Search Results (Searched for: )

- Aciera

18 Nov 2024 11:32

Replied by Aciera on topic Configuring dual independent Z-axis

Configuring dual independent Z-axis

Category: General LinuxCNC Questions

- tommylight

18 Nov 2024 11:25

- tommylight

18 Nov 2024 11:13

Replied by tommylight on topic 10 or 11 stepgen

10 or 11 stepgen

Category: General LinuxCNC Questions

- rbj

- rbj

18 Nov 2024 10:45 - 18 Nov 2024 10:46

Configuring dual independent Z-axis was created by rbj

Configuring dual independent Z-axis

Category: General LinuxCNC Questions

- shaki6996

- shaki6996

18 Nov 2024 10:11 - 18 Nov 2024 11:23

- Aciera

18 Nov 2024 08:57 - 18 Nov 2024 10:32

- Mecanix

- Mecanix

18 Nov 2024 08:40 - 18 Nov 2024 08:51

Replied by Mecanix on topic Strange motion offsets in one direction on one axis

Strange motion offsets in one direction on one axis

Category: General LinuxCNC Questions

- timo

- timo

18 Nov 2024 08:28

Replied by timo on topic LinuxCNC for lathe questions

LinuxCNC for lathe questions

Category: General LinuxCNC Questions

- meister

- meister

18 Nov 2024 07:28

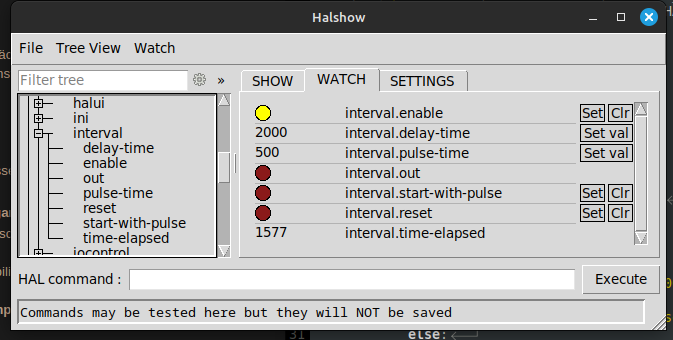

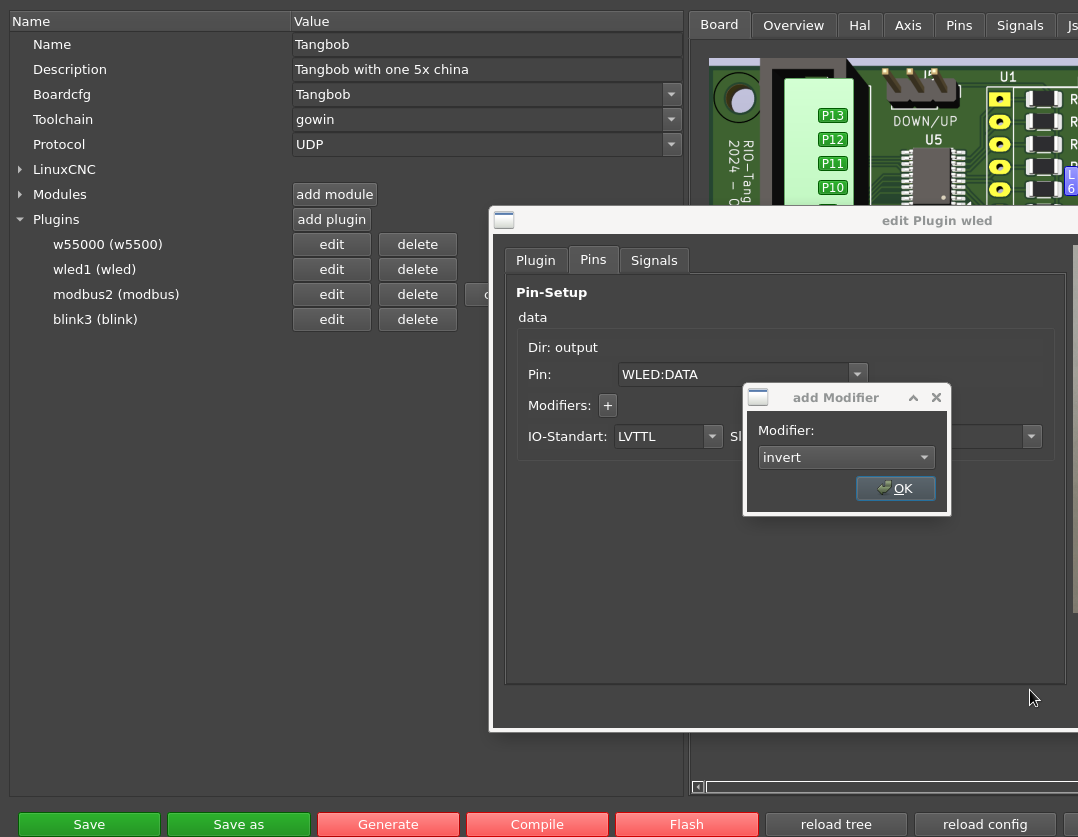

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- 7strideR

18 Nov 2024 05:46 - 18 Nov 2024 07:06

Replied by 7strideR on topic Linux CNC powered Ethercat Mill Retrofit

Linux CNC powered Ethercat Mill Retrofit

Category: EtherCAT

- phillc54

18 Nov 2024 04:28

- PCW

18 Nov 2024 03:20 - 18 Nov 2024 03:36

- rajsekhar

- rajsekhar

18 Nov 2024 03:18

Replied by rajsekhar on topic 10 or 11 stepgen

10 or 11 stepgen

Category: General LinuxCNC Questions

- Philip Lydin

- Philip Lydin

18 Nov 2024 02:15

Replied by Philip Lydin on topic mesa 7i96s analog spindle

mesa 7i96s analog spindle

Category: Driver Boards

- shaying526

- shaying526

18 Nov 2024 01:23

Replied by shaying526 on topic How to move a variable value with G-code

How to move a variable value with G-code

Category: G&M Codes

Time to create page: 0.700 seconds