NativeCAM is Features renamed

- BigDo

- Offline

- Senior Member

-

- Posts: 55

- Thank you received: 8

Regards

Niko

PS: can't add the svg file i get this message: "Unable to get properties for the image." The svg file is in the rar attachment.

Niko

Please Log in or Create an account to join the conversation.

- kjacobs

- Offline

- Junior Member

-

- Posts: 23

- Thank you received: 3

after some inactivity with respect to NativeCAM, I downloaded your new deb package with apt-get install. As I am using NativeCAM with machinekit instead of the standard LinuxCNC, the packaged version does not work out of the box. I found that restore_lcnc.py on the github repository, modified to use an option argument on the command line so that variable cls can be set to False or True, can be conveniently used to solve the problem for machinekit users. Just put restore_lcnc.py into /usr/share/linuxcnc/aux_gladevcp/NativeCAM and start it from there with sudo python restore_lcnc.py By using the option argument, the changes can be undone if required. I also removed the part creating links to the language files.

I found that part of the lathe catalog strings do not appear in the german ncam.po file I found on github. Also, I found some funny "google translations" now in the german translation. If you happen to have a new .po file at hand with the lathe strings added, I would happily translate them to german as I did earlier (and edit the "funnies").

Best,

Karl

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 457

- Thank you received: 124

I do not know what is machinekit but I will take a look at it when I'm back.... I am using NativeCAM with machinekit instead of the standard LinuxCNC, the packaged version does not work out of the box. I found that restore_lcnc.py on the github repository, modified to use an option argument on the command line so that variable cls can be set to False or True, can be conveniently used to solve the problem for machinekit users. Just put restore_lcnc.py into /usr/share/linuxcnc/aux_gladevcp/NativeCAM and start it from there with sudo python restore_lcnc.py By using the option argument, the changes can be undone if required.

I have not tested any of the lathe subroutines, having just completed the cnc conversion but it will need some adjustments.I found that part of the lathe catalog strings do not appear in the german ncam.po file ... If you happen to have a new .po file at hand with the lathe strings added, I would happily translate them to german as I did earlier (and edit the "funnies")

Surely there are terms that will be changed and that is why po file is not updated yet. I will let you know when done.

Thanks a lot Karl

Best regards

Fern

Please Log in or Create an account to join the conversation.

- kjacobs

- Offline

- Junior Member

-

- Posts: 23

- Thank you received: 3

Cheers,

Karl

Please Log in or Create an account to join the conversation.

- vmihalca

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 22

I am at the VERY BEGINNER level with Gcode, lathe programming, etc so I might ask some stupid questions for some of you.

I have a lathe converted to with spindle encoder and all that it needs.

I am using axis interface on 2.7.11 version with embedded native cam

can someone of you explain in a step by step operation (or video) how can I:

1. do the setup for 2 tools, (touch off and how to memorize their x and z coordinates in the tool table)

2. how to do a simple turning operation that reduces the diameter from 15mm to 10mm lets say in multiple passes

3. change the tool and do a parting operation.

I might be asking too much...but I would like to know if nativecam capable of doing these in the way it is now.

Any input would be appreciated.

If my topic is out of the scope of this thread, please tell me where to relocate it.

Thanks,

Vasi

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19631

- Thank you received: 4528

Decide that one of your tools is a "master" tool. That will always have offsets of zero in the tool table.

Load that tool. (I use tool 1)

Then make a test-cut on diameter. Back off. and return to the starting diameter on the DRO. Touch of your Coordinate System (not tool table) to that diameter.

Do the same with a facing cut.

Now, load your second tool and repeat, But this time touch-off into the Tool Table instead.

Now the tool table contains the difference between tool1 and tool2. (and you can then touch-off the work with either tool, as long as you have done the M6T2G43 thing. Never forget the G43. Unless you have remapped Tnn to do it automatically, which many lathe users do.

Please Log in or Create an account to join the conversation.

- vmihalca

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 22

I was able to do it and I have tested with two tools and it works fine. Thanks for your input!

Please Log in or Create an account to join the conversation.

- vmihalca

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 22

I have played today with NativeCam and discovered two issues.

1. I can't set spindle direction. My lathe is manual and I need an M4 code. In the tool_change.cfg, i saw that the spindle dir option is hidden. Can you please make that unhidden? Or tell me how I can edit that file...currently I don't have permissions where its stored after the deb install

2. It doesn't seem to consider the tool offsets. After I homed the machine, I've loaded tool 1 using M6 T1 G43, then I jogged the tool on Z and X and set the ToolTouchOff. After this I jogged away form the part then issues an G0 X0 Z0 and the tool moved into the correct position. After I've tried to run a simple turning using native cam, in the tool change routine, I've selected tool 1, in the Tool Number section. When I hit run, it moves on Z about -40mm from where the zero should be.

If you have time to fix these issues, can you please push an update? I saw that you received some beautiful icons that would be very intuitive.

Thanks!

Vasi

Please Log in or Create an account to join the conversation.

- vmihalca

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 22

I'm very happy that you've made these icons. They look awesome! Can't wait to get an update.

I see that you're running NativeCam as a tab. Can you help me do that? Mine is not a tab and occupies half of the screen all the time.

Thanks!

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 457

- Thank you received: 124

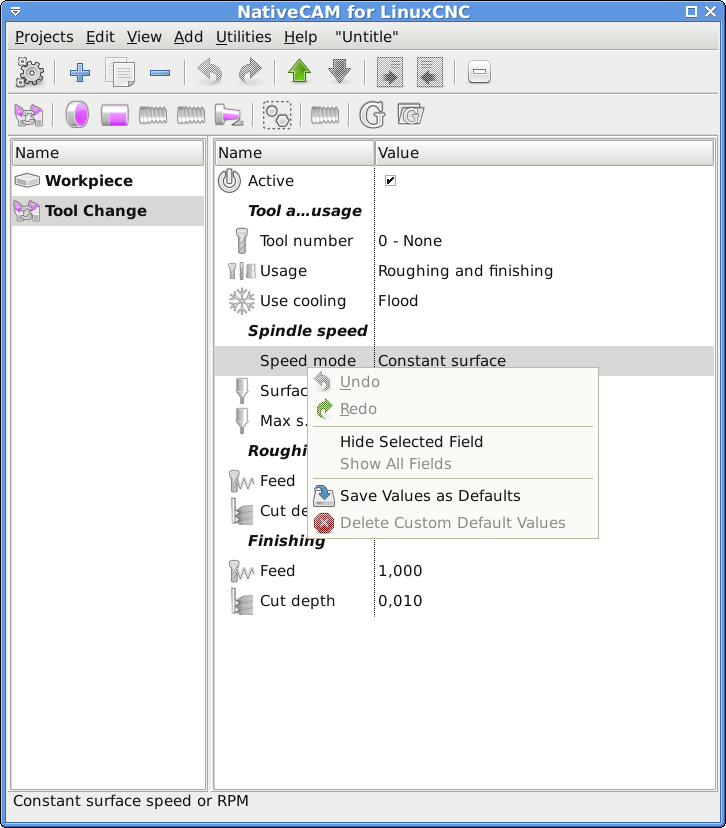

1. I can't set spindle direction. My lathe is manual and I need an M4 code. In the tool_change.cfg, i saw that the spindle dir option is hidden. Can you please make that unhidden? Or tell me how I can edit that file...currently I don't have permissions where its stored after the deb install

- Right click on a parameter in Tool Change

- If 'Show All Fields' is grayed, then hide one of the fields

- Right click again and select 'Show All Fields'

- 'Save as Default Template' or you will have to redo it until I update

2. It doesn't seem to consider the tool offsets. After I homed the machine, I've loaded tool 1 using M6 T1 G43, then I jogged the tool on Z and X and set the ToolTouchOff. After this I jogged away form the part then issues an G0 X0 Z0 and the tool moved into the correct position. After I've tried to run a simple turning using native cam, in the tool change routine, I've selected tool 1, in the Tool Number section. When I hit run, it moves on Z about -40mm from where the zero should be.

I just started testing the subroutines on my lathe and I have some that are OK now. Your issue is probably due to one of the bugs I fixed. I think next week, I will have enough fixes for an update.

Fern

P.S. to learn how to install in a tab execute $ ncam -h

Please Log in or Create an account to join the conversation.