Search Results (Searched for: )

- timo

- timo

28 Dec 2025 08:51 - 28 Dec 2025 09:01

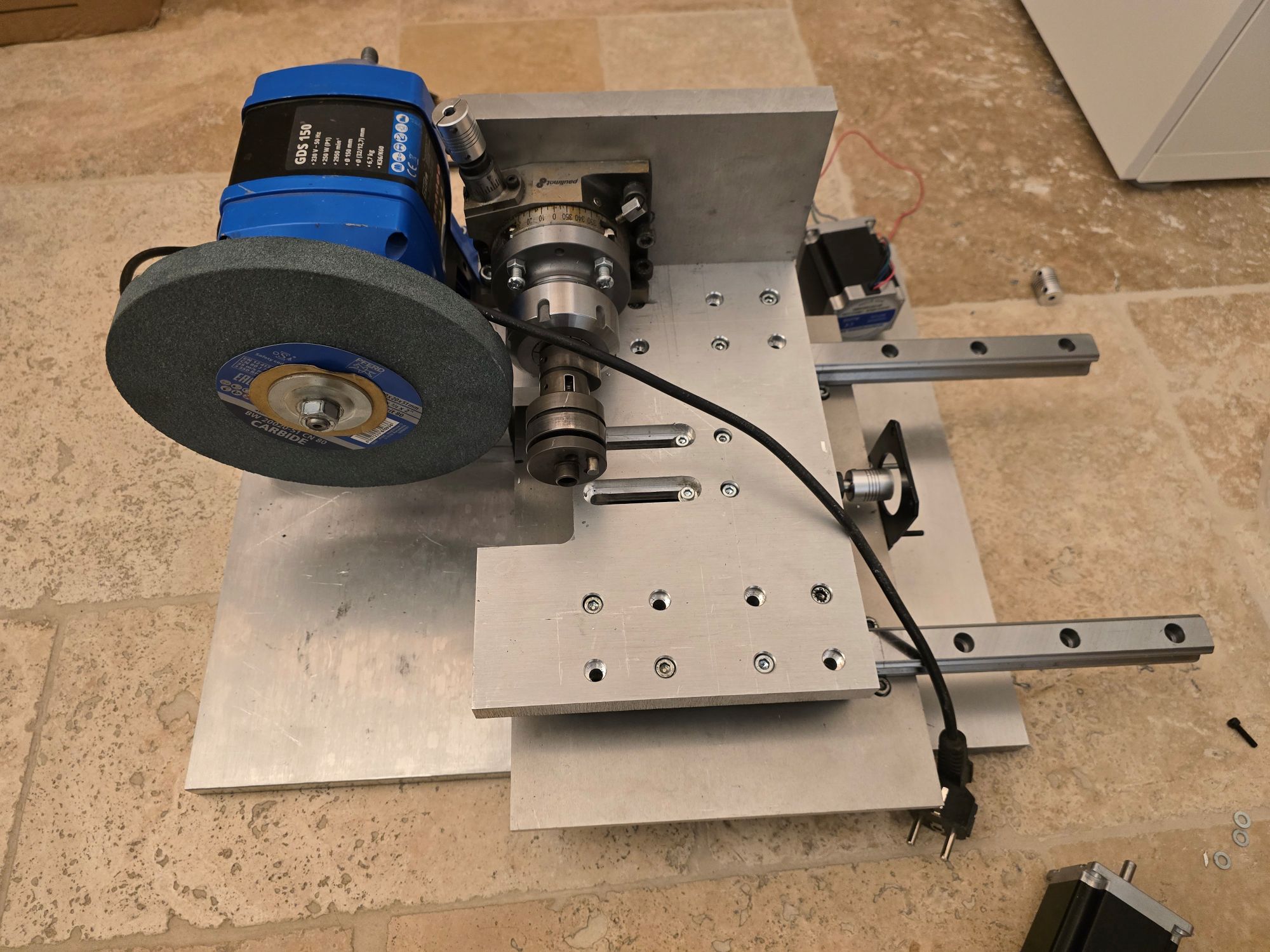

Replied by timo on topic CNC camshaft grinder DIY project

CNC camshaft grinder DIY project

Category: CNC Machines

- jameslc15

- jameslc15

28 Dec 2025 06:36 - 28 Dec 2025 06:37

Replied by jameslc15 on topic No speed control on xhc-wb04b-6 pendant on 3 axis router

No speed control on xhc-wb04b-6 pendant on 3 axis router

Category: Basic Configuration

- grandixximo

28 Dec 2025 06:23

Replied by grandixximo on topic How to fix "Queue is not empty after probing"

How to fix "Queue is not empty after probing"

Category: General LinuxCNC Questions

- rodw

28 Dec 2025 05:45

Replied by rodw on topic Freelancer wanted to get tool sensor working (software)

Freelancer wanted to get tool sensor working (software)

Category: User Exchange

- rodw

28 Dec 2025 05:35

Replied by rodw on topic How to install simplescreenrecorder on old version of Debian?

How to install simplescreenrecorder on old version of Debian?

Category: Computers and Hardware

- Thllll

- Thllll

28 Dec 2025 02:07

Freelancer wanted to get tool sensor working (software) was created by Thllll

Freelancer wanted to get tool sensor working (software)

Category: User Exchange

- rhscdn

- rhscdn

28 Dec 2025 01:35

Replied by rhscdn on topic WHB04B-6 - Change display units and step sizes

WHB04B-6 - Change display units and step sizes

Category: Installing LinuxCNC

- Thllll

- Thllll

28 Dec 2025 00:54 - 28 Dec 2025 01:51

QT Dragon Unable to Set Tool Height was created by Thllll

QT Dragon Unable to Set Tool Height

Category: Qtvcp

- unknown

- unknown

28 Dec 2025 00:05

Replied by unknown on topic CNC camshaft grinder DIY project

CNC camshaft grinder DIY project

Category: CNC Machines

- unknown

- unknown

27 Dec 2025 23:03

Replied by unknown on topic How to install simplescreenrecorder on old version of Debian?

How to install simplescreenrecorder on old version of Debian?

Category: Computers and Hardware

- tommylight

27 Dec 2025 22:24

Replied by tommylight on topic How to install simplescreenrecorder on old version of Debian?

How to install simplescreenrecorder on old version of Debian?

Category: Computers and Hardware

- FPVUALAB

- FPVUALAB

27 Dec 2025 22:20

- RotarySMP

27 Dec 2025 22:06

Replied by RotarySMP on topic How to install simplescreenrecorder on old version of Debian?

How to install simplescreenrecorder on old version of Debian?

Category: Computers and Hardware

- rodw

27 Dec 2025 21:48

Replied by rodw on topic How to install simplescreenrecorder on old version of Debian?

How to install simplescreenrecorder on old version of Debian?

Category: Computers and Hardware

- Juxus

- Juxus

27 Dec 2025 21:22

CNC camshaft grinder DIY project was created by Juxus

CNC camshaft grinder DIY project

Category: CNC Machines

Time to create page: 0.336 seconds