Search Results (Searched for: )

- jtrantow

- jtrantow

10 Feb 2026 20:21 - 10 Feb 2026 21:40

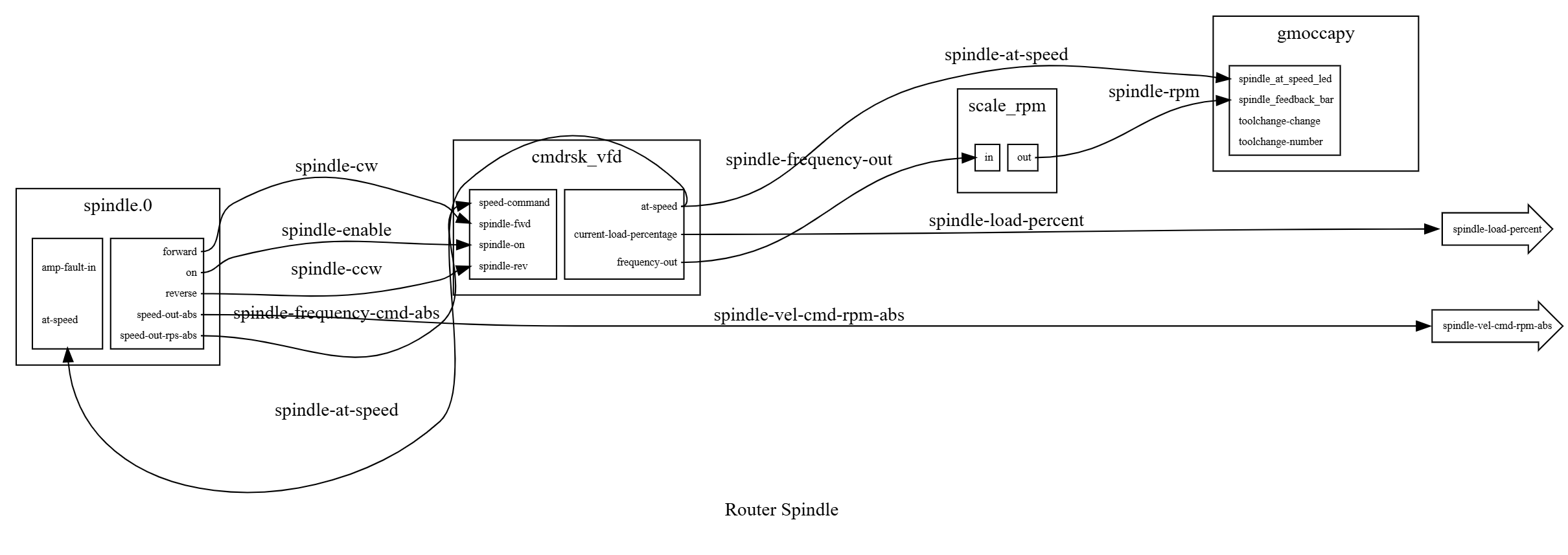

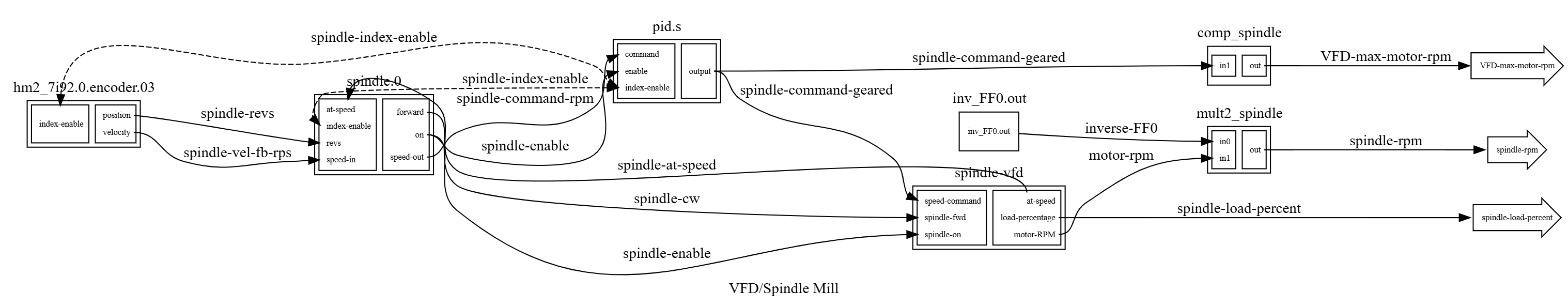

Replied by jtrantow on topic HAL Edits for RS485 / VFD Spindle Control

HAL Edits for RS485 / VFD Spindle Control

Category: HAL

- Elco

- Elco

10 Feb 2026 19:35 - 11 Feb 2026 08:12

Replied by Elco on topic Problème Carte PCIE parallèle

Problème Carte PCIE parallèle

Category: General LinuxCNC Questions

- sconisbee

- sconisbee

10 Feb 2026 19:23

- MaHa

- MaHa

10 Feb 2026 19:07

- Mbrand1901

- Mbrand1901

10 Feb 2026 18:57 - 10 Feb 2026 18:59

Replied by Mbrand1901 on topic Retrofitting Deckel FP4ATC

Retrofitting Deckel FP4ATC

Category: Milling Machines

- turbohoolik

- turbohoolik

10 Feb 2026 18:34

Soft limits are not working all the time... was created by turbohoolik

Soft limits are not working all the time...

Category: Basic Configuration

- Muecke

10 Feb 2026 17:18

- Gogonfa

- Gogonfa

10 Feb 2026 16:50 - 10 Feb 2026 16:51

Replied by Gogonfa on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- sconisbee

- sconisbee

10 Feb 2026 16:30

- PCW

10 Feb 2026 16:04

Replied by PCW on topic Yet another firmware request - 7i92T + 7i77 + 7i85

Yet another firmware request - 7i92T + 7i77 + 7i85

Category: Driver Boards

- PCW

10 Feb 2026 15:43 - 10 Feb 2026 16:05

Replied by PCW on topic Using 7c81 with 5v encoder on bob3 config

Using 7c81 with 5v encoder on bob3 config

Category: Driver Boards

- Bansardo

- Bansardo

10 Feb 2026 15:16

Replied by Bansardo on topic Can the OPI5 be Configured to Run LCNC?

Can the OPI5 be Configured to Run LCNC?

Category: Computers and Hardware

- Finngineering

- Finngineering

10 Feb 2026 14:42

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Henk

- Henk

10 Feb 2026 14:19

Yet another firmware request - 7i92T + 7i77 + 7i85 was created by Henk

Yet another firmware request - 7i92T + 7i77 + 7i85

Category: Driver Boards

- krille

- krille

10 Feb 2026 13:35

Replied by krille on topic Raspberry pi 5 freze

Raspberry pi 5 freze

Category: General LinuxCNC Questions

Time to create page: 0.527 seconds