Search Results (Searched for: )

- Wischi

- Wischi

24 Jun 2024 18:18

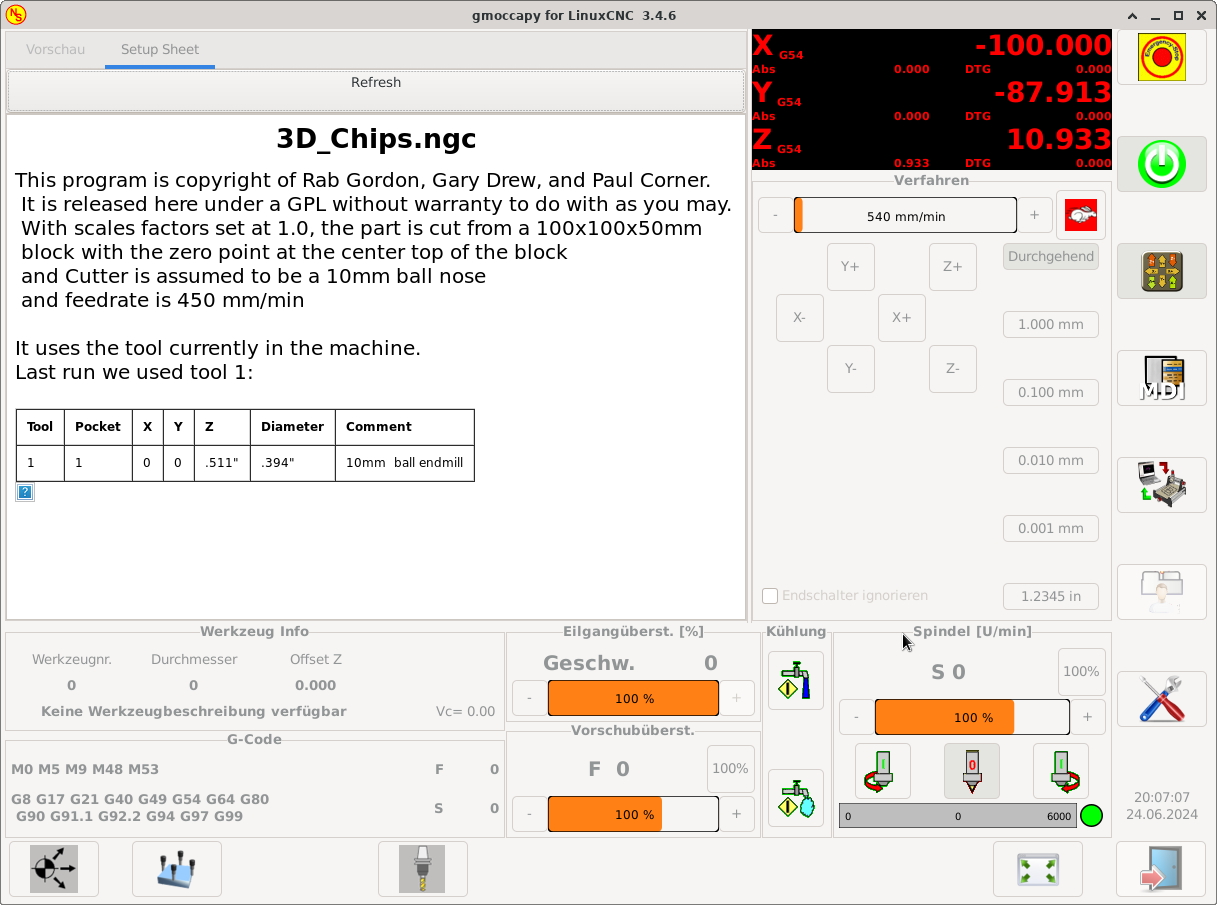

Replied by Wischi on topic Setup Sheet as Embedded Tab

Setup Sheet as Embedded Tab

Category: Gmoccapy

- PCW

24 Jun 2024 18:14

Replied by PCW on topic 3 Achs Fräse mit MESA 7C80 und Raspi 4

3 Achs Fräse mit MESA 7C80 und Raspi 4

Category: Deutsch

- cncbeagle

- cncbeagle

24 Jun 2024 17:23

Replied by cncbeagle on topic Resume not working after M0

Resume not working after M0

Category: General LinuxCNC Questions

- zjjxxsh

- zjjxxsh

24 Jun 2024 17:20 - 24 Jun 2024 17:22

Try to install LInuxCNC without image was created by zjjxxsh

Try to install LInuxCNC without image

Category: Installing LinuxCNC

- jimmyrig

- jimmyrig

24 Jun 2024 17:20

Replied by jimmyrig on topic Best QTplasmac version to use

Best QTplasmac version to use

Category: Plasmac

- Aciera

24 Jun 2024 17:00

Replied by Aciera on topic Resume not working after M0

Resume not working after M0

Category: General LinuxCNC Questions

- Aciera

24 Jun 2024 16:52

Replied by Aciera on topic Deckel FP4 Gearbox Comp

Deckel FP4 Gearbox Comp

Category: Advanced Configuration

- cncbeagle

- cncbeagle

24 Jun 2024 16:36

Resume not working after M0 was created by cncbeagle

Resume not working after M0

Category: General LinuxCNC Questions

- tommylight

24 Jun 2024 16:15

Replied by tommylight on topic LinuxCNC vs Klipper

LinuxCNC vs Klipper

Category: General LinuxCNC Questions

- jimmyrig

- jimmyrig

24 Jun 2024 15:49

Replied by jimmyrig on topic LinuxCNC vs Klipper

LinuxCNC vs Klipper

Category: General LinuxCNC Questions

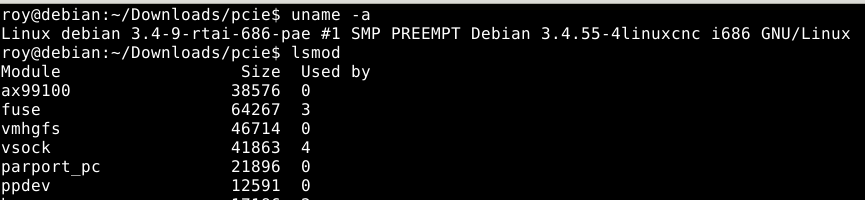

- royka

- royka

24 Jun 2024 15:07 - 24 Jun 2024 16:55

Replied by royka on topic another pci-e to parallel port issue with "make" command

another pci-e to parallel port issue with "make" command

Category: Computers and Hardware

- elovalvo

- elovalvo

24 Jun 2024 15:01 - 24 Jun 2024 15:07

- elovalvo

- elovalvo

24 Jun 2024 14:40 - 25 Jun 2024 06:39

- HPW

- HPW

24 Jun 2024 14:21

Replied by HPW on topic 3 Achs Fräse mit MESA 7C80 und Raspi 4

3 Achs Fräse mit MESA 7C80 und Raspi 4

Category: Deutsch

- cncproject2024

- cncproject2024

24 Jun 2024 14:18

LinuxCNC vs Klipper was created by cncproject2024

LinuxCNC vs Klipper

Category: General LinuxCNC Questions

Time to create page: 0.597 seconds