Search Results (Searched for: )

- sorokin_pro

26 Dec 2025 00:41

Replied by sorokin_pro on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

- Beovoxo

- Beovoxo

25 Dec 2025 22:59

Replied by Beovoxo on topic ethercat driver for EL2564

ethercat driver for EL2564

Category: EtherCAT

- zippoffs

25 Dec 2025 20:51

Replied by zippoffs on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- endian

25 Dec 2025 20:28

- endian

25 Dec 2025 20:26

Replied by endian on topic Following error due 2³¹ 2 147 483 648 jump to -2 147 483 648

Following error due 2³¹ 2 147 483 648 jump to -2 147 483 648

Category: EtherCAT

- Hakan

- Hakan

25 Dec 2025 19:21

Replied by Hakan on topic Following error due 2³¹ 2 147 483 648 jump to -2 147 483 648

Following error due 2³¹ 2 147 483 648 jump to -2 147 483 648

Category: EtherCAT

- Hakan

- Hakan

25 Dec 2025 19:19

- Ahmed.emara

- Ahmed.emara

25 Dec 2025 18:03

- Ahmed.emara

- Ahmed.emara

25 Dec 2025 17:57

Replied by Ahmed.emara on topic Hello, I would like to add an EtherCAT IO device. What should I do

Hello, I would like to add an EtherCAT IO device. What should I do

Category: EtherCAT

- Sandro

- Sandro

25 Dec 2025 16:28 - 25 Dec 2025 16:30

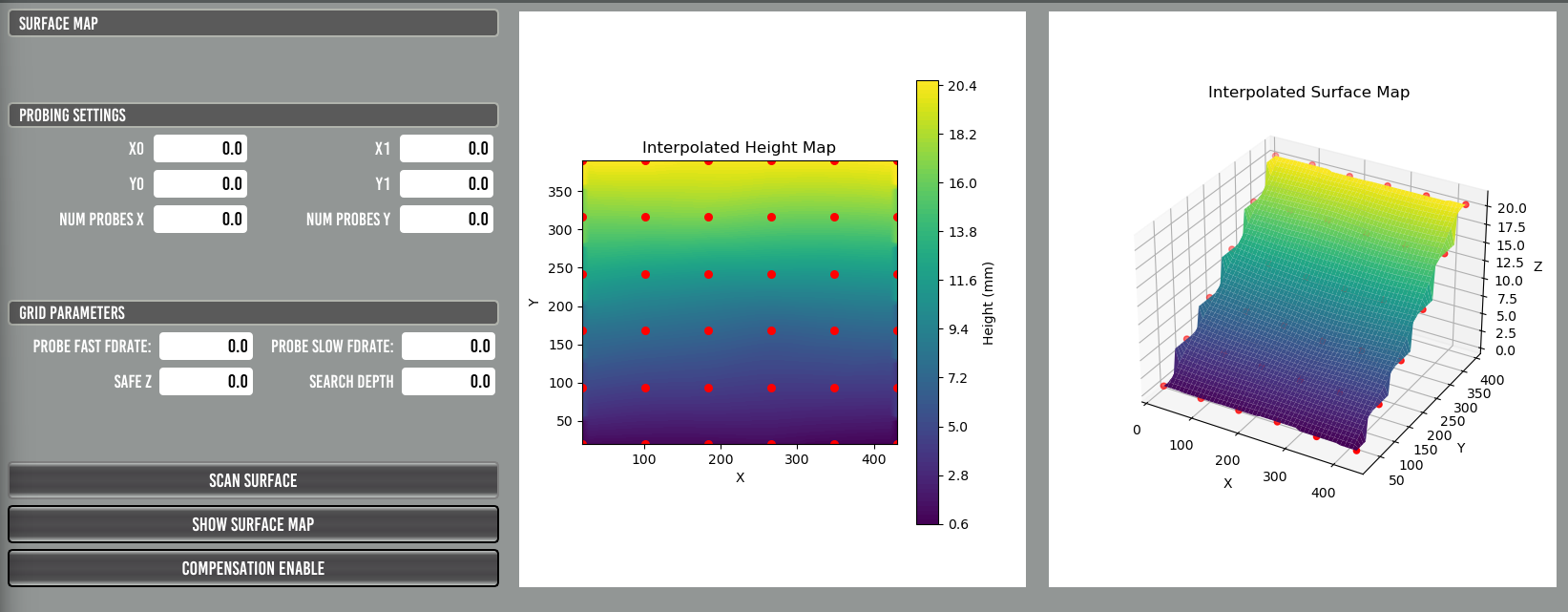

Replied by Sandro on topic Surfacemap Z compensation with Probe Basic

Surfacemap Z compensation with Probe Basic

Category: QtPyVCP

- ts

- ts

25 Dec 2025 15:14 - 25 Dec 2025 15:14

- ts

- ts

25 Dec 2025 14:48 - 25 Dec 2025 16:58

- tommylight

25 Dec 2025 13:05

- medicusdkfz

25 Dec 2025 12:24

Time to create page: 0.251 seconds