Search Results (Searched for: )

- RNJFAB

- RNJFAB

05 May 2025 00:35 - 05 May 2025 00:37

Job not showing in position - 2.9.4 - v2.9-238.315 was created by RNJFAB

Job not showing in position - 2.9.4 - v2.9-238.315

Category: Plasmac

- PCW

05 May 2025 00:08

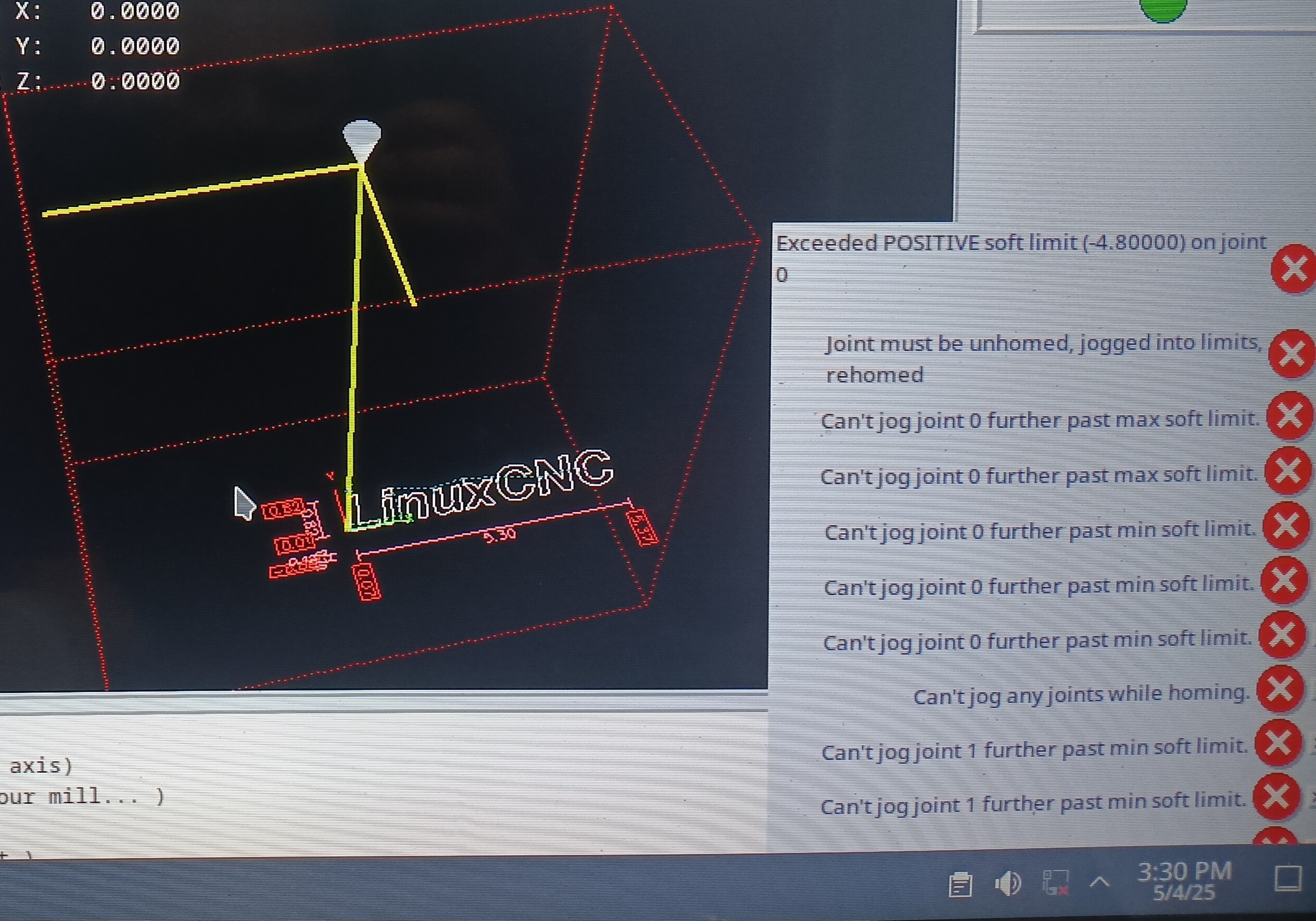

Replied by PCW on topic soft limit error after x homing, does not home y

soft limit error after x homing, does not home y

Category: General LinuxCNC Questions

- Micro2000

- Micro2000

04 May 2025 23:42

Replied by Micro2000 on topic soft limit error after x homing, does not home y

soft limit error after x homing, does not home y

Category: General LinuxCNC Questions

- spincycle

- spincycle

04 May 2025 23:30

Replied by spincycle on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- grijalvap

04 May 2025 23:13

Replied by grijalvap on topic Zero Pierce delay After pierce Only

Zero Pierce delay After pierce Only

Category: Plasmac

- persei8

04 May 2025 22:38

Replied by persei8 on topic GtDragon sometimes called SilverDragon?

GtDragon sometimes called SilverDragon?

Category: Qtvcp

- PCW

04 May 2025 21:28

- tommylight

04 May 2025 21:23

Replied by tommylight on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- spincycle

- spincycle

04 May 2025 21:21

Replied by spincycle on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- tommylight

04 May 2025 21:19

Replied by tommylight on topic soft limit error after x homing, does not home y

soft limit error after x homing, does not home y

Category: General LinuxCNC Questions

- spincycle

- spincycle

04 May 2025 21:18

Replied by spincycle on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- spincycle

- spincycle

04 May 2025 21:13

Replied by spincycle on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- Ismacr63

- Ismacr63

04 May 2025 20:48

- Ismacr63

- Ismacr63

04 May 2025 20:44

Replied by Ismacr63 on topic Porbe basic lathe: Questions about the keyboard

Porbe basic lathe: Questions about the keyboard

Category: QtPyVCP

- Micro2000

- Micro2000

04 May 2025 20:33

soft limit error after x homing, does not home y was created by Micro2000

soft limit error after x homing, does not home y

Category: General LinuxCNC Questions

Time to create page: 0.644 seconds