Search Results (Searched for: stepper spindle)

05 Sep 2023 16:47

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

ok, on the topic of pins....

multiswitch might not be ideal for the mpg, not sure now.

Lets use the 4 buttons on the pendant here.

Button 1: sets the axis you want to move.

Button 2: sets the increment the axis moves per encoder count.

Button 3: turns the spindle on and off.

Button 4: turns the coolant on and off.

3 and 4 are duplicates on the main keyboard which I don't think matters here.

Pressing the spindle button will change the state on a multi switch pin. If the spindle is already on, it turns it off and vice versa. M3 to M5 and back. I think this works. The downside is the LED indication could get confused if there was any sort of hiccup. No big deal though.

The coolant it the same. M7/M9. Same led feedback potential glitch, but not important.

Cycling the axis we may have an issue, but I do not fully grasp how this works internally, so maybe it is fine. When the machine starts, the MPG and the Control have no idea what each other has "set" for MPG functions. On a normal MPG the switches are persistent. If X is set, it is hitting that specific pin on the mesa, so linuxcnc KNOWS what the pendant is set to. With multiswitch you are flying blind a bit like using steppers. You need to preset a common default on both, and then hope there are no glitches that send the display out of sync with the control.

So our trade of having 1 pin per function instead of 4 (xyza) is decidedly more unreliable.

There is a middleground though maybe using binary code. 2 pins will get me 4 settings that cant go out of sync. So 2 mesa input pins (and 2 RP2040 output) per axis button.

So lets count up our IO properly.

M3/M5 - 1 pin, multiswitch on mesa. 1 pin on RP2040.

M4/M5 - 1 pin, multiswitch on mesa. 1 pin on RP2040. Uses same KEY as M3 with shift

M7/M9 - 1 pin, multiswitch on mesa. 1 pin on RP2040.

Cycle Start, Cycle Pause, And Cycle Stop. Hypothetically 3 more pins each, BUT, these are already tied to hotkeys, so potentially they do not need to be pins unless there is a reliability reasoning.

MPG wheel - 4 pins for differential correct? Nothing on the RP2040

MPG AXIS - 2 pins on the mesa, 2 pins on the RP2040, one key.

MPG increment - 2 pins on the mesa, 2 pins on the RP2040, one key.

Jog/MDI mode toggle - 1 pin, multiswitch on mesa. 1 pin on RP2040.

Enable would be one pin each too.

The override wheel i assume is really just another mpg. 2 pins each override (spindle and feed) on the mesa will just increment the override up and down. Pressing the encoder push switch would reset back to 100 so that is 1 more pin each. The RP2040 can read this encoder with 2 pins, and the pushbutton is in the key matrix. Then it needs 6 outputs back to the mesa. We do have the potential again for out led's to be wrong in a glitch, but those aren't super important and would get reset often.

The rest i'm not sure yet how they function.

1 - I want something to instigate a tool change. Press tool/magazine, then a number, then enter and it changes tool.

2 - I want to reference the machine. The ways its done on the DDCS is you press home, then the axis + you want to home, and then enter.

3 - Likewise the same for touching off. Zero, axis +, type a number (or zero), and then enter.

Past that we have some other transparent signals.

- Spindle overload error would be a pin on the mesa and rp2040. PLUS a pin on the rp2040 to read from the spindle drive.

We have used up all the basic IO on the rp2040 already here, but we only need a few more. So we need a 16 pin expander. Not a big deal. If we could serialise some of the lesser functions that would be nice, but I feel a $6 expansion of IO is much easier.

We are still pretty wide open for io on the mesa on the the 7i84.

The last thing we need in the middle is a level converter since all my RP2040 IO is 3,3v.

multiswitch might not be ideal for the mpg, not sure now.

Lets use the 4 buttons on the pendant here.

Button 1: sets the axis you want to move.

Button 2: sets the increment the axis moves per encoder count.

Button 3: turns the spindle on and off.

Button 4: turns the coolant on and off.

3 and 4 are duplicates on the main keyboard which I don't think matters here.

Pressing the spindle button will change the state on a multi switch pin. If the spindle is already on, it turns it off and vice versa. M3 to M5 and back. I think this works. The downside is the LED indication could get confused if there was any sort of hiccup. No big deal though.

The coolant it the same. M7/M9. Same led feedback potential glitch, but not important.

Cycling the axis we may have an issue, but I do not fully grasp how this works internally, so maybe it is fine. When the machine starts, the MPG and the Control have no idea what each other has "set" for MPG functions. On a normal MPG the switches are persistent. If X is set, it is hitting that specific pin on the mesa, so linuxcnc KNOWS what the pendant is set to. With multiswitch you are flying blind a bit like using steppers. You need to preset a common default on both, and then hope there are no glitches that send the display out of sync with the control.

So our trade of having 1 pin per function instead of 4 (xyza) is decidedly more unreliable.

There is a middleground though maybe using binary code. 2 pins will get me 4 settings that cant go out of sync. So 2 mesa input pins (and 2 RP2040 output) per axis button.

So lets count up our IO properly.

M3/M5 - 1 pin, multiswitch on mesa. 1 pin on RP2040.

M4/M5 - 1 pin, multiswitch on mesa. 1 pin on RP2040. Uses same KEY as M3 with shift

M7/M9 - 1 pin, multiswitch on mesa. 1 pin on RP2040.

Cycle Start, Cycle Pause, And Cycle Stop. Hypothetically 3 more pins each, BUT, these are already tied to hotkeys, so potentially they do not need to be pins unless there is a reliability reasoning.

MPG wheel - 4 pins for differential correct? Nothing on the RP2040

MPG AXIS - 2 pins on the mesa, 2 pins on the RP2040, one key.

MPG increment - 2 pins on the mesa, 2 pins on the RP2040, one key.

Jog/MDI mode toggle - 1 pin, multiswitch on mesa. 1 pin on RP2040.

Enable would be one pin each too.

The override wheel i assume is really just another mpg. 2 pins each override (spindle and feed) on the mesa will just increment the override up and down. Pressing the encoder push switch would reset back to 100 so that is 1 more pin each. The RP2040 can read this encoder with 2 pins, and the pushbutton is in the key matrix. Then it needs 6 outputs back to the mesa. We do have the potential again for out led's to be wrong in a glitch, but those aren't super important and would get reset often.

The rest i'm not sure yet how they function.

1 - I want something to instigate a tool change. Press tool/magazine, then a number, then enter and it changes tool.

2 - I want to reference the machine. The ways its done on the DDCS is you press home, then the axis + you want to home, and then enter.

3 - Likewise the same for touching off. Zero, axis +, type a number (or zero), and then enter.

Past that we have some other transparent signals.

- Spindle overload error would be a pin on the mesa and rp2040. PLUS a pin on the rp2040 to read from the spindle drive.

We have used up all the basic IO on the rp2040 already here, but we only need a few more. So we need a 16 pin expander. Not a big deal. If we could serialise some of the lesser functions that would be nice, but I feel a $6 expansion of IO is much easier.

We are still pretty wide open for io on the mesa on the the 7i84.

The last thing we need in the middle is a level converter since all my RP2040 IO is 3,3v.

05 Sep 2023 01:34 - 05 Sep 2023 01:34

Replied by GeramyL on topic Remora - ethernet NVEM cnc board

Remora - ethernet NVEM cnc board

Category: Computers and OS's

Dropped my accuracy down to 0.0005mm per step about 10,000 pulses per per full rotation being 5mm.

With those changes I can accomplish the speeds i was doing last time at around 65khz on the stepper frequency with the links you gave me.

That all worked great and i'm happy with it, I was gonna flip anyways to 10,000 steps per full rotation anyways to give me some more force on my steppers. Now i'm trying to configure PWM for the spindle and the input, when i configure the input though it says no such pin found for remora.input.4 am i doing something wrong in my hal, and does someone have some small examples for the probe input and spindle pwm, without indexer? Thanks so much scott! I'm gonna take a look at your dma commit in a bit now, just saw the latest push.

With those changes I can accomplish the speeds i was doing last time at around 65khz on the stepper frequency with the links you gave me.

That all worked great and i'm happy with it, I was gonna flip anyways to 10,000 steps per full rotation anyways to give me some more force on my steppers. Now i'm trying to configure PWM for the spindle and the input, when i configure the input though it says no such pin found for remora.input.4 am i doing something wrong in my hal, and does someone have some small examples for the probe input and spindle pwm, without indexer? Thanks so much scott! I'm gonna take a look at your dma commit in a bit now, just saw the latest push.

04 Sep 2023 15:16

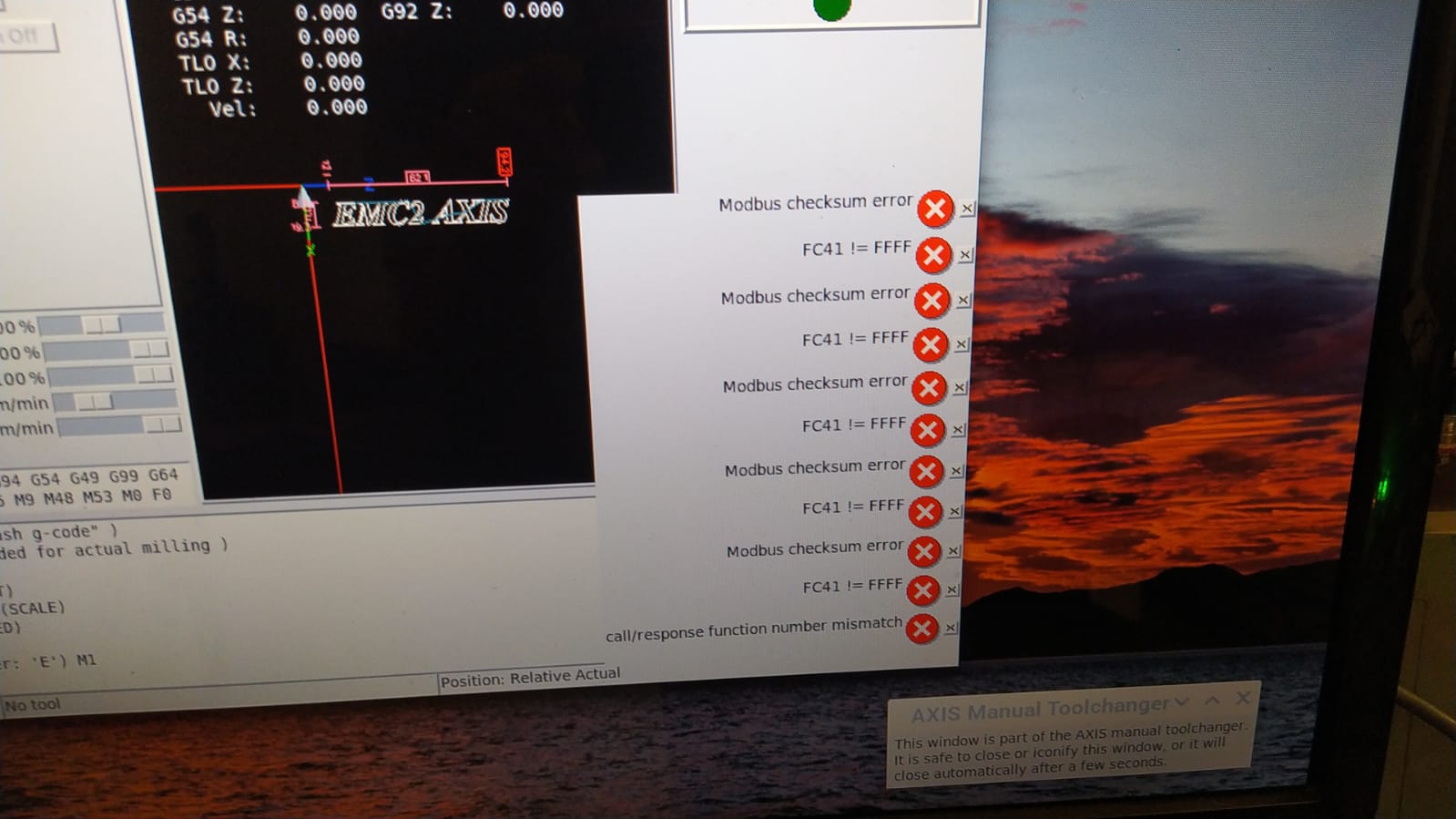

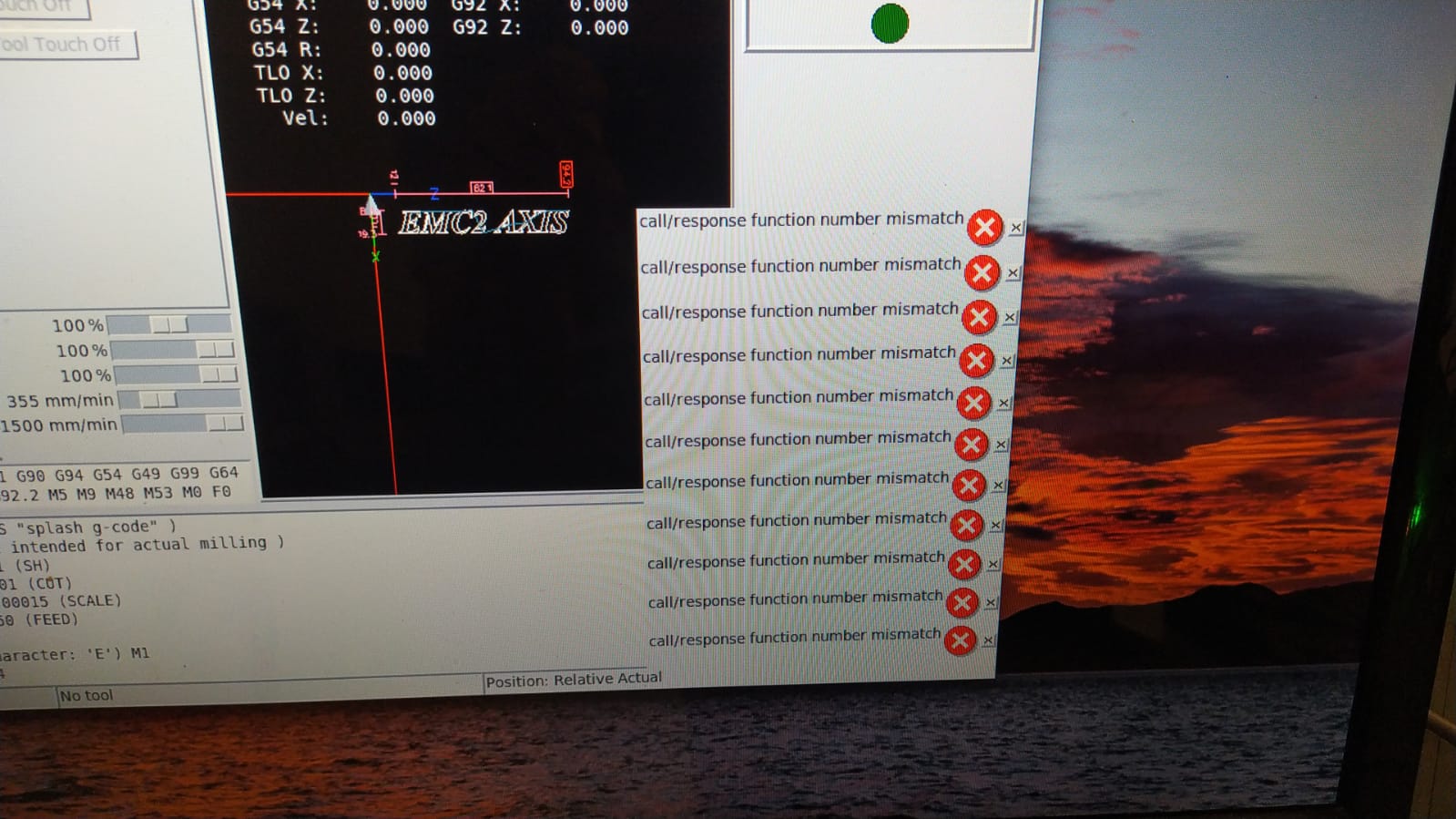

Replied by Donno on topic Mesa modbus and pktUart

Mesa modbus and pktUart

Category: Other User Interfaces

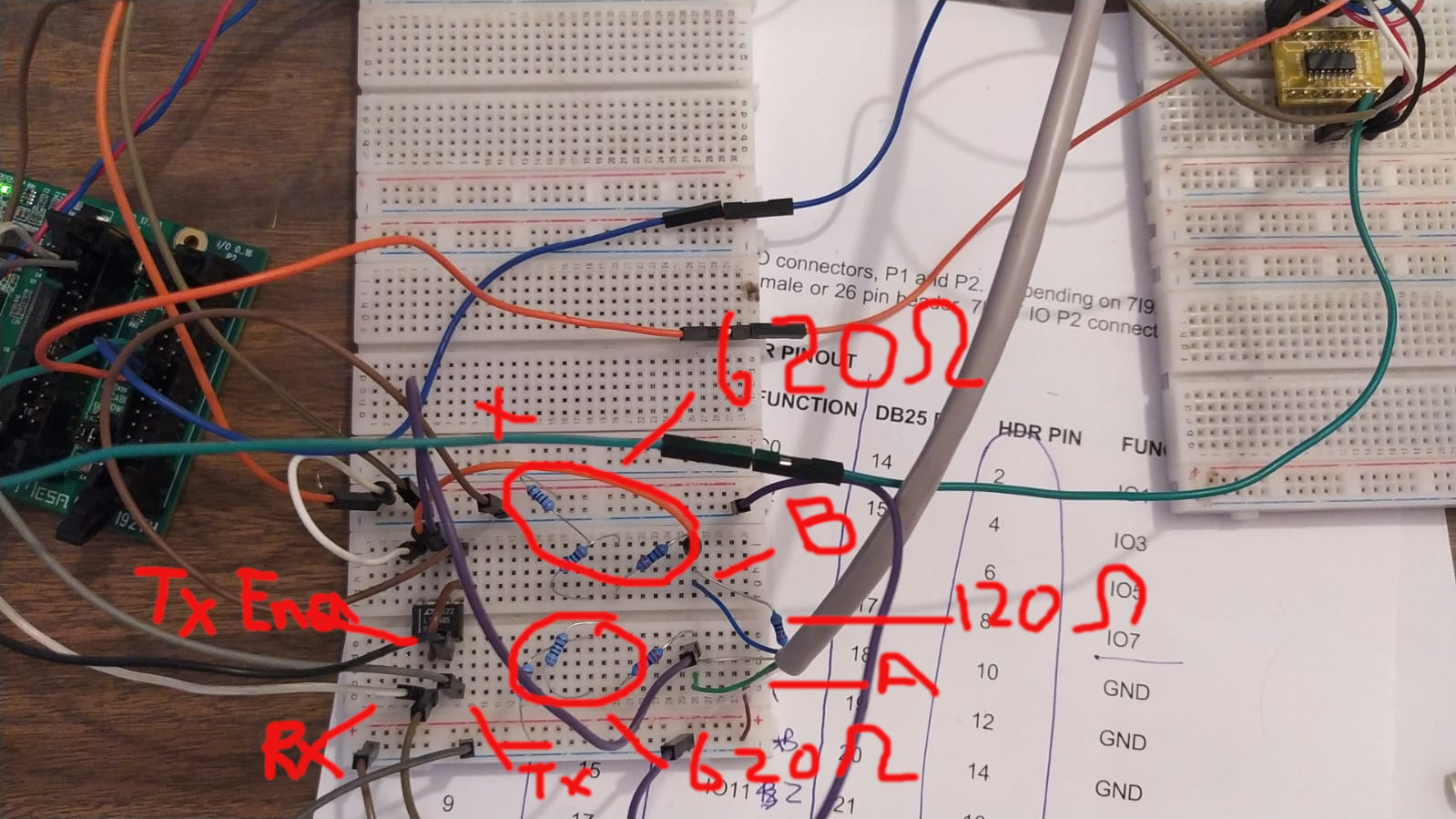

Yes I have Pos - 620ohm - 120 ohm - 620 ohm -Neg

If i wire it any other way i get fault or if i remove 120ohm then i get a fault so i am pretty sure it is connecting. What are the default data and stop bit ?

Test.modHAL File

This is what i am expecting on address 0 to 8

If i wire it any other way i get fault or if i remove 120ohm then i get a fault so i am pretty sure it is connecting. What are the default data and stop bit ?

Test.mod

// Test Driver

#define MAX_MSG_LEN 16 // may be increased if necessary to max 251

#define DEBUG 3

static const hm2_modbus_chan_descriptor_t channels[] = {

/* {TYPE, FUNC, ADDR, COUNT, pin_name} */

{HAL_U32, 3, 0x0000, 1, "test0"},

{HAL_U32, 3, 0x0001, 1, "test1"},

{HAL_U32, 3, 0x0002, 1, "test2"},

{HAL_U32, 3, 0x0003, 1, "test3"},

{HAL_U32, 3, 0x0004, 1, "test4"},

{HAL_U32, 3, 0x0005, 1, "test5"},

{HAL_U32, 3, 0x0006, 1, "test6"},

{HAL_U32, 3, 0x0007, 1, "test7"},

{HAL_U32, 3, 0x0008, 1, "test8"},

};# Generated by PNCconf at Mon Aug 28 20:19:10 2023

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.1.121" config="num_encoders=1 num_pwmgens=0 num_stepgens=2"

loadrt test ports=hm2_7i92.0.pktuart.0

setp hm2_7i92.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

loadrt abs names=abs.spindle

loadrt lowpass names=lowpass.spindle

loadrt scale names=scale.spindle

loadrt near

addf hm2_7i92.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf scale.spindle servo-thread

addf abs.spindle servo-thread

addf lowpass.spindle servo-thread

addf near.0 servo-thread

addf hm2_7i92.0.write servo-thread

addf test.00 servo-thread

setp hm2_7i92.0.dpll.01.timer-us -50

setp hm2_7i92.0.stepgen.timer-number 1

setp test.00.address 1

setp test.00.baudrate 19200

setp test.00.parity 2

setp test.00.update-hz 0.1

# external output signals

# --- DOUT-00 ---

setp hm2_7i92.0.gpio.000.is_output true

net dout-00 => hm2_7i92.0.gpio.000.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.005.is_output true

net spindle-enable => hm2_7i92.0.gpio.005.out

# --- SPINDLE-CW ---

setp hm2_7i92.0.gpio.006.is_output true

net spindle-cw => hm2_7i92.0.gpio.006.out

# --- SPINDLE-CCW ---

setp hm2_7i92.0.gpio.007.is_output true

net spindle-ccw => hm2_7i92.0.gpio.007.out

# --- COOLANT-MIST ---

setp hm2_7i92.0.gpio.008.is_output true

net coolant-mist => hm2_7i92.0.gpio.008.out

# --- DOUT-01 ---

setp hm2_7i92.0.gpio.013.is_output true

net dout-01 => hm2_7i92.0.gpio.013.out

# --- DOUT-02 ---

setp hm2_7i92.0.gpio.015.is_output true

net dout-02 => hm2_7i92.0.gpio.015.out

# --- DOUT-03 ---

setp hm2_7i92.0.gpio.016.is_output true

net dout-03 => hm2_7i92.0.gpio.016.out

# --- ESTOP-OUT ---

setp hm2_7i92.0.gpio.030.is_output true

net estop-out => hm2_7i92.0.gpio.030.out

# --- MACHINE-IS-ENABLED ---

setp hm2_7i92.0.gpio.032.is_output true

net machine-is-enabled => hm2_7i92.0.gpio.032.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.033.is_output true

net spindle-enable => hm2_7i92.0.gpio.033.out

# external input signals

# --- HOME-X ---

net home-x <= hm2_7i92.0.gpio.012.in

# --- HOME-Z ---

net home-z <= hm2_7i92.0.gpio.014.in

# --- DIN-00 ---

net din-00 <= hm2_7i92.0.gpio.019.in

# --- DIN-01 ---

net din-01 <= hm2_7i92.0.gpio.020.in

# --- DIN-02 ---

net din-02 <= hm2_7i92.0.gpio.021.in

# --- DIN-03 ---

net din-03 <= hm2_7i92.0.gpio.022.in

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i92.0.gpio.023.in

# --- PROBE-IN ---

net probe-in <= hm2_7i92.0.gpio.024.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i92.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i92.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i92.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i92.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i92.0.stepgen.00.step_type 0

setp hm2_7i92.0.stepgen.00.control-type 1

setp hm2_7i92.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i92.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i92.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i92.0.stepgen.00.enable

# ---setup home / limit switch signals---

net home-x => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Z JOINT 1

#*******************

setp pid.z.Pgain [JOINT_1]P

setp pid.z.Igain [JOINT_1]I

setp pid.z.Dgain [JOINT_1]D

setp pid.z.bias [JOINT_1]BIAS

setp pid.z.FF0 [JOINT_1]FF0

setp pid.z.FF1 [JOINT_1]FF1

setp pid.z.FF2 [JOINT_1]FF2

setp pid.z.deadband [JOINT_1]DEADBAND

setp pid.z.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i92.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i92.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i92.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i92.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i92.0.stepgen.01.step_type 0

setp hm2_7i92.0.stepgen.01.control-type 1

setp hm2_7i92.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.1.motor-pos-cmd

net z-vel-cmd <= joint.1.vel-cmd

net z-output => hm2_7i92.0.stepgen.01.velocity-cmd

net z-pos-fb <= hm2_7i92.0.stepgen.01.position-fb

net z-pos-fb => joint.1.motor-pos-fb

net z-enable <= joint.1.amp-enable-out

net z-enable => hm2_7i92.0.stepgen.01.enable

# ---setup home / limit switch signals---

net home-z => joint.1.home-sw-in

net z-neg-limit => joint.1.neg-lim-sw-in

net z-pos-limit => joint.1.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---Encoder feedback signals/setup---

setp hm2_7i92.0.encoder.00.counter-mode 0

setp hm2_7i92.0.encoder.00.filter 1

setp hm2_7i92.0.encoder.00.index-invert 0

setp hm2_7i92.0.encoder.00.index-mask 0

setp hm2_7i92.0.encoder.00.index-mask-invert 0

setp hm2_7i92.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= hm2_7i92.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i92.0.encoder.00.velocity

net spindle-vel-fb-rpm <= hm2_7i92.0.encoder.00.velocity-rpm

net spindle-index-enable <=> hm2_7i92.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 0.166667

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.spindle.gain 60

setp lowpass.spindle.gain 1.000000

net spindle-vel-fb-rps => scale.spindle.in

net spindle-fb-rpm scale.spindle.out => abs.spindle.in

net spindle-fb-rpm-abs abs.spindle.out => lowpass.spindle.in

net spindle-fb-rpm-abs-filtered lowpass.spindle.out

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.1.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

net dout-00 <= motion.digital-out-00

net dout-01 <= motion.digital-out-01

net dout-02 <= motion.digital-out-02

net dout-03 <= motion.digital-out-03

net din-00 => motion.digital-in-00

net din-01 => motion.digital-in-01

net din-02 => motion.digital-in-02

net din-03 => motion.digital-in-03

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

This is what i am expecting on address 0 to 8

[color=#ff5454]A5 Servo Driver | 16:59:43 [/color][color=#000000] [/color]

[color=#e74c3c]0 : 14130 | 1 : 0 | 2 : 0 | 3 : 0 | 4 : 0 | 5 : 0 | 6 : 0 | 7 : 0 | 8 : 14100 |[/color][color=#5454ff] [/color]

04 Sep 2023 03:38

Replied by spumco on topic 16 Pocket tool changer with PB and carousel.comp (Working config for reference)

16 Pocket tool changer with PB and carousel.comp (Working config for reference)

Category: QtPyVCP

The carousel encoding can be done in a number of ways. If "INDEX" encoding is chosen you will need two sensors, and one trigger (flag) per pocket, plus one trigger per revolution.

One of the sensors is the 'home' sensor, the other is the 'pocket' sensor. Both of these are connected to carousel.comp via HAL.

On first enable, carousel.comp will home the ATC until the home sensor is triggered. This will be pocket #1. After that, it will move to the correct pocket by counting up/down the index sensor pulses.

This encoding scheme will work with both a Geneva drive as well as a servo/stepper-driven rotation.

If "COUNTS" mode is selected, only a home sensor is required. You pre-program the number of steps between pocket centers, and carousel output pulses through a stepgen to move to the correct pocket. As with index mode, once homed, carousel.comp keeps track of how many pockets have passed up/down from the home position. All you have to do is send it a destination pocket using a motion.analog-out signal from g-code.

The 'flags' mentioned earlier can be holes in the ATC platter that trigger the inductive sensors. Or they can be pins, or anything else that triggers the sensors repeatably. Some people have used microswitches instead of proximity sensors. Even optical sensors are suitable if you have room for a slotted wheel of some sort.

I think the laser sensor(s) in the original description are for determining the presence (or not) of a tool in a pocket, as well the position of the drawbar. They are not required for carousel.comp to control an ATC, but it does add an additional layer of safety in case the tool is not seated in the spindle taper properly or if a tool is in a pocket when one isn't supposed to be there.

One of the sensors is the 'home' sensor, the other is the 'pocket' sensor. Both of these are connected to carousel.comp via HAL.

On first enable, carousel.comp will home the ATC until the home sensor is triggered. This will be pocket #1. After that, it will move to the correct pocket by counting up/down the index sensor pulses.

This encoding scheme will work with both a Geneva drive as well as a servo/stepper-driven rotation.

If "COUNTS" mode is selected, only a home sensor is required. You pre-program the number of steps between pocket centers, and carousel output pulses through a stepgen to move to the correct pocket. As with index mode, once homed, carousel.comp keeps track of how many pockets have passed up/down from the home position. All you have to do is send it a destination pocket using a motion.analog-out signal from g-code.

The 'flags' mentioned earlier can be holes in the ATC platter that trigger the inductive sensors. Or they can be pins, or anything else that triggers the sensors repeatably. Some people have used microswitches instead of proximity sensors. Even optical sensors are suitable if you have room for a slotted wheel of some sort.

I think the laser sensor(s) in the original description are for determining the presence (or not) of a tool in a pocket, as well the position of the drawbar. They are not required for carousel.comp to control an ATC, but it does add an additional layer of safety in case the tool is not seated in the spindle taper properly or if a tool is in a pocket when one isn't supposed to be there.

03 Sep 2023 01:12

Replied by tommylight on topic Only one Y Stepper is working

Only one Y Stepper is working

Category: PnCConf Wizard

There is nothing set up for tandem axis in your files, just 3 axis and spindle.

Use PncConf to create a new config, choose 4 stepgens, choose axis x, choose axis y, choose tandem axis y2, choose axis z.

One more, thing, those two Y axis must have separate home/limit switches.

Use PncConf to create a new config, choose 4 stepgens, choose axis x, choose axis y, choose tandem axis y2, choose axis z.

One more, thing, those two Y axis must have separate home/limit switches.

02 Sep 2023 17:53

Replied by Donno on topic Mesa modbus and pktUart

Mesa modbus and pktUart

Category: Other User Interfaces

mesaflash --device 7i92T --addr 192.168.1.121 --readhmid

Hal File loadrt mesa_modbus_A5_Driver names=hm2_7i92.0.pktuart.0 and addf mesa_modbus_A5_Driver servo-thread

donno@linuxcnc:~/Desktop $ mesaflash --device 7i92T --addr 192.168.1.121 --readhmid

Configuration Name: HOSTMOT2

General configuration information:

BoardName : MESA7I92

FPGA Size: 20 KGates

FPGA Pins: 256

Number of IO Ports: 2

Width of one I/O port: 17

Clock Low frequency: 100.0000 MHz

Clock High frequency: 175.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

Modules in configuration:

Module: DPLL

There are 1 of DPLL in configuration

Version: 0

Registers: 7

BaseAddress: 7000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: WatchDog

There are 1 of WatchDog in configuration

Version: 0

Registers: 3

BaseAddress: 0C00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: IOPort

There are 2 of IOPort in configuration

Version: 0

Registers: 5

BaseAddress: 1000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: QCount

There are 2 of QCount in configuration

Version: 2

Registers: 5

BaseAddress: 3000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: StepGen

There are 10 of StepGen in configuration

Version: 2

Registers: 10

BaseAddress: 2000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PWM

There are 2 of PWM in configuration

Version: 0

Registers: 5

BaseAddress: 4100

ClockFrequency: 175.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: LED

There are 1 of LED in configuration

Version: 0

Registers: 1

BaseAddress: 0200

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PktUARTTX

There are 1 of PktUARTTX in configuration

Version: 0

Registers: 4

BaseAddress: 6100

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PktUARTRX

There are 1 of PktUARTRX in configuration

Version: 0

Registers: 4

BaseAddress: 6500

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Configuration pin-out:

IO Connections for P2

DB25 pin# I/O Pri. func Sec. func Chan Sec. Pin func Sec. Pin Dir

1 0 IOPort PWM 0 PWM (Out)

14 1 IOPort StepGen 0 Step/Table1 (Out)

2 2 IOPort StepGen 0 Dir/Table2 (Out)

15 3 IOPort StepGen 1 Step/Table1 (Out)

3 4 IOPort StepGen 1 Dir/Table2 (Out)

16 5 IOPort None

4 6 IOPort None

17 7 IOPort None

5 8 IOPort None

6 9 IOPort QCount 0 Quad-A (In)

7 10 IOPort QCount 0 Quad-B (In)

8 11 IOPort QCount 0 Quad-IDX (In)

9 12 IOPort None

10 13 IOPort None

11 14 IOPort None

12 15 IOPort None

13 16 IOPort None

IO Connections for P1

DB25 pin# I/O Pri. func Sec. func Chan Sec. Pin func Sec. Pin Dir

1 17 IOPort PktUARTRX 0 RXData (In)

14 18 IOPort PktUARTTX 0 TXData (Out)

2 19 IOPort PktUARTTX 0 TXEna (Out)

15 20 IOPort None

3 21 IOPort None

16 22 IOPort None

4 23 IOPort None

17 24 IOPort None

5 25 IOPort None

6 26 IOPort None

7 27 IOPort None

8 28 IOPort None

9 29 IOPort None

10 30 IOPort None

11 31 IOPort None

12 32 IOPort None

13 33 IOPort None Hal File loadrt mesa_modbus_A5_Driver names=hm2_7i92.0.pktuart.0 and addf mesa_modbus_A5_Driver servo-thread

# Generated by PNCconf at Mon Aug 28 20:19:10 2023

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.1.121" config="num_encoders=1 num_pwmgens=0 num_stepgens=2"

loadrt mesa_modbus_A5_Driver names=hm2_7i92.0.pktuart.0

setp hm2_7i92.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

loadrt abs names=abs.spindle

loadrt lowpass names=lowpass.spindle

loadrt scale names=scale.spindle

loadrt near

addf hm2_7i92.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf scale.spindle servo-thread

addf abs.spindle servo-thread

addf lowpass.spindle servo-thread

addf near.0 servo-thread

addf hm2_7i92.0.write servo-thread

addf mesa_modbus_A5_Driver servo-thread

setp hm2_7i92.0.dpll.01.timer-us -50

setp hm2_7i92.0.stepgen.timer-number 1

# external output signals

# --- DOUT-00 ---

setp hm2_7i92.0.gpio.000.is_output true

net dout-00 => hm2_7i92.0.gpio.000.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.005.is_output true

net spindle-enable => hm2_7i92.0.gpio.005.out

# --- SPINDLE-CW ---

setp hm2_7i92.0.gpio.006.is_output true

net spindle-cw => hm2_7i92.0.gpio.006.out

# --- SPINDLE-CCW ---

setp hm2_7i92.0.gpio.007.is_output true

net spindle-ccw => hm2_7i92.0.gpio.007.out

# --- COOLANT-MIST ---

setp hm2_7i92.0.gpio.008.is_output true

net coolant-mist => hm2_7i92.0.gpio.008.out

# --- DOUT-01 ---

setp hm2_7i92.0.gpio.013.is_output true

net dout-01 => hm2_7i92.0.gpio.013.out

# --- DOUT-02 ---

setp hm2_7i92.0.gpio.015.is_output true

net dout-02 => hm2_7i92.0.gpio.015.out

# --- DOUT-03 ---

setp hm2_7i92.0.gpio.016.is_output true

net dout-03 => hm2_7i92.0.gpio.016.out

# --- ESTOP-OUT ---

setp hm2_7i92.0.gpio.030.is_output true

net estop-out => hm2_7i92.0.gpio.030.out

# --- MACHINE-IS-ENABLED ---

setp hm2_7i92.0.gpio.032.is_output true

net machine-is-enabled => hm2_7i92.0.gpio.032.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.033.is_output true

net spindle-enable => hm2_7i92.0.gpio.033.out

# external input signals

# --- HOME-X ---

net home-x <= hm2_7i92.0.gpio.012.in

# --- HOME-Z ---

net home-z <= hm2_7i92.0.gpio.014.in

# --- DIN-00 ---

net din-00 <= hm2_7i92.0.gpio.019.in

# --- DIN-01 ---

net din-01 <= hm2_7i92.0.gpio.020.in

# --- DIN-02 ---

net din-02 <= hm2_7i92.0.gpio.021.in

# --- DIN-03 ---

net din-03 <= hm2_7i92.0.gpio.022.in

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i92.0.gpio.023.in

# --- PROBE-IN ---

net probe-in <= hm2_7i92.0.gpio.024.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i92.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i92.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i92.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i92.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i92.0.stepgen.00.step_type 0

setp hm2_7i92.0.stepgen.00.control-type 1

setp hm2_7i92.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i92.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i92.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i92.0.stepgen.00.enable

# ---setup home / limit switch signals---

net home-x => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Z JOINT 1

#*******************

setp pid.z.Pgain [JOINT_1]P

setp pid.z.Igain [JOINT_1]I

setp pid.z.Dgain [JOINT_1]D

setp pid.z.bias [JOINT_1]BIAS

setp pid.z.FF0 [JOINT_1]FF0

setp pid.z.FF1 [JOINT_1]FF1

setp pid.z.FF2 [JOINT_1]FF2

setp pid.z.deadband [JOINT_1]DEADBAND

setp pid.z.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i92.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i92.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i92.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i92.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i92.0.stepgen.01.step_type 0

setp hm2_7i92.0.stepgen.01.control-type 1

setp hm2_7i92.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.1.motor-pos-cmd

net z-vel-cmd <= joint.1.vel-cmd

net z-output => hm2_7i92.0.stepgen.01.velocity-cmd

net z-pos-fb <= hm2_7i92.0.stepgen.01.position-fb

net z-pos-fb => joint.1.motor-pos-fb

net z-enable <= joint.1.amp-enable-out

net z-enable => hm2_7i92.0.stepgen.01.enable

# ---setup home / limit switch signals---

net home-z => joint.1.home-sw-in

net z-neg-limit => joint.1.neg-lim-sw-in

net z-pos-limit => joint.1.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---Encoder feedback signals/setup---

setp hm2_7i92.0.encoder.00.counter-mode 0

setp hm2_7i92.0.encoder.00.filter 1

setp hm2_7i92.0.encoder.00.index-invert 0

setp hm2_7i92.0.encoder.00.index-mask 0

setp hm2_7i92.0.encoder.00.index-mask-invert 0

setp hm2_7i92.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= hm2_7i92.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i92.0.encoder.00.velocity

net spindle-vel-fb-rpm <= hm2_7i92.0.encoder.00.velocity-rpm

net spindle-index-enable <=> hm2_7i92.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 0.166667

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.spindle.gain 60

setp lowpass.spindle.gain 1.000000

net spindle-vel-fb-rps => scale.spindle.in

net spindle-fb-rpm scale.spindle.out => abs.spindle.in

net spindle-fb-rpm-abs abs.spindle.out => lowpass.spindle.in

net spindle-fb-rpm-abs-filtered lowpass.spindle.out

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.1.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

net dout-00 <= motion.digital-out-00

net dout-01 <= motion.digital-out-01

net dout-02 <= motion.digital-out-02

net dout-03 <= motion.digital-out-03

net din-00 => motion.digital-in-00

net din-01 => motion.digital-in-01

net din-02 => motion.digital-in-02

net din-03 => motion.digital-in-03

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

01 Sep 2023 20:20 - 04 Sep 2023 04:11

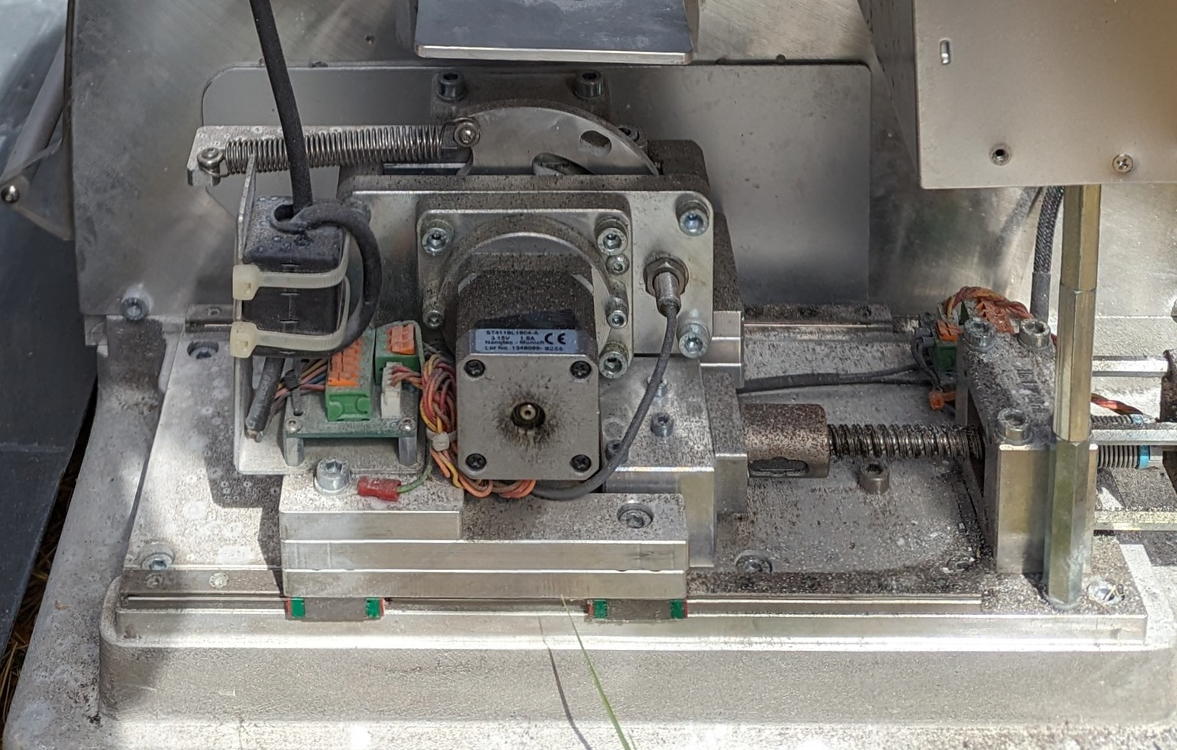

Reverse Engineering a 5-axis benchtop CNC was created by drdoc

Reverse Engineering a 5-axis benchtop CNC

Category: CNC Machines

Long story, but I'm retrofitting a 7i96 (and probably a ChinaBoB) to a VHF CAM5 S2 dental mill. TL;DR I don't have the license dongle it sold with and don't have the money to pay for the proprietary control software.

The motion part is pretty straightforward. Open loop NEMA17 steppers with ball screws, I don't expect any problem controlling the motion. I might at some point build a bigger frame but for now, I'm looking at a working envelope of about 4" x 3.5" x 3" plus I think 90 degrees on A and 360 on B.

I'm going to either forego the tool changer or re-work it as a 6 or 8 tool instead of 16. Tools with that depth-gauge circlip are way out of my budget, and I think that's integral to operating it as a 16-tool magazine. The spindle, however. It's an VHF-branded SFS 300P. Neither SFS nor VHF publish any pinout, voltage requirement, control frequency range or any useful build info. The motor control daughterboard gives me the pinout for the motor, but I don't have the electronics fu to get any farther than that.

So, my questions are:1) Does anyone here have knowledge or experience with this particular machine? A service manual or any maintenance information would be miraculous.2) Same question for the spindle assembly. I do have the pressure & flow specs for the air seal and chuck controls, but working out the input voltage and speed control are out of my depth.3) Assuming the absence of model-specific details, how should I go about reverse-engineering the motor? I have multimeters and oscilloscope.

Thanks!

Doc

The motion part is pretty straightforward. Open loop NEMA17 steppers with ball screws, I don't expect any problem controlling the motion. I might at some point build a bigger frame but for now, I'm looking at a working envelope of about 4" x 3.5" x 3" plus I think 90 degrees on A and 360 on B.

I'm going to either forego the tool changer or re-work it as a 6 or 8 tool instead of 16. Tools with that depth-gauge circlip are way out of my budget, and I think that's integral to operating it as a 16-tool magazine. The spindle, however. It's an VHF-branded SFS 300P. Neither SFS nor VHF publish any pinout, voltage requirement, control frequency range or any useful build info. The motor control daughterboard gives me the pinout for the motor, but I don't have the electronics fu to get any farther than that.

So, my questions are:1) Does anyone here have knowledge or experience with this particular machine? A service manual or any maintenance information would be miraculous.2) Same question for the spindle assembly. I do have the pressure & flow specs for the air seal and chuck controls, but working out the input voltage and speed control are out of my depth.3) Assuming the absence of model-specific details, how should I go about reverse-engineering the motor? I have multimeters and oscilloscope.

Thanks!

Doc

01 Sep 2023 00:28

Replied by spumco on topic Mesa board with support for DROmagnetic encoders

Mesa board with support for DROmagnetic encoders

Category: Driver Boards

SLOW DOWN!

First - there's a 7I85 and a 7i85S. The difference is:

The 7i96S + 7i85S is a great combo... it's what I'm using in my current lathe project. But I had to add more IO (lots) and now I'm out of serial expansion ports. No regrets, but I'm not expanding any further without swapping out a board.

Second - there are numerous threads in this forum about closing the loop back to LCNC with steppers. The problem is searching the forum is a bit difficult... but get used to it. Read as much as you can. Maybe search for "loop" and limit it to search titles only.

One of the users here (Hakan) posted a number of nice videos about closing the loop with steppers (and later servos) on you tube. Search YT for some good overviews.

More importantly... dealing with closed loop is WAY down the road you're about to travel. The LCNC learning curve is steep, especially if you aren't a 'computer person' (like me). There are multiple concepts you'll need to become familiar with to get an open loop system sorted out. Once it's happy, then you can close the loop and sort out the tuning.

Read the LCNC online manual.

Read about HAL and INI files.

Read about user interfaces (GUI's)

Search YT for "Feral Engineer" and watch EVERY linuxcnc video he published.

Come back when your brain hurts.

First - there's a 7I85 and a 7i85S. The difference is:

- 7i85

- 4 encoder inputs

- 5 serial expansion ports

- 7i85S

- 4 step & direction outputs (more axes)

- 4 encoder inputs

- 1 serial expansion port

- Does the 7i96S and one of the two 7i85's have all the IO you need?

- What's your spindle?

- How many IO points do you have (or want)?

- What sensors do you have? PNP? NPN? Switches? What voltage?

- Do you want a tool changer?

- Do you plan on a couple - or a bunch - of physical control buttons for the operator?

- How much room do you have in your electrical cabinet?

The 7i96S + 7i85S is a great combo... it's what I'm using in my current lathe project. But I had to add more IO (lots) and now I'm out of serial expansion ports. No regrets, but I'm not expanding any further without swapping out a board.

Second - there are numerous threads in this forum about closing the loop back to LCNC with steppers. The problem is searching the forum is a bit difficult... but get used to it. Read as much as you can. Maybe search for "loop" and limit it to search titles only.

One of the users here (Hakan) posted a number of nice videos about closing the loop with steppers (and later servos) on you tube. Search YT for some good overviews.

More importantly... dealing with closed loop is WAY down the road you're about to travel. The LCNC learning curve is steep, especially if you aren't a 'computer person' (like me). There are multiple concepts you'll need to become familiar with to get an open loop system sorted out. Once it's happy, then you can close the loop and sort out the tuning.

Read the LCNC online manual.

Read about HAL and INI files.

Read about user interfaces (GUI's)

Search YT for "Feral Engineer" and watch EVERY linuxcnc video he published.

Come back when your brain hurts.

30 Aug 2023 10:02

7i96S and Emergency / E-Stop was created by kevin_allein

7i96S and Emergency / E-Stop

Category: Driver Boards

Hi all, I have a CNC lathe, that I used to run with MACH4 and the Ethernet Smooth Stepper and want to convert it to LinuxCNC now.

I connected the Ethernet Smooth Stepper to parallel breakout boards from Langenfeld for Step / Dir ( www.pro-tos.de/shop/Interface/Parallel-Interface-12-5.html ) and also their analog spindle drive ( www.pro-tos.de/shop/Interface/Frequenzum...euerung-0---10V.html )

This had the benefit, that the signal from the E-Stop would directly stop both the spindle as well as all Steppers immediately without needing to go through the PC (in case of any problems)

I now ordered a MESA 7i96S (basically the only thing I could find). This would obviously not require the Langenfeld cards anymore, but how can I get the same functionality with direct E-Stop not relying on LinuxCNC ?

To use the P1 connector I would need a special bit file mapping Step and Dir to the correct pins of that header. But once I need a special bit file, I could also implement the logic in the FPGA to gat everything with an E-Stop signal.

So do I need to write a custom bit file ? Is there a getting started guide ? There seems to be lots of info on the web about creating bit files for the XILINX FPGAs used before, but I read, that the 7i96S is using a different FPGA.

Thanks for any help

I connected the Ethernet Smooth Stepper to parallel breakout boards from Langenfeld for Step / Dir ( www.pro-tos.de/shop/Interface/Parallel-Interface-12-5.html ) and also their analog spindle drive ( www.pro-tos.de/shop/Interface/Frequenzum...euerung-0---10V.html )

This had the benefit, that the signal from the E-Stop would directly stop both the spindle as well as all Steppers immediately without needing to go through the PC (in case of any problems)

I now ordered a MESA 7i96S (basically the only thing I could find). This would obviously not require the Langenfeld cards anymore, but how can I get the same functionality with direct E-Stop not relying on LinuxCNC ?

To use the P1 connector I would need a special bit file mapping Step and Dir to the correct pins of that header. But once I need a special bit file, I could also implement the logic in the FPGA to gat everything with an E-Stop signal.

So do I need to write a custom bit file ? Is there a getting started guide ? There seems to be lots of info on the web about creating bit files for the XILINX FPGAs used before, but I read, that the 7i96S is using a different FPGA.

Thanks for any help

29 Aug 2023 17:08 - 29 Aug 2023 18:02

Fast pulse for stepper with EL2202 was created by JoBoCNC

Fast pulse for stepper with EL2202

Category: EtherCAT

Hello,

I would like to replace my parallel port system with Ethercat. My existing system uses closed loop stepper drivers with parallel port.

My idea was to use a fast Beckhoff module for the stepper pulses. So I bought the EL2202 module.

To test the setup, I added the Ethercat commands for Y-axis to my previous configuration files.

At low speed everything works fine. But at higher speed the stepper loses steps.

The other axes with the parallel port work fine at these speeds.

So I think that the EL2202 is not generating the pulses fast enough.

In my opinion, with my config it is at least possible to generate the same speed as the parallel port axis.

Any suggestion what i can try? Think it is a configuration issue. So here my config files.

Thank you very much!

Here my .hal

.ini:

And my Ethercat config file:

I would like to replace my parallel port system with Ethercat. My existing system uses closed loop stepper drivers with parallel port.

My idea was to use a fast Beckhoff module for the stepper pulses. So I bought the EL2202 module.

To test the setup, I added the Ethercat commands for Y-axis to my previous configuration files.

At low speed everything works fine. But at higher speed the stepper loses steps.

The other axes with the parallel port work fine at these speeds.

So I think that the EL2202 is not generating the pulses fast enough.

In my opinion, with my config it is at least possible to generate the same speed as the parallel port axis.

Any suggestion what i can try? Think it is a configuration issue. So here my config files.

Thank you very much!

Here my .hal

# Generated by stepconf 1.1 at Sat Sep 3 11:45:09 2022

# Änderungen an dieser Datei werden beim nächsten

# Aufruf von stepconf überschrieben.

#loadrt trivkins

loadusr -W lcec_conf ethercat-conf.xml

loadrt lcec

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hal_parport cfg="0 out"

setp parport.0.reset-time 50 #5000

loadrt stepgen step_type=0,0,0,0

loadrt pwmgen output_type=1 #1

addf stepgen.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread #servo

addf pwmgen.update servo-thread

addf lcec.read-all base-thread #servo

#addf lcec.write-all servo-thread

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf pwmgen.make-pulses base-thread

addf parport.0.write base-thread

addf parport.0.reset base-thread

addf lcec.write-all base-thread #testservo

net spindle-cmd-rpm => pwmgen.0.value

net spindle-on <= spindle.0.on => pwmgen.0.enable

net spindle-pwm <= pwmgen.0.pwm

setp pwmgen.0.pwm-freq 8000.0

setp pwmgen.0.scale 24000

setp pwmgen.0.offset 0

setp pwmgen.0.dither-pwm true

net spindle-cmd-rpm <= spindle.0.speed-out

net spindle-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-cmd-rps <= spindle.0.speed-out-rps

net spindle-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-at-speed => spindle.0.at-speed

net dout-00 <= motion.digital-out-00

setp parport.0.pin-01-out-invert 1

net spindle-pwm => parport.0.pin-01-out

setp parport.0.pin-02-out-invert 1

net zstep => parport.0.pin-02-out

setp parport.0.pin-02-out-reset 1

setp parport.0.pin-03-out-invert 1

net zdir => parport.0.pin-03-out

#setp parport.0.pin-04-out-invert 1

#net ystep => parport.0.pin-04-out

net ystep => lcec.0.1.dout-1 #changed to ethercat

#setp parport.0.pin-04-out-reset 1

#setp lcec.0.1.dout-1-reset 1

setp parport.0.pin-05-out-invert 1

net ydir => parport.0.pin-05-out

setp parport.0.pin-06-out-invert 1

net xstep => parport.0.pin-06-out

setp parport.0.pin-06-out-reset 1

net xdir => parport.0.pin-07-out

setp parport.0.pin-08-out-invert 1

net x2step => parport.0.pin-08-out

setp parport.0.pin-08-out-reset 1

net x2dir => parport.0.pin-09-out

net xenable => parport.0.pin-14-out

net dout-00 => parport.0.pin-16-out

net spindle-on => parport.0.pin-17-out

net home-z <= parport.0.pin-10-in-not

net home-y <= parport.0.pin-11-in-not

net home-x <= parport.0.pin-13-in-not

net home-x2 <= parport.0.pin-12-in-not

net estop-ext <= parport.0.pin-15-in-not

setp stepgen.0.position-scale [JOINT_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 0

setp stepgen.0.dirhold 44000

setp stepgen.0.dirsetup 44000

setp stepgen.0.maxaccel [JOINT_0]STEPGEN_MAXACCEL

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.position-cmd

net xpos-fb stepgen.0.position-fb => joint.0.motor-pos-fb

net xstep <= stepgen.0.step

net xdir <= stepgen.0.dir

net xenable joint.0.amp-enable-out => stepgen.0.enable

net home-x => joint.0.home-sw-in

setp stepgen.1.position-scale [JOINT_1]SCALE

setp stepgen.1.steplen 1

setp stepgen.1.stepspace 0

setp stepgen.1.dirhold 27000

setp stepgen.1.dirsetup 27000

setp stepgen.1.maxaccel [JOINT_1]STEPGEN_MAXACCEL

net x2pos-cmd joint.1.motor-pos-cmd => stepgen.1.position-cmd

net x2pos-fb stepgen.1.position-fb => joint.1.motor-pos-fb

net x2step <= stepgen.1.step

net x2dir <= stepgen.1.dir

net x2enable joint.1.amp-enable-out => stepgen.1.enable

net home-x2 => joint.1.home-sw-in

setp stepgen.2.position-scale [JOINT_2]SCALE

setp stepgen.2.steplen 1 #1

setp stepgen.2.stepspace 0 #0

setp stepgen.2.dirhold 35000 #27000

setp stepgen.2.dirsetup 35000

setp stepgen.2.maxaccel [JOINT_2]STEPGEN_MAXACCEL

net ypos-cmd joint.2.motor-pos-cmd => stepgen.2.position-cmd

net ypos-fb stepgen.2.position-fb => joint.2.motor-pos-fb

net ystep <= stepgen.2.step

net ydir <= stepgen.2.dir

net yenable joint.2.amp-enable-out => stepgen.2.enable

net home-y => joint.2.home-sw-in

setp stepgen.3.position-scale [JOINT_3]SCALE

setp stepgen.3.steplen 1

setp stepgen.3.stepspace 0

setp stepgen.3.dirhold 27000

setp stepgen.3.dirsetup 27000

setp stepgen.3.maxaccel [JOINT_3]STEPGEN_MAXACCEL

net zpos-cmd joint.3.motor-pos-cmd => stepgen.3.position-cmd

net zpos-fb stepgen.3.position-fb => joint.3.motor-pos-fb

net zstep <= stepgen.3.step

net zdir <= stepgen.3.dir

net zenable joint.3.amp-enable-out => stepgen.3.enable

net home-z => joint.3.home-sw-in

#setp stepgen.3.position-scale [AXIS_Z]SCALE

#setp stepgen.3.steplen 1

#setp stepgen.3.stepspace 0

#setp stepgen.3.dirhold 27000

#setp stepgen.3.dirsetup 27000

#setp stepgen.3.maxaccel [AXIS_3]STEPGEN_MAXACCEL

#net apos-cmd joint.3.motor-pos-cmd => stepgen.3.position-cmd

#net apos-fb stepgen.3.position-fb => joint.3.motor-pos-fb

#net astep <= stepgen.3.step

#net adir <= stepgen.3.dir

#net aenable joint.3.amp-enable-out => stepgen.3.enable

#net home-a => joint.3.home-sw-in

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

loadusr -W hal_manualtoolchange

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared.ini:

# This config file was created 2022-09-09 17:56:09.071663 by the update_ini script

# The original config files may be found in the /home/jobo/linuxcnc/configs/Meine-Maschine/Meine-Maschine.old directory

# Generated by stepconf 1.1 at Sat Sep 3 11:45:09 2022

# Änderungen an dieser Datei werden beim nächsten

# Aufruf von stepconf überschrieben.

[EMC]

# The version string for this INI file.

VERSION = 1.1

MACHINE = Meine-Maschine

DEBUG = 0

[DISPLAY]

DISPLAY = axis

EDITOR = gedit

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

ARCDIVISION = 64

GRIDS = 10mm 20mm 50mm 100mm 1in 2in 5in 10in

MAX_FEED_OVERRIDE = 1.2

MIN_SPINDLE_OVERRIDE = 0.5

MAX_SPINDLE_OVERRIDE = 1.2

DEFAULT_LINEAR_VELOCITY = 30.00

MIN_LINEAR_VELOCITY = 0

MAX_LINEAR_VELOCITY = 750.00

DEFAULT_ANGULAR_VELOCITY = 10

MIN_ANGULAR_VELOCITY = 0

MAX_ANGULAR_VELOCITY = 50.00

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 2

PROGRAM_PREFIX = /home/jobo/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

PYVCP = custompanel.xml

#GEOMETRY = xyz

[KINS]

JOINTS = 4

KINEMATICS = trivkins coordinates=XXYZ

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

BASE_PERIOD = 30000

SERVO_PERIOD = 1050000

#120000

[TASK]

TASK = milltask

CYCLE_TIME = 0.001

[HAL]

HALFILE = Meine-Maschine.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

[HALUI]

#No Content

[TRAJ]

COORDINATES = X X Y Z

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 10

MAX_LINEAR_VELOCITY = 750.00

#NO_FORCE_HOMING = 0

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[AXIS_X]

MIN_LIMIT = -0.001

MAX_LIMIT = 572.0

MAX_VELOCITY = 750

MAX_ACCELERATION = 750.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 572.0

MAX_VELOCITY = 750

MAX_ACCELERATION = 750.0

STEPGEN_MAXACCEL = 937.5

SCALE = 320.0

FERROR = 1

MIN_FERROR = .25

#HOME_OFFSET = 0.000000

#HOME_SEARCH_VEL = -10.000000

#HOME_LATCH_VEL = -0.2

#HOME_SEQUENCE = 1

HOME_OFFSET = -0.800000

HOME_SEARCH_VEL = -12.000000

HOME_LATCH_VEL = -0.2

HOME_SEQUENCE = -1

HOME_FINAL_VEL = 5

HOME_USE_INDEX = NO

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 572.0

MAX_VELOCITY = 750

MAX_ACCELERATION = 750.0

STEPGEN_MAXACCEL = 937.5

SCALE = 320.0

FERROR = 1

MIN_FERROR = .25

#HOME_OFFSET = 0.000000

#HOME_SEARCH_VEL = -10.000000

#HOME_LATCH_VEL = -0.2

#HOME_SEQUENCE = 1

HOME_OFFSET = -0.600000

HOME_SEARCH_VEL = -12.000000

HOME_LATCH_VEL = -0.2

HOME_SEQUENCE = -1

HOME_FINAL_VEL = 5

HOME_USE_INDEX = NO

[AXIS_Y]

MIN_LIMIT = 0.0

MAX_LIMIT = 480.001

MAX_VELOCITY = 75

MAX_ACCELERATION = 750.0

[JOINT_2]

TYPE = LINEAR

HOME = 480.0

MAX_VELOCITY = 75

MAX_ACCELERATION = 750.0

STEPGEN_MAXACCEL = 937.5

SCALE = 320.0

FERROR = 1

MIN_FERROR = .25

MIN_LIMIT = -0.001

MAX_LIMIT = 480.001

HOME_OFFSET = 480.000000

HOME_SEARCH_VEL = 12.000000

HOME_LATCH_VEL = 0.2

HOME_SEQUENCE = 2

[AXIS_Z]

MIN_LIMIT = -250.00

MAX_LIMIT = 0.001

MAX_VELOCITY = 50

MAX_ACCELERATION = 750.0

[JOINT_3]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 50

MAX_ACCELERATION = 750.0

STEPGEN_MAXACCEL = 937.5

SCALE = 320.0

FERROR = 1

MIN_FERROR = .25

MIN_LIMIT = -250.00

MAX_LIMIT = 0.001

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 12.000000

HOME_LATCH_VEL = 0.2

HOME_SEQUENCE = 0And my Ethercat config file:

<masters>

<master idx="0" appTimePeriod="30000" refClockSyncCycles="5">

<slave idx="0" type="EK1100"/>

<slave idx="1" type="EL2202"/>

<slave idx="2" type="EL1819"/>

</master>

</masters>

27 Aug 2023 21:05

5i25 and 7i76 issue was created by HenrikWJ

5i25 and 7i76 issue

Category: General LinuxCNC Questions

I have installed 5i25 and 7i76. Power is fed from 5i25. 7i76 is connected to a single iHSV57 just to make it work.

Pncconf is started but does not show the drop down for selecting boards:

I would like to insert a screenshot but that does not appear to be possible. You will have to take my word for it: no drop down box.

I get to the configuration page where I select:

5i25 - internal data

7i76x2 with one 7i76

I then define 4 axis's with all default parameters.

When I load the file i get this in the report:

./init3.hal:55: parameter or pin 'hm2_5i25.0.stepgen.00.dirsetup' not found

What is wrong here?

Is the the pin not not found hardware or something in the firmware?

I am new at this, and have my sincere apologies for the naive approach!

Any help is much appreciated.

KR

Henrik

The report and other files generated:

Error report created by /usr/lib/tcltk/linuxcnc/show_errors.tcl:

Print file information:

RUN_IN_PLACE=no

LINUXCNC_DIR=

LINUXCNC_BIN_DIR=/usr/bin

LINUXCNC_TCL_DIR=/usr/lib/tcltk/linuxcnc

LINUXCNC_SCRIPT_DIR=

LINUXCNC_RTLIB_DIR=/usr/lib/linuxcnc/modules

LINUXCNC_CONFIG_DIR=

LINUXCNC_LANG_DIR=/usr/lib/tcltk/linuxcnc/msgs

INIVAR=inivar

HALCMD=halcmd

LINUXCNC_EMCSH=/usr/bin/wish8.6

LINUXCNC - 2.8.4-1-gb7824717b

Machine configuration directory is '/home/hwj/linuxcnc/configs/init3'

Machine configuration file is 'init3.ini'

INIFILE=/home/hwj/linuxcnc/configs/init3/init3.ini

VERSION=1.1

PARAMETER_FILE=linuxcnc.var

TASK=milltask

HALUI=halui

DISPLAY=axis

COORDINATES=XYZ

KINEMATICS=trivkins coordinates=XYZ

Starting LinuxCNC...

Starting LinuxCNC server program: linuxcncsvr

Loading Real Time OS, RTAPI, and HAL_LIB modules

Starting LinuxCNC IO program: io

Starting HAL User Interface program: halui

Found file(REL): ./init3.hal

Shutting down and cleaning up LinuxCNC...

Running HAL shutdown script

hm2: loading Mesa HostMot2 driver version 0.15

hm2_pci: loading Mesa AnyIO HostMot2 driver version 0.7

hm2_pci: discovered 5i25 at 0000:04:05.0

hm2/hm2_5i25.0: Low Level init 0.15

hm2/hm2_5i25.0: Smart Serial Firmware Version 43

hm2/hm2_5i25.0: 34 I/O Pins used:

hm2/hm2_5i25.0: IO Pin 000 (P3-01): IOPort

hm2/hm2_5i25.0: IO Pin 001 (P3-14): IOPort

hm2/hm2_5i25.0: IO Pin 002 (P3-02): IOPort

hm2/hm2_5i25.0: IO Pin 003 (P3-15): IOPort

hm2/hm2_5i25.0: IO Pin 004 (P3-03): IOPort

hm2/hm2_5i25.0: IO Pin 005 (P3-16): IOPort

hm2/hm2_5i25.0: IO Pin 006 (P3-04): IOPort

hm2/hm2_5i25.0: IO Pin 007 (P3-17): Muxed Encoder Select #0, pin Mux Select 0 (Output)

hm2/hm2_5i25.0: IO Pin 008 (P3-05): Muxed Encoder #0, pin Muxed A (Input)

hm2/hm2_5i25.0: IO Pin 009 (P3-06): Muxed Encoder #0, pin Muxed B (Input)

hm2/hm2_5i25.0: IO Pin 010 (P3-07): Muxed Encoder #0, pin Muxed Index (Input)

hm2/hm2_5i25.0: IO Pin 011 (P3-08): IOPort

hm2/hm2_5i25.0: IO Pin 012 (P3-09): IOPort

hm2/hm2_5i25.0: IO Pin 013 (P3-10): IOPort

hm2/hm2_5i25.0: IO Pin 014 (P3-11): IOPort

hm2/hm2_5i25.0: IO Pin 015 (P3-12): IOPort

hm2/hm2_5i25.0: IO Pin 016 (P3-13): IOPort

hm2/hm2_5i25.0: IO Pin 017 (P2-01): IOPort

hm2/hm2_5i25.0: IO Pin 018 (P2-14): IOPort

hm2/hm2_5i25.0: IO Pin 019 (P2-02): IOPort

hm2/hm2_5i25.0: IO Pin 020 (P2-15): IOPort

hm2/hm2_5i25.0: IO Pin 021 (P2-03): IOPort

hm2/hm2_5i25.0: IO Pin 022 (P2-16): IOPort

hm2/hm2_5i25.0: IO Pin 023 (P2-04): IOPort

hm2/hm2_5i25.0: IO Pin 024 (P2-17): IOPort

hm2/hm2_5i25.0: IO Pin 025 (P2-05): IOPort

hm2/hm2_5i25.0: IO Pin 026 (P2-06): IOPort

hm2/hm2_5i25.0: IO Pin 027 (P2-07): IOPort

hm2/hm2_5i25.0: IO Pin 028 (P2-08): IOPort

hm2/hm2_5i25.0: IO Pin 029 (P2-09): IOPort

hm2/hm2_5i25.0: IO Pin 030 (P2-10): IOPort

hm2/hm2_5i25.0: IO Pin 031 (P2-11): IOPort

hm2/hm2_5i25.0: IO Pin 032 (P2-12): IOPort

hm2/hm2_5i25.0: IO Pin 033 (P2-13): IOPort

hm2/hm2_5i25.0: registered

hm2_5i25.0: initialized AnyIO board at 0000:04:05.0

hm2_5i25.0: dropping AnyIO board at 0000:04:05.0

hm2/hm2_5i25.0: unregistered

hm2_pci: driver unloaded

hm2: unloading

Removing HAL_LIB, RTAPI, and Real Time OS modules

Removing NML shared memory segments

Debug file information:

Note: Using POSIX realtime

./init3.hal:55: parameter or pin 'hm2_5i25.0.stepgen.00.dirsetup' not found

1727

Stopping realtime threads

Unloading hal components

RTAPI_PCI: Unmapped 65536 bytes at 0x7fbfd5ed0000

Note: Using POSIX realtime

Info report created by linuxcnc_info:

The file: /tmp/linuxcnc_info.txt

can be posted to a forum or a web site like:

pastebin.com

in order to provide information about the linuxcnc

system and configuration.

Date: Sun 27 Aug 2023 10:53:47 PM CEST

UTC Date: Sun 27 Aug 2023 08:53:47 PM UTC

this program: /usr/bin/linuxcnc_info

uptime: 22:53:47 up 32 min, 1 user, load average: 0.50, 0.44, 0.66

lsb_release -sa: Debian Debian GNU/Linux 10 (buster) 10 buster

which linuxcnc: /usr/bin/linuxcnc

pwd: /home/hwj/linuxcnc/configs/init3

USER: hwj

LOGNAME: hwj

HOME: /home/hwj

EDITOR:

VISUAL:

LANGUAGE: en_US:en

TERM: dumb

COLORTERM:

DISPLAY: :0.0

DESKTOP: xfce

display size: 1920x1080 pixels (508x285 millimeters)

PATH: /usr/bin:/home/hwj/linuxcnc/configs/init3/bin:/usr/bin:/usr/local/bin:/usr/bin:/bin:/usr/local/games:/usr/games

uname items:

nodename -n: LinuxCNC

kernel-name -s: Linux

kernel-vers -v: #1 SMP PREEMPT RT Debian 4.19.249-2 (2022-06-30)

machine -m: x86_64

processor -p: unknown

platform -i: unknown

oper system -o: GNU/Linux

/proc items:

cmdline: BOOT_IMAGE=/boot/vmlinuz-4.19.0-21-rt-amd64 root=UUID=646dfacc-5136-478c-833a-a7febaa524cd ro quiet

model name: AMD FX(tm)-4130 Quad-Core Processor

cores: 2

cpu MHz: 1929.439

parport:

serial: 0000-0000 : serial

Versions:

gcc: gcc (Debian 8.3.0-6) 8.3.0

python: Python 2.7.16

git: not_in_PATH

git commit: NA

tcl: 8.6

tk: 8.6

glade: not_in_PATH

glade-gtk2: not_in_PATH

linuxcnc_var all:

LINUXCNCVERSION: 2.8.4-1-gb7824717b

LINUXCNC_AUX_GLADEVCP: /usr/share/linuxcnc/aux_gladevcp

LINUXCNC_AUX_EXAMPLES: /usr/share/linuxcnc/aux_examples

REALTIME: /etc/init.d/realtime

RTS: uspace

HALLIB_DIR: /usr/share/linuxcnc/hallib

dpkg -l '*linuxcnc*':

Desired=Unknown/Install/Remove/Purge/Hold

| Status=Not/Inst/Conf-files/Unpacked/halF-conf/Half-inst/trig-aWait/Trig-pend

|/ Err?=(none)/Reinst-required (Status,Err: uppercase=bad)

||/ Name Version Architecture Description

+++-===================-====================-============-=====================================================================

un linuxcnc <none> <none> (no description available)

un linuxcnc-dev <none> <none> (no description available)

un linuxcnc-doc <none> <none> (no description available)

ii linuxcnc-doc-en 1:2.8.4.1.gb7824717b all motion controller for CNC machines and robots (English documentation)

ii linuxcnc-doc-es 1:2.8.4.1.gb7824717b all controlador de movimiento para máquinas CNC y robots (Español).

ii linuxcnc-doc-fr 1:2.8.4.1.gb7824717b all motion controller for CNC machines and robots (French documentation)

un linuxcnc-sim <none> <none> (no description available)

un linuxcnc-sim-dev <none> <none> (no description available)

ii linuxcnc-uspace 1:2.8.4.1.gb7824717b amd64 motion controller for CNC machines and robots

ii linuxcnc-uspace-dev 1:2.8.4.1.gb7824717b amd64 PC based motion controller for real-time Linux

The hal file is:

# Generated by PNCconf at Sun Aug 27 22:52:59 2023

# Using LinuxCNC version: 2.8

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_pci config="num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=00xxxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.000500

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_5i25.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_5i25.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_5i25.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_5i25.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_5i25.0.stepgen.00.step_type 0

setp hm2_5i25.0.stepgen.00.control-type 1

setp hm2_5i25.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_5i25.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_5i25.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_5i25.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.000500

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_5i25.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_5i25.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_5i25.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_5i25.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_5i25.0.stepgen.01.step_type 0

setp hm2_5i25.0.stepgen.01.control-type 1

setp hm2_5i25.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => hm2_5i25.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_5i25.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P