Search Results (Searched for: )

- zz912

13 Mar 2025 12:17

Replied by zz912 on topic LCNC 2.10 - Ask for AUTOMATIC_G43

LCNC 2.10 - Ask for AUTOMATIC_G43

Category: Gmoccapy

- snowgoer540

13 Mar 2025 11:45

Replied by snowgoer540 on topic QTPlasmaC post processor - SheetCam?

QTPlasmaC post processor - SheetCam?

Category: Plasmac

- HansU

13 Mar 2025 11:36

Replied by HansU on topic LCNC 2.10 - Ask for AUTOMATIC_G43

LCNC 2.10 - Ask for AUTOMATIC_G43

Category: Gmoccapy

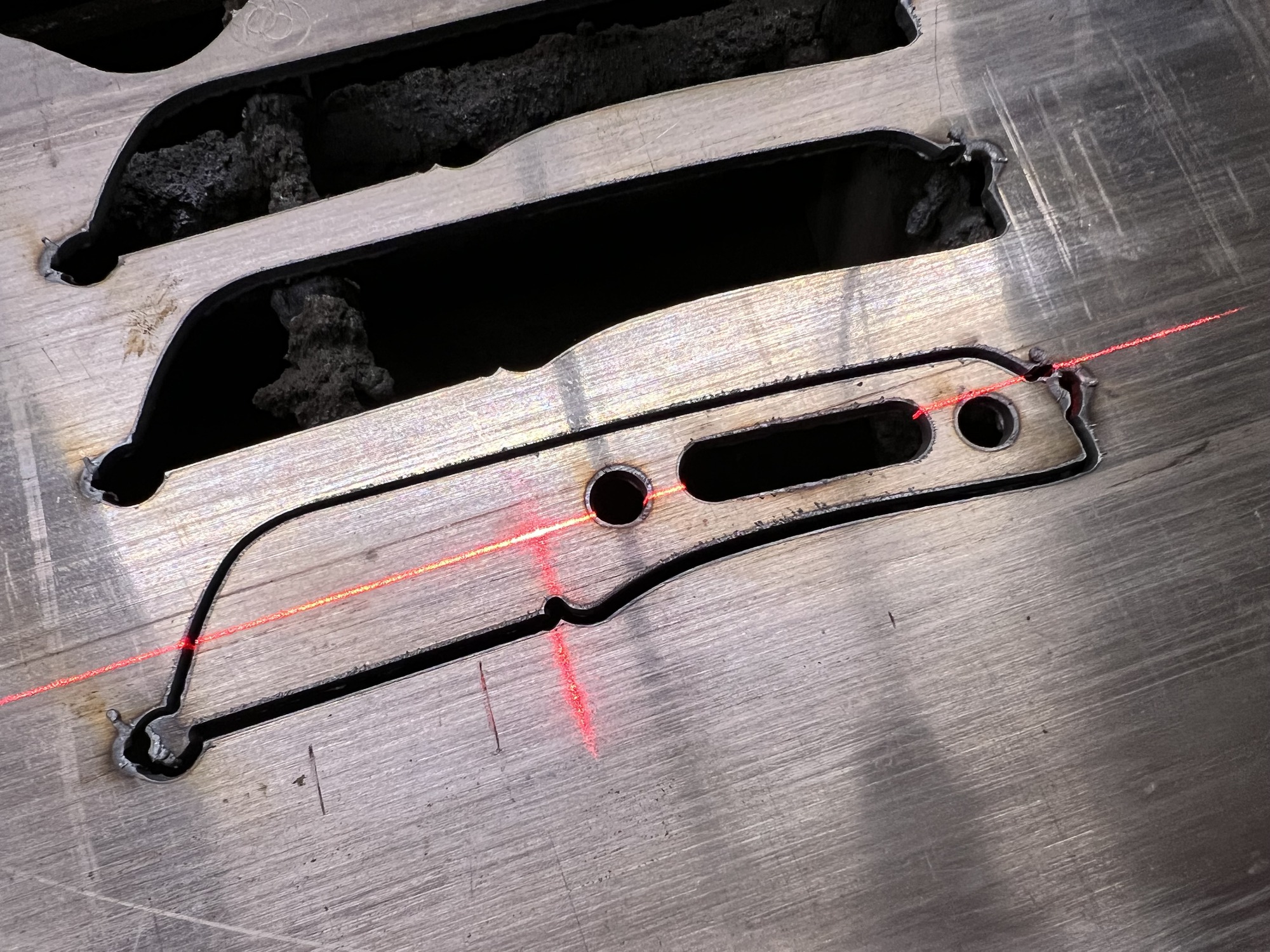

- stkvit

- stkvit

13 Mar 2025 11:18 - 13 Mar 2025 11:19

Replied by stkvit on topic Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

Category: Plasma & Laser

- atrex77

13 Mar 2025 11:10

- Wischi

- Wischi

13 Mar 2025 10:19 - 13 Mar 2025 14:26

Replied by Wischi on topic Spindle PID RPM oscillates under load

Spindle PID RPM oscillates under load

Category: Advanced Configuration

- JTknives

13 Mar 2025 10:12

Replied by JTknives on topic QTPlasmaC post processor - SheetCam?

QTPlasmaC post processor - SheetCam?

Category: Plasmac

- besriworld

- besriworld

13 Mar 2025 10:06

Replied by besriworld on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- rodw

13 Mar 2025 10:02

Replied by rodw on topic QTPlasmaC post processor - SheetCam?

QTPlasmaC post processor - SheetCam?

Category: Plasmac

- UrKibin

- UrKibin

13 Mar 2025 09:52

- snowgoer540

13 Mar 2025 09:51 - 13 Mar 2025 10:05

Replied by snowgoer540 on topic QTPlasmaC post processor - SheetCam?

QTPlasmaC post processor - SheetCam?

Category: Plasmac

- ArkadiuszGr

- ArkadiuszGr

13 Mar 2025 09:21

Replied by ArkadiuszGr on topic Lichuan Ethercat Nema23 closed loop stepper motor XML configuration

Lichuan Ethercat Nema23 closed loop stepper motor XML configuration

Category: EtherCAT

- JTknives

13 Mar 2025 08:54

Replied by JTknives on topic QTPlasmaC post processor - SheetCam?

QTPlasmaC post processor - SheetCam?

Category: Plasmac

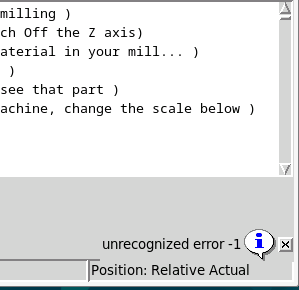

- NT4Boy

- NT4Boy

13 Mar 2025 08:49 - 13 Mar 2025 08:51

Replied by NT4Boy on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- JTknives

13 Mar 2025 08:43

Replied by JTknives on topic QTPlasmaC post processor - SheetCam?

QTPlasmaC post processor - SheetCam?

Category: Plasmac

Time to create page: 0.385 seconds