Search Results (Searched for: )

- Aciera

03 Sep 2024 07:17

Replied by Aciera on topic Adjusting maxvel stops my routine

Adjusting maxvel stops my routine

Category: General LinuxCNC Questions

- onceloved

03 Sep 2024 07:13

Replied by onceloved on topic Marco Reps video on youtube about EtherCAT

Marco Reps video on youtube about EtherCAT

Category: EtherCAT

- Moutomation

- Moutomation

03 Sep 2024 06:57

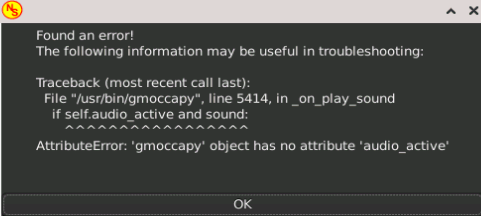

Replied by Moutomation on topic found an error! audio_ative

found an error! audio_ative

Category: Gmoccapy

- greg23_78

- greg23_78

03 Sep 2024 06:19

Replied by greg23_78 on topic encoder.N.velocity-rpm

encoder.N.velocity-rpm

Category: Basic Configuration

- Cant do this anymore bye all

03 Sep 2024 05:57

Replied by Cant do this anymore bye all on topic Pendant with 7i73: question with analog inputs

Pendant with 7i73: question with analog inputs

Category: Driver Boards

- rajsekhar

- rajsekhar

03 Sep 2024 05:52

Replied by rajsekhar on topic Error while Running Linuxcnc

Error while Running Linuxcnc

Category: Driver Boards

- stenly

- stenly

03 Sep 2024 05:48

- Ho Er

- Ho Er

03 Sep 2024 05:39

Replied by Ho Er on topic Pendant with 7i73: question with analog inputs

Pendant with 7i73: question with analog inputs

Category: Driver Boards

- cmorley

- cmorley

03 Sep 2024 05:30

Replied by cmorley on topic How can I make G30 move in Z first?

How can I make G30 move in Z first?

Category: General LinuxCNC Questions

- cmorley

- cmorley

03 Sep 2024 05:21

Replied by cmorley on topic Adjusting maxvel stops my routine

Adjusting maxvel stops my routine

Category: General LinuxCNC Questions

- cmorley

- cmorley

03 Sep 2024 04:49

Replied by cmorley on topic GdkWindow unexpectedly destroyed

GdkWindow unexpectedly destroyed

Category: GladeVCP

- cmorley

- cmorley

03 Sep 2024 04:44

Replied by cmorley on topic Inspect current G64 parameters?

Inspect current G64 parameters?

Category: General LinuxCNC Questions

- Moutomation

- Moutomation

03 Sep 2024 04:32

found an error! audio_ative was created by Moutomation

found an error! audio_ative

Category: Gmoccapy

- bentiggin

- bentiggin

03 Sep 2024 04:30

- casilio55

- casilio55

03 Sep 2024 04:07

Replied by casilio55 on topic Mill Tapping G code Generator

Mill Tapping G code Generator

Category: CAD CAM

Time to create page: 0.455 seconds