Search Results (Searched for: stepper spindle)

- Appliedmarine

- Appliedmarine

17 Oct 2024 05:45

Mazak Quickturn 10 x2 retrofit ideas! was created by Appliedmarine

Mazak Quickturn 10 x2 retrofit ideas!

Category: Turning

- automata

- automata

14 Oct 2024 09:30

Replied by automata on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- freemoore

- freemoore

13 Oct 2024 12:01

Replied by freemoore on topic Request for Mesa 5i23_7i48_7i52 firmware

Request for Mesa 5i23_7i48_7i52 firmware

Category: Driver Boards

- C0bra

- C0bra

08 Oct 2024 07:39

Replied by C0bra on topic Retrofiting Scm record 220

Retrofiting Scm record 220

Category: CNC Machines

- PhilipME

04 Oct 2024 03:32 - 04 Oct 2024 04:14

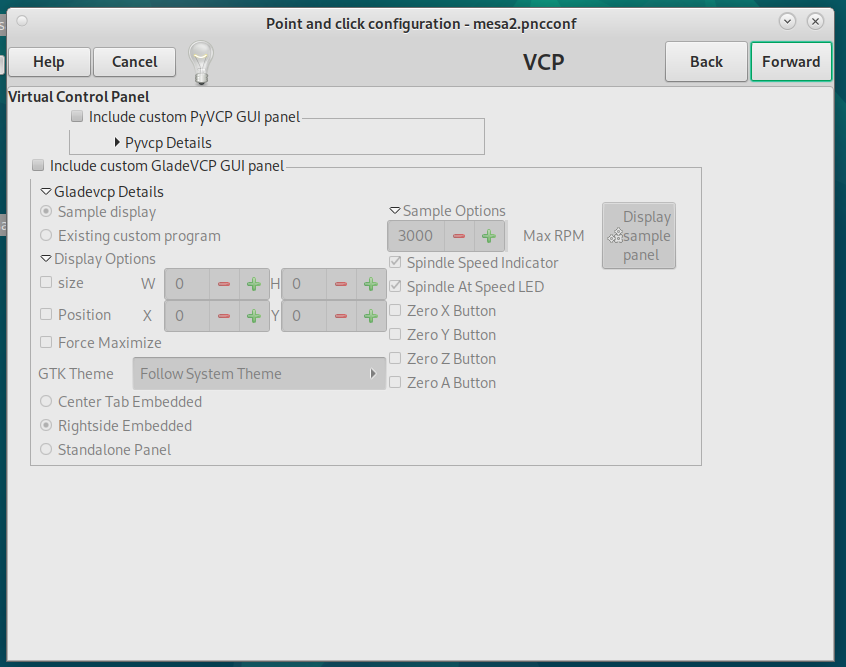

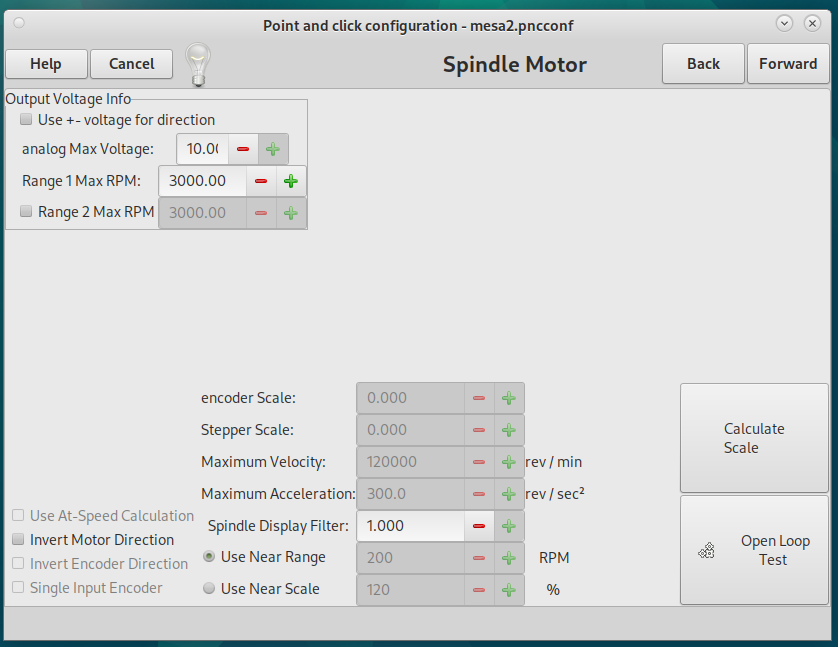

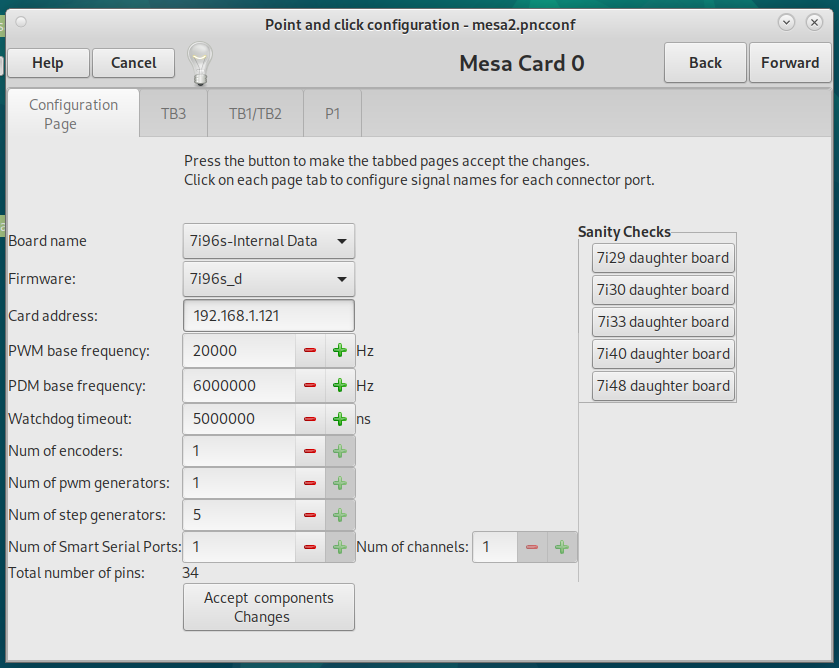

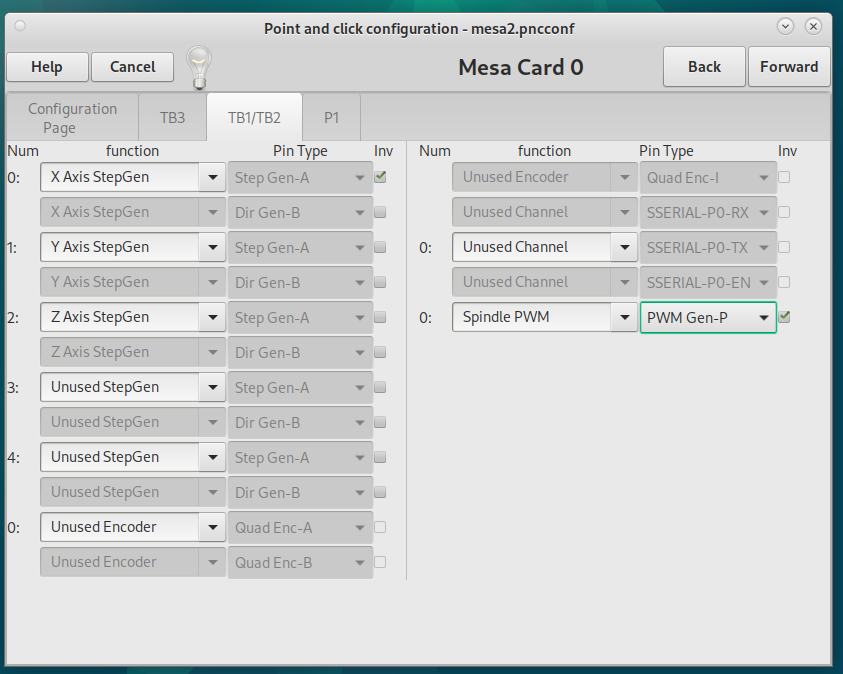

help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21 was created by PhilipME

help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21

Category: PnCConf Wizard

- spumco

- spumco

02 Oct 2024 05:05

Replied by spumco on topic Carousel Toolchanger

Carousel Toolchanger

Category: Advanced Configuration

- Aleksi

- Aleksi

02 Oct 2024 01:44

Replied by Aleksi on topic Connecting two 7i92 boards

Connecting two 7i92 boards

Category: General LinuxCNC Questions

- ConSonar

- ConSonar

30 Sep 2024 23:11

Help me decide. To Retrofit or not to Retrofit....... was created by ConSonar

Help me decide. To Retrofit or not to Retrofit.......

Category: General LinuxCNC Questions

- PhilipME

26 Sep 2024 04:31 - 26 Sep 2024 06:39

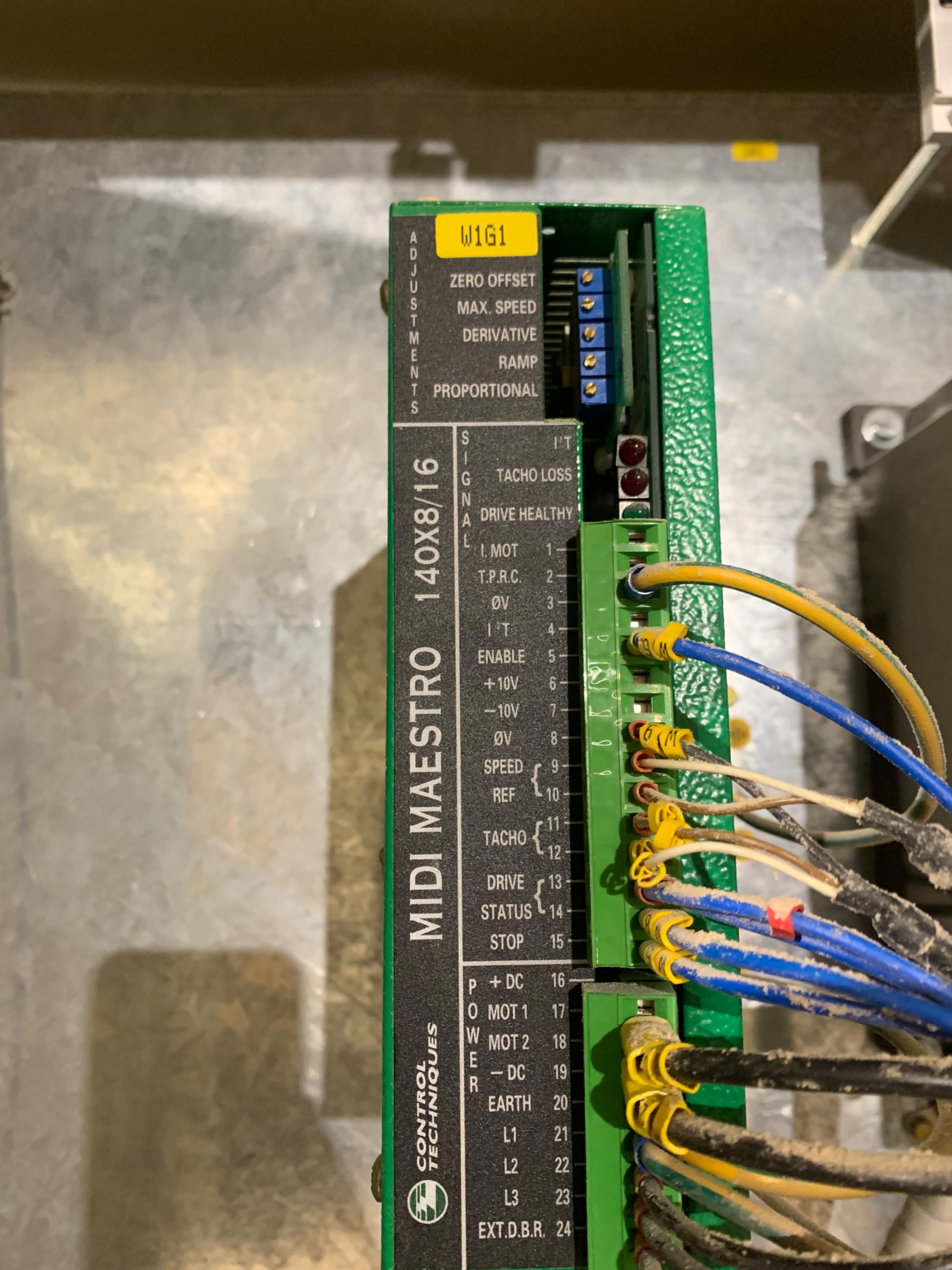

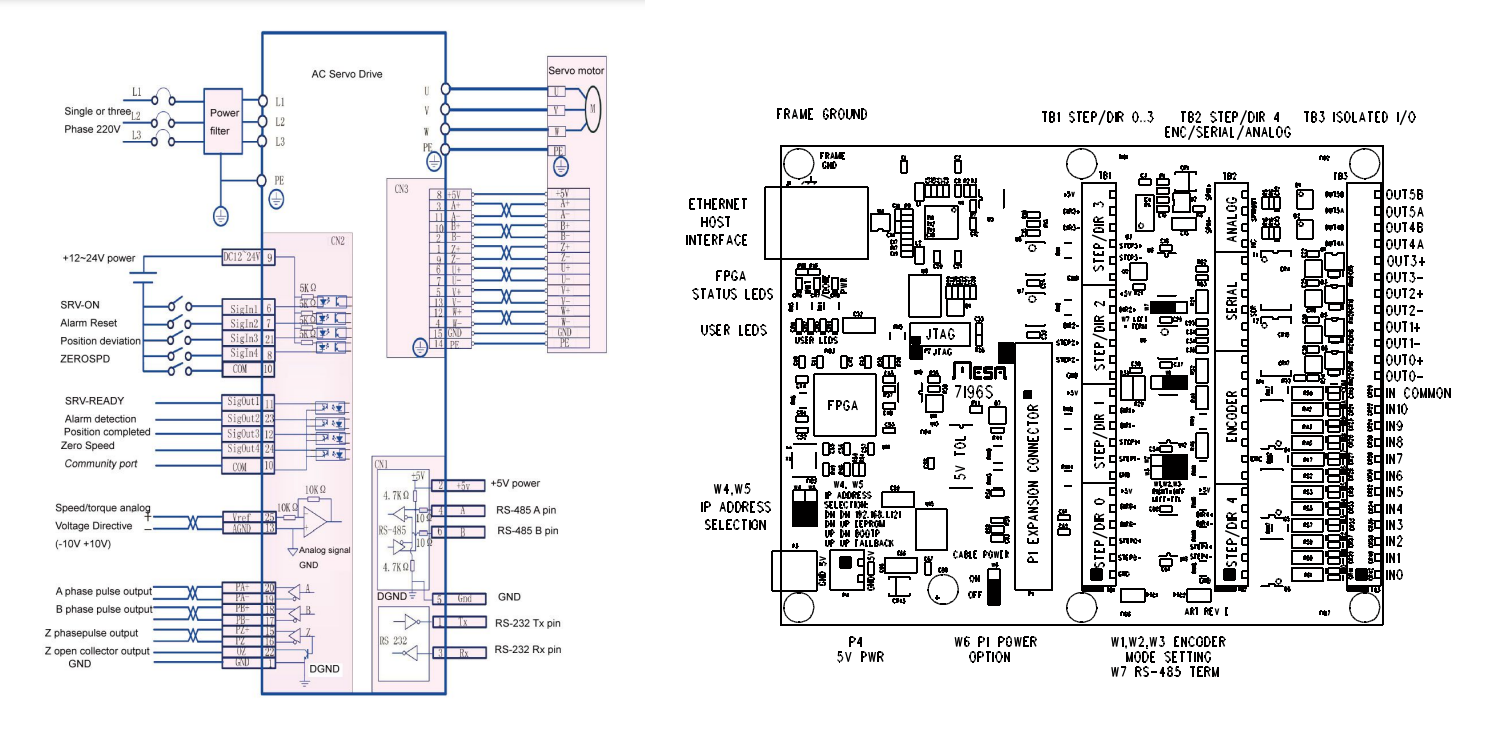

wiring mesa 7i96s to servo driver as a spindle was created by PhilipME

wiring mesa 7i96s to servo driver as a spindle

Category: Driver Boards

- PhilipME

23 Sep 2024 17:12

Replied by PhilipME on topic intending to use a servo motor as a spindle with mesa 7i96s

intending to use a servo motor as a spindle with mesa 7i96s

Category: PnCConf Wizard

- PhilipME

23 Sep 2024 14:26

Replied by PhilipME on topic intending to use a servo motor as a spindle with mesa 7i96s

intending to use a servo motor as a spindle with mesa 7i96s

Category: PnCConf Wizard

- tommylight

23 Sep 2024 14:17

Replied by tommylight on topic intending to use a servo motor as a spindle with mesa 7i96s

intending to use a servo motor as a spindle with mesa 7i96s

Category: PnCConf Wizard

- millikari

- millikari

22 Sep 2024 22:56

Indicator LED behavior of action buttons changed in version 2.9.3? was created by millikari

Indicator LED behavior of action buttons changed in version 2.9.3?

Category: Qtvcp

- xaxexa

20 Sep 2024 03:06

Replied by xaxexa on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- 2703adam

- 2703adam

18 Sep 2024 18:13

New and overwhelmed. was created by 2703adam

New and overwhelmed.

Category: General LinuxCNC Questions

Time to create page: 0.933 seconds