Hello everyone!

My hobby-interest in TIG-welding has opened up new paths on my fabricators journey. I mainly build exercise machines for my own use and I want to expand on my capabilities by building a CNC plasma table. Taking the long way is my go to in pretty much everything I do. I seem to be unable to just buy a plasma cutter and start cutting. I have some experience in using Fusion 360 and a few uni courses on Python coding (a long time ago). I have been relentlessly studying on my off time about plasma cutting in general, and about electrical motors for around three months.

This forum was a fantastic discovery, along with associated youtube channels. And ofcourse, I'm here to learn and ask for help before I buy the components.

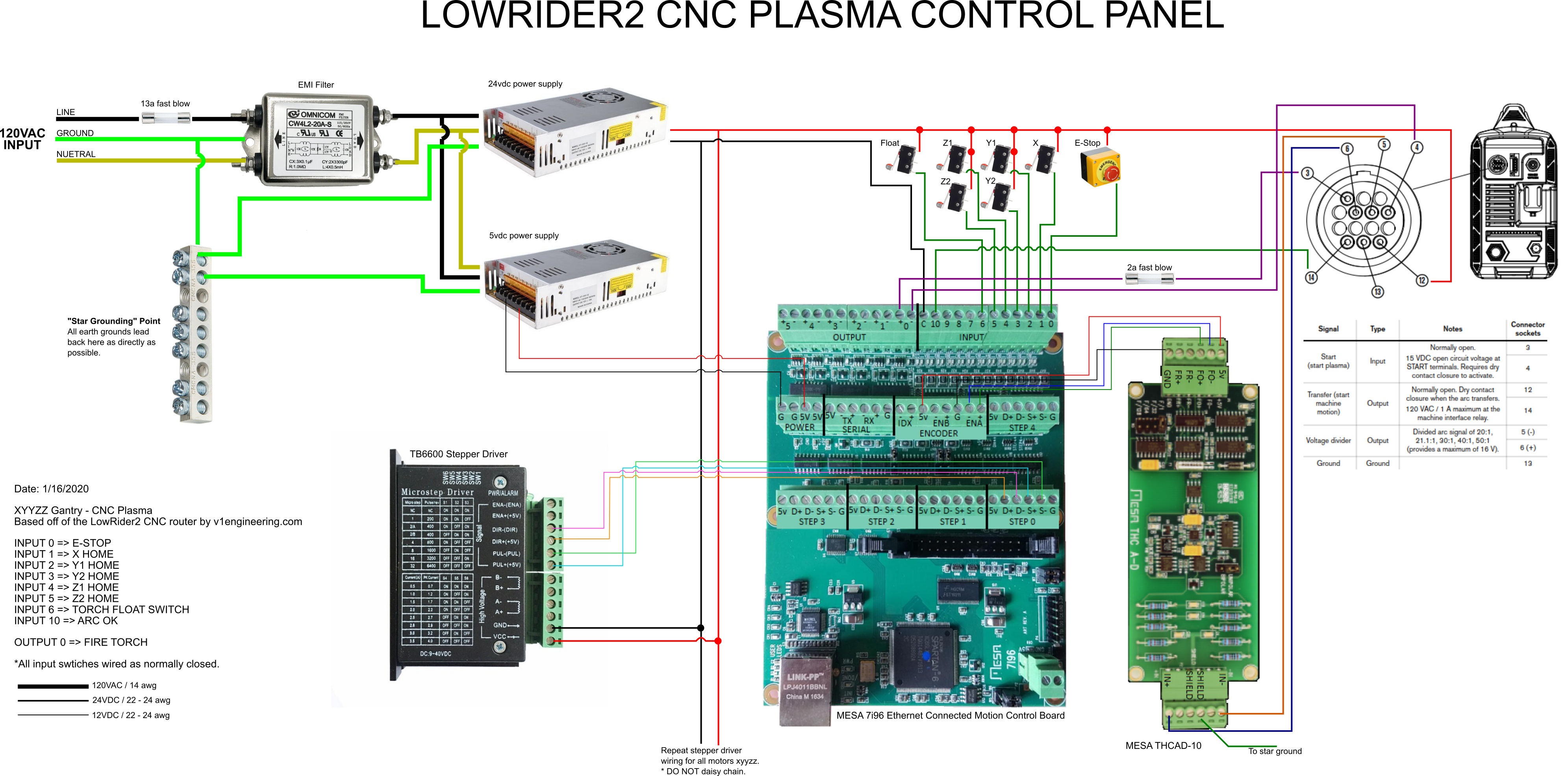

MESAs mothercard and THCADs are what I want to go with and due to shortage on the EU-market I cannot pick up exactly the same parts as lets say Rod's Spaceship build.

I will be converting my laptop for Linux and use LinuxCNC. For features, I want to have voltage and ohmic sensing, as the build is going to be fairly large. (half a sheet) Having axes feedback is not a must, but would be great. The frame will be fabricated from 3 millimeters thick 70x70 steel box section. The gantry itself I might choose something like 2 millimeters thick 100x50 box section. Rack and pinion on all axes except Z-axes will have a ball screw.

The main components:

MESA 7i95T eusurplus.com/index.php?route=product/pr...=59_62&product_id=64

It has encoder feedback on all of the axes and I would like to use either hybrid-type stepper motor or servo motors for all axes.

2x

MESA THCAD2 eusurplus.com/index.php?route=product/product&product_id=161

One for controlling the Z-axes by voltage monitoring and one for ohmic sensing.

If I go with hybrid nema 23 stepper motors, do I need additional stepper drivers, or will the 7i95T be enough?

I would prefer non chinese built power supplies, but to my surprise they are not as easy to get as I would have liked them to be. Am I being too picky?

I have absolutely no idea what kind of wiring I should use in the build. We have 230 V 50 Hz mains in Finland. I was adviced not to get any wire crimpers as most of the wiring is done with screw terminals because of the added resistance from the crimps.

I have hopes of using a Hypertherm plasma cutter, but If my budget wont allow it I will choose Everlasts plasma cutter as I was highly impressed by the neat insides of one of their welders on one of Kevin Carons videos.

Any feedback on my ideas for the build would be greatly appreciated. Hopefully I can document the whole journey well enough to be shared for everyone.

Best regards,

Olli