Search Results (Searched for: )

- PCW

25 Jul 2025 15:51

Replied by PCW on topic Connecting my 7i96s to the VFD

Connecting my 7i96s to the VFD

Category: Driver Boards

- Waggi

- Waggi

25 Jul 2025 15:32

Replied by Waggi on topic Vorschau Berechnung der Grenzwerte passt nicht wenn M6 enthalten

Vorschau Berechnung der Grenzwerte passt nicht wenn M6 enthalten

Category: Deutsch

- scsmith1451

- scsmith1451

25 Jul 2025 14:05

Replied by scsmith1451 on topic Set program zero using XY positioning laser

Set program zero using XY positioning laser

Category: Advanced Configuration

- PCW

25 Jul 2025 13:43 - 25 Jul 2025 16:03

Replied by PCW on topic threading - spindle encoder synchonization issues

threading - spindle encoder synchonization issues

Category: Turning

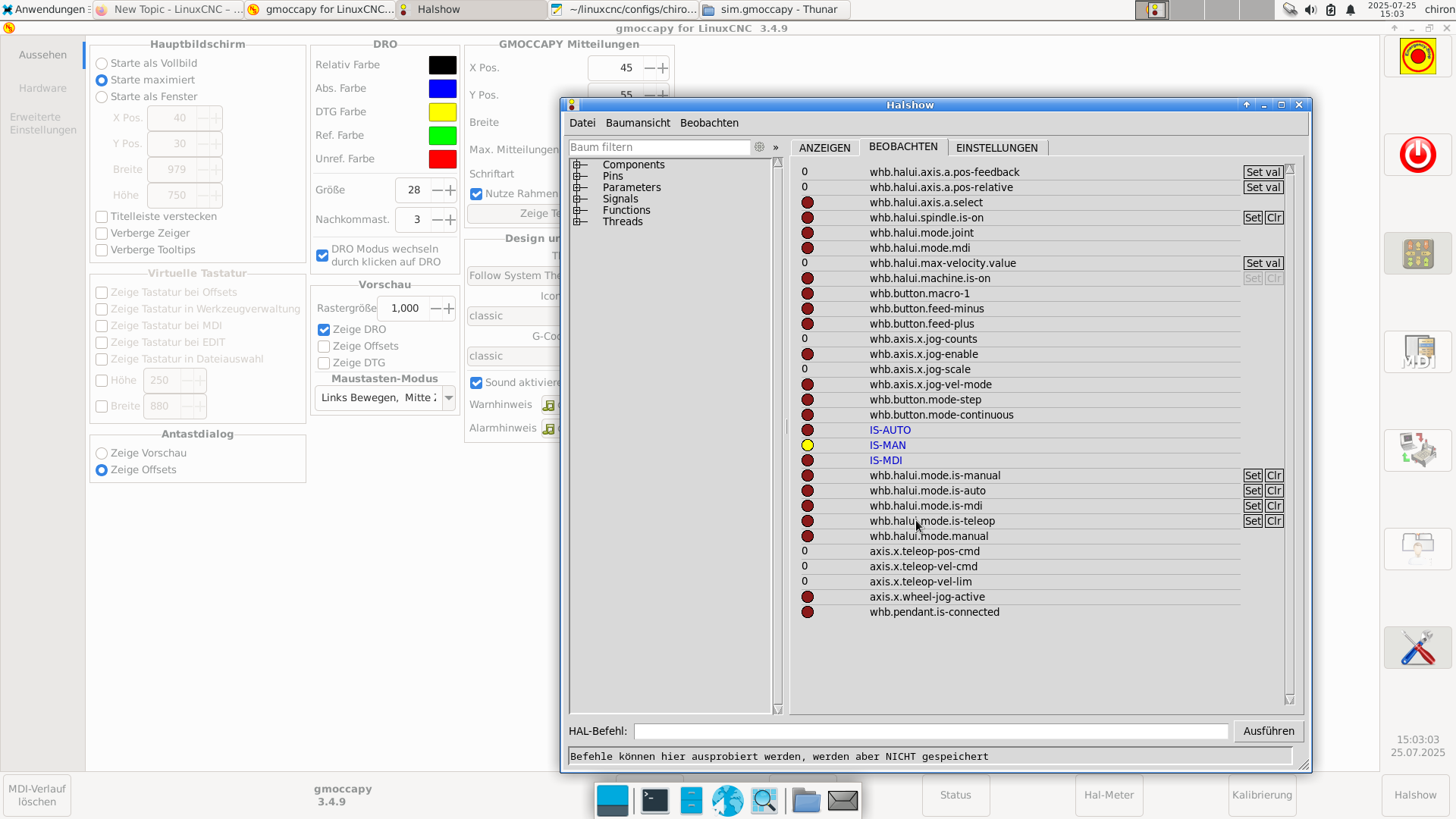

- ChironFZ16

25 Jul 2025 13:05 - 25 Jul 2025 13:08

- tommylight

25 Jul 2025 12:02

Replied by tommylight on topic How to install kernel patch? (Moschip 9900)

How to install kernel patch? (Moschip 9900)

Category: Installing LinuxCNC

- Todd Zuercher

25 Jul 2025 11:59

- tommylight

25 Jul 2025 11:58

Replied by tommylight on topic Connecting my 7i96s to the VFD

Connecting my 7i96s to the VFD

Category: Driver Boards

- tommylight

25 Jul 2025 11:57

- dunnitagain

- dunnitagain

25 Jul 2025 11:38

Replied by dunnitagain on topic Linuxcnc 2.4.5 with Ubuntu 10.04, Correct file path or structure ?

Linuxcnc 2.4.5 with Ubuntu 10.04, Correct file path or structure ?

Category: General LinuxCNC Questions

- Todd Zuercher

25 Jul 2025 10:49

- Gautham

- Gautham

25 Jul 2025 10:43

Connecting my 7i96s to the VFD was created by Gautham

Connecting my 7i96s to the VFD

Category: Driver Boards

- dm17ry

25 Jul 2025 09:13

Replied by dm17ry on topic threading - spindle encoder synchonization issues

threading - spindle encoder synchonization issues

Category: Turning

- andypugh

25 Jul 2025 08:57

Replied by andypugh on topic Simulating a hm2_eth driver (e.g. mesacard 7i76e)

Simulating a hm2_eth driver (e.g. mesacard 7i76e)

Category: Driver Boards

- ziggi

25 Jul 2025 05:30

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Troubles to get started with SD240 Retrofit

Category: Turning

Time to create page: 0.229 seconds