Search Results (Searched for: )

- electrosteam

- electrosteam

22 Jun 2024 01:05

Mesa 7i96 Ethernet Socket Problems - LC2.9.2 on Raspberry Pi 4B was created by electrosteam

Mesa 7i96 Ethernet Socket Problems - LC2.9.2 on Raspberry Pi 4B

Category: Driver Boards

- cakeslob

- cakeslob

22 Jun 2024 01:00

Replied by cakeslob on topic use a older snapon plasma50 for DIY CNC

use a older snapon plasma50 for DIY CNC

Category: Plasmac

- ewans

- ewans

22 Jun 2024 00:54 - 13 Jul 2024 21:15

[Solved] Help with setup 7i97T was created by ewans

[Solved] Help with setup 7i97T

Category: Driver Boards

- tommylight

21 Jun 2024 22:33

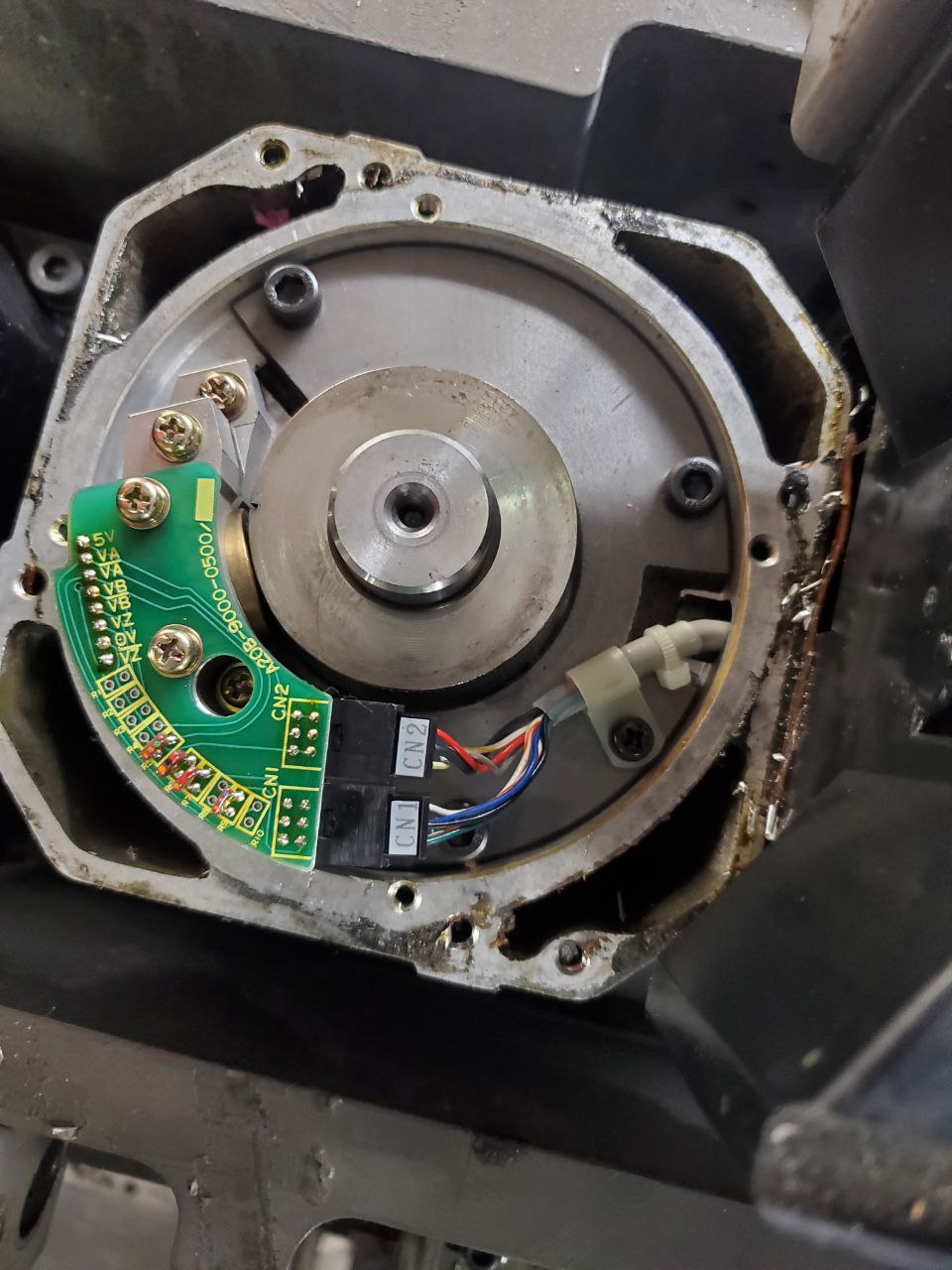

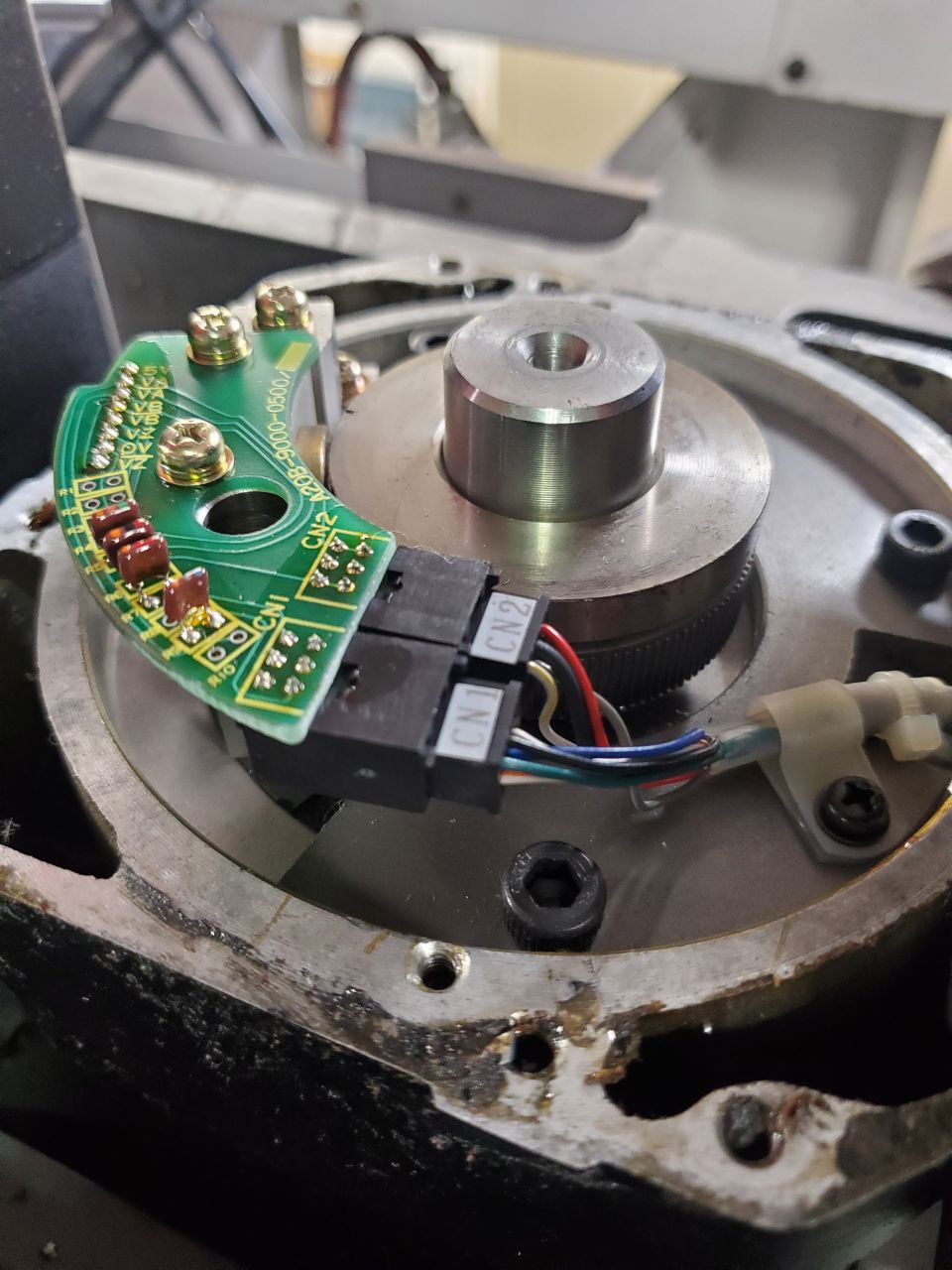

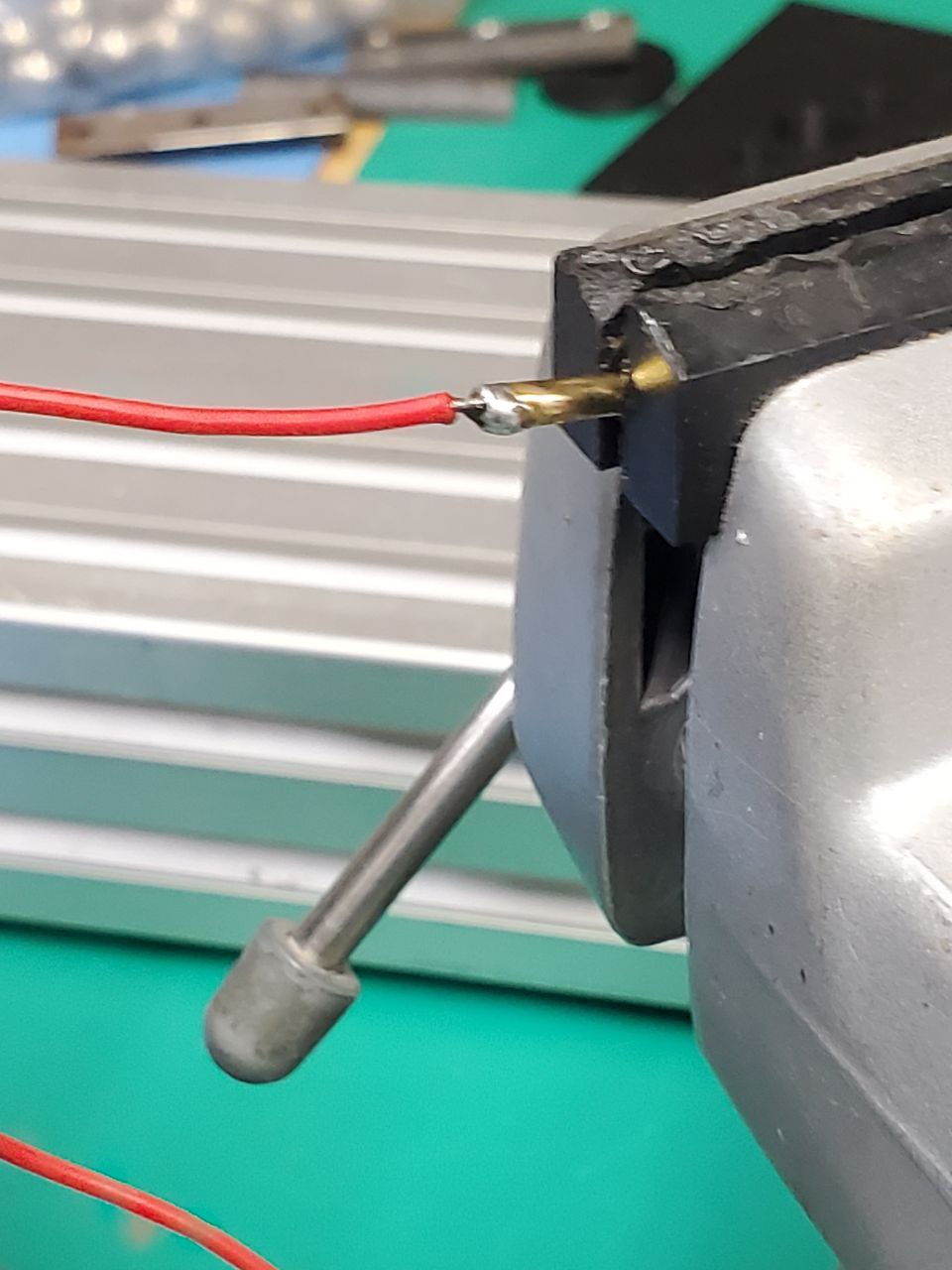

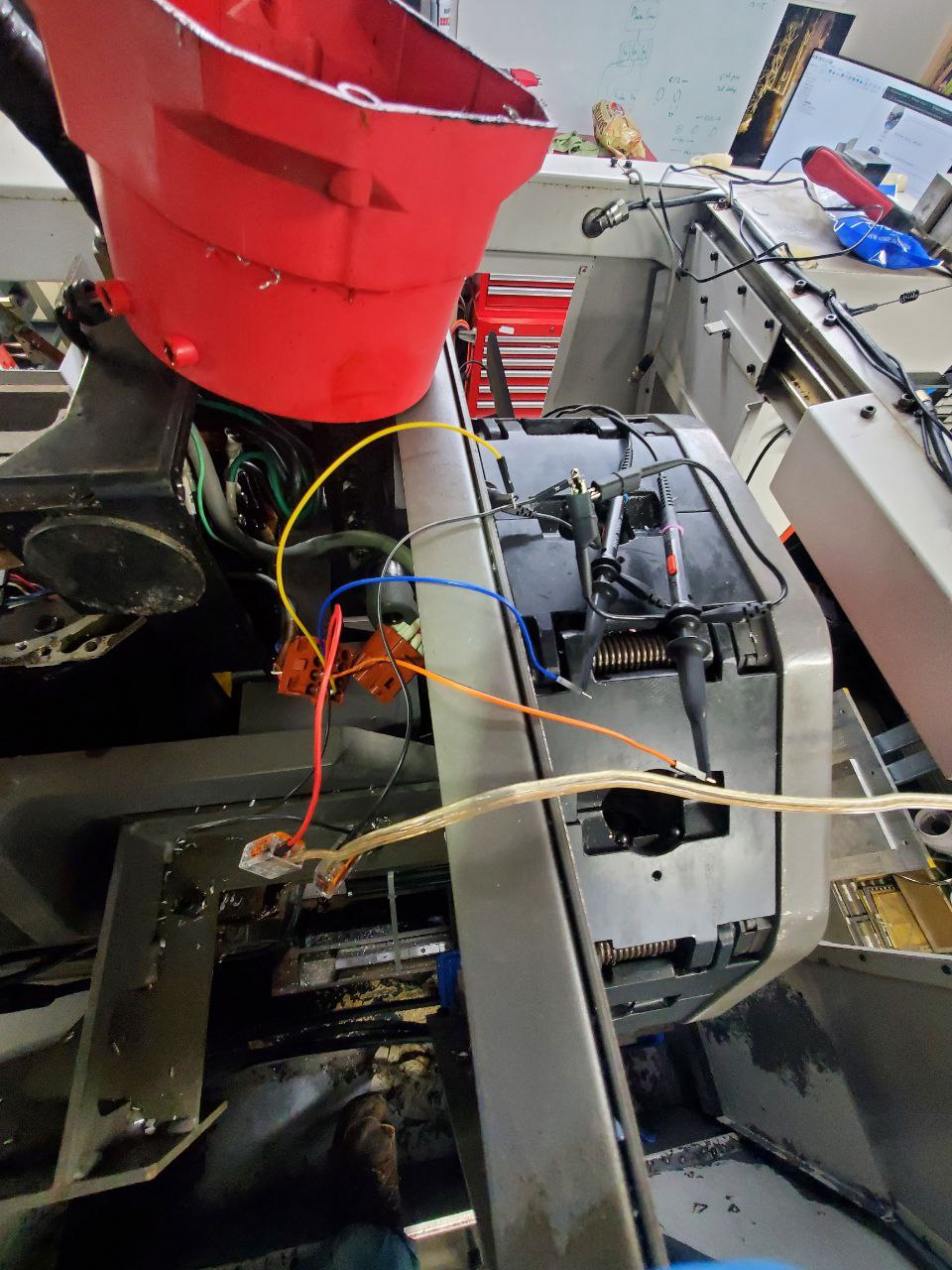

Replied by tommylight on topic Tree Kira VTC30 Retrofit

Tree Kira VTC30 Retrofit

Category: Milling Machines

- chrisfischer

- chrisfischer

21 Jun 2024 22:24

Replied by chrisfischer on topic Tree Kira VTC30 Retrofit

Tree Kira VTC30 Retrofit

Category: Milling Machines

- chrisfischer

- chrisfischer

21 Jun 2024 22:19

Replied by chrisfischer on topic Tree Kira VTC30 Retrofit

Tree Kira VTC30 Retrofit

Category: Milling Machines

- chrisfischer

- chrisfischer

21 Jun 2024 22:09

Replied by chrisfischer on topic Tree Kira VTC30 Retrofit

Tree Kira VTC30 Retrofit

Category: Milling Machines

- MennilTossFlykune

- MennilTossFlykune

21 Jun 2024 22:03

Replied by MennilTossFlykune on topic Gremlin rewrite for OpenGL ES and possible optimization

Gremlin rewrite for OpenGL ES and possible optimization

Category: General LinuxCNC Questions

- gardenweazel

21 Jun 2024 21:22

- Becksvill

- Becksvill

21 Jun 2024 21:04

Replied by Becksvill on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- PCW

21 Jun 2024 20:52

Replied by PCW on topic Scaling power based on % of imposed velocity

Scaling power based on % of imposed velocity

Category: General LinuxCNC Questions

- tommylight

21 Jun 2024 19:06

Replied by tommylight on topic Busco micros de límite para hardinge II

Busco micros de límite para hardinge II

Category: Turning

- tommylight

21 Jun 2024 19:04

Replied by tommylight on topic Tree Kira VTC30 Retrofit

Tree Kira VTC30 Retrofit

Category: Milling Machines

- snowgoer540

21 Jun 2024 18:53

- Enriquemexico

- Enriquemexico

21 Jun 2024 18:38

Replied by Enriquemexico on topic Busco micros de límite para hardinge II

Busco micros de límite para hardinge II

Category: Turning

Time to create page: 0.934 seconds