Search Results (Searched for: )

- spumco

- spumco

09 Nov 2024 05:36

- cmorley

- cmorley

09 Nov 2024 04:06

Replied by cmorley on topic QT Dragon - Funktionstaste mit "Override limits" belegen?

QT Dragon - Funktionstaste mit "Override limits" belegen?

Category: Deutsch

- spumco

- spumco

09 Nov 2024 03:18

Replied by spumco on topic probe basic - toolpath/file preview loading error

probe basic - toolpath/file preview loading error

Category: QtPyVCP

- MarkoPolo

- MarkoPolo

09 Nov 2024 02:47

Replied by MarkoPolo on topic Rotary axis Display

Rotary axis Display

Category: Advanced Configuration

- ihavenofish

- ihavenofish

09 Nov 2024 02:26

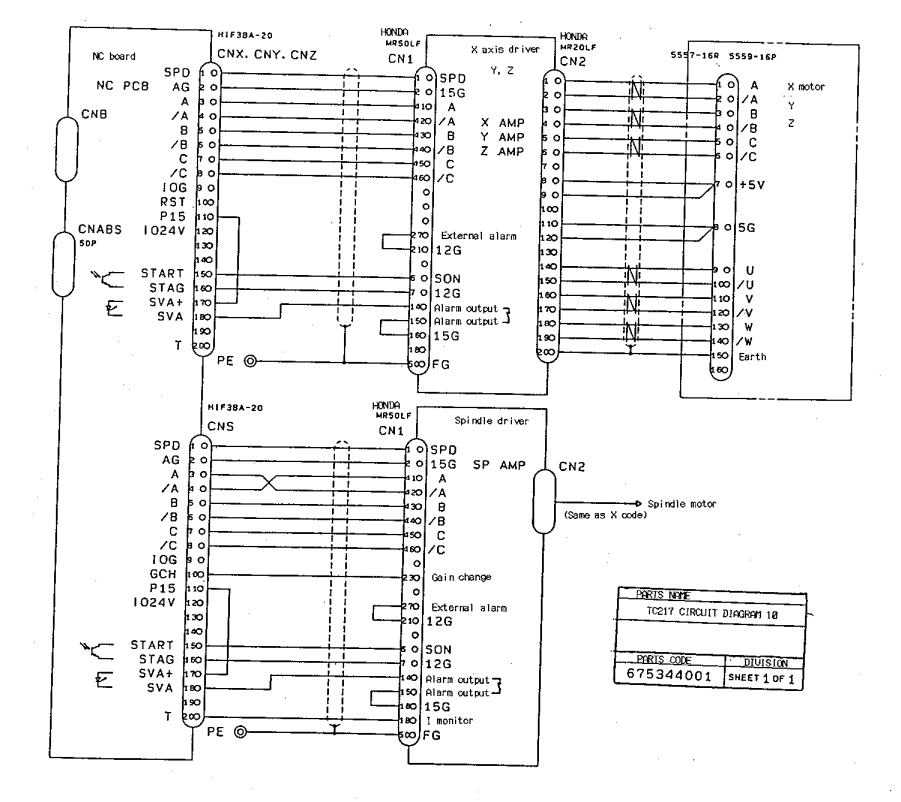

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

Brother TC-225 / TC-229 adventure!

Category: CNC Machines

- NTULINUX

09 Nov 2024 02:25 - 17 Nov 2024 02:39

Replied by NTULINUX on topic Linux is an RTOS NOW

Linux is an RTOS NOW

Category: Installing LinuxCNC

- Philip Lydin

- Philip Lydin

09 Nov 2024 02:10

Replied by Philip Lydin on topic Brother TC-225 / TC-229 adventure!

Brother TC-225 / TC-229 adventure!

Category: CNC Machines

- IronManDylan

- IronManDylan

09 Nov 2024 01:26

Replied by IronManDylan on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- Grotius

08 Nov 2024 23:33

Replied by Grotius on topic Controlling a compressor with Linuxcnc.

Controlling a compressor with Linuxcnc.

Category: Plasmac

- Grotius

08 Nov 2024 23:14

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- ihavenofish

- ihavenofish

08 Nov 2024 21:27

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

Brother TC-225 / TC-229 adventure!

Category: CNC Machines

- ihavenofish

- ihavenofish

08 Nov 2024 21:24

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

Brother TC-225 / TC-229 adventure!

Category: CNC Machines

- ihavenofish

- ihavenofish

08 Nov 2024 21:23 - 08 Nov 2024 22:10

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

Brother TC-225 / TC-229 adventure!

Category: CNC Machines

- alexbrem89

- alexbrem89

08 Nov 2024 21:13

Replied by alexbrem89 on topic Brother TC-225 / TC-229 adventure!

Brother TC-225 / TC-229 adventure!

Category: CNC Machines

- tommylight

08 Nov 2024 21:12

Replied by tommylight on topic Brother TC-225 / TC-229 adventure!

Brother TC-225 / TC-229 adventure!

Category: CNC Machines

Time to create page: 0.633 seconds