Search Results (Searched for: )

- turbohoolik

- turbohoolik

15 Feb 2026 15:35

Replied by turbohoolik on topic Soft limits are not working all the time...

Soft limits are not working all the time...

Category: Basic Configuration

- PCW

15 Feb 2026 15:15

Replied by PCW on topic Integrating a BCL-AMP capacitive sensor to LinuxCNC

Integrating a BCL-AMP capacitive sensor to LinuxCNC

Category: Plasma & Laser

- tommylight

15 Feb 2026 14:44

- Marcos DC

15 Feb 2026 14:12

Replied by Marcos DC on topic Technical questions about CIA402 and homecomp.comp on A6

Technical questions about CIA402 and homecomp.comp on A6

Category: EtherCAT

- MRx

- MRx

15 Feb 2026 13:38

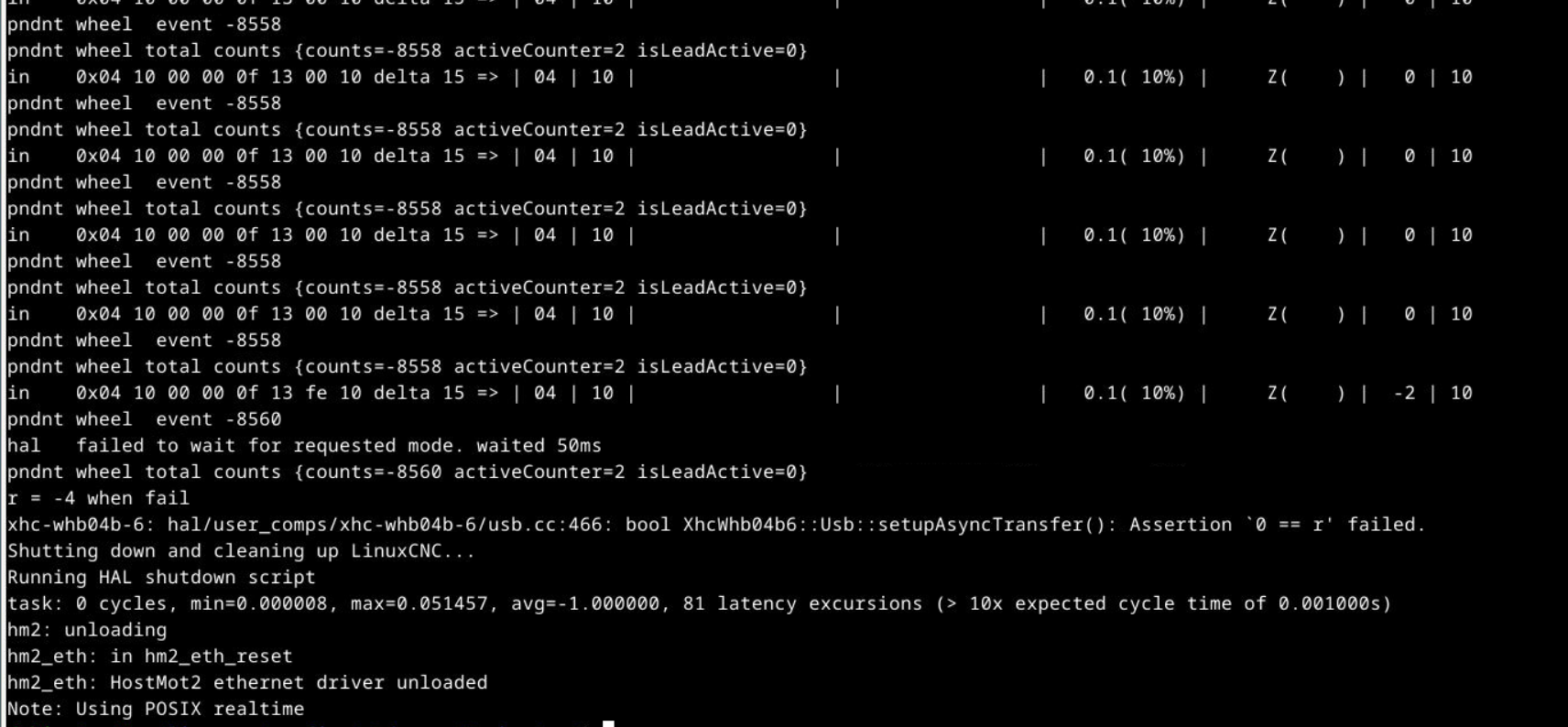

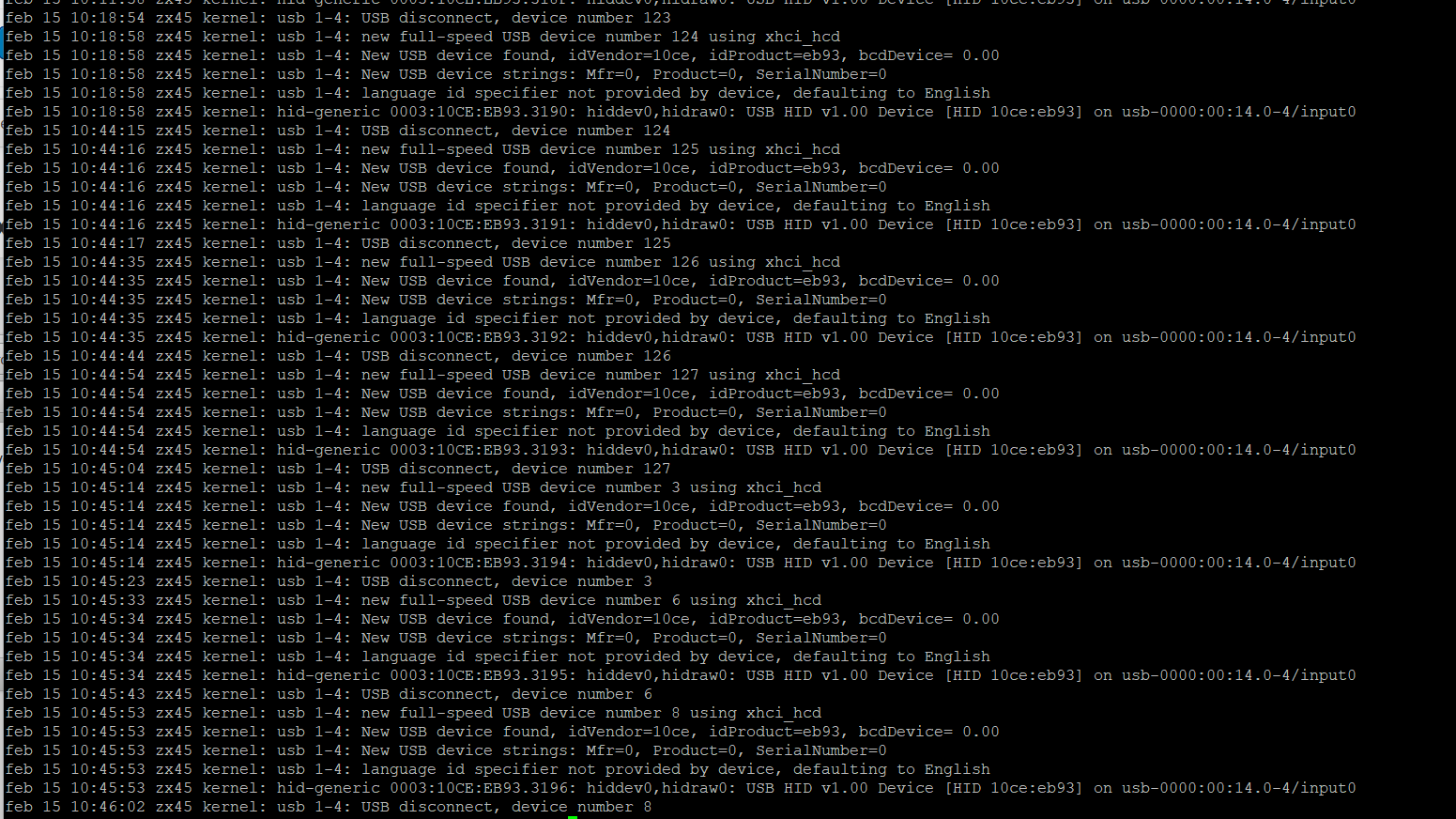

Replied by MRx on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Aciera

15 Feb 2026 13:30

- Mr. Mass

15 Feb 2026 13:02

- Looby

- Looby

15 Feb 2026 13:00

Replied by Looby on topic Electrical Contactors/Relay Help?

Electrical Contactors/Relay Help?

Category: Milling Machines

- Hakan

- Hakan

15 Feb 2026 12:49 - 15 Feb 2026 13:00

Replied by Hakan on topic Ethercat beckho el2819 conf

Ethercat beckho el2819 conf

Category: EtherCAT

- GDTH

15 Feb 2026 11:07

- BIBIGUL

- BIBIGUL

15 Feb 2026 11:06

- rodw

15 Feb 2026 10:35

Replied by rodw on topic Technical questions about CIA402 and homecomp.comp on A6

Technical questions about CIA402 and homecomp.comp on A6

Category: EtherCAT

- Hakan

- Hakan

15 Feb 2026 10:18 - 15 Feb 2026 10:27

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Aciera

15 Feb 2026 10:08

- andrax

15 Feb 2026 09:45

Replied by andrax on topic Technical questions about CIA402 and homecomp.comp on A6

Technical questions about CIA402 and homecomp.comp on A6

Category: EtherCAT

Time to create page: 0.660 seconds