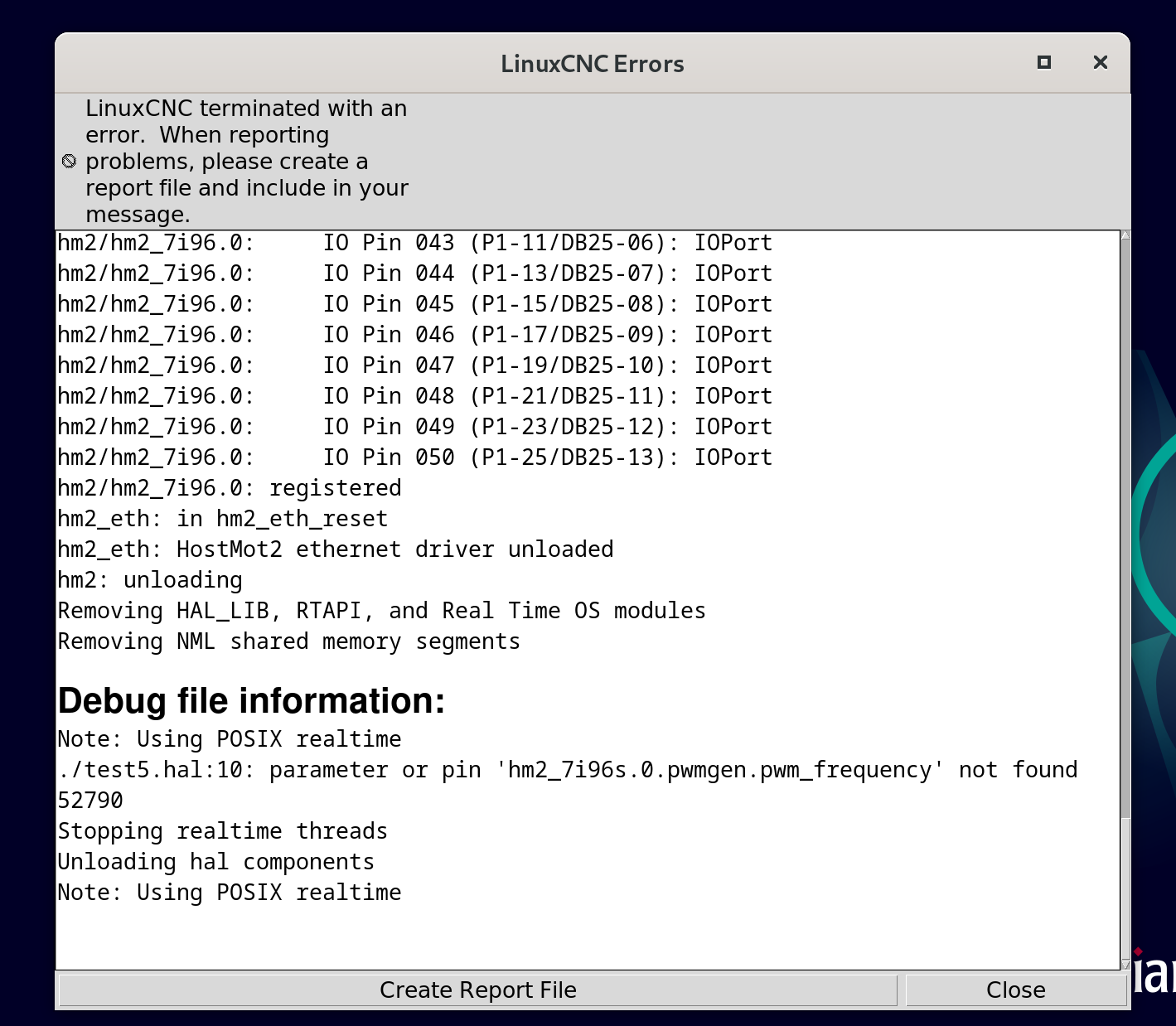

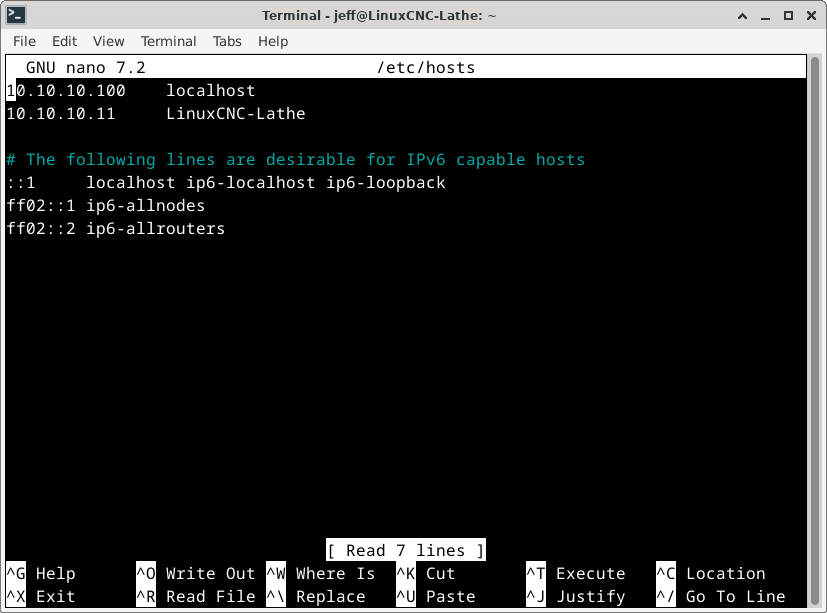

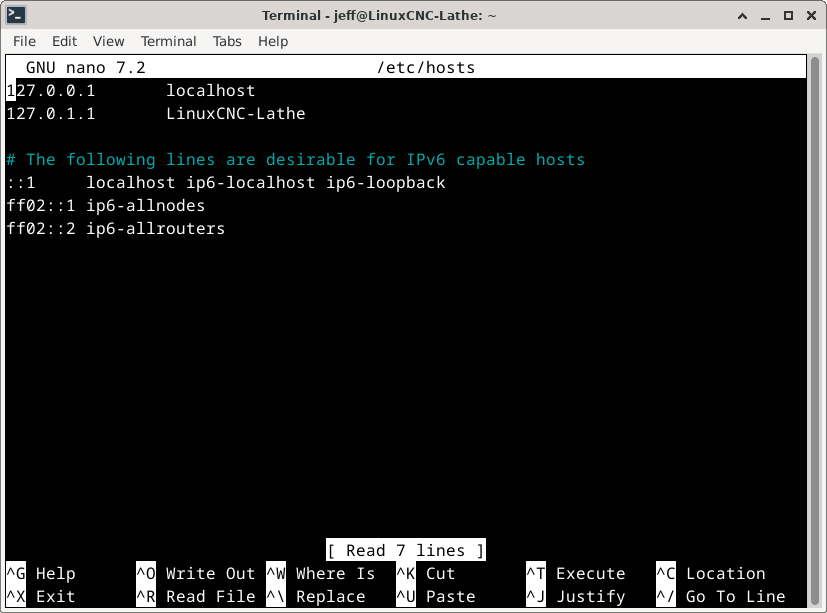

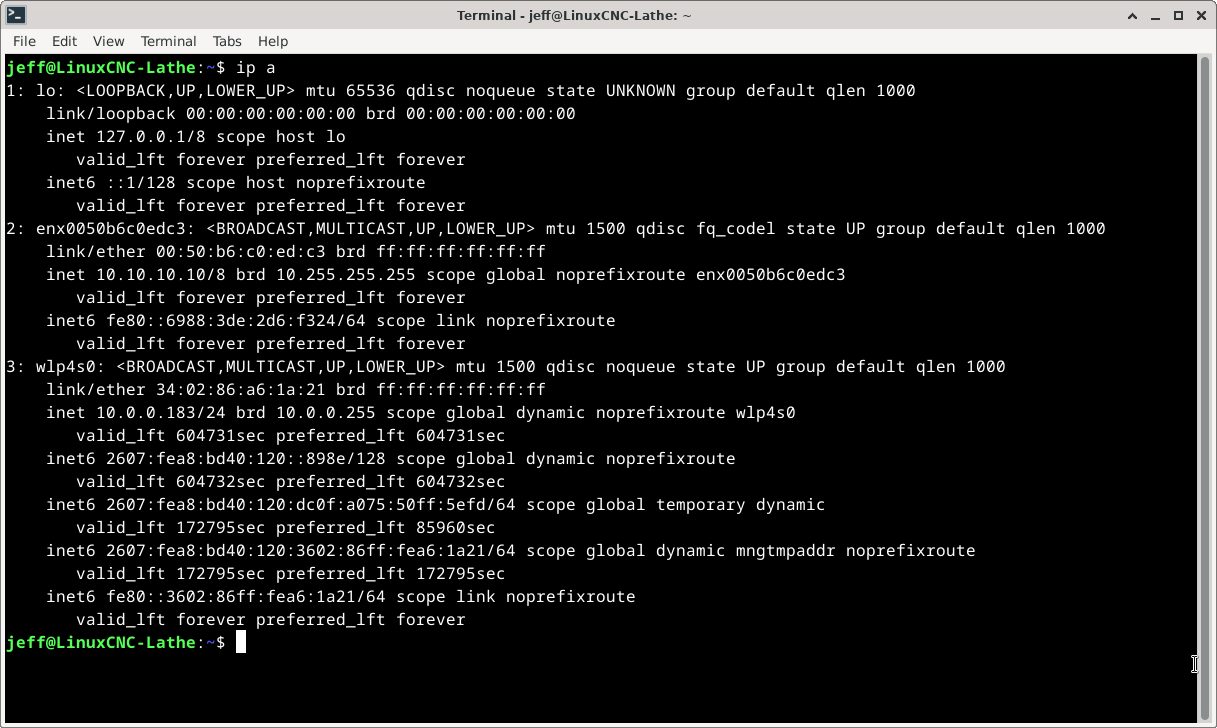

Replied by slowpoke on topic 7i96s not recognized

7i96s not recognized

Category: Basic Configuration

- Grotius

01 Jan 2025 22:00

- RNJFAB

- RNJFAB

01 Jan 2025 21:41 - 01 Jan 2025 21:44

Replied by RNJFAB on topic Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Category: Show Your Stuff

- kzali

- kzali

01 Jan 2025 21:38 - 01 Jan 2025 21:41

- cmorley

- cmorley

01 Jan 2025 21:24

- PCW

01 Jan 2025 21:08

- cmorley

- cmorley

01 Jan 2025 20:48

Replied by cmorley on topic qtDragon LED Probe und Spindeldrehzahl anzeigen

qtDragon LED Probe und Spindeldrehzahl anzeigen

Category: Deutsch

- slowpoke

- slowpoke

01 Jan 2025 20:46

Replied by slowpoke on topic 7i96s not recognized

7i96s not recognized

Category: Basic Configuration

- RV3Dtech

- RV3Dtech

01 Jan 2025 20:07

Replied by RV3Dtech on topic qtDragon LED Probe und Spindeldrehzahl anzeigen

qtDragon LED Probe und Spindeldrehzahl anzeigen

Category: Deutsch

- gilesclement

- gilesclement

01 Jan 2025 19:47

Replied by gilesclement on topic Trouble Shooting USB Jogging with an Xbox Controller

Trouble Shooting USB Jogging with an Xbox Controller

Category: General LinuxCNC Questions

- zelo

- zelo

01 Jan 2025 18:33 - 01 Jan 2025 18:37

Replied by zelo on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- PCW

01 Jan 2025 18:29

Replied by PCW on topic Spindle speed and instatnly powered led

Spindle speed and instatnly powered led

Category: Qtvcp

- ihavenofish

- ihavenofish

01 Jan 2025 18:05 - 01 Jan 2025 18:05

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- ErwinCNC

- ErwinCNC

01 Jan 2025 18:00

Replied by ErwinCNC on topic Linux CNC startet nicht mehr

Linux CNC startet nicht mehr

Category: Deutsch

- BSOD

- BSOD

01 Jan 2025 17:48 - 01 Jan 2025 18:31

Replied by BSOD on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

Time to create page: 0.797 seconds