Search Results (Searched for: )

- bobwolf

- bobwolf

17 Jan 2026 16:42

- cmorley

- cmorley

17 Jan 2026 16:34

- cmorley

- cmorley

17 Jan 2026 15:39

- harindugamlath

- harindugamlath

17 Jan 2026 15:27

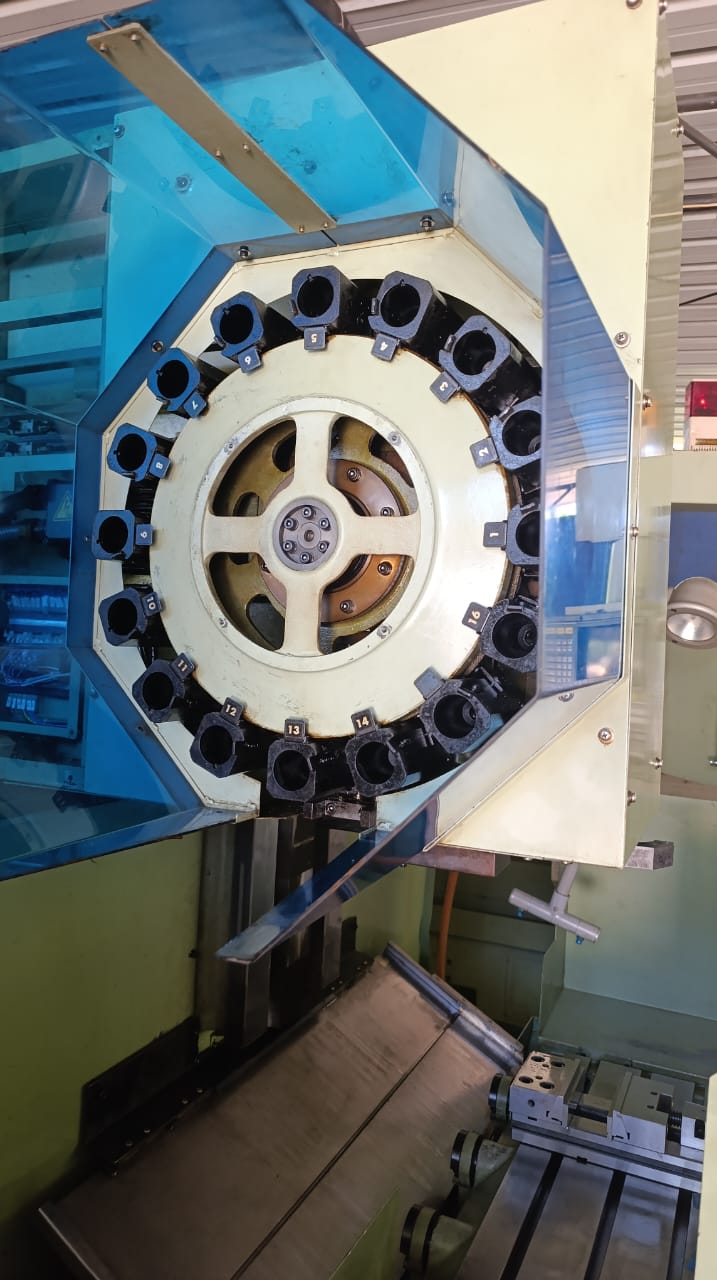

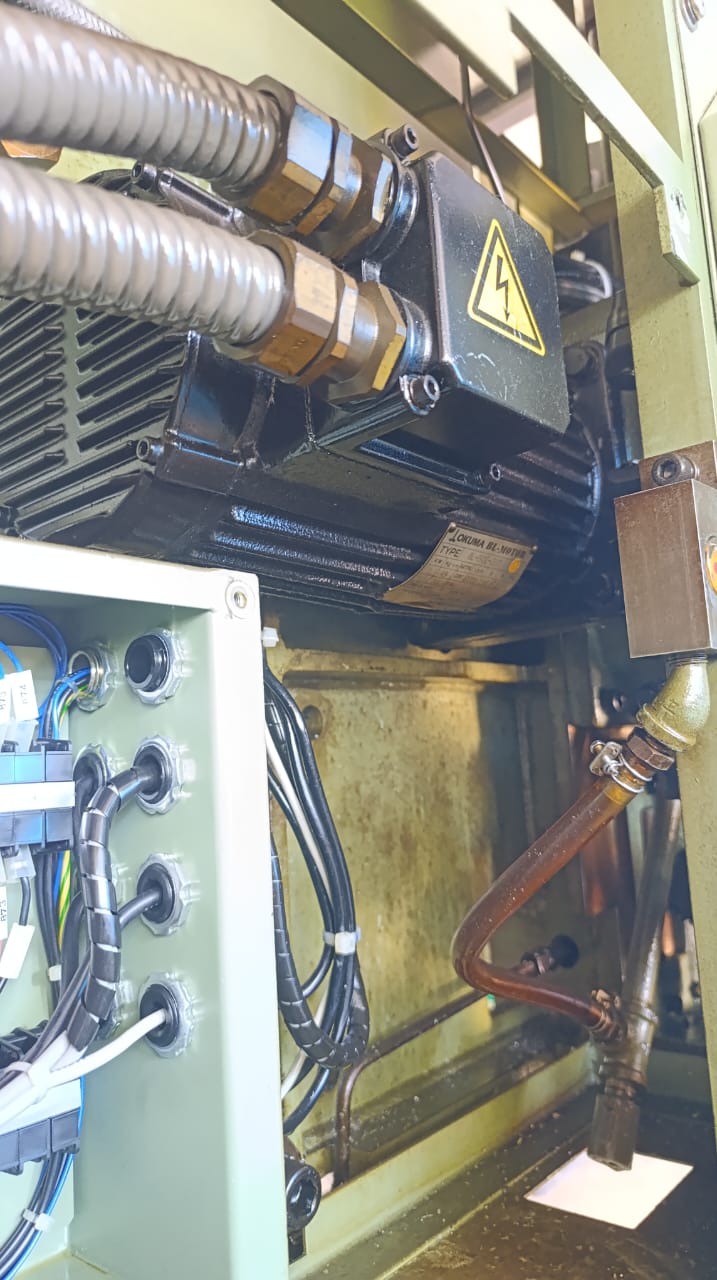

Servo Driven tool changer - How to set up was created by harindugamlath

Servo Driven tool changer - How to set up

Category: Advanced Configuration

- cmorley

- cmorley

17 Jan 2026 15:11

- grandixximo

17 Jan 2026 14:50 - 17 Jan 2026 16:01

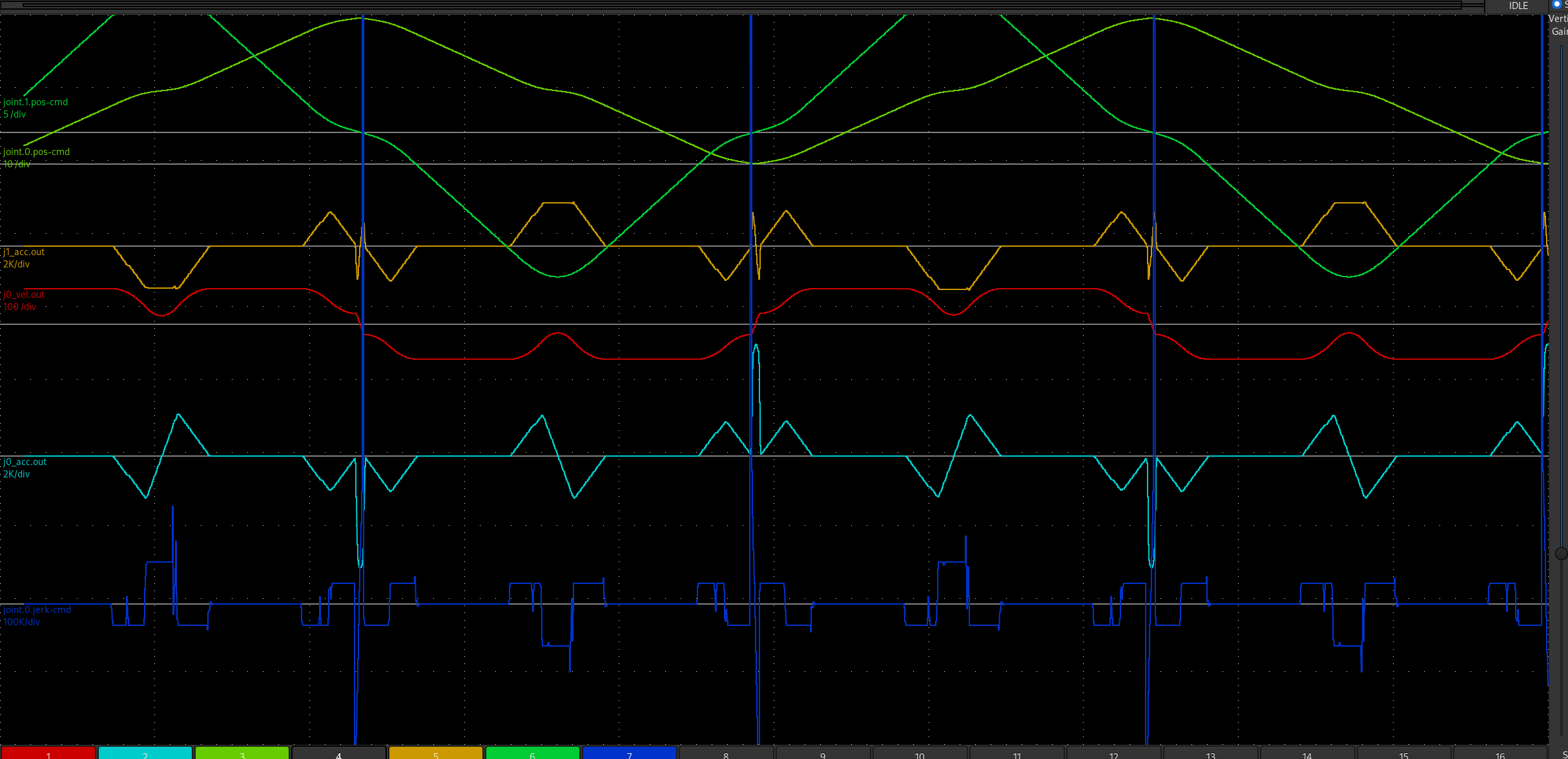

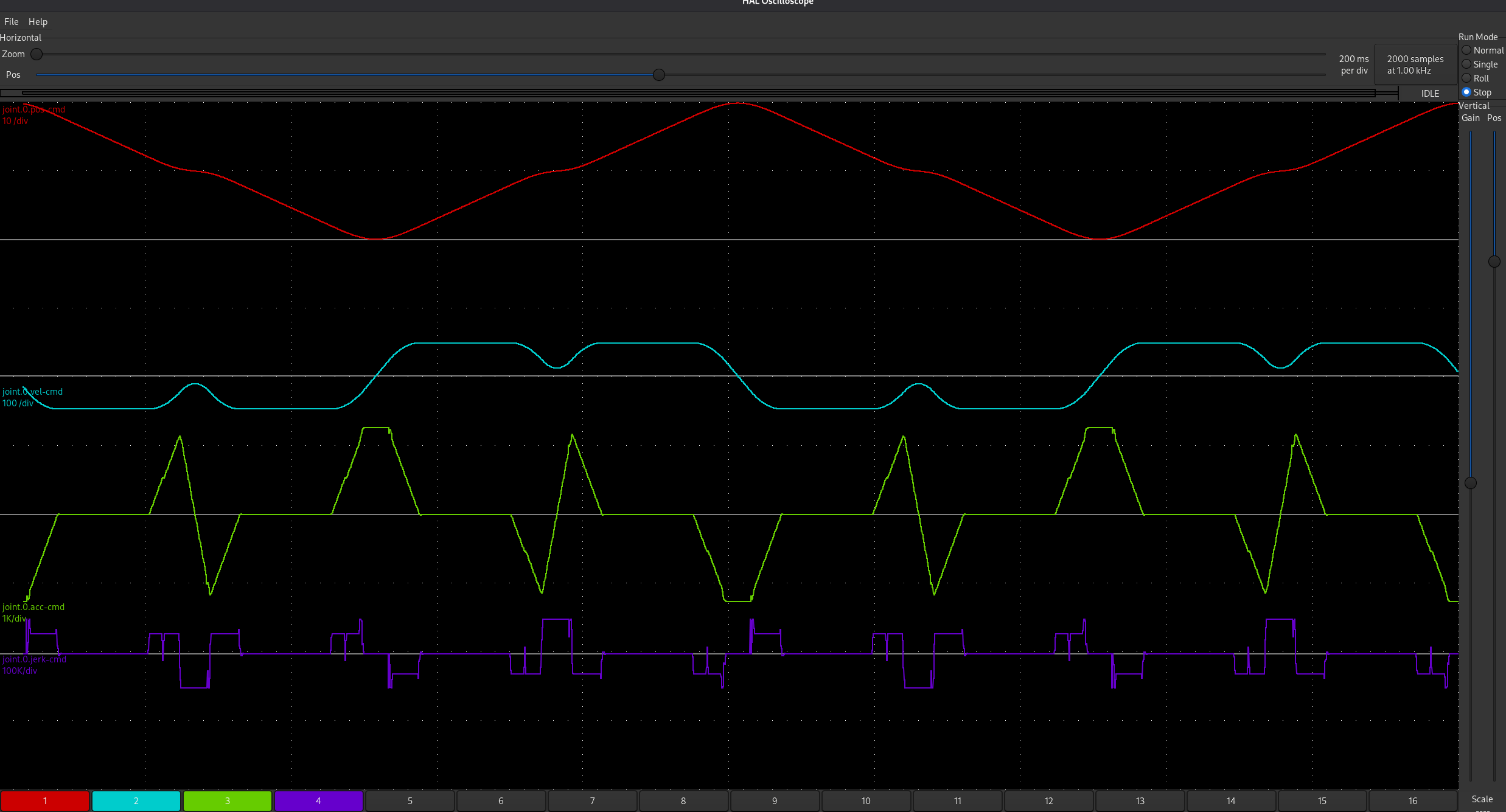

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- amanker

- amanker

17 Jan 2026 13:53

Replied by amanker on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- 3404gerber

- 3404gerber

17 Jan 2026 13:32

Replied by 3404gerber on topic Linuxcnc erste Schritte und erste Probleme, NVEM und Remora

Linuxcnc erste Schritte und erste Probleme, NVEM und Remora

Category: Deutsch

- tommylight

17 Jan 2026 12:52

- harindugamlath

- harindugamlath

17 Jan 2026 11:49

Replied by harindugamlath on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- Aciera

17 Jan 2026 11:47

Replied by Aciera on topic Can my account and post history be deleted please

Can my account and post history be deleted please

Category: Forum Questions

- Mark Kraus

- Mark Kraus

17 Jan 2026 11:45

Replied by Mark Kraus on topic Trying to move from UCCNC to Linuxcnc and using 7i96s but having trouble

Trying to move from UCCNC to Linuxcnc and using 7i96s but having trouble

Category: StepConf Wizard

- rodw

17 Jan 2026 11:44

Replied by rodw on topic Can my account and post history be deleted please

Can my account and post history be deleted please

Category: Forum Questions

- rodw

17 Jan 2026 11:33 - 18 Jan 2026 00:40

Replied by rodw on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- 2tinker

- 2tinker

17 Jan 2026 10:43

How do I lubricate correctly? was created by 2tinker

How do I lubricate correctly?

Category: Milling Machines

Time to create page: 0.285 seconds