Search Results (Searched for: )

- aDm1N

20 Aug 2024 19:32 - 20 Aug 2024 19:59

Replied by aDm1N on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- PCW

20 Aug 2024 18:43

- PCW

20 Aug 2024 18:06

Replied by PCW on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- AndyDM01

- AndyDM01

20 Aug 2024 18:05

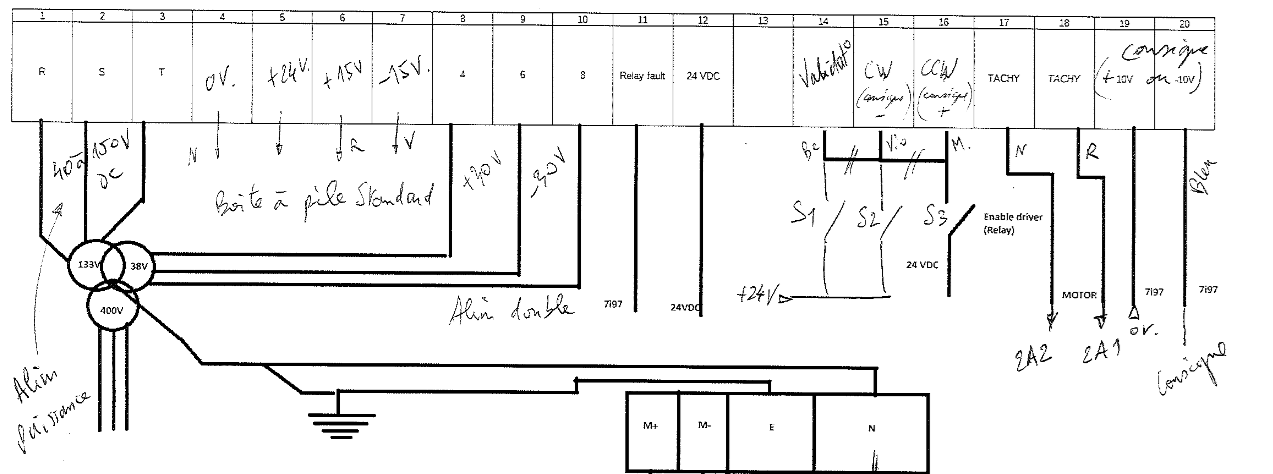

is there some basic list to build the net ? was created by AndyDM01

is there some basic list to build the net ?

Category: EtherCAT

- RMJ fabrication

- RMJ fabrication

20 Aug 2024 17:42

Replied by RMJ fabrication on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- greg23_78

- greg23_78

20 Aug 2024 17:41

- PCW

20 Aug 2024 17:25

Replied by PCW on topic Open Configuration tool issue

Open Configuration tool issue

Category: Configuration Tools

- AndyDM01

- AndyDM01

20 Aug 2024 17:22

- PCW

20 Aug 2024 17:06

- AndyDM01

- AndyDM01

20 Aug 2024 16:36 - 20 Aug 2024 16:37

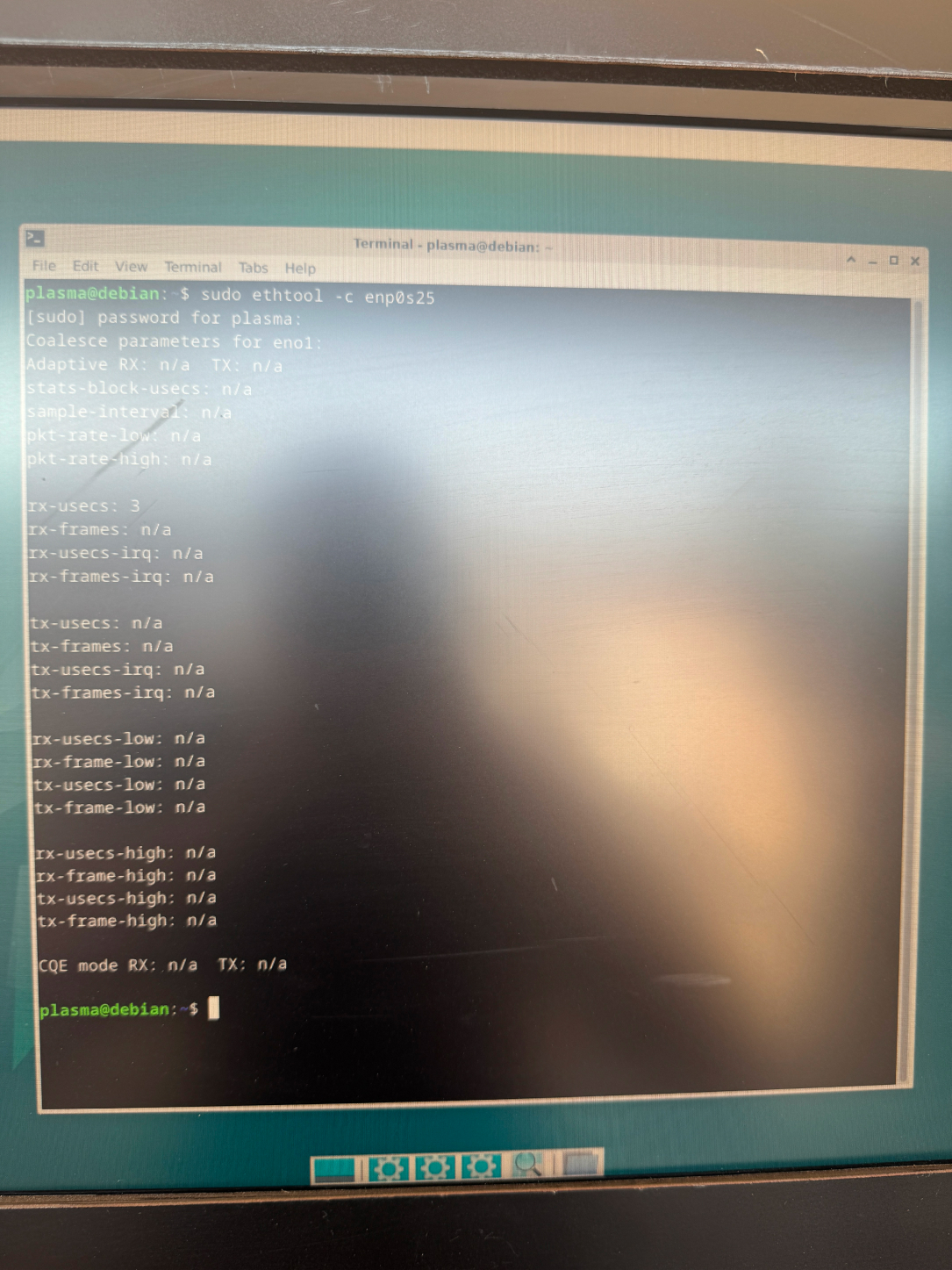

Replied by AndyDM01 on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- greg23_78

- greg23_78

20 Aug 2024 16:34

- RLA

- RLA

20 Aug 2024 16:29

Replied by RLA on topic Open Configuration tool issue

Open Configuration tool issue

Category: Configuration Tools

- PCW

20 Aug 2024 16:16

Replied by PCW on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- HPW

- HPW

20 Aug 2024 16:05 - 20 Aug 2024 16:07

Replied by HPW on topic 3 Achs Fräse mit MESA 7C80 und Raspi 4

3 Achs Fräse mit MESA 7C80 und Raspi 4

Category: Deutsch

- Aciera

20 Aug 2024 16:04 - 20 Aug 2024 16:22

Time to create page: 0.435 seconds