Search Results (Searched for: )

- emresensoy

- emresensoy

03 Dec 2025 18:08

Replied by emresensoy on topic Beckhoff EL2522 lcec xml file

Beckhoff EL2522 lcec xml file

Category: EtherCAT

- Hakan

- Hakan

03 Dec 2025 17:51

Replied by Hakan on topic Beckhoff EL2522 lcec xml file

Beckhoff EL2522 lcec xml file

Category: EtherCAT

- emresensoy

- emresensoy

03 Dec 2025 17:44

Beckhoff EL2522 lcec xml file was created by emresensoy

Beckhoff EL2522 lcec xml file

Category: EtherCAT

- PCW

03 Dec 2025 17:19

Replied by PCW on topic MesaCT 2.1.8: Scale vs Encoder Scale

MesaCT 2.1.8: Scale vs Encoder Scale

Category: Configuration Tools

- CaliusOptimus

- CaliusOptimus

03 Dec 2025 16:59 - 03 Dec 2025 17:00

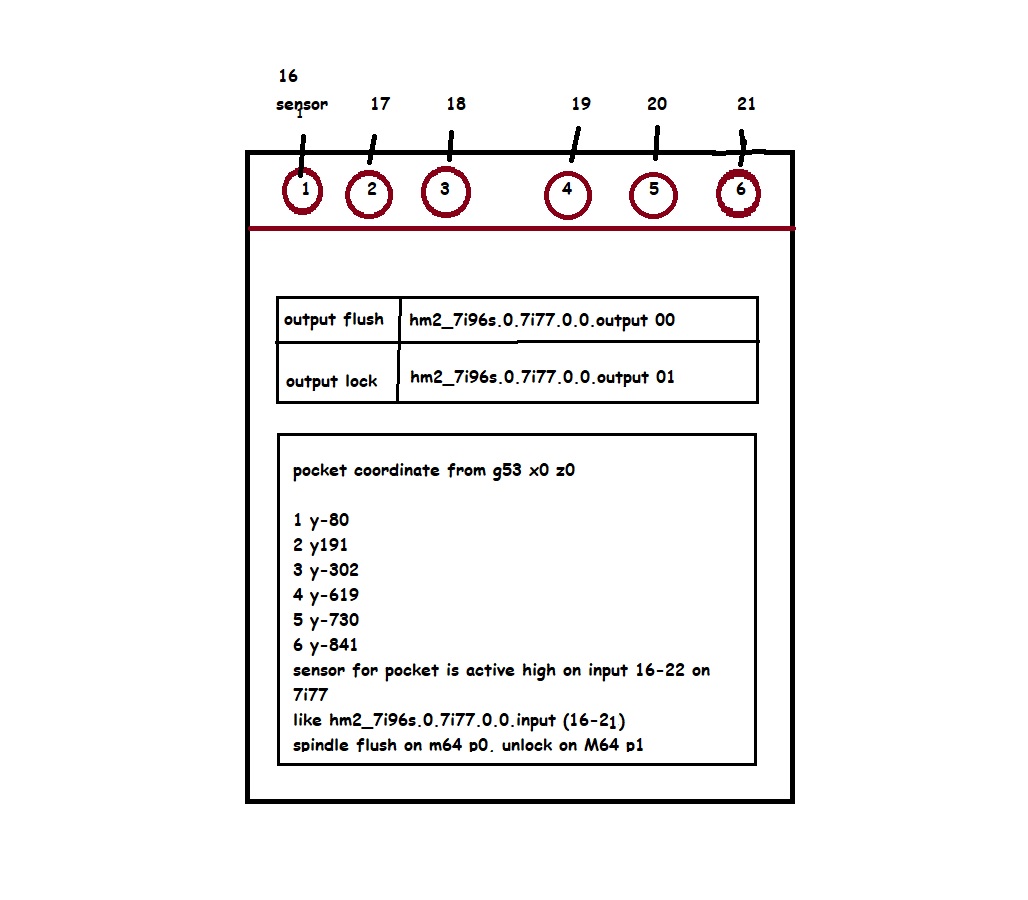

Replied by CaliusOptimus on topic Lathe project needs a turret

Lathe project needs a turret

Category: Turning

- Hakan

- Hakan

03 Dec 2025 14:57

Replied by Hakan on topic Long initialization of Ethercat on servo drive SV660N

Long initialization of Ethercat on servo drive SV660N

Category: EtherCAT

- ArthurG

- ArthurG

03 Dec 2025 13:59

Replied by ArthurG on topic Looking for freelancer to finish retrofit of K2 router

Looking for freelancer to finish retrofit of K2 router

Category: User Exchange

- HaroldHarvey

- HaroldHarvey

03 Dec 2025 11:00 - 20 Dec 2025 08:30

Replied by HaroldHarvey on topic SmartSerial on cheap ESP32-8ch-Relais Card

SmartSerial on cheap ESP32-8ch-Relais Card

Category: Driver Boards

- hdhedhu

- hdhedhu

03 Dec 2025 10:42

Replied by hdhedhu on topic Long initialization of Ethercat on servo drive SV660N

Long initialization of Ethercat on servo drive SV660N

Category: EtherCAT

- Masiwood123

03 Dec 2025 09:53

Replied by Masiwood123 on topic beta bulleri for retrofit?

beta bulleri for retrofit?

Category: CNC Machines

- rodw

03 Dec 2025 09:27

Replied by rodw on topic Reduce read-all timing 7i76e + 7i77

Reduce read-all timing 7i76e + 7i77

Category: Advanced Configuration

- Aciera

03 Dec 2025 08:30

Replied by Aciera on topic Ursviken Pullmax Optima 130 press brake retrofit with 4 axis backgage

Ursviken Pullmax Optima 130 press brake retrofit with 4 axis backgage

Category: Show Your Stuff

- unknown

- unknown

03 Dec 2025 08:17

Replied by unknown on topic Linuxcnc Image for Raspberry Pi 3

Linuxcnc Image for Raspberry Pi 3

Category: General LinuxCNC Questions

- masawee

- masawee

03 Dec 2025 07:54

- Aciera

03 Dec 2025 07:51

Replied by Aciera on topic Test to check if I can submit a post

Test to check if I can submit a post

Category: Off Topic and Test Posts

Time to create page: 0.307 seconds